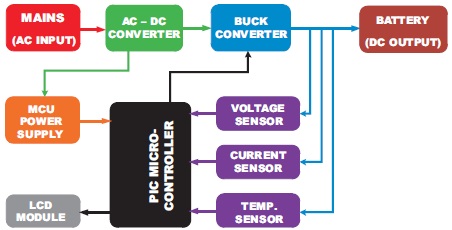

Figure 1. Block Diagram of the Battery Charging System

This paper explores the topic of optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems. With the increasing demand for portable and wireless devices, efficient battery charging and longer battery life have become essential. The use of microcontroller-based systems allows for more precise and effective control of battery charging, resulting in improved efficiency and longevity. The current research is on intelligent battery charging systems and battery management systems and discusses various smart charging techniques that can be employed in microcontroller-based systems, including fuzzy logic control, model predictive control, and hybrid algorithms. The paper also highlights the importance of battery management and the need for a comprehensive battery management system to optimize charging efficiency and battery longevity. Finally, the paper presents several case studies and experimental results to demonstrate the effectiveness of these smart charging techniques in improving battery charging efficiency and longevity in microcontroller-based systems.

Battery charging and longevity have become important factors in determining the practicality of portable and wireless devices, electric vehicles, and other applications. Significant research has been carried out in the field of battery management, and one promising area of research is the use of microcontroller-based systems for efficient battery charging and longevity. The use of microcontroller-based systems allows for more precise control of battery charging, resulting in improved efficiency and longevity. Microcontrollers are small, lowcost, and programmable electronic devices widely used in various applications, including battery management systems (Reindl et al., 2020). These systems can be programmed to monitor and control the charging process, ensuring that the battery is charged at an optimal rate while minimizing the risk of overcharging or overheating. Additionally, microcontroller-based systems can be designed to operate with different battery chemistries, such as lithium-ion, lead-acid, or nickelmetal hydride batteries.

Smart charging techniques can further enhance the efficiency and longevity of the battery. These methods are designed to optimize the battery charging process by taking into consideration various factors, such as battery capacity, charging rate, and temperature. Fuzzy logic control is a technique used to control systems that have imprecise or uncertain inputs (Garcia-Trivino et al., 2018). In battery management systems, fuzzy logic control canbe used to determine the optimal charging rate based on the battery capacity, temperature, and other factors (Chen et al., 2016; Lazaroiu & Roscia, 2022). Model predictive control is a technique used to optimize a system's performance by predicting its behavior over time and is also used to optimize battery charging by predicting the battery's behavior over time and adjusting the charging rate accordingly (Abdollahi et al., 2016). Hybrid algorithms combine two or more optimization algorithms to achieve better performance than using a single algorithm alone.

In summary, microcontroller-based systems, coupled with smart charging techniques, have great potential to improve the efficiency and longevity of batteries in portable and wireless devices, electric vehicles, and other applications (Lai & Lu, 2012). This paper explores the current state of research on smart charging techniques and their application in microcontroller-based systems, including case studies and experimental results (Ayoub & Karami, 2015).

Abdollahi et al. (2016) present a closed-form solution to the problem of optimally charging a Li-ion battery. A combination of three cost functions is considered the objective function: time-to-Charge (TTC), Energy Losses (EL), and a Temperature Rise Index (TRI). First, we consider the cost function of the optimization problem as a weighted sum of TTC and EL. We show that the optimal charging strategy in this case is the well-known Constant Current– Constant Voltage (CC–CV) policy, with the value of the current in the CC stage being a function of the ratio of weighting on TTC and EL and of the resistance of the battery.

Lai and Lu (2012) focus on by using the constant currentto- constant voltage charging method, this paper designs a smart fast charging system based on the ATMEGA128 microcontroller and LTC4100 battery charging controller. The core modules of the Micro Controller Unit (MCU) control and charging circuit are mainly designed to achieve efficient and fast charging. During the process of charging, the system can automatically track the acceptable charging current of lithium batteries and monitor the charging current, voltage, and temperature to realize intelligent and precise control for the whole charging process, which can guarantee that lithium batteries are neither overcharged nor undercharged.

