Figure 1. Block Diagram of the Proposed System

Automation or automatic control is the use of various control systems for operating equipments, such as machinery, processes in industries and other applications with minimal or reduced human intervention. Industrial automation can be achieved by several different means, including mechanical, electrical, electronic, hydraulic, pneumatic, and computers. Here, the authors have implemented Industrial IoT system that allows a single industry operator to control industry appliances with ease using Raspberry Pi 3B. The primary drive for automation using Internet of Things (IoT) is to significantly reduce operating expenditures when sensors and actuators become Internet-enabled devices. The proposed system allows for automation of industrial loads based on continuous monitoring of temperature, pressure, and presence of volatile gas in industrial environment to achieve automation over internet. Here, TruVnc Mobile app is used for monitoring the industrial parameters. User is allowed to control machine/load switching over internet using PubNub interface from anywhere in the world over internet. The Raspberry pi 3 model B processor captures these commands (Controlling signals) by internet and processes the received data to extract user commands. After receiving Sensor data it displays it on a monitor. Also it enables to switch the loads ON/OFF based on received commands to achieve user desired output. Thus Internet of Things (IoT) help in increasing output and automating processes across a lot of industries.

Several industrial IoT applications have been developed and deployed in this world. Evolution of this starts from the RFID technology in which using RFID readers, people can identify, track, and monitor any objects attached with RFID tags automatically. The other technology is the Wireless Sensor Networks (WSN) which uses interconnected intelligent sensors to sense and monitor. Its applications, include environmental monitoring, industrial monitoring, traffic monitoring, etc. Both RFID and WSN are used to develop IoT. Wireless Sensor Networks are distributed autonomous sensors to monitor physical or environmental conditions, such as temperature, sound, pressure, etc., and to cooperatively pass their data through the network to a main location. There are numerous applications of WSNs in industrial automation, traffic monitoring and control, medical device monitoring, and in many other areas.

In industrial automation system remotely controlled systems such as computers are used to control industrial machiner y and processes by replacing human operators. Automation often requires devices with different interfaces to be able to communicate with each other. Internet of Things (IoT) help in interconnection between people or object to exchange the data over network without involving human-to-human or human-to computer interaction. In Industry Internet of Things (IoT) is used to monitor and inform the responsible person to take appropriate measures.

Industrial automation can be achieved by several different means, including mechanical, electrical, electronic, hydraulic, pneumatic, and computers. Here the authors have implemented an IoT based industry automation system that allows a single industry operator to control industry appliances with ease using Raspberry Pi 3B.

Industrial automation systems are very complex having large number of devices with merging of technologies working in synchronization. Various components used in an industrial automation system can be explained using the automation pyramid [7]. Here, various layers represent the wideness and fastness of components on the timescale. Industrial Sensor System consists of two major elements, the sensing element and the actuator. The sensing element is actually a signal conditioning and processing. The second element is the actuator which takes the logic information from the controller and then converts it to a physical plant input. The logic information is not so powerful [7], hence it requires a lot of power amplification. Various sensors are used in implementation of Industrial IoT for measuring temperature, pressure, humidity, gas, etc. [8], [9]. Temperature sensor is used in a clean room indicator to calculate the dew point and estimate the good condition of room, and cancel out cold junction compensation effect [2]. The exerted pressure in a plant causes a material to conduct electricity at a certain rate, therefore leading to a specific level of charge flow that is associated with a specific level of pressure. This charge is fed to a wire that leads to a control panel and a display for human analysis. Piezo resistive pressure sensor is used to carry out the measurement of physical quantity [6]. Gas sensors are commonly used to detect hydrogen, oxygen, alcohol vapour, and harmful gases such as carbon monoxide. In food industries garbage decomposition produces methane, which could be very dangerous if not detected properly. The system was implemented using methane gas sensor to detect the presence of methane from the decomposition of fish guts waste [4].

Automatic control layer computes control input for the plant at each sample time or for a large duration. The automatic control level is a hardware and it is not embedded into the machine. The software is generic and not a special purpose, but it runs on hardware like PLC, industrial PCs, etc. [7]. Supervisory controller will typically look after a number of automatic control loops. At the supervisory control, the hardware is mostly a general purpose computer with strong data interface. Here many channels data from the whole process are connected to the supervisory control unit [7]. Supervisory control systems perform some of the functions, such as set point computation, performance monitoring or diagnostics, start-up or shut down or emergency operations, control reconfiguration or tuning, operator interface, etc.

The microcontroller receives the input from various sensors and processes it to do task automatically. Microcontroller issues commands to the appliances and the devices connected switch as ON or OFF based on the commands. A digital controller using 8051 microcontroller is used for active power line conditioning system to improve the power quality in the distribution network. The Digital Controller is designed using MCS 8051 microcontroller which becomes independent of process technology [3]. The Home Industrial System [HIS] includes hardware which consists of an ARM 7 TDMI core processor. ARM is adopted as a controller [8] because of most recent ARM programmable technology and intelligent device specification, ie., it helps in monitoring of temperature, smoke, and fire present in the industrial environment on the website and helps in handling situation from anywhere in the world through IoT. Arduino is an open source platform based on easy use of softwares as well as hardwares. Arduino boards are able to read the inputs such as light on sensor, a finger on a button and convert it into outputs like turning ON the lights, activating a motor [1], etc. Raspberry pi is a low cost, low power ARM based minicomputer which can communicate through Local Area Network (LAN) or the external Wi-Fi module. Commands are processed at the Raspberry Pi using Python language. The data can be monitored using terminal devices like Laptop, Smartphone and Tablet with internet facility allowing access to real-time information about an industrial environment which includes the parameters: temperature, humidity, pressure, PIR sensor [5].

