In this paper, performance analysis of different structures of organic solar cell is represented. Organic Photovoltaic (OPV) solar cell is recently progressing at a rapid pace due to its low cost, simple manufacturing processing, flexibility and large area devices for future technology. In order to develop efficient and economical photovoltaic cells with good electrical and optical properties, more attention is given to development of better materials and novel structures. Therefore, in this paper different structures of organic solar cell by using different organic materials have been simulated and studied in order to find the best material for the device. The performance of OPVs is discussed on the basis of its basic performance parameters, i.e., short circuit current density, open circuit voltage, fill factor, and power conversion efficiency. The simulation of OPVs is performed in Silvaco ATLAS TCAD tool. Basic equations used by the software is also covered in this paper. This paper shows that bulk heterojunction has good performance.

Organic Photovoltaic (OPV) solar cell is an emerging area in research and academics. It has captured a great attention of innovative scientists in recent 3-4 years, due to its low cost and low temperature manufacturability, flexibility and roll to roll processing. OPV has a good future in commercialization, but still it has two serious problems, i.e., its efficiency is very less in comparison to the silicon solar cell which have captured most of the market in energy production by solar energy [1]. The second limitation is its stability as organic materials are degradable in the atmosphere. But during last decade, tremendous efforts have been done to improve its efficiency and stability. Researchers are using different polymers and small molecules as donor materials and different fullerene derivatives as acceptors materials for improving performance of OPV. Some new acceptor and donor materials have shown attractive electrical and optical properties [2]. Electrode materials also play an important role in designing an efficient OPV. Work function of electrodes can alter the I-V characteristics of the device [3]. Organic solar cell basically have four processes these are, 1. Absorption of illumination light by donor material to create excitons within the organic material, 2. Generation of excitons (strongly bounded ehole pair by coulombic force of attraction), 3. Diffusion and dissociation of excitons at the interface of donor and acceptor to create photogenerated carriers, and 4. Collection of photogenerated carriers at the electrodes (electrons towards cathode and holes towards anode) [4]. There are four important parameters of OPV, short circuit current (Isc), open circuit voltage (Voc), Fill Factor (FF), and power conversion efficiency, which measures the performance of the device.

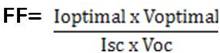

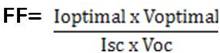

Here in Figure 1, Voc shows the maximum bias voltage at which all the photogenerated carriers are recombined and gives 0 current and at this point power is 0 watt. Isc is the maximum current when both the electrodes are short circuited or there is no external load. FF shows the ratio between maximum powers to the dummy power of OPV. This also can be represented as,

Power Conversion Efficiency (PCE) is the measure of how efficiently input illumination is being converted into output electrical power [5].

Figure 1. Graphical Representation for Maximum Power Curve of OPV

In this paper, different structures of organic solar cells is simulated by using different organic layer materials and electrode materials and by varying its thickness, the effects has been shown. This paper has been organized as follows. Section 1 contains the materials, section 2 presents the physical model, result and discussions of organic solar cell in covered in section 3, and the final section provides the conclusion.

