A Review On Concentrated Solar Power (Csp) And Emerging Technology

D. Rene Dev * D. Sam Harison **

* Department of Electronics and Communication Engineering, C. S. I Institute of Technology, Thovalai, Kanyakumari District, Tamil Nadu, India.

** Department of Electrical and Electronics Engineering, Rohini College of Engineering and Technology, Kanyakumari District, Tamil Nadu, India.

Abstract

Solar power generation is one of the fastest-growing sources of renewable energy in the world. The economic benefits of technologies used to capture sunlight are increasing every year, expanding the opportunities for cleaner power generation. The global energy production model is changing from fossil fuels to renewable and nuclear energy. This paper provides a brief overview of the solar power generation system called Concentrated Solar Power (CSP), which is an emerging technology that is leading the way. The energy extracted from CSP technology is very clean, reliable, and environmentally friendly. This growth implies the complexity and size of systems and therefore requires an increase in maintenance tasks to ensure reliability, availability, maintainability, and security. This paper describes the various configurations of CSP, and the main causes and consequences of the CSP components are also analyzed.

Keywords:

- Concentrated Solar Power,

- Thermal Storage System,

- Heat Transfer Fluid,

- Optimization.

Introduction

Solar photovoltaic systems are energy systems that convert sunlight into electricity using the photovoltaic effect. It is a process in which semiconductor materials generate voltage and current when exposed to light. Photovoltaic systems usually consist of six separate components, such as a solar photovoltaic generator, a charge controller, a storage battery, an inverter, a utility meter, an electrical grid, and a busbar system. The efficiency of solar panels is determined by the proper installation of all of these components.

For generation planning and dispatching purposes, electric utilities are interested in having solar Photovoltaics (PV) available on an hourly basis. Hourly meteorological data is needed to model solar energy performance. Figure 1 shows a grid-connected solar PV system with a battery. The actual battery size will depend on the desired peak smoothing.

Figure 1. Solar Energy System Connected to Solar PV System with Battery Storage

In contrast to photovoltaic cells, Concentrating Solar Power (CSP) can transform direct solar energy into thermal energy using a light condensing and thermal collecting device, providing steam drive for a steam turbine, and driving a generator to generate electricity. CSP systems are usually equipped with large heat storage devices that can compensate for the short output time and large fluctuations of PV cells, producing relatively stable and controllable electricity. The internal "solar thermal electricity" multi-energy conversion mode, which may achieve a bidirectional closed-loop flow of electrical and thermal energy, is also helpful for the regional integrated energy system's complete use of energy. In recent years, research on CSP systems has primarily focused on the cooptimization of other renewable energy sources.

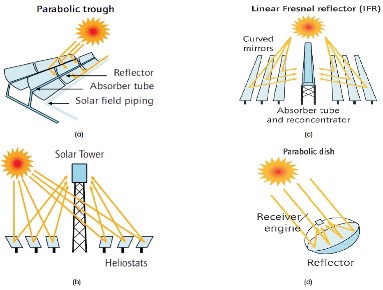

Using mirrors and concentrators, Concentrated Solar Power (CSP) heats a fluid to produce electricity. Figures 2(a) to 2(d) show the configurations of CSP.

- Parabolic Trough Collector (PTK): This technology is based on the reflection of direct sunlight by parabolic mirrors towards an absorption tube containing a Heat Transfer Fluid (HTF) (Zhang et al., 2013).

- Solar Power Tower (SPT): The reflections of hundreds of mirrors, called heliostats, are concentrated at one point (Zavoico, 2001). Electricity is generated by the thermodynamic cycle.

- Linear Fresnel Reflector (LFS): It is based on previous configurations. Unlike the PTK, the receiver is located not inside the mirrors but in a separate tower (Abbas et al., 2012). A recent design called the Compact Linear Fresnel Reflector (CLFR) uses two parallel receivers in each row, making it more compact than the PTC. This design has already been tested in operating plants, i.e., Puerto Herrado, Spain (Mills & amp; Morrison, 2000).

