Figure 1. Block Diagram of Proposed Robotic Seed Sowing Machine

Agriculture plays the primary role in food production. Ploughing the land and sowing seeds are important prerequisites for any plantation or cultivation. In the traditional method, the farmer sows the seed manually without using any machinery. The main problem of traditional technology is that uniform seed distribution cannot be achieved. The basic goal of seed sowing process is to sow the seeds at required depth and at required spacing. The foremost objective of this paper is to design the Agribot (Automatic Seed Sowing Machine) using solar energy. In this proposed system, ultrasonic sensors give the signal to the micro-controller. It gives the signal to the motor driver circuit, then Agribot turns automatically and with the help of a linear actuator it sows the seeds in the next line after sensing the furrows in the agricultural field. Solar panel is used to charge the battery that provides the necessary power to the gear motors. The boost converter is connected between the solar panel and the battery. ATmega328 microcontroller is used to control all the operations performed by the machine. The Agribot has been designed and tested in real time (small scale).

The discovery of agriculture is the first step towards civilized life, and the advancement of agricultural tools is the basic trend of agricultural improvement. It is the backbone of our economical growth. Nowadays, most of the agricultural processes are advanced to modify the mechanism in farming, which works automatically with reduced manpower requirement. Mechanization of the agricultural industry across the globe is yet to be improved due to the lack of acquaintance and the unavailability of highly developed tools and technology. The proposed Agrirobot can be a good alternative to the above mentioned problem. Even an ordinary person can use this proposed machine. The seed sowing preparation technique is based on the row per column depending on the type of cultivar. The main objective of the proposed system is to automate the process of sowing the seeds in agricultural lands, which is controlled by microcontroller assembly. The structure and the design of the machine depends on the various constraints such as the type of soil ploughed, the depth required to sow the seeds, and types of crop and so on.

The seed sowing machine is a device which helps in the sowing of seeds in the desired position, hence it assists the farmers by saving their time. This paper discusses different aspects of seed sowing machine which will be helpful for the agriculture industry to improve mechanization. The agricultural industry has always been the backbone of India's sustained growth. As the population continues to grow, the demand grows as well. Hence, there is a need of efficient and high-capacity agricultural machines. Traditional sowing methods have the following limitations: Poor control over the depth of seeds placement, and high labor requirement. A farmer can sow the seeds at the desired seed rate, but inter-row and intra-row distribution of seeds are likely to be uneven, resulting in bunching and gaps in the agricultural field.

Currently, seed sowing machine should be designed in such a way that, it should be suitable for all kind of farms, all types of crops, reliable and robust construction. These points are basic requirements of the sowing machine. Hence, we made an effort to design the automatic seed sowing machine that reduces the efforts of the farmers. Using the proposed Agribot, we can plant different types and different size of seeds. We have simplified its design for effective handling of the machine by any farmers. The existing method, semi-automatic seed sowing machine needs some manual assistance for the seed sowing process. Drill sowing and dribbling are the best methods for sowing the seeds in the agricultural field. Once the seeds are sown in the field, they are covered with the soil. These methods save the time and prevent the damage of the seeds by birds. But, the seed sown in the soil may be irregular in manner. This is the major drawback of the traditional method. The proposed model increases the efficiency of planting and also reduces the problems encountered in the traditional planting.

In this proposed work, we focused on automatic seed sowing process. There are some drawbacks in the existing method. Even, an uneducated farmer can easily operate this automatic seed sowing system. Researchers have presented various methods and to achieve good seed sowing capacity using new advanced agriculture process, in which it includes robotic operation based cultivation.