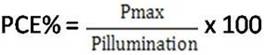

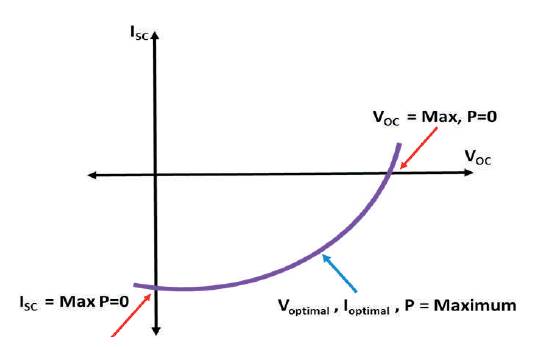

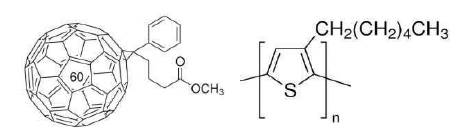

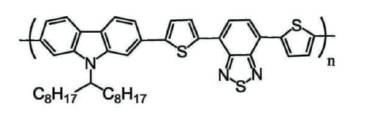

As in nature, the plants convert solar energy into chemical energy, where they absorb light using the chlorophyll molecule. The same process involved in OPV is the absorption of light and for this there must be good organic material which can cover more spectrum of light and absorb more photons for creation of photogenerated charge carriers. In this paper, the basically used organic materials are PCBM (1-(3-methoxycarbonyl) propyl-1- phenyl [6,6] C61), P3HT (poly(3-hexylthiophene-2,5-diyl), PCDTBT (poly(N-9'-heptadecanyl-2–7-carbazolealt-5,5- ( 4', 7'-di-2 thienyl-2'-1'-3'-benzothiadiazole) ) , PC71BM([6,6]- phenyl-C71 butyric acid methyl ester), and Polyphenylene Vinylene (PPV) [6].

Here, Figure 2 shows the molecular structure of the n-type acceptor material PCBM and p-type donor material P3HT. Figure 3 shows the molecular structure of p-type donor material PCDTBT. Blend of these materials are also used, such as P3HT: PCBM, PCDTBT: PC71BM, and PPV: PCBM.

Figure 2. Molecular Structure of PCBM and P3HT [6]

Figure 3. Molecular Structure of PCDTBT [6]

Electrode materials used in this paper are aluminum, gold, graphene, and ITO (Indium Tin Oxide), where these are cathode and anode materials [7]. Work function difference of these materials provide driving force to separate out electron and holes at interface. Electron and hole blocking materials are also used to improve the photogenerated carrier collection efficiency at electrodes. These materials are NiOx, ZnO, MoO3 , TiOx , and PEDOT: PSS [8].

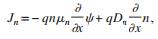

OPV structures are simulated by using TCAD Atlas Silvaco tool. OPV have drift diffusion processes inside it. There is a basic physical phenomenon which take part in processing of OPV that is energy level of donor and acceptor materials, photocurrent generation and photo voltage. Energy level of semiconductor material is a crucial property which affects the performance of the device. There are two levels of energy, i.e. HOMO (Highest Occupied Molecular Orbital) and LUMO (Lowest Unoccupied Molecular Orbital). There must be a proper arrangement between HOMO and LUMO levels of the acceptor and donor materials. Major processes inside the device are drift and diffusion of charge carriers, charge carrier generation and recombination. Drift and diffusion current density from Korster's device model [9] is given as,

where first term in right hand side of the equation shows drift current density and second term shows diffusion current density.

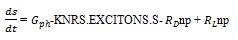

OPV is simulated in TCAD Atlas Silvaco tool. Its model includes singlet exciton continuity equation which is related to the electron and hole continuity equation and Poisson's equation,

where Gph is the photogeneration rate, S is the singlet concentration, KNRS.EXCITONS is the non-radiative singlet decay rate, RDnp is the Langevin recombination rate, and RLnp is the exciton dissociation rate.

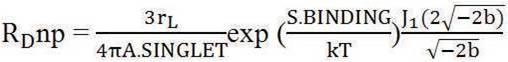

The equation that shows exciton dissociation in Silvaco is given by,

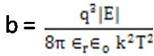

where A.SINGLET and S.BINDING are user defined parameters that show the electron hole pair distance and singlet exciton binding energy, rL is the Langevin recombination rate constant, J1 is the first order Bessel function and parameter b is given by,

Here E shows electric field, ∈r is the relative permittivity & T is the temperature. The software uses the ray tracing method, transfer matrix method and beam propagation method for optical modelling [10].