- Parabolic Dish Systems (PDS): A set of mirrors form a parabolic shape that concentrates sunlight at a focal point. This system can follow the sun in two directions, making it more efficient.

Table 1 shows various CSP technologies. The parabolic dish has the highest efficiency (18% to 25%), but its hybrid operation is still under research and development. The efficiency of the solar tower is the second highest, at about 14% to 17%, and it has the highest High-Temperature Fluid (HTF) operating temperature of 1000°C. The efficiency and operating temperature of HTF linear Fresnel are the lowest, but the cost of linear Fresnel is cheaper than other CSP systems. Even though the parabolic trough has an efficiency of 10% to 15%, it has the lowest material requirements, such as a good land utilization ratio, modularity, heat storage, and others. The parabolic trough has a total capacity of 354 MW and has become the largest operating solar power plant in the world.

Table 1. Different CSP Configurations

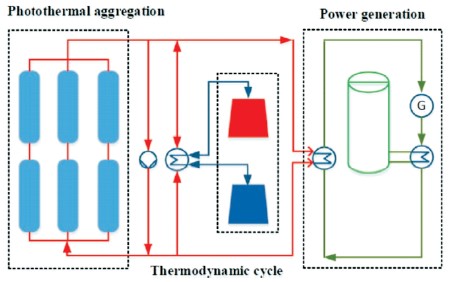

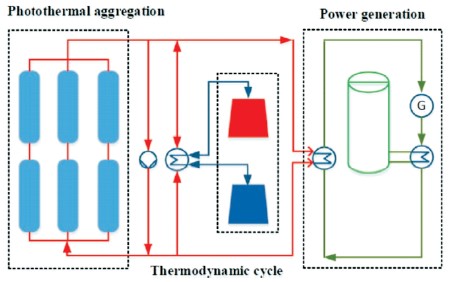

The CSP system consists of three components, such as the light field, the thermal storage system, and the thermal cycle. The heat transfer fluid is used to transfer energy between the three components. Solar energy is captured by a thermal collector in the CSP system and converted into thermal energy. It does this by transferring thermal energy to a thermal cycle system using a coolant, and then creating steam to power a steam turbine to produce electricity, realizing the solar-thermal-electricity conversion process (Jiang et al., 2020). In addition, thermal energy can be used to generate electricity in response to the need for dispatch while it is stored in the CSP system using a heat transfer medium. The key difference between CSP and other new energy sources is the configuration of its Thermal Energy Storage (TES) system, which can control the conversion of solar thermal energy into electricity and then control the output of that electricity generation.

Solar energy is captured by a thermal collector at the CSP power plant and converted into thermal energy. The conversion of photothermal and thermoelectric energy is carried out by transferring thermal energy to the thermal cycle system through a heat carrier, which subsequently generates steam to operate a steam turbine and generate electricity. In addition, thermal energy can be used to generate electricity according to the needs of the dispatcher, storing it in heat storage systems using a heat carrier. The basic principles of the CSP system are shown in Figure 3.

Figure 3. Basic Principles of CSP

1. Effects due to Weather and Durability of CSP Components

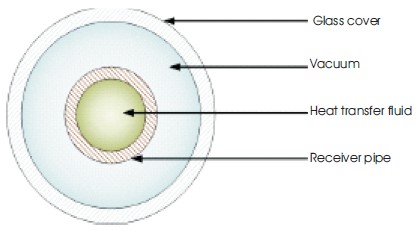

1.1 Deformation and Cracks of Absorber Tube

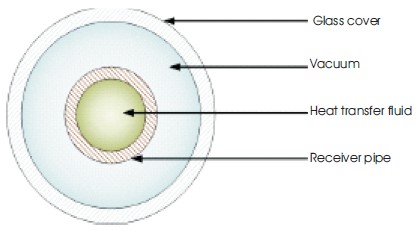

Heat Transfer Fluid (HTF) circulates through pipelines throughout the installation of the Plant Cell Technology (PCT) plant, where it can cause corrosion or deformation of the internal part of the pipeline (Pérez et al., 2017). Pipelines usually have a steel base with coatings to improve the absorption capacity of the outer surface (Kennedy, 2002; Dong et al., 2008). Figure 4 shows a schematic diagram of an Absorption Tube (AT).