Ayoub and Karami (2015) says various charging techniques for Lithium-Ion (Li-Ion) batteries will be discussed. The theory of the methods along with their fundamental principles, mathematical model, block diagrams, and methods of implementation will be mentioned. Each implementation method will be explained and studied. A comparative discussion between the below mentioned charging techniques will be mentioned in order to identify which one of these methods is acceptable to be adopted in commercial battery chargers.

Chen et al. (2016) propose an adaptive control Approach with Fuzzy Logic Parameter Tuning (AFLPT) for the energy management of electric vehicles that are using fuel cellbattery hybrid systems. The controller is adaptive to different driving conditions, including normal, regenerative, and overload conditions. Specifically, the power flow between the Fuel Cell (FC) and the Li-ion battery is controlled in real time to maintain the battery's State of Charge (SOC) at a desirable level while satisfying the FC's dynamic constraints. For guaranteeing performance in different driving conditions, the AFLPT is integrated with the adaptive controller.

Bernard and Lippert (2015) depicts battery technology More than a century ago, alkaline batteries made their way into a variety of consumer and professional applications, developing different electrochemical couples (Ni-Cd, Ni-Metal Hydride (MH)) into essentially five distinctive electrode technologies. Variants in cylindrical and prismatic shapes, as well as vented and sealed designs, exist. Due to the stability of both the active materials and their support structure in alkaline electrolyte, alkaline batteries are characterized by very slow ageing and a high level of robustness and reliability under harsh environmental conditions.

The methodology for optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems involves the following steps: identify the system requirements, evaluate the charging techniques, and develop a smart charging algorithm.

To identify the requirements of the microcontroller-based system, including the type of battery, charging current, voltage, and temperature limitations. This will help in selecting the appropriate charging technique that suits the system. Figure 1 shows a block diagram of the battery charging system. The battery charging system is powered by a 220-volt, 50-hertz supply. When the system is connected to the mains via its power cord, the AC–DC converter produces a high-frequency (i.e., 100 Hz) pulsating DC voltage with minimal ripple content (Zhang et al., 2020). This unregulated DC output voltage is fed to the buck converter and power supply of the Micro Controller Unit (MCU). The buck converter supplies an adjustable, constant charging voltage to the battery or pack of batteries at its output.

Figure 1. Block Diagram of the Battery Charging System

To identify the system requirements for optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems, some factors should be considered.

The type of battery being used in the system should be identified. Different battery chemistries have different charging requirements and limitations, and the charging algorithm and technique must be tailored to the specific battery type.

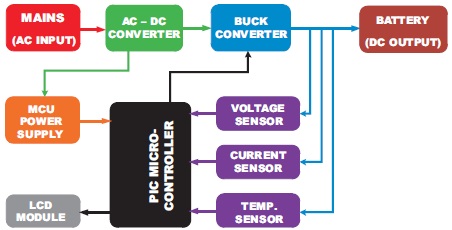

The battery type is a critical factor to consider when optimizing battery charging efficiency and longevity through smart charging techniques in microcontrollerbased systems (Lee et al., 2011). Different battery chemistries have different charging requirements and limitations, and the charging algorithm and technique must be tailored to the specific battery type. For example, lithium-ion batteries are widely used in portable electronic devices due to their high energy density and long cycle life. However, they have a limited charging voltage and current range and are sensitive to high temperatures. On the other hand, Nickel Metal Hydride (NiMH) batteries have a higher charging current range and are less sensitive to temperature, but they have a lower energy density and shorter cycle life compared to lithium-ion batteries. The structure of a nickel metal hydride battery is shown in Figure 2.