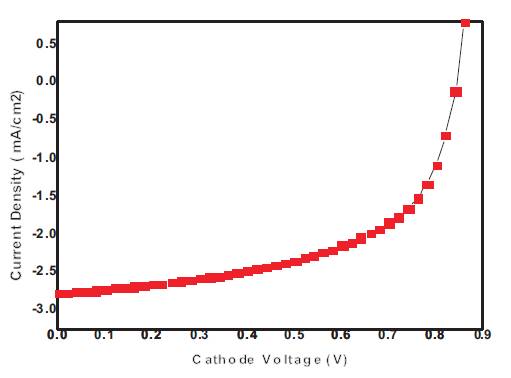

Various structures are simulated using TCAD Atlas Silvaco tool. OPV have basically four structures, i.e. single layer structure, bilayer structure, bulk heterojunction, and tandem. In this discussion, focus have been made on bulk heterojunction. Three structures are simulated under the AM 1.5 G light of intensity 1 Sun, which have organic semiconductor layer sandwiched between the anode and cathode. Here, aluminum is used as a cathode to collect electrons and ITO (Indium Tin Oxide) is used as an anode. Figure 4 shows the voltage verses current density graph for OPV using PPV: PCBM as organic layer. These results are obtained by providing some basic material properties of the organic materials in the TCAD Silvaco tool. It shows that the OPV structure with PPV: PCBM have very good open circuit voltage.

Figure 4. Bulk Heterojunction using PPV: PCBM Blend

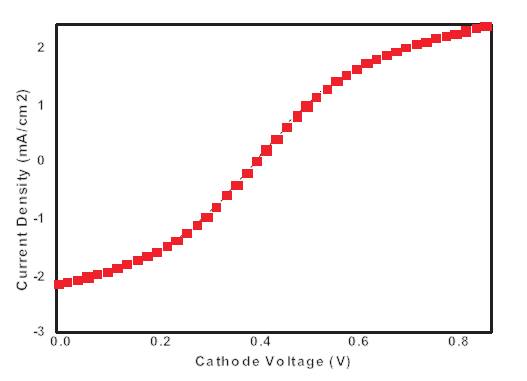

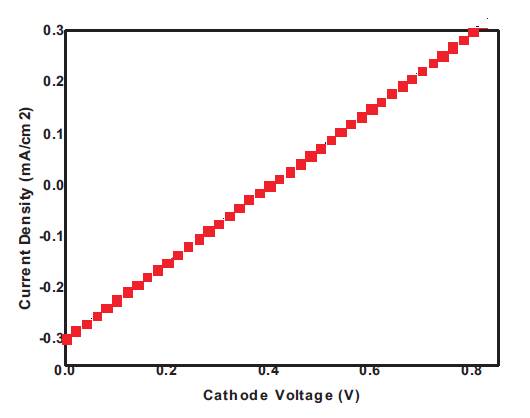

Figure 4 shows the diode shaped characteristic under illumination which is providing a good output. Figure 5 has s-shaped kink, which means there is much barrier between the contact of organic layer and the electrodes. Figure 6 shows the output characteristics of the OPV solar cell by using blend of P3HT: PCBM material. It shows that the current density has linear relationship with the input cathode voltage.

Figure 5. Bulk Heterojunction using PCDTBT: PC70BM Blend

Figure 6. Bulk Heterojunction using P3HT: PCBM Blend

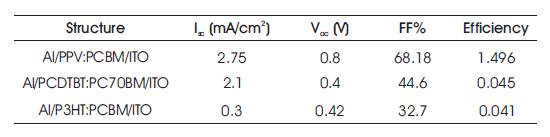

Table 1 shows the values are listed for performance parameters of the simulated structures. It shows that the structure with PPV: PCBM has the good open circuit voltage and fill factor and thus good efficiency. The main reason for this is that PPV: PCBM blend material have good transportation properties and has better hole and electron mobility and low bandgap than the PCDTBT: PC70BM and P3HT: PCBM. Due to this low bandgap PPV: PCBM can allow more photons to be absorbed by the cell and high mobility of charge carriers lead to lessen the recombination at the interface of the D/A. Thus more photogenerated carriers take part in energy conversion and efficiency increases. Therefore according to above comparison between different structures of organic solar cells, Al/PPV: PCBM/ITO shows the best result.

Table 1. Performance Parameters of Different Structures of Organic Solar Cells

Energy needs of our world are rising with a tremendous speed. During recent years, researchers have shown a lot of interest in the development of organic solar cells due to their low cost, more versatile fabrication process, and less complex mechanisms for harnessing solar energy. In this paper, three structures of organic solar cell have been compared in terms of short circuit current density, open circuit voltage, fill factor, and efficiency, in which the structure using PPV: PCBM as blend material gives the best result among them. This paper has also covered the device physics of organic solar cell to understand what is going inside the device. This project has a future scope, where can be done using modification by using extraction layers to increase the performance of OPV making it available at commercial level.