The Objectives of the work are listed below.

Literature review will be made to study the different Smart Sensor Interface technologies for industrial monitoring and sensors used in those technologies, along with the advantages and limitations of each.

The technical specifications and data regarding the types of sensors used in the Smart Sensor Interface technologies for industrial monitoring system will be extracted from the available literature and hardware manuals.

Depending upon the advantages and limitations of the technologies, we will arrive at the specific sensors used, as well as their design specifications along with the appropriate technical parameters.

The appropriately selected sensors and Raspberry Pi processor will be mounted upon the hardware system.

TruVnc app is used for data monitoring and PubNub website for controlling of parameters.

The performance of the designed hardware will be tested and verified for variations of industrial parameters.

The block diagram of the implemented system is as shown in Figure 1. The block diagram consists of Raspberry pi 3B, Temperature Sensor, Pressure Sensor, Gas Sensor, Buffer, Relay driver, Load (DC Motor).

A temperature sensor gathers data concerning the temperature from a source and then converts it into a form that can be displayed and understood by a user or another device. Pressure sensors are used to monitor the change in pressure. A gas sensor detects the presence of volatile gases in surrounding area, often as part of a safety system. Buffers are normally used to provide extra current drive at the output, but can also be used to regularize the logic present at an interface. Relay is used to drive the load connected across the relay.

The Raspberry pi 3 model B processor captures these controlling signals by internet and processes the received data to extract user commands. After receiving sensor data it displays it on a monitor (PC) and allows user to switch the loads ON/OFF based on received commands to achieve desired output. User is allowed to control machine/load switching over internet using PubNub interface from anywhere in the world over internet. Here TruVnc Mobile app is used for monitoring the industrial parameters. Thus Internet of Things (IoT) help in automating processes across a lot of industries.

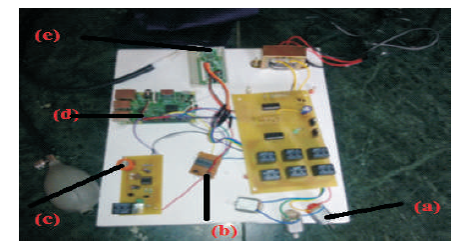

The implemented system shown in Figure 2 has temperature sensor (LM35), gas sensor (MQ3), and pressure sensor (MP3V5050) interfaced to Raspberry pi 3 model B to monitor the rise in temperature, for detecting various gases, such as alcohol, benzene, hexane, LPG, etc., and for detecting variation in pressure present in the industrial environment.

Figure 2. Implemented System using Raspberry Pi 3B Model (a) Loads, (b) Temperature Sensor, (c) Gas Sensor, (d) Raspberry Pi 3B, (e) Pressure Sensor with Squeeze Hand Rubber Pump

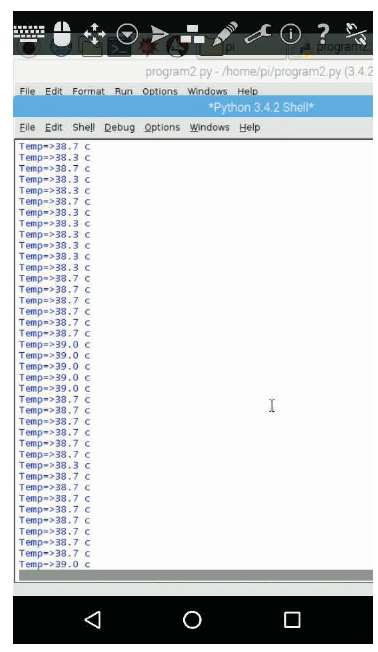

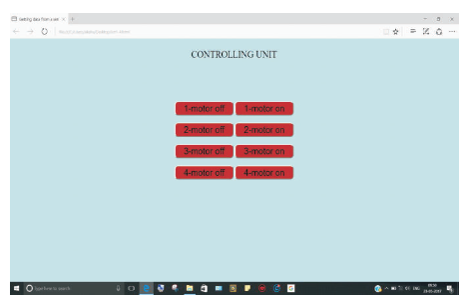

TruVnc mobile app is used for monitoring the variations in parameters in industrial environment as shown in Figure 3. PubNub a freeware website as shown in Figure 4 is used for controlling loads upon variation in industrial parameters. Using this we can turn ON/OFF the loads.

Figure 3. TruVnc Mobile App for Monitoring

Figure 4. Web Interface using PubNub

Monitoring of temperature variation can be seen in TruVnc mobile app and if temperature rises beyond 500 C the load (motor 1) can be activated by turning ON the motor using PubNub website to control the temperature as shown in Figure 5. Figure 6 shows detection of gas molecules (spirit for testing purpose), monitoring and controlling of load (motor 2) upon gas detection. Figure 7 shows creation of pressure using squeeze hand rubber pump (motor 3). Once the desired pressure is created it can be monitored as low, medium, and high pressure values and corresponding loads can be controlled.

The implemented work simplifies manufacturing process in industries and speeds up the production rate. The implemented system can continuously acquire different values of the parameters, such as temperature, pressure, and presence of volatile gas in the environment. The data acquired from the sensors is transferred to Raspberry Pi 3 for further processing.

In the present system, monitoring and controlling systems are different units, but in future they can be integrated as single unit for better user interface.