Figure 1. Block Diagram of ESUI

Indeed, for many industrial applications, precise and reliable monitoring of temperature is significantly important. To ensure this, various temperature sensors such as Thermocouples, Thermistors, Resistance Temperature Detectors (RTDs), Pyrometers, Semiconductor sensors, etc., are readily available. These sensors depict their own salient features. For accurate and reliable temperature monitoring, the monolithic temperature sensors are always recommended. Moreover, it is found that, monolithic temperature sensors demonstrate diversity in sensing mechanism, which results into diversity in the values of the temperature to be monitored. This may result into degradation in reliability of the temperature monitoring system. To explore the details, an embedded system is designed for comparative performance analysis of monolithic temperature sensors, and results of the investigation are presented in this paper

The multichannel embedded system is developed by deploying the 89S52 microcontroller wherein data acquisition and computing are carried out precisely. Two monolithic temperature sensors; temperature dependent voltage sensor, 0 (LM35: a = 1 mV/ C) and temperature dependent current sensor (AD590 : a = 1 mA/K), have been interfaced. Digital readout (DRO) unit is developed about on a 16X2 Liquid Crystal Display (LCD) module. The Integrated Development Environment (IDE), Keil uVision4, is utilized for the firmware development in C environment. The present monitoring system is scientifically calibrated to the temperature in degree Celsius. Temperature values shown by both temperature sensors are simultaneously recorded and the results are interpreted in this paper.

The precise and accurate measurement of temperature is vital across broad domain of applications such as physical and chemical laboratories, health care, industry, meteorology, etc. Temperature is critical and widely measured physical parameter for wide variety of needs and applications (Rongxia, 2009; Raji et al., 2016; Singh et al., 2015). To cater these needs, variety of temperature sensors of different sensing mechanism are available. These temperature sensing devices are broadly classified according to the fabrication processes, materials used, characteristics, working principles, output and application areas etc. Generally, the temperature monitoring devices are of two types such as direct type (Thermometers, Temperature probes, etc.) and indirect type (Transducers). The transducers are mostly utilized for many applications and are broadly categorized as resistance elements, thermopiles, semiconductor devices and monolithic devices. In fact, sensors are featured with the characteristics such as sensitivity, range of implementation, accuracy, response times, repeatability, hysteresis, stability etc. and play a crucial role in designing the temperature measuring instrumentation (Rajita et al., 2016).

The present Embedded System Under Investigation (ESUI), is designed, wherein the comparative study of two monolithic semiconductor temperature sensors of different working principles are emphasized. Most recommended monolithic temperature sensors such as LM35 and AD590 are employed for the present ESUI design and comparative performance analysis. The sensor LM35 operates with the principle of change in voltage in proportion with change in temperature and 0 exhibits temperature coefficient as a = 1 mV/ C (Arunaganesan et al., 2013). Moreover, another temperature sensor, AD590, is an integrated circuit. It demonstrates proportional variation current with temperature in Kelvin and gives temperature coefficient as a = 1 mA/K (Pease et al., 2007).These two temperature sensors are considered for the present ESUI as these temperature sensors are recommended by many investigators to employ for temperature measurement instrumentation (Chatterji et al., 2013; Deshmukh et al., 2016; Luo and Su, 2007; Tilekar and Ladgaonkar, 2008).

Indeed, the microcontroller based embedded system design is a highly suitable technology for the development of instrumentation for precise and reliable measurement of physical quantities such as humidity, pressure, temperature, etc. (Kumaravel et al., 2010; Saleha Begum et al., 2013; Tamayo et al., 2010). In earlier days, the electronic system designers rely on discrete circuit components and such electronic systems are well known as System on Board (SoB). Nowadays a microcontroller based embedded technology is flourishing well realizing the themes of System on Chip (SoC). Therefore, it is proposed to avail the most pervasive technology i.e. embedded technology, for the present investigation. An embedded system is developed to explore the behaviour of these two monolithic temperature sensors, and results of the comparative performance analysis are interpreted in this paper.

The present ESUI emphasizes the design and development of microcontroller AT89S52 based on embedded system, for simultaneous performance analysis of monolithic temperature sensors. The hardware and software co-development is mandatory for any embedded system. Both hardware and firmware are developed and details are presented.

