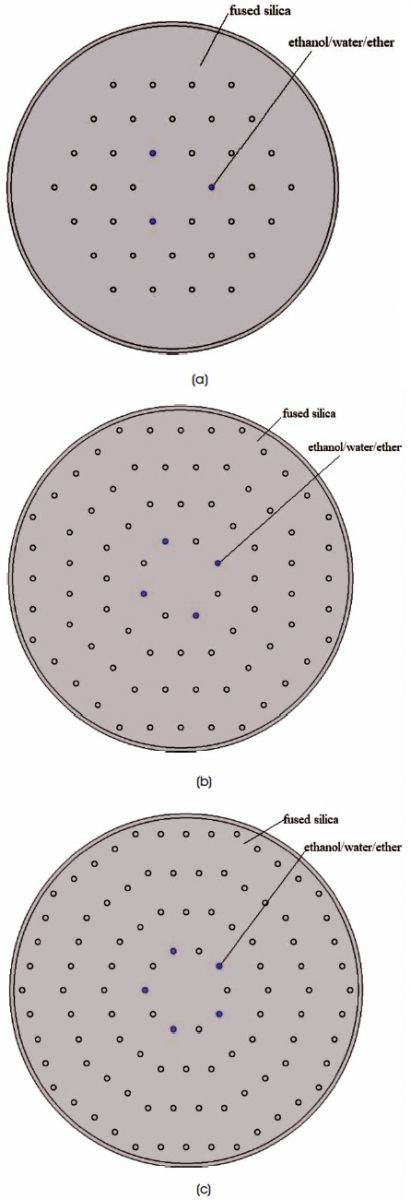

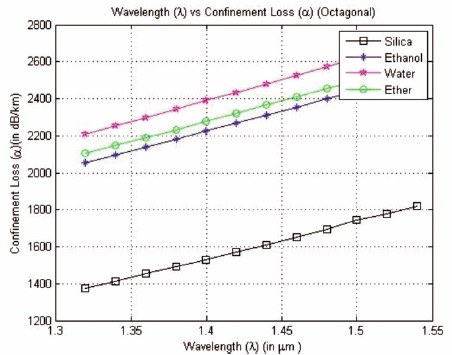

Figure 1. (a) Hexagonal MCF with Doped Liquids, (b) Octagonal MCF with Doped Liquids, (c) Decagonal MCF with Doped Liquids

This paper presents the analysis of confinement loss and dispersion of Multi-Core Fiber (MFC) by varying the structural parameters like wavelength, diameter of holes and pitch length. The different geometries of Multi-Core Fiber used for this analysis are Hexagonal, Octagonal and Decagonal structures. The simulation is done by doping few inner ring holes of the MCF with different liquids having refractive index lower than that of the actual core. The calculation of confinement loss and dispersion is done in COMSOL Multiphysics software while the graphs are plotted in MATLAB. It has been observed that variation of structural parameters has been found to cause change in confinement loss and dispersion. After comparing these three structures, it is seen that hexagonal structure shows a better outcome than others.

As new technologies are emerging, the demand for larger bandwidth and internet traffic is growing significantly (Saitoh & Matsuo, 2013). Among the various optical components, optical fiber has low loss and large capacity transmission, which plays the crucial role. It is made up of transparent core, surrounded by a transparent cladding material having lower refractive index ( Shrivastava et al., 2016). Recently, a new type of fiber called heterogeneous Multi-Core Fiber (MCF) was invented. MCF uses Space Division Multiplexing (SDM) to enhance the capacity of transmission of the fiber (Koshiba et al., 2009). With the help of SDM, various signals can be transmitted simultaneously by using multiple spatial paths into the fiber (Saitoh & Matsuo, 2016). Many researches have been done in the field of MCF, which includes the variation in number of cores, modes and geometrical structures. Similarly, previous work done in Photonic Crystal Fiber (PCF) has different materials used to fabricate the core of the optical fiber (Panda et al, 2018). Few air holes are replaced with different mediums and the variations are studied (Panda et al, 2018). The variations are in the terms of confinement loss, effective area, dispersion, etc. (Chiang & Wu, 2006).

In this paper, the selective silica holes (initially) of the MCF are filled with three different liquids having refractive indices lower than that of the core material. These liquids are ethanol (refractive index (n) =1.361), diethyl ether (refractive index (n) =1.3526), and water (refractive index (n) =1.333). Some parameters such as humidity, atmospheric temperature and pressure are assumed to be constant. Only a few holes are selected because the large amount of these liquids may turn core into the cladding (Panda et al., 2018).

