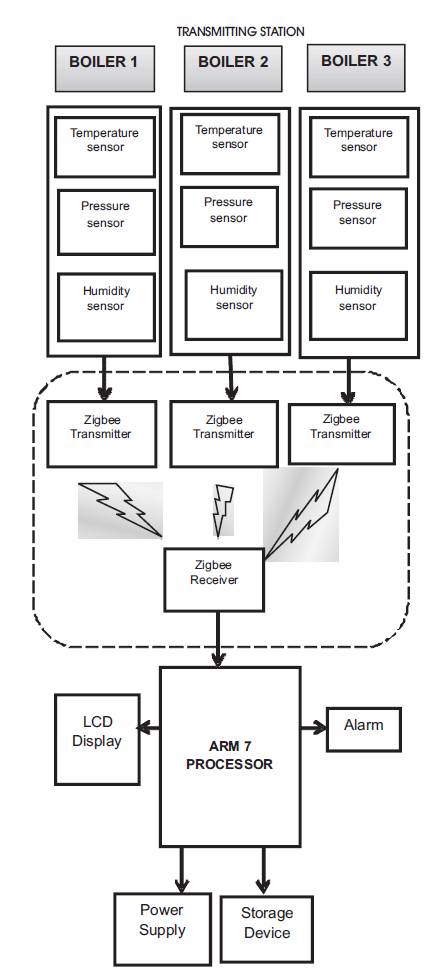

Figure 1. Block diagram of the proposed system.

The main objective of this research paper is to monitor the various physical parameters in the large scale industries in an effective manner for the proper maintenance and to avoid the major accidents in the industries. At present, due to the poor real time monitoring system, fault identification and system accuracy have become very tedious and frequent field visit is required in industries. In order to overcome and provide solution to the existing system, Wireless Sensor Networks (WSN) with high speed advanced ARM processor which executes large instructions is used for the implementation of the proposed system. The automatic industrial parameter monitoring system has been capable of monitoring multiple boiler sections or any other units at the same time. Zigbee is the emerging wireless network technology which is used for data communication in hardware system. The physical parameters like temperature, pressure and humidity are sensed using the suitable sensors and transmitted through the zigbee module over the wireless network to the base station. The ARM processor is located in the base station programmed in such a manner to receive the data through the zigbee module from multiple boiler units. The simulation of the automated system is achieved by the Keil C μ vision 4 software to get the desired output.

Currently there are many innovations and rapid growth in science and technology, which sophisticates the human life. In a similar way, it also makes the huge changes in the development of industrial sectors in all ways one of the key examples is the Industrial automation. But supervision of the large scale industries with multiple units has been facing lot of issues like performance, cost, and need of more manpower. At present, most of the industries are facing problems like how to identify a machinery fault before it reaches a critical level to avoid system malfunction, and catastrophic failure. It is a challenging task to predict the quality of the environment in the industries. In order to overcome the conventional problem industry monitoring and automation are becoming more essential in the industry. Recently Embedded Controlled Sensor Network (ECSN) [1] plays a vital role in the environmental monitoring system which is formed by communicating over wireless links without u sing permanent networked infrastructure microcontroller. The main characteristics of present embedded systems are function integration and rapid development cycle.

ECSN is a real-time embedded system which has advanced features and fast executing microcontroller in which embedded software is used to develop the applications. This system can also be practised in the industry monitoring and controlling which gives the best result in real time operations. Wireless sensor networks [6] is a latest technology that can deliver processed real-time industry data from sensors physically connected to the monitoring station. Over a period of time, there is a dramatic progress in the wireless sensor networks [3], like Bluetooth, Wi-Fi, Wi-Max, Wireless Mobile Ad-hoc Network (WMANET), UMB, and wireless HART. The wireless technology applications include industry Monitoring System, Agricultural Patient Monitoring System, environment and wild life monitoring.

WSN[7],[8] shows significant development over traditional sensors and collaborative effort of a large number of nodes. Implementing the WSN in the industries will give very quick response, replaces the wired system, reduced cost, easy replacement, increased system reliability etc... Energy management is one of the add-on features in the industry monitoring using the WSN. Zigbee [2], [10] technology provides different types of network topology and it has the latent to register 65000 Zigbee devices in individual network. To overcome the existing problems in industries the proposed system provides effective with fast wireless data transmission, early warning system, and multiple units monitoring with storage device. The zigbee [9] module supports for the data transmission of different parameters value from multiple boiler units with different sensors and ARM 7 processor to receive the data from the zigbee receiver to perform the suitable operations.