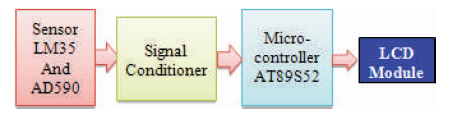

The architecture of the system is depicted in the block diagram, shown in Figure 1. It consists of monolithic temperature sensors; LM35 and AD590, signal conditioning unit, a microcontroller AT89S52, smart Liquid Crystal Display (LCD), power supply unit, etc. Ensuring the importance of the virtual instrumentation, the hardware of the system is designed and simulated in Proteus7, an Integrated Development Environment (IDE). While simulating with Proteus, it is found that circuit designing is one of the interesting works in the electronic industry (Khan and Sankar, 2014). The schematic of the circuit designed in Proteus tool is shown in Figure 2. The required embedded firmware is developed in Keil μVision4 in embedded C environment and programmed into target memory of the device with virtual programmer. Both hardware and software are optimized for proper synchronization. After programming the device, it is simulated.

Figure 1. Block Diagram of ESUI

The three-terminal precision monolithic temperature sensor LM35 is popular in various industrial applications 0 0 0 due to its wide sensing range (-55 C to +150 C) with 0.5 C accuracy, excellent characteristics, inexpensive and wide operating voltage range (4 V to 30 V). This precision temperature sensor has linear output voltage with a 0 temperature coefficient of 10 mV/ C. The LM35 is suitable for remote applications due to its low output impedance, 0.1 Ω for 1 mA load. Furthermore, it has less than 60 mA 0 current drain and low self-heating, 0.08 C in still air. For the present ESUI, TO-92 plastic package LM35 is powered with 5 V at pin 1 and temperature dependent output at pin 2 is extracted in mV, which has adequate signal strength and is applied to the channel-0 of the ADC0808 for further processing. In the present investigation, the output of LM35 is not extracted across load resistor, but it is extracted directly, as shown in Figure 2.

Another precision monolithic temperature sensor Ad590 of two or three terminal, is having wide temperature range 0 0 0 (-55 C to +150 C) with ±0.5 C accuracy, expensive, possess excellent linearity and good stability. This sensor depicts high impedance and has inherent monolithic integrated circuit combined with the elimination of support circuitry, which makes the AD590 an attractive alternative for many temperature measurement situations. Moreover, linearization circuitry, precision voltage amplifiers, resistance measuring circuitry and cold junction compensation are not needed while deploying AD590. As this device provides high impedance current output, it is insensitive to voltage drop over long transmission line. In the present ESUI, TO-52 three-terminal metal package AD590 is powered with 5V, at pin1, and the temperature dependent output current (I ) is extracted from pin 2. This analog current is extracted T in voltage (mV), across the 1 KΩ load. It also has adequate signal strength and is applied to Channel-1 of the ADC0808 for further processing (Pease et al., 2007).

The Complementar y metal-oxide-semiconductor (CMOS) ADC0808 device is utilized for present ESUI to digitize the sensors signal. It is utilized to minimize the complexity of the design and to avoid unnecessary utilization large number of I/O ports of the microcontroller (Tilekar and Ladgaonkar, 2013). The Analog-to-digital Converter (ADC) has 8-bit resolution, 8-channel multiplexer, 15 mW low power consumption and 100 ms conversion time. As depicted in Figure 2, LM35 and AD590 are interfaced to Channel-0 and Channel-1 of ADC respectively. The digitized 8-bit output of ADC is interfaced to the port P2 of the microcontroller. The remaining channels from Channel-2 to Channel-7 are grounded as they are not needed. The Channel Selection (CS) input ADD A is controlled through the software, so, it is interfaced to microcontroller port P1.3. Other two CS inputs ADD B and ADD C are grounded as they are not needed. The Output Enable (OE) terminal is connected to the 5 V, Collector Voltage (VCC). The START, End of Conversion (EOC) and Address Latch Enable (ALE) terminals are software controlled, so, they are interfaced to the microcontroller ports P3.4, P1.2 and P1.0, respectively. The necessary 500 KHz clock signal for ADC is generated through software and extracted from the microcontroller port P3.3, which is applied to the Clock input pin of ADC.