Figure 4. Absorber Tube

Akbarimoosavi and Yaghoubi (2014) discusses the theoretical effects of deformation on ATs in two different CSP setups. This paper modeled the AT using Finite Element Modeling (FEM) and analyzed the concentration ratio on its surface. The results show a drop in optical efficiency below 2% at a maximum deformation of the glass coating of 20 mm. A correlation between the HTF convection coefficient and temperature with respect to deformation has been revealed.

Tripathy et al. (2018) discusses pipe bending and how it uses FEM to test the behavior of pipes when working with different materials, such as steel or multilayer metal composites, and with different mass flow rates. The results showed similar stress distributions for all flow rates, but with different temperature distributions depending on the materials. All materials show a negative correlation between mass flow and strain.

1.2 Thermal Storage System Tanks and Corrosion in Absorber Tubes

Corrosion is considered to be one of the most important degradation mechanisms of CSP. This can affect the AT and the Thermal Energy Storage System (TES). Most of the research is devoted to TES systems; therefore, various stainless-steel sheets are most commonly used and often treated with chromium. Even in these cases, they are affected by temperature and molten salts.

He et al. (2012) developed early corrosion characterizations of steel in marine environments. This paper focused on coated and uncoated steel components with exposure times of 1 to 10 months and concluded that corrosion is a convergent process and that some of the electrical characteristics of steel are degraded by eddy currents.

Liu et al. (2016) reviewed the main storage systems, classifying it into sensible, latent, and thermochemical storages. This paper also mentioned the latest developments in TES regarding the materials and technologies used, the compatibility of containment materials, and the corrosive effects.

1.3 Thermal Issues in AT and TES

Heat transfer, heat loss, and thermal stresses are the most important conditions to consider in the design and verification of any AT installation, as it operates at high temperatures.

Heat transfer and heat loss depend on the relative vacuum and the composition of the gas inside it. Vasallo and Bravo (2016) demonstrated different approaches to studying the behavior and cost of both, i.e., thermal, exergy, and energy or numerical models. These approaches are also useful for modeling the behavior of tubes.

1.4 Soiling and Dust Accumulation in Mirror

Deserts and dry areas are used to host CSP plants due to solar radiation. However, these places are usually affected by natural phenomena such as sandstorms, airborne particles of sand, or dust, which can cause soiling and abrasion of mirrors. Pollution is the buildup of sand and dust on the surface of solar panels, resulting in reduced performance. Pennetta et al. (2016) identified the main variables contributing to dust accumulation, such as temperature, wind speed, and direction.

Karim et al. (2014) proposed a methodology to analyze the effect of certain parameters on mirror degradation at two sites in Morocco. It classifies the influencing parameters into climatic (wind speed and direction and humidity) and geological (particle size, shape distribution, and hardness). It confirms the correlation between wind speed and the amount of sand carried and also emphasizes the importance of moisture for the particle adhesion process.

1.5 Erosion of Mirror

Erosion of mirrors in CSP occurs mainly due to the impact of abrasive particles on the surface, while the reflection coefficient decreases. These particles are usually sand or dust. Völker et al. (2014) studied that the sand seepage was used more to study coatings based on falling sand from a certain height and sandblasting, consisting of throwing sand from a horizontal pipe onto a sample at several angles and velocities.

2. Optimization in Concentrated Solar Power System

The problem of system optimization is aimed at optimal economic planning of the system. A particular optimization process always takes as its objective function of the minimum total cost of operating the system. The total operating costs of the system can be described as the difference between the operating costs of the system and operating income. System operating costs mainly include system operation costs and environmental protection costs. Operating income mainly refers to the income received by the energy system and market from the exchange of energy as well as the income received from participation in the process. The electrical characteristics of a solar cell are mainly referred to as current-voltage characteristics, also known as the I-U curve. The I-U curve shows the relationship between the current I passed through the solar module and the voltage U under a certain amount of sunlight. The I-U curve of a photovoltaic cell is shown in Figure 5.