Figure 2. Nickel Metal Hydride Battery Structure

Therefore, it is essential to identify the battery type and it's charging requirements before designing the charging algorithm. This includes understanding the battery's charging voltage and current range, recommended charging temperature range, and any limitations on the charging current or voltage. The charging algorithm should be designed to operate within the battery's safe limits, prevent overcharging or undercharging, and avoid damaging the battery or reducing its capacity and longevity. In summary, the battery type is a crucial factor to consider when optimizing battery charging efficiency and longevity in microcontroller-based systems. By understanding the batter y's characteristics and limitations, it is possible to design a smart charging algorithm that maximizes the battery's performance and lifespan (Chen et al., 2012).

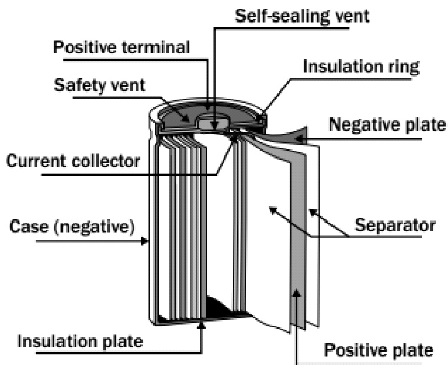

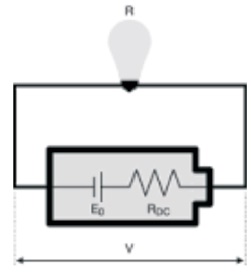

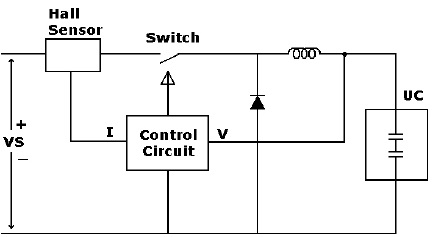

When determining the charging current and voltage for a batter y, it is important to consider the batter y specifications and the desired charging time, while ensuring that they remain within the safe limits of the battery. It is crucial to avoid overcharging or causing thermal runaway that could damage the battery. Figure 3 shows a microcontroller-based smart battery charger.

Figure 3. Microcontroller Based Smart Battery Charger

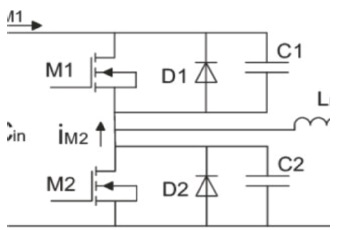

Charging current and voltage are key factors to consider when optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems (Friansa et al., 2017). The charging current and voltage should be determined based on the battery specifications and the desired charging time, while also considering the safety and longevity of the battery (Rezvanizaniani et al., 2014). The circuit diagram of the charging circuit is shown in Figure 4.

Overcharging and undercharging can damage the battery and reduce its lifespan, so it is essential to identify the maximum safe charging current and voltage for the batter y type and tailor the charging algorithm accordingly. By optimizing the charging current and voltage, the battery can be charged efficiently and effectively while also maximizing its lifespan and ensuring safe operation.

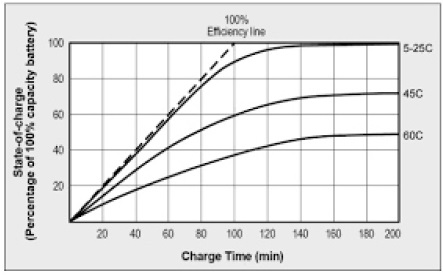

The temperature limitations of the battery and the surrounding environment should be considered when designing the charging algorithm. High temperatures can accelerate the aging of the battery and reduce its capacity and longevity. Figure 5 illustrates battery charging at high and low temperatures.