The multiplexed temperature dependent unprocessed digital data of these two temperature sensors are processed by the microcontroller AT89S52. The unprocessed digital data of the AD590 is in mV/K form and 0 the LM35 is in mV/ C form. Both these unprocessed data of 0 sensors are processed in real temperature form in C unit. The necessary clock and reset circuits are designed around the microcontroller. The processed real temperature data of the two sensors are displayed on the smart 16X2 LCD module which is interfaced to the microcontroller port P0. The control lines data/instruction select (RS), read/write(R/W), enable (E) necessary for LCD module are software controlled, so, they are derived from port P3.0 and P3.1, respectively, and control line RW is directly grounded to avoid unnecessary utilization of I/O ports of the microcontroller.

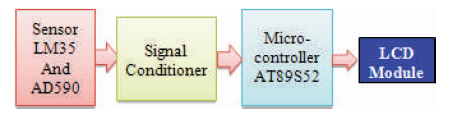

The firmware development is equally important in case of embedded system, as hardware and firmware are the two sides of the coin. The software, mentioned earlier, is developed in 'C' using Keil mVision4, an IDE, wherein various 'users defined function' are called in the main programme wherever necessary. Prior to the main programme listing AT89S52 header file, reg51.h, is included to initialize the entire architecture of the microcontroller and then required variables, ports and subroutines are declared globally. The main programme reflects the use of the super-loop and it is prime important characteristic of the embedded software, which is incorporated in the main programme of ESUI. The various subroutines such as Clock Generation Routine, ADC Channel Selection Routine, Calibration Routine, Character Display Routine, BCD Conversion Routine, LCD Initialization, Control and Data Command Routine and Delay Routine etc. are utilized for data processing and displaying the respective sensor's real temperature data o in C unit. In between, super-loop executes continuously which detects the real temperature dependent data continuously and, processes and displays it continuously. Typical temperature calibration module developed for present ESUI is as presented in Figure 3.

Figure 3. Firmware Module for Calibration o of the ESUI for Temperature in C

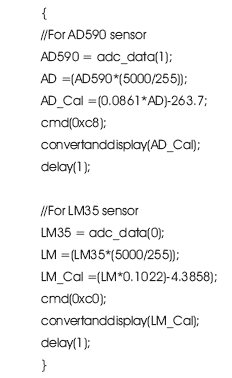

The ESUI extracts the temperature dependant analog data from both the monolithic sensors under investigation and it is proportional to the body temperature of the sensors. Both the sensors are well standardized by manufacturer to optimise the sensitivity over the mentioned temperature range. Moreover, present ESUI, because of dedicated design of analog and digital part of the hardware, should be essentially calibrated to the scientific units (Pertijs et al., 2010). Therefore, the ESUI is subjected to the process of calibration. An experimental arrangement of the same is shown in Figure 4. For calibration and standardization, the standard digital thermometer/ Scientech made model DM97 is deployed.

Figure 4. The Experimental Setup of ESUI for Calibration

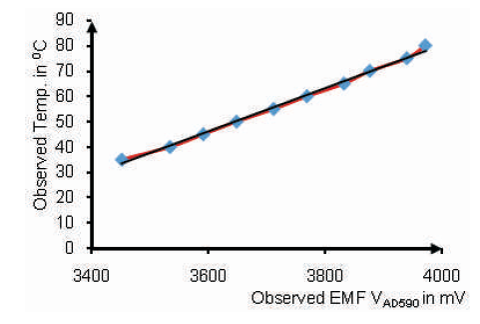

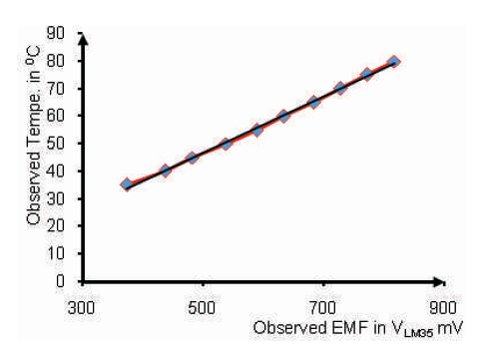

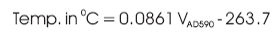

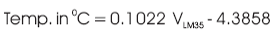

The ESUI's two temperature sensors; AD590 and LM35, and digital thermometer are exposed to the same temperature by using temperature bath having 0 0 temperature ranging from 35 C to 80 C. The electromotive force (emf)s, obtained from respective channels, V and V , in mV shown by the system under AD590 LM35 investigation are recorded against the temperature values shown by the standard thermometer. For more accuracy and reliability of the ESUI, the three iterations are recorded for each sensor for same environmental conditions and then it is averaged and plotted. The graphs of observed emf, V and V , against applied AD590 LM35 temperature are shown in Figures 5 and 6 respectively for AD590 and LM35. From these calibration graphs, it can be said that, the relation of observed emf, V and V , with applied temperature is quite linear through the entire range of investigation. So, to find the respective empirical relations, the curve is subjected to the statistical process of regression (Pertijs et al., 2010; Frischer et al., 2014). The linear empirical expressions obtained are as follows:

Figure 5. The Plot of emf Observed in mV on ESUI against 0 Temperature in C on Standard Meter for Sensor Ad590

Figure 6. The Plot of emf Observed in mV on ESUI against 0 Temperature in C on Standard Meter for Sensor LM35

For monolithic temperature sensor AD590,

For monolithic temperature sensor LM35,

Both expressions, (1) and (2), are employed in the firmware 0 (Figure 3), to standardize the ESUI in C unit. Thus, this ESUI is calibrated and standardized to temperature scale in 0 scientific unit degree centigrade ( C).

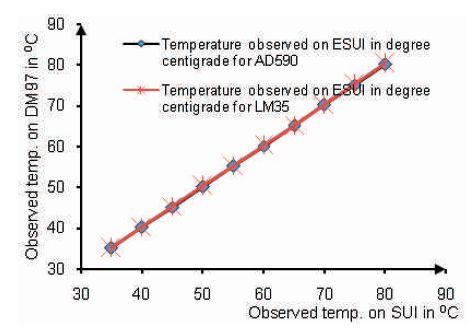

To validate the ESUI design and to ensure investigation of temperature measurement, the ESUI is subjected to 0 0 measure the varying temperature, 35 C to 80 C, in temperature bath, wherein both temperature sensors and same digital thermometer are again housed in the same temperature bath. The observations on ESUI for AD590 and LM35 against digital thermometer are recorded for number of iterations; the same temperature data is recorded at every time. The graph of observed 0 temperatures in C on ESUI, by both the sensors against applied temperature on digital thermometer, is plotted and shown in Figure 7. From Figure 7, it is found that, the temperature values of both the monolithic temperature sensors observed on ESUI are precise, and shows a good agreement in most of the cases to each other, and also shows a good agreement with the standard digital thermometer. This validates the developed ESUI for precise temperature measurements (Che, and Xie, 2017).

Figure 7. The Plot of Temperature Observed in C on ESUI against 0 Temperature in C on DM97 Meter for Sensor AD590 and Lm35

After successful standardization, performance of two sensors is investigated. The temperature values shown by both sensors are recorded for various applied temperature. It is found that, there is significant deviation from expected results. Deviation in the temperature values shown by the two sensors, and the actual temperature are estimated. This estimation of the deviation is carried out for number of iterations. Resulting deviations are plotted against the temperature shown by standard digital thermometer which is presented in Figure 8. The average temperature deviation between 0 the digital thermometer and monolithic sensor is 0.172 C 0 for AD590 and 0.341 C for LM35, respectively. On statistical analysis, it is found that the standard deviation for AD590 and LM35 is 0.0133 % and 0.0885 %, respectively. This clears that the standard deviation for temperature sensor AD590 is minimum than that of temperature sensor LM35. The deviation in temperature values obtained from, the two sensors are also plotted (Figure 8). From Figure 8, it can be said that, the two sensors are not showing same temperatures. A significant deviation is recorded. The average temperature 0 difference of 0.169 C is observed between the temperature sensors on ESUI. Figure 8 also shows the non linearity in the deviations. This may be due to design tolerances ±0.8 % and ±0.35% in the monolithic temperature sensors AD590 and LM35 mentioned by the manufacturer, respectively (Rajita et al., 2016; Arunaganesan et al., 2013). From the results of investigation, it can be concluded that AD590 is the most suitable sensor for the development of temperature monitoring system.

Figure 8. The Plot of Difference in Temperature Observed in between DM97 Thermometer and Monolithic Temperature Sensors on ESUI in C

The microcontroller AT89S52 based embedded system is designed and developed for comparative performance analysis of two monolithic temperature sensors, LM35 and AD590, successfully. Upon performance analysis, it can be concluded that the temperature sensor AD590 is more precise and having minimum standard deviation over the range of investigation than that of the temperature sensor LM35.