Adalinge et al. (2017) designed the seed sowing machine to achieve optimum yields. Mohan et al. (2018) designed the electrical seed sowing machine to increase the efficiency and productivity. Swapnil et al. (2017) designed the seed sowing machine to reduce the problems encountered in the manual seed sowing process. Ramesh and Girishkumar (2017) explained about agriculture seed sowing equipments. Senthilnathan et al. (2018) put forward a method for fabrication and automation of seed sowing machine using IoT. Marode et al. (2013) proposed a method to design and implement the multi seed sowing machine. Andure et al. (2018) proposed a method to design and fabricate of manual seed sowing machine with fertilizers. Umarkar and Karwankar (2016) suggested a method for automated seed sowing Agribot. Thampatty et al. (2019) presented a paper to analyse the frequently occurring rotor bearing fault on an induction motor. The fault analysis was conducted using ANSYS Maxwell 2D. Narasimha et al. (2018) developed the model for the farmers to harvest the paddy crops at low cost using the solar energy. A multipurpose cutting machine was also developed by them.

In our proposed method, seed sowing machine is completely automated and also we have included the solar panel for charging the batteries in the proposed model. The major advantage of this proposed method is that the seed sowing will be at regular interval of the time. This method reduces the manpower and consumes less time.

Overall operation of proposed model is explained in this section. In the robotic seed sowing machine, body and wheel of the Agribot is made up of cast iron, three ultrasonic sensors are connected to the three sides of the Agribot to sense the furrows in the agriculture field and it gives the signal to the micro-controller. We simplified the design of the Agribot. In this proposed design, we have connected the drive shaft to metering mechanism, which eliminates the attachments such as pulleys and belt system. DC motor drives the shaft of the motor, which is coupled with a battery bank. Seed storage tank is connected at the top of the robot near the rear wheels. The IR sensor is fitted in the Agribot that senses the level of seeds in the storage tank. Whenever, seed storage tank is empty, then it will give an alarm signal to the farmers. If the seed sowing process is completed, the entire process of the Agribot will be stopped.

The block diagram of the proposed seed sowing machine is shown in Figure 1. The voltage rating of 12V is required to drive the gear motor driver circuit. This 12V is obtained by connecting 12V battery. An additional support of 12V-10W Solar panel is also connected in the proposed system. ATmega328 microcontroller and ultrasonic sensors require 5V supply, which is given by the 5V voltage regulator. The gear motor requires 6V supply, so the buck converter is used to reduce the voltage to 6V.

The ultrasonic sensors are used to sense the furrow and it will give the signals to the controller. Then, the motor will be operated. If the left sensor is ON, then the motor 1 and the motor 2 will move in a forward direction and the seed mechanism gets turned ON by the gear motor. Now, the seed stored in the storage tank are lifted by seeding mechanism and the seeds get dropped in the ground through a hole in the seed storage tank.

After this process gets completed, the linear actuator gets turned ON and it moves in a linear direction to sow the seed in the soil. This process will continue until the left and straight ultrasonic sensors sense the furrows in the agricultural field, and if they sense any furrows, then the Agribot will take Uturn and continue the process of seed sowing. The operation time of the motor can be varied by the delay time, which is programmed by the micro-controller. If any obstacle comes in front of the robot, the ultrasonic sensors give the signal to the controller, which diverts the path of the robot.

When the Agribot reaches the other end and it completes its task, it creates an alarm signal, so that the farmer can fill the seed storage tank.

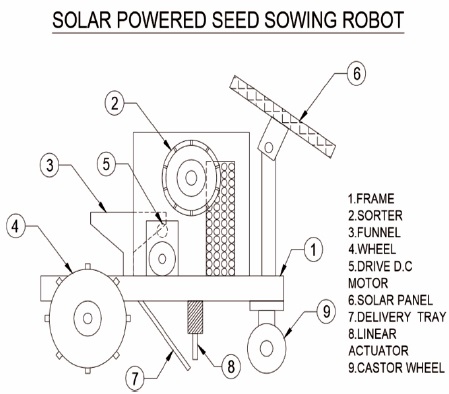

Figure 2 shows mechanical construction of the robotic seed sowing machine with the major components of the proposed system. In this machine, two wheels are made for forward movement with gear motor and the castor wheel is made for the rear movement of the machine. The seed sowing mechanism is used to drop the seeds from the storage tank. The delivery tray is used to drop the seeds on the ground. The linear actuator is used to sow the seed in the soil. Figure 3 shows the circuit diagram of the robotic seed sowing machine. In this proposed system, the ATmega328 controller is used to control the machine and it is connected to the motor driver circuit for controlling the gear motor and the linear actuator for sowing the seed in the soil.