Figure 5. Solar Cell Current-Voltage Characteristics

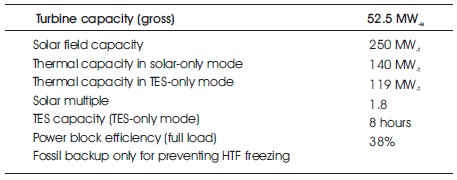

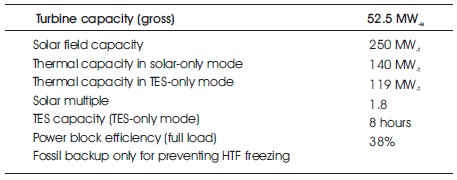

Figure 5 shows the solar cell current-voltage characteristics, where ISC is the short circuit current, I is the maximum m operating current, U is the open circuit voltage, U is the OC m maximum operating voltage, and P is the maximum m power. If a short circuit occurs in the solar module, i.e., U = 0, the current at that time is called the ISC short circuit current. If the circuit is open, i.e., I = 0, the voltage at this moment is called the open circuit voltage U . The output oc power of the solar battery module is equal to the product of current and voltage, i.e., P = UI. According to the I-U curve for a certain light intensity and temperature, we can use the maximum power point tracking method to find the maximum output power on the curve. Table 2 shows some of the characteristics of this model and a sensitivity study of the penalty parameters.

Table 2. Characteristics of the CSP Plant

2.1 MILP Model for Generation Scheduling

The Mixed Integer Linear Programming (MILP) model consists of energy variables, binary variables, input data, and parameters. The model parameters reflect the structural characteristics of the object or are adjustment mechanisms in the optimization process. The input data are known variables (forecasts of maximum thermal power from the PF and electricity prices) and estimates of initial conditions. The energy variables represent the thermal energy in the Thermal Energy Storage (TES) and the average hourly values of the heat or electricity flow between the individual elements of the plant. Binary variables are needed to formulate operational constraints.

2.2 Day-Ahead Scheduling Strategy Implementation

Initially, a Mixed Integer Linear Programming (MILP) scheduler is tuned to generation setpoints obtained by solving the MILP model. The setpoint provider then provides the current setpoint for power generation. The initial condition estimator provides the current setpoint for power generation. The detailed SF model provides the scheduler with an estimate of the initial state of the CSP object for the next day. Finally, the electricity price predictor provides energy price predictions (Law et al., 2014).

Conclusion

The Government of India has set a 2,000 MW off-grid solar PV target as part of its National Solar Mission to be achieved between 2017 and 2022. Concentrated Solar Power (CSP) technologies can be put into operation in states with high levels of solar radiation, such as Rajasthan, Gujarat, and Tamil Nadu, as alternative energy sources instead of putting into operation new fossil fuel power plants such as natural gas, lignite, and coal, or decommissioning thermal power plants. Thus, there is a need for specific policies that ensure that the goals of energy security and climate security are achieved in parallel. CSP is a great way to move forward in sustainable energy production to meet peak power demand and maintain grid stability without any significant environmental impact. This paper presents an effects due to weather and durability of CSP components and discussed on optimization in Concentrated Solar Power System.

References

[1]. Abbas, R., Montes, M. J., Piera, M., & Martínez-Val, J. M. (2012). Solar radiation concentration features in linear Fresnel reflector arrays. Energy Conversion and Management, 54(1), 133-144. https://doi.org/10.1016/ j.enconman.2011.10.010

[2]. Akbarimoosavi, S. M., & Yaghoubi, M. (2014). 3D Thermal-structural analysis of an absorber tube of a parabolic trough collector and the effect of tube deflection on optical efficiency. Energy Procedia, 49, 2433-2443. https://doi.org/10.1016/j.egypro.2014.03. 258