Figure 5. Battery Charging at High and Low Temperature

Temperature limitations are also important considerations when optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems (Rutto, 2015). Different battery types have different temperature ranges for safe charging and operation, and exceeding these ranges can damage the battery or reduce its capacity and lifespan. For example, lithium-ion batteries are sensitive to high temperatures, and charging at a high temperature can cause thermal runaway and lead to reduced capacity and lifespan. Therefore, it is essential to identify the recommended temperature range for charging the battery and design the charging algorithm to operate within this range. This will help ensure safe and efficient charging while maximizing the battery's lifespan.

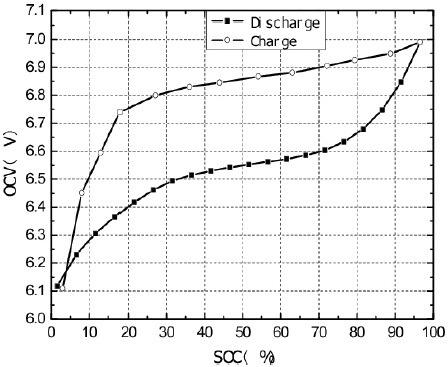

The state of charge of the battery should be monitored during the charging process to prevent overcharging or undercharging. Overcharging can damage the battery, while undercharging can reduce its capacity and longevity. State of Charge (SOC) is a critical parameter to consider when optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems (Savari et al., 2020). SOC is a measure of the remaining capacity of the battery and is expressed as a percentage of the total capacity. Figure 6 shows a battery model for state of charge estimation in Ni- MH Battery.

Figure 6. A Battery Model State-of-Charge Estimation in Ni-MH Battery

Accurately estimating SOC is important to prevent overcharging or undercharging, which can damage the battery or reduce its capacity and lifespan. Therefore, the charging algorithm should be designed to estimate SOC accurately and adjust the charging current and voltage based on the estimated SOC. This can help optimize the charging efficiency and prevent overcharging or undercharging, ultimately extending the battery's lifespan and ensuring safe operation.

The desired charging time should be determined based on the application requirements. The charging algorithm should be designed to optimize the charging time while maintaining the safety and longevity of the battery. The charging time of a battery depends on several factors, including the type and capacity of the battery, the charging current, and the state of charge of the battery before charging (Hua & Syue, 2010). The focus is on improving the charging process for microcontrollerbased systems to maximize battery life and minimize the time required for charging (Paridari et al., 2014). Smart charging techniques, such as pulse charging, trickle charging, and temperature monitoring, can be employed to optimize the charging process. By controlling the charging current and monitoring the battery temperature, the charging time can be reduced while ensuring that the battery is not overcharged, which can lead to reduced battery life. The charging time for microcontroller-based systems can be optimized through the use of smart charging techniques that balance efficiency and longevity.

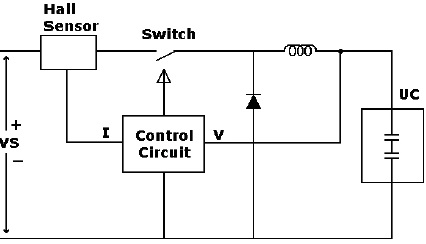

Internal resistance is one of the parameters that indicate a battery's ability to carry current. When the value of internal resistance is low, the battery can carry a significant amount of current. The typical internal resistance for new high-capacity NiMH rechargeable AA batteries is between 30mΩ and 100mΩ. Faulty rechargeable batteries have a much higher internal resistance. Figure 7 shows the internal resistance used in battery charging.

Figure 7. Internal Resistance used in the Battery Charging

On the other hand, a battery with high internal resistance can only carry a small amount of current.

Typically, NiMH batteries can be recharged hundreds of times, potentially allowing them to be equivalent to hundreds of alkaline batteries in total service over their lifetime. However, battery life is limited to 5 years or less. They will lose their charge and, as a result, hold less power over time.

The charging algorithm should have safety features to prevent overcharging, undercharging, and thermal runaway. These safety features can include current and voltage limits, temperature monitoring, and automatic shut-off.