Figure 2. Schematic Diagram of Seed Sowing Machine

Solar panel refers to a panel designed to absorb the sun's rays as a source of energy for generating electricity or heating. Photovoltaic modules constitute the photovoltaic array of a photovoltaic system that generates and supplies solar electricity. Photovoltaic modules use light energy (photons) from the sun to generate electricity through photovoltaic effect. The modules are made in series of electrical lines to achieve the output voltage.

In this proposed method, we have used the solar panel to supply additional power to the Agribot. The ratings of solar panel used for the proposed system is given below:

Solar Panel-10-Watt 12-Volt

Maximum Power - 10 W-Maximum

Power Voltage - 17.83 V

Maximum Power Current - 0.57 A

Open Circuit Voltage - 21.75 V

Short Circuit Current - 0.61 A

Production Tolerance - ±3%

Solar penal size - 250×250×17 mm

The solar panel is connected to the battery to increase the operation time of the Agribot during the seed sowing process in the agricultural field. The machine is operated by using a 6V DC motor with rated speed of 100 RPM. In this research work, utmost care has taken to achieve uniform seed sowing by the Agribot. The motor driver circuit requires 12V for its operation, but the gear motor requires only 6V, so the buck converter is used to get variable voltage.

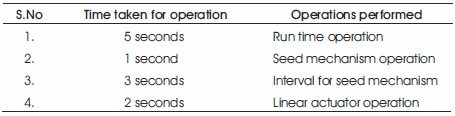

We can increase the number of linear actions given by the linear actuator during the seed sowing process. These actions can be increased by the delay time of the controller circuit. The run time operation of the machine during forward direction takes 5 seconds. The seed sowing mechanism takes 1 second. The time taken to carry the seed from storage tank to the land is 3 seconds gap. The delivery tray is connected through the bottom of the machine to carry the seed to near the linear actuator. The linear actuator takes 2 seconds to complete its operation.

Figure 4 shows the flow chart of the proposed robotic seed sowing process. Ultrasonic sensor detects any obstacle in the path of the machine. It continuously sends data to the microcontroller, and if there is any obstacle in the path of the machine, the information is sent to the microcontroller. When the power switch is turned ON, then the machine gets started. The ultrasonic sensors read the output data, and the limit is not exceeded, then the two gear motors gets turned ON and the Agribot moves in forward direction. Then, it sows the seed by the linear actuator for every preset value of time until it reaches the furrow end in the agricultural field. Yet again, the output will be read by the ultrasonic sensors. If the left and straight ultrasonic sensors sense any obstacle, the first motor gets turn ON and the second motor gets turned OFF. The Agribot takes U-turn if it finds any furrow end in the agricultural field. If the left and straight ultrasonic sensors are not sensed or not read the output, then the seed sowing process will continue in the field until the next output data is read by the ultrasonic sensors.

When the right Ultrasonic sensors read the data from the output furrow in the field, then the seed sowing process comes to an end, by turn OFF the motor 1 and motor 2. If the right ultrasonic sensor is not sensed or not read the output, then the seed sowing process will continue in the filed until the next output data is read by the ultrasonic sensor.

Following components are used to design the Agribot.

A gear motor is a specific type of electrical motor that is designed to produce high torque while maintaining a low horsepower or low speed motor output.

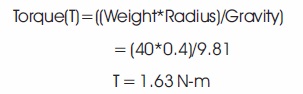

In this seed sowing machine, there are two gear box motors which are used to run the Agribot in the field. The motor rated at 100 RPM with 6V input supply and it is controlled by the motor driver circuit which is interfaced with the Arduino micro-controller in the Agribot. Each motor is controlled by the driver circuit. Then, there is another gear motor which is used to carry the seeds in the seed mechanism. The operation of the Agribot is controlled by the Arduino microcontroller. Design calculation is done for designing the Agribot. The required torque to drive the Agribot is calculated as follows.