[3]. Dong, R. F., Sun, L. G., Zhe, L. I. U., Wang, X. L., & Liu, Q. Y. (2008). Microstructures and properties of X60 grade pipeline strip steel in CSP plant. Journal of Iron and Steel Research, International, 15(2), 71-75. https://doi.org/10. 1016/S1006-706X(08)60035-7

[4]. He, Y., Tian, G., Zhang, H., Alamin, M., Simm, A., & Jackson, P. (2012). Steel corrosion characterization using pulsed eddy current systems. IEEE Sensors Journal, 12(6), 2113-2120. https://doi.org/10.1109/JSEN.2012.2184280

[5]. Jiang, P., Dong, J., & Huang, H. (2020). Optimal integrated demand response scheduling in regional integrated energy system with concentrating solar power. Applied Thermal Engineering, 166, 114754. https://doi. org/10.1016/j.applthermaleng.2019.114754

[6]. Karim, M., Naamane, S., Hassani, I. E. A. E., Delord, C., Belcadi, S., Tochon, P., & Bennouna, A. (2014). Towards the prediction of CSP mirrors wear: Methodology of analysis of influencing parameters on the mirrors surface degradation: Application in two different sites in Morocco. Solar energy, 108, 41-50. https://doi.org/10. 1016/j.solener.2014.06.036

[7]. Kennedy, C E. (2002). Review of Mid- to High- Temperature Solar Selective Absorber Materials. United States. https://doi.org/10.2172/15000706

[8]. Law, E. W., Prasad, A. A., Kay, M., & Taylor, R. A. (2014). Direct normal irradiance forecasting and its application to concentrated solar thermal output forecasting–A review. Solar Energy, 108, 287-307. https://doi.org/10. 1016/j.solener.2014.07.008

[9]. Liu, M., Tay, N. S., Bell, S., Belusko, M., Jacob, R., Will, G., & Bruno, F. (2016). Review on concentrating solar power plants and new developments in high temperature thermal energy storage technologies. Renewable and Sustainable Energy Reviews, 53, 1411-1432. https://doi. org/10.1016/j.rser.2015.09.026

[10]. Mills, D. R., & Morrison, G. L. (2000). Compact linear Fresnel reflector solar thermal powerplants. Solar Energy, 68(3), 263-283. https://doi.org/10.1016/S0038-092X(99) 00068-7

[11]. Pennetta, S., Yu, S., Borghesani, P., Cholette, M., Barry, J., & Guan, Z. (2016, May). An investigation on factors influencing dust accumulation on CSP mirrors. In AIP Conference Proceedings, 1734(1), 070024. https:// doi.org/10.1063/1.4949171

[12]. Pérez, J. M. P., Márquez, F. P. G., & Papaelias, M. (2017). Techno-economical advances for maintenance management of concentrated solar power plants. In Proceedings of the Tenth International Conference on Management Science and Engineering Management (pp. 967-979). Springer, Singapore. https://doi.org/10. 1007/978-981-10-1837-4_81

[13]. Tripathy, A. K., Ray, S., Sahoo, S. S., & Chakrabarty, S. (2018). Structural analysis of absorber tube used in parabolic trough solar collector and effect of materials on its bending: A computational study. Solar Energy, 163, 471-485. https://doi.org/10.1016/j.solener.2018.02.028

[14]. Vasallo, M. J., & Bravo, J. M. (2016). A novel twomodel based approach for optimal scheduling in CSP plants. Solar Energy, 126, 73-92. https://doi.org/10.1016/ j.solener.2015.12.041

[15]. Völker, C., Philipp, D., Masche, M., & Kaltenbach, T. (2014). Development of a test method for the investigation of the abrasive effect of sand particles on components of solar energy systems. In Proceedings 29th European PV Solar Energy Conference and Exhibition.

[16]. Zavoico, A. B. (2001). Solar Power Tower Design Basis Document, Revision 0. United States. https://doi.org/10. 2172/786629

[17]. Zhang, H. L., Baeyens, J., Degrève, J., & Cacères, G. (2013). Concentrated solar power plants: Review and design methodology. Renewable and Sustainable Energy Reviews, 22, 466-481. https://doi.org/10.1016/ j.rser.2013.01.032