The major objective of this paper is to analyze the optical properties of hexagonal, octagonal and decagonal structured MCF and compare the results to obtain the better outcome and structure. The optical properties to be analyzed are mainly confinement loss and dispersion. It is done by varying the structural parameters like diameter of hole (d), pitch length (Ʌ) and wavelength (λ).

The simulation and analysis of different parameters are done on hexagonal, octagonal and decagonal MCFs, and these structures are designed in COMSOL Multiphysics. In the experiment, octagonal and decagonal MCF structures have 4 concentric rings, whereas hexagonal structure has 3 concentric rings. The background material used in the given structures is silica, which has refractive index of 1.4443. Other holes except selectively filled holes have refractive index of 1.4445. The selected liquids are filled into the inner ring of the structure and the holes are selected alternatively for better simulation and result. Figure 1 (a), (b) and (c) mention the structure of proposed MCF with selective holes when filled with given liquids, i.e., ethanol, water and ether.

Figure 1. (a) Hexagonal MCF with Doped Liquids, (b) Octagonal MCF with Doped Liquids, (c) Decagonal MCF with Doped Liquids

First step includes the selection of initial dimensions of multicore fiber structures followed by the selection of desired materials for the proposed structures. Desired materials consists of water (refractive index, n=1.333), ethanol (refractive index, n=1.361) and ether (refractive index, n=1.3526), which will be used for doping holes by replacing silica (used initially). Then the evaluation of the electric field is done by performing finite element method.

Next step includes checking whether the electric field is confined or not. If yes, proceed further by calculating real and imaginary part of effective refractive index and if not, the previous steps mentioned above are repeated until the field is confined. Real part is used for calculating dispersion whereas imaginary part is used for calculating confinement loss. Analysis of the frequency domain is done to obtain the effective area of the field.

When pitch length (Ʌ) is varied from 3 to 5 μm for hexagonal, octagonal and decagonal MCFs, the real part of the effective refractive index can be seen to increase. In the hexagonal structure, all three liquids have same values, whereas in octagonal and decagonal structure variation was observed.

As the pitch length was varied from 3 to 5 μm, the result shows that confinement loss decreases exponentially with increase in pitch length. Among the three mentioned liquids, ethanol has lowest value compared to all three structures. It was observed that hexagonal structure has the lowest confinement loss.

On varying diameter (d) from 0.4 to 0.95 μm, the real part of the effective refractive index could be seen to decrease as the diameter increases. In decagonal structure, water has the lowest value whereas in other structures all three liquids attain the same lower values.

It is observed in all three structures, namely hexagonal, octagonal and decagonal MCFs, in which when diameter of hole (d) increases from 0.4 to 0.95 μm, confinement loss also increases.

It was seen from the obtained result that, when wavelength (λ) is varied from 1.32 to 1.52 μm, real part of the effective refractive index decreases gradually.