Gear Motor-100 rpm:

where,

P-Power in Watts

N-Speed in RPM

T-Torque in N-m

P = (2*3.14*100*1.63)/60

P =17.06 W

Using equations (1) and (2) design calculations for DC motor is computed.

A linear actuator is a mechanical device that converts energy to create motion in a straight line contrasted with the circular motion of a conventional electric motor. It can be used to apply a force. The types of motion include: blocking, clamping, ejecting, lifting, descending, pushing or pulling.

Ultrasonic sensors measure the distance using ultrasonic waves. The sensor head emits an ultrasonic wave and receives the wave reflected back from the target. The Ultrasonic sensors measure the distance to the target by measuring the time between emission and reception.

The interfacing of ultrasonic sensor with Arduino is done through the digital pin of the Arduino. The ultrasonic sensor has 4 pins. The pins are Vcc , Trigger, echo and ground. All the four pins are digital output pins from an ultrasonic sensor. The pin Vcc and the ground are connected to the supply and ground of Arduino. Trigger pin and echo pin are connected to any of the two digital pins of the Arduino.

Atmega328 is an 8-bit and 28 pins AVR micro-controller, manufactured by Microchip, and has a flash type program memory of 32KB. UNO is based on Atmega328 microcontroller. It operates ranging from 3.3V to 5.5V, but we use 5V as a standard. It is normally used in Embedded Systems applications. ATmega328 is used to control the speed of the motor, receives information from sensor, display information to the LCD and user interface. These functions are done by Arduino code.

In the Agribot, the ATmega328 controller is used to control the device communication. The three ultrasonic sensors are connected with the ATmega328 micro-controller. The motors are controlled by the instructions given in the ATmega328 and motor driver circuit. The motor operation time and linear action operation time can be controlled by the Atmega 328, the delay time can be changed according to the type of soil used in seed sowing process.

The moderate level of seed sowing machine is developed for testing purpose in this research work. The proposed model can be implemented for a large scale level. In order to increase efficiency in agriculture, this Agribot may be used.

The important constraint imposed on our proposed design is that the seed sowing, which will be in regular interval even though any obstacle occurs in the field and furrow. The following constraints are considered in this research work. Seeds should be placed constantly, and it should equally distribute onward rows and the seed should be constantly covered by soil. In order to make proper seed sowing process, some technical arrangements are made in the seed sowing Agribot. The presence of any barrier or obstacle along the path of the Agribot is identified through ultrasonic sensors. Three ultrasonic sensors are placed in front of the vehicle.

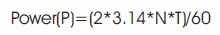

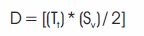

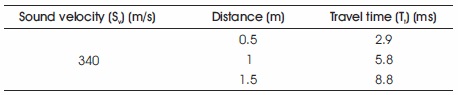

Using equation (3), design calculations for Ultrasonic sensors are computed. The obstacle distance from the subject, repeated information sampling and averaging are performed. As ambient light conditions do not affect the ultrasonic sensors, object detection and distance calculation can be performed accurately.

where, D - Distance in m

T - Travel time of sound wave in ms

S - Sound Velocity in m/s (340m/s)

S = 340 m/s

D = 50 cm

0.5 = [(Tt) * (340 / 2)]

0.5 = [(Tt) * 170]

0.0029 s = Tt

Tt = 2.9 ms

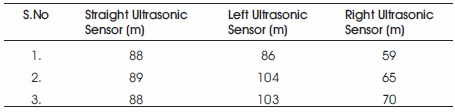

Table 1 shows the output characteristics of the ultrasonic sensor. In the proposed model, the square gear box motors are used. It is mechanically commutated DC electric motor that equips gear boxes to provide a great balance between torque-speed. This square gearbox DC motor is a very high torque motor, which is used to make big robots. The motor will run at 100 RPM when powered with 12V DC supply. The motor shaft is made up of good quality Engineering steel with nickel plating to handle high torsion stress. In the proposed Agribot, linkage mechanism is used to steer the vehicle with the aid of DC geared motor. The seed sowing mechanism is controlled by a gear motor. If the Agribot reaches the end of the agricultural field, the seed sowing process will be turned off automatically.

