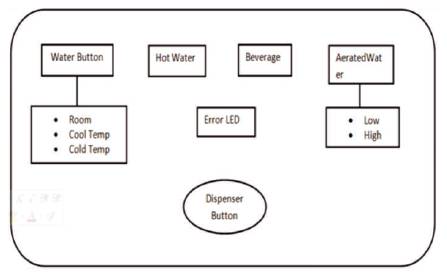

Figure 1. User Interface Button and LED’s Display Position

The scope of this paper is to design an entire control for the Beverage Machine. This machine is able to dispense natural water, cool water, cold water, hot water, and aerated water. Also it is capable to produce many beverages like juice and soft drinks using capsules. Dispenser machine operates with customer interaction, i.e., whenever customers press the main dispenser button and option key to select natural water, cool water, cold water, hot water or other beverages like juice and soft drinks through UI like pantry Control. For dispensing, the beverages which are prepared after capsule identification with barcode are mounted on beverage capsule. The user interface board will contain the illuminated display, microcontroller and drivers to drive the display. Theory of operation is that the user will interact through commands. The command will be interpreted and sent to the microcontroller at the Appliance Control Unit (ACU) for processing. The user interface should handle the entire user interaction. The user interface will interpret the commands and determine the beverage dispense mode, the temperature and time length for a mode, and then send it to the appliance manager (Appliance Control Unit) to perform operations like handling of water filling and dispensing beverage preparation in the system.

Dispenser machine is an automated product dispenser which is normally installed in supermarkets, railway stations, offices, schools, and various other public areas. Market feasibility, includes switching speed i.e. how fast will system be responding, timing constraint i.e. to perform operations within less time, power and area requirement of dispenser machine. It will also save precious time of employees in companies.

This paper is to design entire control of the Beverage Dispenser Machine. This machine is able to dispense natural water, cool water, cold water, hot water and aerated water and also capable to produce many beverages like juice and soft drinks using capsules. Based on user requirements, beverages are dispensed with an interaction between user and machine using UI that is pantry control like touchscreen. The user interface board will contain the illuminated display, microcontroller, and drivers to drive the display. This dispenser machine has beverage capsules. Each and every capsules are identified with a barcode. This barcode is matched with the barcode sensor and according to which the capsule identification is done.

This machine is divided into two systems; one is User Interface (UI) and the other is Appliance Control Unit (ACU). The ACU will drive circuits for AC compressor, Pump and Boiler Heater, DC pumps, Valves, Motor Fan, and LED Lighting. This is used to control crushing capsules composed by a DC Motor, Solenoid and Switches. All functions are controlled by a UI, where the user communicates through commands present in the UI. Each beverage identifies the barcode on every capsule. Here barcode includes all information according to beverages like how much quantity of water and aeration are required to prepare beverage, etc. with deciding water and gas status according to the recipe.

Once the UI interaction is performed by the user, the machine operations will be executed according to the input.

Figure 1 shows pantry control board, i. e. User Interface (UI). With the help of Pantry control board the user can interact with the system. User will press or select any beverage option key from pantry control board. According to selection control, signals are provided to the system for performing the operation and to dispense beverage.

Figure 1. User Interface Button and LED’s Display Position

Dispenser machine includes following Mechanisms:

The dispenser machine operation totally depends on user interaction with User Interface (UI) board like pantry control board. The operations are performed according to the user demand and cover market feasibility. Market feasibility includes switching speed that means how fast system will respond, time, power, and space requirements of a dispenser machine. It also saves precious time of employees in companies.

Different dispensing machines are available in the market. These machines work in different manners like a user inserts the coin after which it dispenses the beverages, or for dispensing beverages, the user raises ticket. User press the option key and then dispenses the beverages with different controlled manners. An automatic beverages dispensing machine using Finite State Machine (FSM) has been developed. It has more advantages compared to the aspects used in dispensing machine design [1], [2].