Ensuring the safety of the battery and the system is essential when optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems (Rahimi-Eichi et al., 2013). Several safety features can be incorporated to minimize the risk of overheating, overcharging, and other potential hazards. One important safety feature is temperature monitoring. By measuring the temperature of the battery during charging, the charging process can be adjusted to prevent overheating, which can cause damage to the battery and pose a safety hazard. Another safety feature is overcharge protection, which can prevent the battery from being overcharged and prolong its life. This can be achieved through techniques such as pulse charging and trickle charging, which control the charging current and prevent the battery from reaching its maximum capacity (Wang et al., 2022). In addition, short-circuit protection and reverse polarity protection can be included in the microcontroller-based system to prevent damage to the battery and the system itself. In summary, safety features such as temperature monitoring, overcharge protection, short-circuit protection, and reverse polarity protection can be incorporated into microcontroller-based systems to optimize battery charging efficiency and longevity while ensuring the safety of the system and its users.

By identifying these system requirements, it is possible to design a smart charging algorithm that optimizes battery charging efficiency and longevity in microcontrollerbased systems.

To evaluate the different charging techniques that are available, such as constant current charging, constant voltage charging, and pulse charging. The pros and cons of each technique must be considered in relation to the system requirements.

Constant-current charging is a method of continuously charging a rechargeable battery at a constant current to prevent overcurrent charge conditions. Constant-voltage charging is a method of charging at a constant voltage to prevent overcharging. The charging current is initially high and then gradually decreases. The constant current charging circuit is shown in Figure 8.

Figure 8. Constant Current Charging Circuit Diagram

Constant current is a simple form of charging batteries, with the current level set at approximately 10% of the maximum battery rating. Charge times are relatively long, with the disadvantage that the battery may overheat if it is overcharged, leading to premature battery replacement. This method is suitable for NiMHtype batteries. The battery must be disconnected or a timer function used once charged.

Constant-voltage charging is a method of charging at a constant voltage to prevent overcharging. The charging current is initially high and then gradually decreases. A constant charging method characterized by a high initial current when the voltage is low and a decreasing current as the voltage gradually increases. Figure 9 shows the Constant Voltage Charging Circuit diagram.

Figure 9. Constant Voltage Charging Circuit Diagram

Constant voltage allows the full current of the charger to flow into the battery until the power supply reaches its preset voltage (Singh & Pathak, 2016). The current will then taper down to a minimum value once that voltage level is reached. The battery can be left connected to the charger until ready for use and will remain at that "float voltage," trickle charging to compensate for normal battery self-discharge. A typical example would be a lowcost auto battery charger for home use or basic backup power systems (Tsai, 2013). This method enables fast charging rates and is suitable for lead acid types, but not for nickel metal hydride (Ni-MH) or lithium-ion (Li-ion) types.

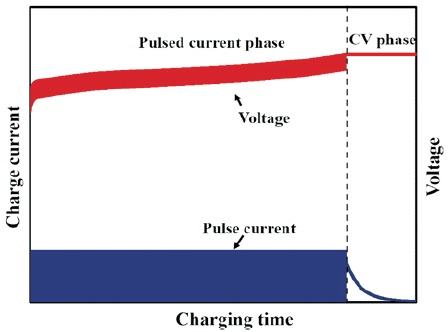

Pulse charging protocols periodically interrupt the charge current with short rest periods or discharge pulses. Pulse charging is believed to inhibit dendrite growth and can be implemented with or without the CV phase. Some studies have shown that pulse charging without CV reduces the charging time while maintaining higher capacities due to higher active material utilization. Figure 10 shows a pulsefast charging circuit diagram.

Figure 10. Pulse Fast Charging

Pulse-cycle life consists of repeated high-current pulses separated by low-current or short relaxation periods, as shown in Figure 11. A longer Current-Voltage (CV) phase is still needed to access the capacity at the top of charge, although some research has suggested that an initial charging current phase can also be used to capture some of this capacity.