Table 1. Characteristics of Ultrasonic Sensor

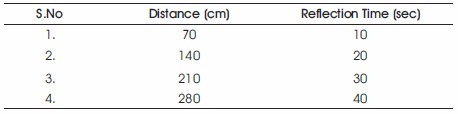

Table 2 shows the distance and time measurement of normal surface of the soil sensed by the ultrasonic sensors. The machine moves for 70 cm of distance of every 10 seconds in the normal surface of the soil.

Table 2. Distance and Time Measurement at Normal Surface

The machine completes its operation until the seed gets empty in the seed storage tank. We can vary the distance of the seed to be sown in the field by changing the delay time. The seed sowing process is accomplished for every preset value of the time.

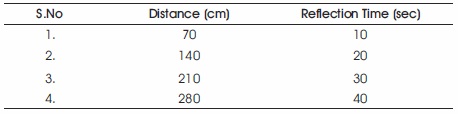

Table 3 shows the distance and speed measurement of the seed sowing machine at ploughed soil. In the ploughed surface, the soil will be uneven, so the wheel takes more time to move when compared to the flat surface. Our developed Agribot was tested in a 20 x 20 square feet land. The above readings are obtained by testing the machine in the land. The machine moves 55cm for every 10 seconds at ploughed soil.

Table 3. Distance and Speed Measurement of Seed Sowing Machine

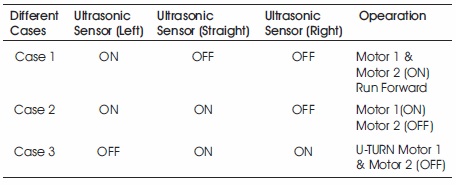

In the Agribot, the ultrasonic sensor plays a foremost role. So, the various tests and measurements are taken by the ultrasonic sensors at the normal surface and ploughed soil surface. Table 4 shows the ON/OFF status of the three ultrasonic sensors. At this juncture, three cases are considered, i.e., case 1, case 2 and case 3. From the analysis obtained from the ultrasonic sensor outputs, the ON/OFF status of the motors is tabulated.

Table 4. Results for Ultrasonic Sensor

In case 1, if the left ultrasonic sensor is in ON condition, then the both straight and right ultrasonic sensors will be in OFF condition, then the motor 1 and motor 2 will run in forward direction. In case 2, if the right ultrasonic is in OFF condition and the left and straight ultrasonic sensors will be in ON condition. Then the Motor 1 is in ON status and the Motor 2 is in OFF status. So the U-TURN condition is accomplished. In case 3, if the left ultrasonic sensor is in OFF condition, then the straight and right is in ON condition, in this case both motors will come to OFF condition.

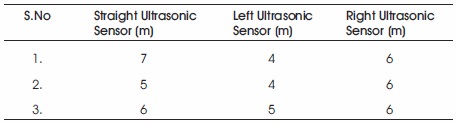

Table 5 shows the distance indicated by the three ultrasonic sensors at normal condition. During the normal condition, three ultrasonic sensors do not sense any obstacle in the field. The distance value of the three ultrasonic sensors is varying from each sensor. Table 6 shows the distance indicated by the three ultrasonic sensors at operating condition. During the operating condition, the ultrasonic sensors sense the obstacles in front of the Agribot in the agricultural field. The distance value of the right ultrasonic sensor is changing from the remaining sensors due to the presence of furrows in the agriculture field.

Table 5. Ultrasonic Sensor at Normal Condition

Table 6. Ultrasonic Sensor at Operating Condition

Table 7 shows the time taken by various components for its operation in the designed Agribot. Seed sowing mechanism takes 3 seconds for its operation and the linear actuator take 2 seconds for the seed sowing process. Figure 5 shows the developed seed sowing Agribot. All the constraints are satisfied while designing the seed sowing machine.