Vaneet Singh, et al [1] “Environment monitoring and device control using ARM based Embedded Controlled Sensor Network”, deals about the ECSN with zigbee data transmission which has multi-hop networking technology. The hardware system consist of master system of ARM7 based LPC2148 microcontroller with GSM and zigbee module which is connected with the 3 slave network which has 8 bit 89C51 microcontroller and zigbee module used to monitor the light sensor, humidity sensor, and temperature sensor. All these data are processed by the master circuit and transmitted through GSM to user, The master circuit is connected with a PC, and it can be controlled by the internet.

P. Kumar, et al [2]. “Design and Implementation of Arm Intelligent Monitoring system using Zigbee” portrays the laboratory monitoring intelligence system using the zigbee technology with ARM9 S3C2440 processor, embedded database and USB device.The zigbee monitoring sensor network with sensor, humidity sensor and the fire sensor are controlled by the sensor control board. All the system topology has been connected with the ARM intelligent monitoring center through PSTN and TCP/IP network.

P.V.Mane-Deshmukh, et al [3] “Microcontroller PIC 18f4550 based Wireless Sensor Node to Monitor Industrial Environmental”. This research paper deals with monitoring the temperature and alcohol gas in the industry. The parameters are sensed by using LM35 temperature sensor and MQ-3 alcohol sensor. After that the data is transmitted by the zigbee RF module to the base station receiving signal module which is connected to the personal computer where the data monitoring takes place. The PIC 18F4550 microcontroller is used in this system.

Archana R.Raut, et al [4] “Zigbee Based Industrial Automation Profile for Power Monitoring Systems”. This paper focuses on the industrial automation with the help of zigbee features. The processes are monitoring, diagnosis, and supervisory of power system parameters current and voltage of an industry using the star topology network of zigbee. If the value exists as its pre-set value, the buzzer will indicate on both the sides of the transmitting and receiving stations.

Mohd Abdul Samad, et al [5] “Design of remote intelligent smart home system based on Zigbee and GSM technology”. The design of remote intelligent smart home system discusses about the combination of two wireless network systems i.e., Zigbee and GSM. The host system consists of LPC2148 with GPRS module, Zigbee module, PIR sensor and SPDT relay to control the home appliances like AC, fan etc. When the user sends the message to the host control system to know about or to switch ON/OFF about any home device, this host control system will communicate with the sub function system through the zigbee network to perform the user task. It makes the user more comfortable for remote controlling of home devices.

Industries like steel plant and many other industries consist of multiple boiler sections and other sections in adjacent way. Conventionally it is very difficult to monitor. The proposed automatic system will satisfy the industry's expectation. As shown in Figure1, the hardware design consists of transmitting station and base station. There are three transmitting stations, each consisting of one boiler unit with three sensors like, temperature sensor(TS752-8), humidity (HSll01) sensor and pressure sensor (BLPS-300) .The base station consists of the ARM 7 (LPC 2378) processor, zigbee receiver, power supply, storage device, LCD display and alarm. The ETRX3 series is the 3rd generation of zigbee module from Telegesis which is used for transmitting and receiving the data. ARM 7 processor’s function is to process the received data according to the instruction programmed in the memory and Power circuit will provide the necessary supply to operate the system. Storage device is used to store the parameters value in the regular interval of time to analyze the different boiler environment. Alarm status indicates the emergency and LCD display is used to display the results according to the users’ need. During the operation of the automatic system, each sensor is placed separately in the three boiler units. The sensors will measure the value of temperature, pressure, humidity. Further, the measured values are transmitted with the support of zigbee module. The zigbee transmitter is connected with the system in each transmitting side through wireless network to the base station and the data are received by the Zigbee receiver in the base station which is interfaced with the ARM 7 processor. The embedded processor will perform different operations according to the given instructions. The ARM 7 processor provides two modes of operation. The mode 1 is “MONITORING” in which the ARM 7 processor will display the monitoring parameters value. The mode2 operation is “RETRIVING THE STORED DATAS” in which the ARM 7 processor will display the stored boiler parameters value. According to the users’ needs, they can select their preferred operation and can choose which from boiler the user wants to analyze the data. Figure 2 shows the operation of the proposed system.