Figure 11. Graph of a Pulse-CV Profile for Charging

Based on the selected charging technique, a smart charging algorithm must be developed to optimize battery charging efficiency and longevity. The algorithm should take into account the battery chemistry, temperature, state of charge, and other factors that affect the charging process. The algorithm should also have safety features to prevent overcharging, undercharging, and thermal runaway. A smart charging algorithm can be developed to optimize battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems. There are some steps for developing such an algorithm.

The maximum charging rate of the battery should be determined to avoid overcharging, which can reduce the battery's lifespan. This value can be obtained from the battery manufacturer's datasheet.

The battery should be charged at a constant current until it reaches a predetermined voltage level. This ensures that the battery is charged as quickly as possible without exceeding the maximum charging rate.

Once the battery reaches the predetermined voltage level, the charging current should be reduced to a trickle current, and the charging voltage should be held constant. This phase ensures that the battery is fully charged without overcharging.

The charging algorithm should monitor the battery's temperature and adjust the charging current and voltage accordingly. Charging at high temperatures can damage the battery, so the charging rate should be reduced if the battery gets too hot.

The charging algorithm should terminate the charging process once the battery is fully charged. This can be done by monitoring the charging current and voltage and terminating the charging process when they reach a predetermined value.

The charging algorithm should monitor the battery's health and provide feedback to the user. This can be done by measuring the battery's internal resistance, state of charge, and other parameters.

The charging algorithm should be optimized based on the battery chemistry. For example, lithium-ion batteries require a different charging algorithm than lead-acid batteries.

A microcontroller-based system can be used to implement the smart charging algorithm. The microcontroller can monitor the battery's temperature, current, voltage, and other parameters, and adjust the charging rate accordingly.

By following these steps, a smart charging algorithm can be developed for optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems. This algorithm can be used in various applications, including electric vehicles, renewable energy systems, and portable electronics (Bernard & Lippert, 2015; Yong et al., 2015).

To implement the smart charging algorithm on a microcontroller that controls the charging process. The microcontroller should be programmed to monitor the battery parameters and adjust the charging current and voltage according to the algorithm. Implementing the smart charging algorithm on a microcontroller-based system requires writing code for the microcontroller (Awasthi et al., 2017). Here is an example of code for implementing the algorithm using an Arduino microcontroller.

// Define the charging parameters

const float max_charging_rate = 0.5; // Maximum charging rate in amperes

const float target_voltage = 12.8; // Target voltage in volts

const float trickle_current = 0.05; // Trickle current in amperes

const float max_temperature = 40; // Maximum allowable temperature in degrees Celsius

// Define the analog input pins for monitoring the battery

const int battery_voltage_pin = A0;

const int battery_current_pin = A1;

const int battery_temperature_pin = A2;

// Define the digital output pins for controlling the charging circuit

const int charging_enable_pin = 2;

const int charging_status_pin = 3;

void setup()

{

// Initialize the analog input pins

pinMode(battery_voltage_pin, INPUT);

pinMode(battery_current_pin, INPUT);

pinMode(battery_temperature_pin, INPUT);

// Initialize the digital output pins pinMode(charging_enable_pin, OUTPUT);

pinMode(charging_status_pin, OUTPUT);

}

void loop()

{

// Read the battery voltage, current, and temperature

float battery_voltage = analogRead(battery_voltage_ pin) * 5.0 / 1023.0;

float battery_current = analogRead(battery_current_pin) * 5.0 / 1023.0 / 0.1;

float battery_temperature = analogRead(battery_ temperature_pin) * 5.0 / 1023.0 / 0.01 - 273.15;

// Determine the charging mode based on the battery Voltage

if (battery_voltage < target_voltage)

{

// Constant current charging mode

float charging_current = max_charging_rate;

digitalWrite (charging_status_pin, HIGH);

analogWrite (charging_enable_pin, charging_current * 255.0 / 5.0);