Table 7. Time Taken for the Operation of the Seed Sowing Machine

Figure 5. Proposed Developed Seed Sowing Machine

Most of the microcontrollers work on very low voltage (5V) and current while the motors require higher voltages and current. Therefore, the microcontrollers cannot provide them such higher current. Hence, we use motor driver ICs. Motor driver is a little current amplifier. It takes a low current signal and gives out a high current signal, which can drive a motor. It can also control the direction of motor. Motor drives are of many kinds that depends on the maximum supply voltage, maximum output current, rated power dissipation, load voltage, number outputs, etc. In this project, we have used the motor driver L298N.

Total weight of the developed Agribot is approximately 30 kg, since it is made up of hardened iron. For testing purpose, 1 kg of groundnut is taken to sow the seeds in the agricultural field. Similarly the cultivation of crops such as sunflower, baby corn, peanut and beans, lady finger, pumpkin and black gram can be sown in the field using our proposed Agribot. The speed of the developed Agribot is 3.2 meters/minute. Following process has been done for the software design to control the Agribot: Initially, the file is created in the Arduino software. Subsequently, software code is used to compile and test the various conditions of the proposed method.

Software code:

#include

UltraSonicDistanceSensor right(A1, A0);

UltraSonicDistanceSensor straight(A3, A2);

UltraSonicDistanceSensor left(A5, A4);

bool str = false;

bool lt = false;

bool rt = false;

const int m1_fwd = 5;

const int m1_rev = 6;

const int m2_fwd = 7;

const int m2_rev = 8;

int ss_state = 0;

int sl_state = 0;

int sr_state = 0;

int initial = 0;

bool toright = false;

bool toleft = false;

int s_right = 0;

int s_left = 0;

int rep = 0;

int rep1 = 0;

void setup () {

Serial.begin(9600);

pinMode(m1_fwd, OUTPUT);

pinMode(m1_rev, OUTPUT);

pinMode(m2_fwd, OUTPUT);

pinMode(m2_rev, OUTPUT);

}

void loop () {

int ss = straight.measureDistanceCm();

delay(1000);

int sl = left.measureDistanceCm();

delay(1000);

int sr = right.measureDistanceCm();

delay(1000);

if(ss >30 && sl <15 && sr >30 && ss_state == 0 ){

str = true;

ss_state = 1;

initial = 1;

}

if(ss <15 && sl <15 && sr >30 && sr_state == 0 ){

rt = true;

sr_state = 1;

}

if(ss <15 && sl > 30 && sr < 15 && sl_state == 0 ){

lt = true;

sl_state = 1;

}

if (ss >30 && sl >30 && sr >30){

rt = false;

}

if (ss < 15 && sl > 30 && sr >30 && initial == 1 && s_right== 0 ){

toright = true;

s_right = 1;

rep = 1;

}

if (ss >30 && sl >30 && sr >30 && rep == 1 && toright ==true){

toright = false;

}

if (ss < 15 && sl > 30 && sr >30 && rep == 1 && s_left ==0){

toleft = true;

rep1 = 1;

s_left = 1;

}

if (ss >30 && sl >30 && sr >30 && rep1 == 1 ){

toleft = false;

s_right = 0;

s_left = 0;

rep = 0;

rep1 = 0;

}

if (str && !rt && !lt && !toleft && !toright){

digitalWrite(m1_fwd, HIGH);

digitalWrite(m2_fwd, HIGH);

digitalWrite(m1_rev, LOW);

digitalWrite(m1_rev, LOW);

delay(3000);

digitalWrite(m1_fwd, LOW);

digitalWrite(m2_fwd, LOW);

digitalWrite(m1_rev, LOW);

digitalWrite(m1_rev, LOW);

}

Implementation of this proposed system in agriculture will predominantly increase mechanization. Agribot automatically sows the seeds in the agriculture field. This reduces the labour dependency. In traditional method, it is not possible to achieve uniform seed distribution. Other biggest advantages of this proposed system are very low noise and zero pollution from the Agribot. In the future, we have plans to add more features. Once the seed is sown in the soil, water can be poured automatically. Unwanted weeds can be removed from the agriculture field. Fertilizers can be sprayed by using the proposed Agribot. The Agribot can be developed to accommodate more seeds in large scale.