An improved DTC scheme based on space vector modulation (SVM) for Permanent Magnet Synchronous Machine(PMSM) drives. The new scheme provides a alternative option for the improvement of DTC controlled PMSM in reducing the torque ripple. Closed-loop control of both torque and flux is developed with proportional Integral controllers. The stator voltage vector is generated through Space Vector Modulation unit. The torque and flux ripples are greatly reduced with space vector modulation technique comparing with classical switching-table based DTC scheme. The analysis of the control principle provides a guide to design the controller parameters. Modeling results present the features effectiveness of the proposed scheme.

Permanent Magnet Synchronous Machine(PMSM) offers many advantages over the induction machine, such as overall efficiency, effective use of reluctance torque, smaller losses and compact motor size. Moreover, use of flux weakening control based on salient pole behavior supports a wide range of speeds at any given output level. In the late 1990's, Direct Torque Control(DTC) technique for the PMSM was proposed [1-3]. The advantages of the DTC include fast responses and the elimination of the current controllers, associated coordinate transformation, and the rotor position sensor required for the coordinate transformation. Although DTC has many advantages over vector control, it still has some demerits as reported in some literatures. The ripples in torque and flux are relatively higher when compared with those in vector control. Furthermore, the switching frequency of the inverter is not constant which changes with rotor speed, load torque and the bandwidth of the two hysteresis comparators.

In order to improve the performance of the classical DTC [4,5], there exist different solutions. By using multiple level inverters [6], more control voltage space vectors can be generated to make torque response smooth. With more power switches needed, the system cost and complexity increase. Predictive algorithms are adopted to calculate the most appropriate voltage space vectors to minimize deviation between the estimated values and actual ones of flux linkage and torque. In such efforts, some modified DTC schemes based on space vector modulation for induction machine drive were reported in [7-11]. With these schemes, fixed switching frequency and lower torque ripple were achieved with the help of proportionalintegral (PI) controller and space vector modulation(SVM) technique [12].

This paper proposed a new DTC-SVM scheme for PMSM drives. Closed-loop digital control for both torque and flux is implemented with two PI controllers, and the stator voltage is produced by a SVM unit. This scheme features low flux and torque ripples and fixed switching frequency. The analysis of the control principle of proposed scheme is given. Modeling results of the PMSM drive show its good performance for dynamic and steady state with low torque and flux ripples.

This paper is organized as follows. Section 1 describes the machine model in the stator flux reference frame. The structure of the proposed DTC-SVM scheme is presented in Section 3. Modeling results of the proposed scheme are discussed consequently.

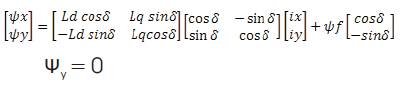

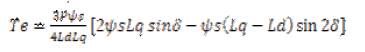

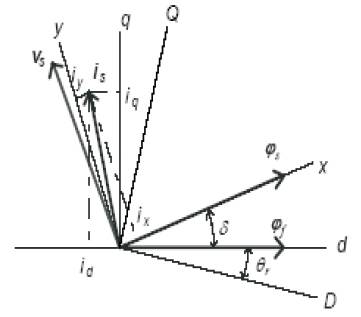

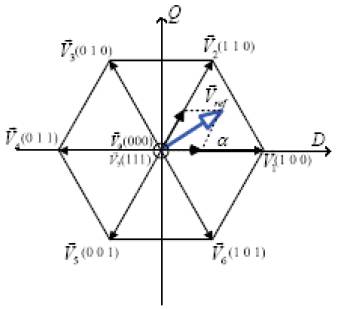

As stated in [3], the stator flux linkage vector ,Ψs, and rotor(magnet) flux linkage vector, Ψt ,can be drawn in the rotor flux(d-q),stator flux(x-y) and stationary(D-Q) reference frames as in Figure 1. The stator flux and torque in the xy reference frame can be expressed as

Where Ld ,Lq are direct and quadrature inductances, ωr is the electrical rotor speed, Te is the electromagnetic torque, P is the pole pairs, δ is the load angle, and Ψs , Ψf are stator and magnetic flux linkages.

The angle between the stator and rotor flux linkages δ, is the load angle. In the steady state, δ is constant corresponding to a load torque and both stator and rotor fluxes rotate at the synchronous speed. In transient operation, δ varies and the stator and rotor fluxes rotate at different speeds. Since the electrical time-constant, is much smaller than the mechanical time-constant, the rotating speed of stator flux with respect to the rotor flux can be easily changed. It will be seen that fast change of torque can be brought about by controlling the change of δ or the rotating speed of the stator flux vector. This is the fundamental idea of the DTC for PMSM.

The angle δ can be obtained by

where θs and θr are the angles of stator and rotor magnetic flux vector in stationary(D-Q) frame, respectively.

As shown in (3), the control of the torque can be eventually realized by varying the angular speed ωs of the stator flux vector.

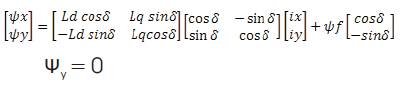

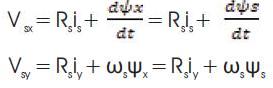

The voltage equations of the PMSM in the stator flux reference frame(x-y), which can be derived as

Where Rs is the stator armature resistance.