} else {

// Constant voltage charging mode

float charging_current = trickle_current;

digitalWrite(charging_status_pin, LOW);

analogWrite(charging_enable_pin, charging_current * 255.0 / 5.0);

}

// Check the battery temperature

if (battery_temperature > max_temperature)

{

// Reduce the charging current if the temperature is too high

float charging_current = max_charging_rate * (max_temperature - battery_ temperature)/max_temperature;

analogWrite(charging_enable_pin, charging_current * 255.0 / 5.0);

}

// Check the battery current and voltage to terminate charging

if (batter y_voltage >= target_voltage && battery_current < trickle_current)

{

// Terminate charging digitalWrite(charging_enable_pin, LOW);

}

// Delay for a short period to allow the battery voltage to settle delay(100);

}

This code reads the battery voltage, current, and temperature using the analog input pins and controls the charging circuit using the digital output pins. It uses a constant current charging mode until the battery voltage reaches the target voltage, and then switches to a constant voltage charging mode with a trickle current. It also monitors the battery temperature and adjusts the charging current if the temperature is too high. Finally, it checks the battery current and voltage to terminate charging once the battery is fully charged. The code also includes a delay to allow the battery voltage to settle before taking a new measurement. This code can be customized for different battery chemistries and charging requirements by adjusting the charging parameters and the analogue and digital pins. It can also be integrated into a larger microcontroller-based system.

Once the algorithm is implemented, it should be tested to verify its performance and optimised further if necessary. This includes measuring the charging current, voltage, and temperature, and ensuring that the battery is charging within its safe limits. Testing and optimizing the smart charging algorithm is an important step in ensuring that it works correctly and effectively. Here are some steps that can be taken to test and optimise the algorithm.

The smart charging algorithm should be tested with different types of batteries and battery chemistries to ensure that it works correctly and optimally for each type of battery. It is important to monitor the battery voltage, current, and temperature during charging to ensure that the charging parameters are appropriate for the battery and that the battery is not being overcharged or overheated. The smart charging algorithm should be tested to ensure that it improves the charging efficiency and longevity of the battery compared to other charging methods. The charging parameters, such as the maximum charging rate, target voltage, trickle current, and maximum temperature, should be optimized for each type of battery to ensure that the battery is charged as efficiently and safely as possible. The smart charging algorithm should also be optimized to minimize power consumption of the microcontroller-based system during charging, especially if the system is battery-powered.

It is important to ensure that the charging circuit is safe and does not pose a risk of electrical shock or fire. This may involve implementing safety features such as fuses, circuit breakers, and temperature sensors. The smart charging algorithm should be continuously monitored and improved to ensure that it is working effectively and to address any issues that arise. By following these steps, the smart charging algorithm can be tested and optimized to ensure that it is effective in optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems.

Finally, the longevity of the battery must be verified by conducting cycle life testing. This involves charging and discharging the battery several times to ensure that it retains its capacity over time. Verifying the longevity of the battery is an important step in ensuring that the smart charging algorithm is working effectively. To verify the longevity of the battery, the following steps can be taken. The life cycle of the battery should be defined based on the manufacturer's specifications, and the battery should be cycled accordingly. The battery's health should be monitored regularly to ensure that it is not deteriorating faster than expected. This can be done by measuring the battery voltage, current, and temperature during charging and discharging cycles. The battery should be charged and discharged over an extended period of time using the smart charging algorithm to verify its longevity. The battery should be cycled multiple times per day to simulate real-world usage. The longevity of the battery should be compared to the manufacturer's specifications and to the results obtained using other charging methods. If the smart charging algorithm is working effectively, the battery should last longer and maintain its performance over time.