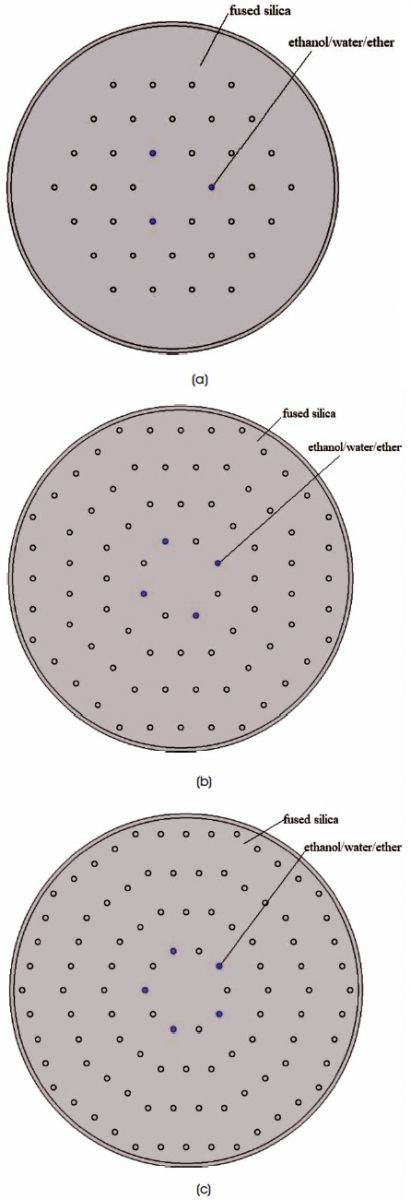

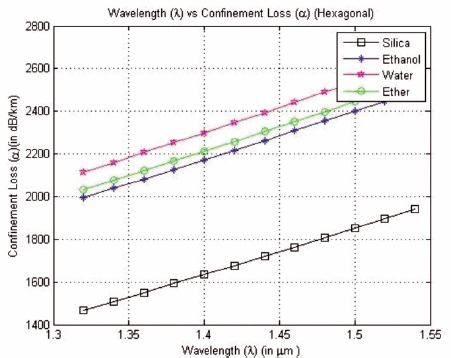

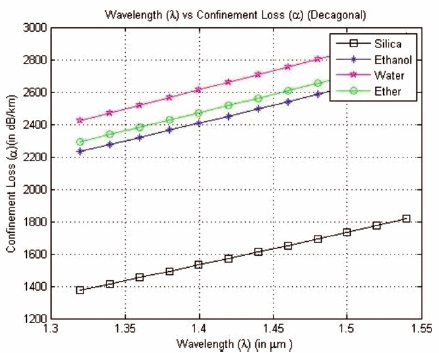

When wavelength (λ) is changed from 1.32 to 1.54 μm, it has been observed that as wavelength increases, confinement loss also increases. In all three different structured MCFs, ethanol has the lowest value when compared with three liquids. When liquids and silica were compared, it was clearly seen that the silica is the lowest of all tried materials. And among all three structured MCFs, hexagonal structure shows the better outcome. Figure 2, 3 and 4 shows the variation in confinement loss when wavelength is varied for hexagonal, octagonal and decagonal MCFs.

Figure 2. Wavelength vs. Confinement Loss for Hexagonal MCF

Figure 3. Wavelength vs. Confinement Loss for Octagonal MCF

Figure 4. Wavelength vs. Confinement Loss for Decagonal MCF

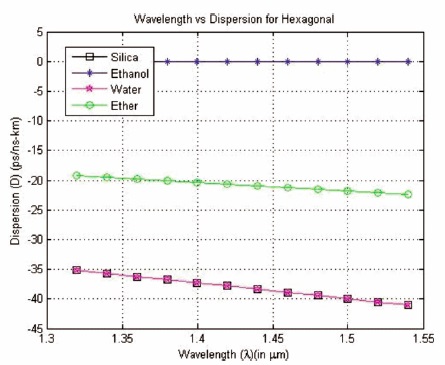

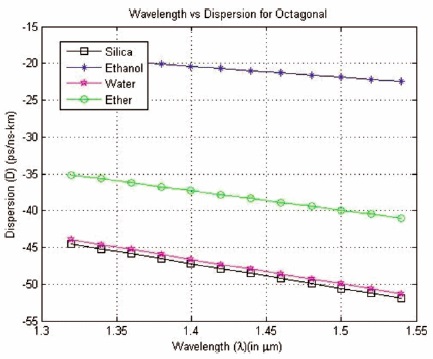

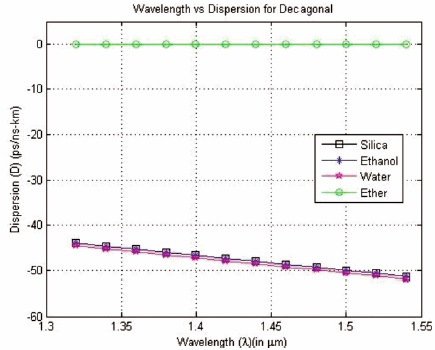

In the hexagonal structure, as shown in Figure 5, ethanol shows a constant value with lowest dispersion. Whereas silica and water show same values and has highest dispersion of all materials filled in the holes. In octagonal structure, from Figure 6, it is observed that as wavelength (λ) increases dispersion also increases negatively. Ethanol has lowest dispersion whereas silica has highest among all. In liquids, water has the highest value. In decagonal structure, from Figure 7, it is clear that ether is shows a constant value as the wavelength (λ) increases and has lowest dispersion of all. Other materials such as ethanol, silica and water show similar values.

Figure 5. Wavelength vs. Dispersion for Hexagonal MCF

Figure 6. Wavelength vs. Dispersion for Octagonal MCF

Figure 7. Wavelength vs. Dispersion for Decagonal MCF

After various simulations and comparisons between heterogeneous Multi-Core Fiber (MCF) with different geometries namely hexagonal, octagonal and decagonal structures using three different liquid materials such as ethanol, diethyl ether and water, following conclusions can be drawn out.

The author is very grateful to the supervisors for their extraordinary guidance, cooperation, encouragement and advice during the preparation of research paper.