Equation (4) shows the rotating speed of the stator flux vector can be controlled by appropriate stator voltage vector. It is obvious that the amplitude of stator flux vector can be regulated by x component of stator voltage directly. And the torque can be indirectly regulated by y component of stator voltage once the load angle δ is regulated by the movement of the stator flux vector.

Note that calculation of the commanded voltage vector by equ.4 requires the derivation of the stator flux magnitude, which is a dc quantity. Thus, this scheme is less noisy [10].

Figure 1. The stator and rotor flux linkage vectors in different reference frames

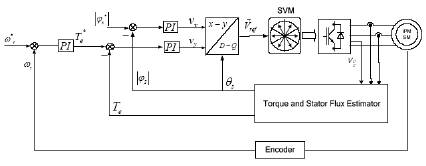

Based on above analysis, a complete scheme of direct torque and flux control for PMSM that allows effective torque control has been developed and it is indicated in Figure 2 .

The structure of proposed DTC-SVM scheme is similar with the Stator Flux Oriented Control scheme(SFOC).However, they are totally different. Firstly, no current control and decoupling are required with DTC-SVM. Secondly, all the feedback variables are in stationary frame and no rotating frame orientation is required.

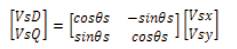

As for the basic DTC, relatively higher ripples in flux and torque are produced. These drawbacks of basic DTC are due to the selection of stator voltage vector which is not the appropriate one. In three-phase inverter, a space voltage vector can be composed with the eight basic space voltage vectors with SVM technique. In the proposed scheme, the appropriate space voltage vector can be generated with SVM as long as the reference voltage vector is produced by the PI controllers. Therefore, the stator flux-linkage and torque can be regulated precisely and fixed switching frequency can be obtained. The voltage vector should be transferred from the stator flux reference frame(x-y) to the stationary frame(D-Q),by equ.5 before using SVM algorithm.

Figure 2. Control Structure of DTC-SVM for PMSM

Where θs is the angle between the stator flux frame(x-y) and stationary frame(D-Q) i.e, the angle of stator flux linkage vector in the stationary frame.

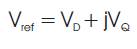

Then the reference voltage vector is

With SVM technique, the demand space voltage vector can be composed by two active and one zero voltage vectors, which is illustrated in right part of Figure 3.

Figure 3. Reference Space Voltage Vector

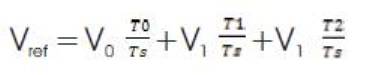

For example, when Vref locates between V1 and V2 , it can be expressed as

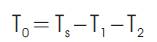

Where To ,T1 , and T2 are the effective time intervals of Vo ,V1 and V2 respectively within the sampling period Ts .

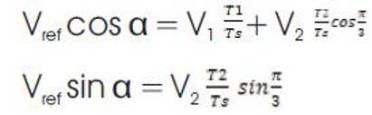

From Figure 3, it can be obtained

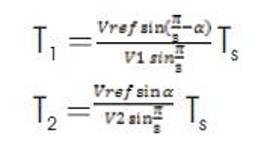

Thus

Then

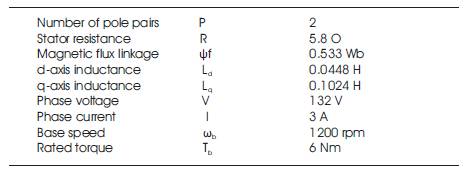

Matlab/Simulink models were constructed to examine the proposed scheme. The parameters of PMSM are shown in Table 1

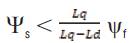

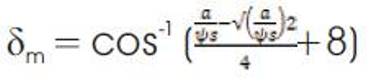

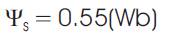

As indicated in [3], stable torque control can be achieved if

where a=

Therefore, the selection of rated stator flux linkage is according to(11).

Then the maximum load angle is calculated from (12)

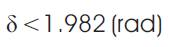

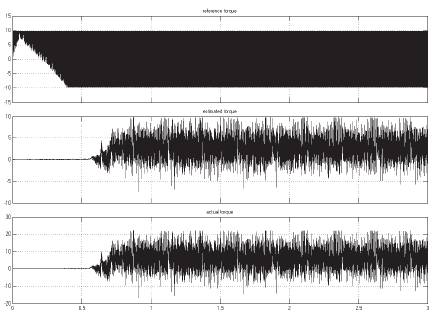

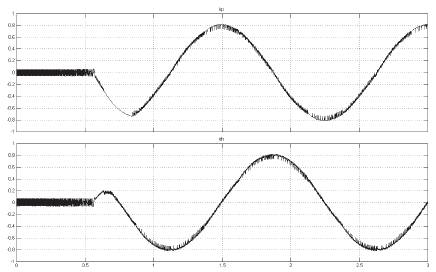

In the Simulink models, both steady state and dynamic behaviors of the proposed scheme are presented in the Figures (4),(5) and (6) respectively.

Figure 4. Steady State performance of Torque in DTC-SVM

Figure 5. Steady State performance of stator flux in DTC-SVM

Figure 6. Dynamic Performance of torque in DTC-SVM

Table 1. Parameters Of PMSM Machine

In this paper, a new direct torque control scheme for PMSM with space vector modulation is developed. Both torque and flux are controlled to ensure best steady state and dynamic performance. The modeling results confirm that it is an effective solution for the direct control of PMSM drives with constant inverter switching frequency and low torque ripple.