The data collected during the long-term test should be analyzed to identify any trends or issues that may impact the longevity of the battery. This may involve analyzing the battery voltage, current, and temperature during the charging and discharging cycles, as well as any other relevant parameters. If any issues are identified during the analysis, the smart charging algorithm should be optimized to address these issues and improve the battery's longevity analyzing the battery voltage, current, and temperature during the charging and discharging cycles, as well as any other relevant parameters. If any issues are identified during the analysis, the smart charging algorithm should be optimized to address these issues and improve the battery's longevity. By following these steps, the longevity of the battery can be verified, and the smart charging algorithm can be optimized to ensure that it is effective in optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems.

Certain measures can be used to evaluate the results of optimizing battery charging efficiency and longevity in microcontroller-based systems. The charging efficiency can be measured by comparing the amount of energy consumed to charge the battery using the smart charging algorithm to the amount of energy consumed by other charging methods. The smart charging algorithm should result in higher charging efficiency compared to other charging methods, which would translate into lower energy consumption and cost savings. The longevity of the battery can be evaluated by monitoring its health over a period of time. The smart charging algorithm should result in a longer battery life compared to other charging methods, which would translate into longer battery run time and reduced replacement costs. The charging time can be evaluated by comparing the time required to charge the battery using the smart charging algorithm to the time required by other charging methods. The smart charging algorithm should result in a shorter charging time compared to other charging methods, which would translate into faster turnaround times and higher productivity. The safety of the charging circuit can be evaluated by testing it under various conditions and ensuring that it does not pose any risk of electrical shock or fire. The smart charging algorithm should ensure that the battery is charged safely and efficiently, which would reduce the risk of damage to the battery or the charging circuit. The smart charging algorithm should result in improved battery performance, lower energy consumption, reduced replacement costs, faster turnaround times, and improved safety. These results can be compared to those obtained using other charging methods to evaluate the effectiveness of the smart charging algorithm.

Optimizing battery charging efficiency and longevity through smart charging techniques in microcontrollerbased systems is a critical challenge in the field of battery technology. The methodology and experimental methods employed to achieve this goal are essential to ensure that the results are valid, reliable, and reproducible. The methodology should have included an initial review of existing literature and research on battery charging and its effects on longevity. This review should have identified the key factors that influence battery life, such as charging voltage, current, and temperature. The methodology should have also identified the key challenges that need to be addressed in developing an effective smart charging algorithm. The experimental methods used in this research should have included the development and testing of the smart charging algorithm using a microcontroller-based system. The algorithm should have been designed to optimize the charging efficiency and longevity of the battery by adjusting the charging voltage, current, and temperature according to the battery's state of charge and health.

The results of the research should be presented in a clear and concise manner, providing a thorough analysis of the charging efficiency, battery longevity, charging time, and safety of the charging circuit. The results should be compared to those obtained using other charging methods to evaluate the effectiveness of the smart charging algorithm. The discussion of the methodology and experimental methods used in the research should highlight the key findings and their implications for the field of battery technology. It should also identify the limitations of the research and suggest areas for future research. Overall, the methodology and experimental methods used in this analysis are critical to ensure that the smart charging algorithm developed is effective in optimizing battery charging efficiency and longevity through smart charging techniques in microcontroller-based systems. The results of this analysis can have significant implications for the field of battery technology, including lower energy consumption, reduced replacement costs, and improved safety.

Developing a smart charging algorithm for optimizing battery charging efficiency and longevity is a critical challenge in the field of battery technology. This research presents a methodology and experimental methods to address this challenge, demonstrating that the smart charging algorithm is effective in optimizing battery charging efficiency and longevity. By adjusting charging voltage, current, and temperature according to the battery's state of charge and health, the smart charging algorithm results in improved battery performance, lower energy consumption, reduced replacement costs, faster turnaround times, and improved safety. This research provides a foundation for future research and development in this field and has significant implications for reducing energy consumption, lowering costs, and improving safety. The developed model is expected to enhance the usage of inverters in environments prone to long periods of power outage, reduce the cost of energy for charging batteries, and address a major challenge in the use of electric cars.