Vending machine is an automated product maintained within the sequential finite state providing any self-service or an automated dispensing machine for public domain offers to save precious time of human life, upon insertion of a coin or token, where according to the coin value, the dispenses unit serves beverages like coffee, tea, or snacks [5], [6].

Dispensing machine mainly focuses on new technologies which are given to make human daily life be more suitable. The network observes the internal environment of the dispensing machine and adjusts the taste of beverages according to preference of the customers to manage the amount of sugar and powered milk which are to be mixed into a cup. The dispensing machine and the smartphone can interchange their information via Bluetooth connection. A lots of people buy beverages without knowing the cleaning status of dispensing machine, i.e, how clean they are. To know the cleaning status of beverages which are dispensed from the dispensing machine, a wireless sensor and actuator network to group of sensors and actuators connected by wireless medium to perform operation of sensing and actuating task which is installed inside a dispenser machine has been developed [3] .

Time-consuming takes too much time to buy and working operation failures could often happen in the usages of dispensing machines due to the contraventions between human behaviour and human machine interaction with system design interface. Each step of human's habitual buy situation behaviours on dispensing machine were examined, so that the features of operations are removed to save the valuable time of human life [1], [4].

Figure 2 shows how the code performs with different devices on the actual system. All software tools are installed in PC. With the help of software tools, the codes are dumped into actual board that is HMI and ACU. Code dumped into actual system with the help of Renesas programmer is the code used for code compiling as well as debugging for error correction. All are connected with isolation transformer because it provides current for all devices. Check Dumped code is checked whether it is working properly or not with the help of test verification kit.

Figure 2. Design and Test Code with this Flow

The setup used for testing and debugging are:

The above testing and debugging setup use 230 V power supply to ACU and Isolation transformer used to protect against electric shock also provides power to other devices the function verification test kit, Appliance control unit, and Human machine interface uses 12 V power supply. Design of ACU and UI operations are done with software tools which are IAR Embedded Workbench for dumping the program in the circuits, Source Repository and other communication software with communication box are shown in Figure 2.

The communication between UI and ACU for performing a particular operation depends on user demand or requirement. UI and ACU communicate with communication protocol. When the user presses any option key from UI, it sends control signals to ACU for performing operation. UI provides option key for user demand. ACU performs two main operations like handling of water filling and dispensing, it also handles beverage preparation and dispensing after identifying capsules with barcode. When the barcode identification is completed, the beverage preparation will start. Each and every barcodes include details of how much amount of water and gas will be required tor prepare the beverage.

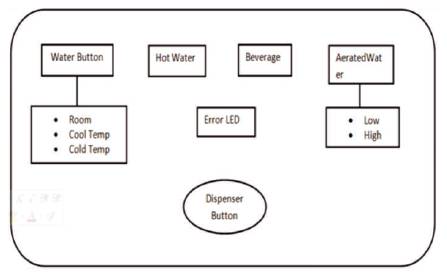

UI decidies threshold value of each key with the help of Communication Box software along with parameters.

These parameters are shown in the homepage of the communication box software used for communication between ACU and UI. In communication box, global touch configuration is used for identifying the status of communication between ACU and UI with a message “Good Communication”.

Showing whether the key is pressed or not with the help of bar graph monitoring according to these status, sets the threshold value. Bar graph monitoring is shown in Figure 3.

Figure 3. Bar Graph Monitoring

After 4 minutes without any customer interaction with the UI, the product enters to the idle mode. In the idle mode, all LEDs previously activated will decrease their intensity from 100% to 40%. If any customer interaction happens during idle mode, previously settings will have to be recovered and intensity will be increased from 50% to 100%.

Appliance Control Unit perform operations, whenever user presses any key from UI command and the control signals provided to ACU. An Appliance Control Unit includes the operations performed according to user demand. For example, if the user selects cold water, then the command is send to ACU, thus performing operations according to that particular option, providing the required load to dispense it.