Figure 1. Block diagram of the proposed system.

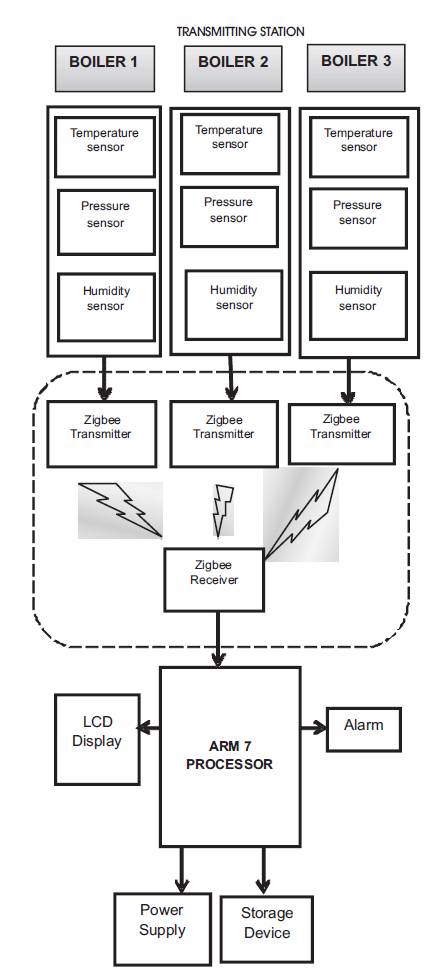

Figure 2. Flow chart of the Proposed System

The Keil C development tools for the 8051 microcontroller family support every level of developer from the professional applications engineer to the student just learning about embedded software development. The industry-standard Keil C compilers, Macro Assemblers, Debuggers, Real-time Kernels, and Single-board computers support all 8051-compatible derivatives and help us get the projects, completed on schedule. With the help of Keil tools, it is possible to generate embedded applications for virtually every 8051 derivative. The Keil Software 8051 development tools are designed for the professional software developer; any level of programmer can use them to get the most out of the 8051 microcontroller architecture. Keil C software provides various simulation output.

Step1: Start the process.

Step2: Initialize the sensors.

Step3: Synchronize the zigbee protocol.

Step4: Choose the mode of operation.

1. Monitoring

(a) Option 1, Display boiler 1 Parameters

(b) Option2, Display boiler 2 Parameters

(c) Option 3, Display boiler 3 Parameters

(d) Option 4, Display all the Boiler Parameter

2. Retrieving the stored value.

(a) Option 1, Display boiler 1 saved parameters.

(b) Option 2, Display boiler 2 Saved Parameters.

(c) Option 3, Display saved Parameters.

(d) Option 4, Display all the boilers saved Parameters.

Step5: Selection of boiler.

Step6: Display the selected boiler parameters value.

Step7: Stop the process.

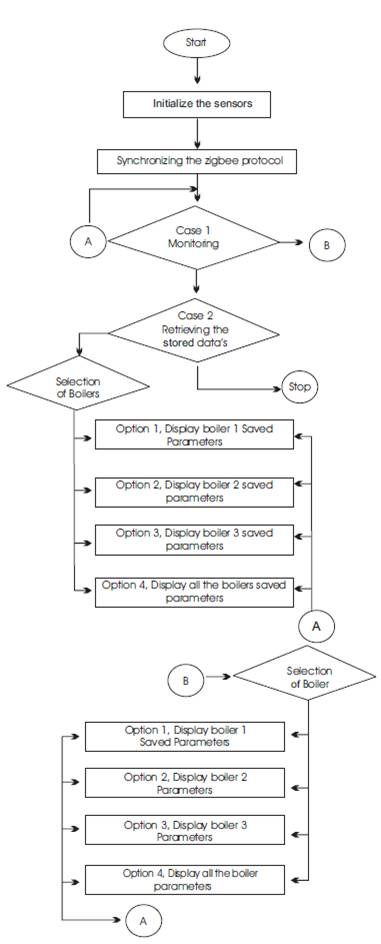

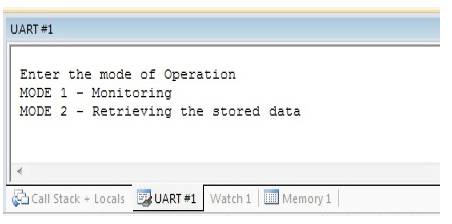

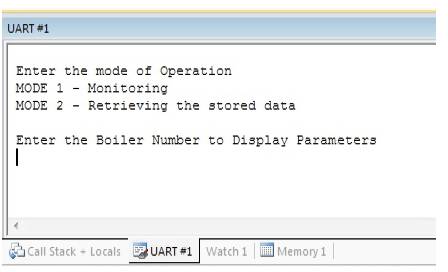

In the proposed research, the embedded ARM7 processor provides the excellent solution to the industry. ARM 7 processor supports the entire control and monitoring of the system. After debugging, the results will be displayed in UART window.

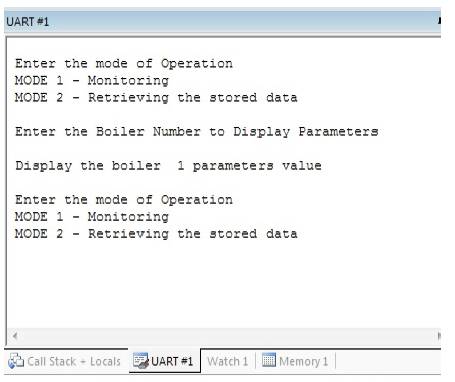

In Figure 3, UART shows that the microcontroller is displaying the modes of operation and waits for input. In Figure 4, MODE 1 is selected, UART displays to select the desired boiler number 1, 2, 3, or 4. Ffor displaying all the boilers parameters value, all the boiler numbers can be given.

In Figure 5, UART displays the boiler 1 parameters value and shows the next modes of operation that need to be selected.

Figure 3. Different modes of operation.

Figure 4. Getting the input from user.

Figure 5. Displaying the monitoring value

Figure 6. Displaying the stored values

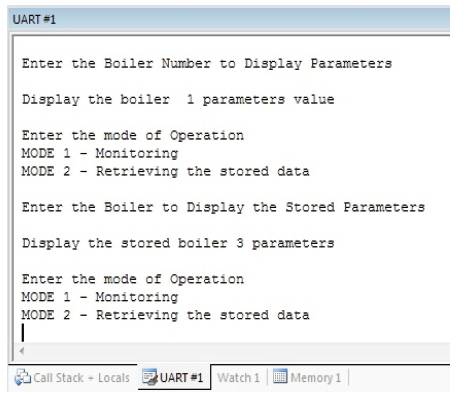

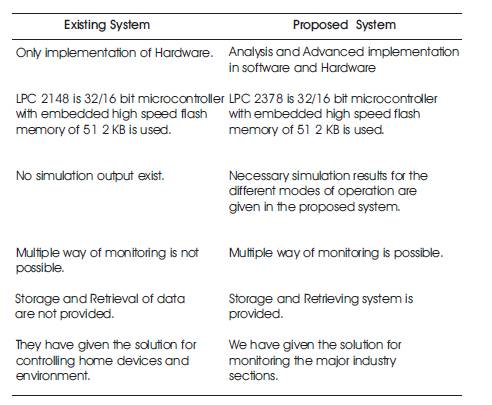

In Figure 6, MODE 2 operation was selected, UART displays to select the desired boiler number 1, 2, 3, or 4. Then UARTdisplays the boiler 3 stored parameters value. Table 1 illustrates the comparision Existing method with the proposed system.

Table 1. Comparision of Existing and Proposed System

The proposed system provides solution to the issues present in the conventional system. The research focuses mainly on solving the real time problems in the Industrial Monitoring System automatically. The various parameters like temperature, pressure, humidity are monitored and the data's are retrieved at any time, thus giving complete protection to the industry. In case of any problem in any one boiler section, the faults are easily identified and isolated within a specific period of time, without affecting the entire process. Further, any mis-operation in the industries is fully controlled and monitored. The implementation of the real time system efficiency is achieved by the embedded processor. The simulation of the result is done by the Keil C software after the information is transmitted by Zigbee wireless technology. The Fault in the boiler section can also easily identified and rectified. In future, the same research work can also be implemented using Wi-Fi or Wi-Max in any other protocols for long distance communication.