In an actual system, compressor and CO pressure tanks 2 are mounted inside the system. According to user demand the system will perform an operation and dispense beverages.

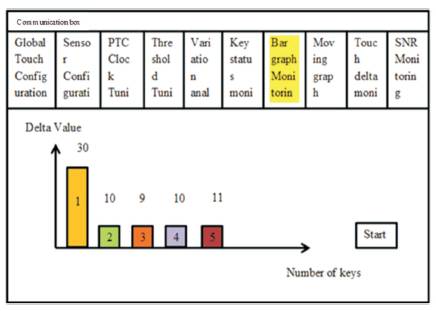

Figure 4 shows actual system look a like after manufacturing the product.

Figure 4. Actual System Look Alike

Figure 5 shows example of barcode pattern with thick and thin black lines for each recipes used for beverage preparation. The barcode pattern, includes thin and thick lines with white background. In a Barcode, thin line is considered as logic 0 and thick line is considered as logic 1.

Figure 5. Barcode Pattern

On beverage demand, use capsules are used with barcode strip mounted on a capsule. In that, barcode includes information about water and aerated quantity. This capsule is crushed with DC motor and mixed in water before it gets dispensed.

The a barcode is mounted on a capsule, but for testing purposes sticks on the capsule cap and this barcode is recognized with barcode sensors installed in the system. Lens is mounted on barcode sensor in Figure 6.

Figure 6. Barcode being Recognized with Barcode Sensor [7]

In this prototype, dispenser machine is based on Arduino with microcontroller ATmega328 using arduino sketch for compilation and programming to design the code. This dispenser machine is used to dispense coffee, tea, and hot water, but these operations occur only after the user has swiped the RFID card. If the card details are matched then the user is an authorized person and then he goes to the next operation where he selects any option to dispense the required beverage.

Figure 7 shows the RFID identification where swiped the RFID card can be swiped and read by RFID reader.

Figure 7. RFID Identification

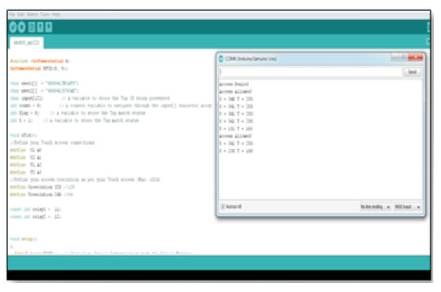

Figure 8 shows threshold value on TFT display after the user touches the screen shown in Arduino sketch compilation platform.

Figure 8. Serial Communication to show RFID Identification and Threshold Value

Figure 9 shows the interface TFT display and DC water motor for dispensing purpose.

Figure 9. TFT Display Interface with Option Selection

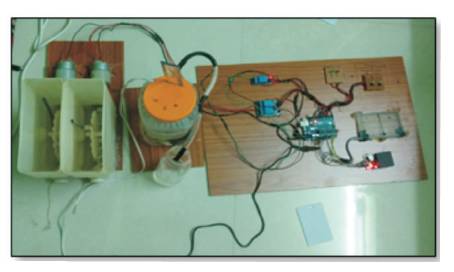

Figure 10 shows the whole prototype of dispenser machine to show tea, coffee, and hot water with half and full quantity depending on user preferences.

Figure 10. Prototype of Dispenser Machine

With the User interface platform interaction between user and Dispenser Machine, the user presses the main dispenser button and the option key like hot water, or cold water, and also cool water dispenses beverages like soft drinks by using capsules with crushing them. This Dispensing depends on timer and also filling depends on timer and level sensors that means whenever the user presses the button, it dispenses beverage in particular time and then filling process starts instantly at the same time and fill the tank. Also after which the level of the cold and aerated tanks are checked.

The prototype of dispenser machine, dispenses coffee, tea, and hot water after user selection from TFT display. All these operations are done after the person was authorized with RFID tag and reader. It is useful for saving precious time of human life in corporate world.