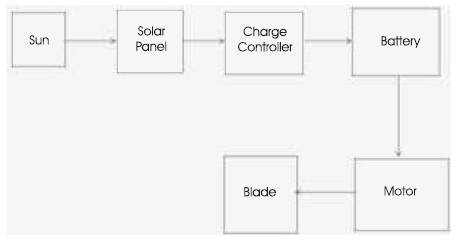

Figure 1. Schematic Diagram

The main aim of this paper is to provide a facility to farmers in harvesting the paddy crop at low cost by using solar energy. A design for a crop multipurpose cutting machine was developed. The proposed design of machine is very simple, robust and easy to operate. It has been designed and tested in the real time paddy crop harvesting effectively with low cost, and it does not contribute to greenhouse gas emission. Also, it has been examined for harvesting various crop varieties, and found to be reducing operation time and cost.

Harvesting is the process in which the matured paddy is being cut. Traditional process of harvesting is cutting of paddy crops with the help of sickle. A group of labors cut the paddy crops in the paddy field. There is a considerable grain loss and damage to the crop while harvesting by the use of sickle, which is a manually harvesting process. Paddy harvesting is one of the most important processes in the practices of paddy field. Nowadays, the paddy harvesting machines are available in the market which runs by using engine, driven by petrol.

India has the largest paddy output in the world, and also is the fourth largest exporter of rice in the world. Paddy is cultivated atleast twice a year in most parts of India; the two seasons being known as Rabi and Kharif respectively. The total area planted under rice crop in India is 42.20 million hectares. Improved weeder reduces weeding cost by 79-90%. A real time harvesting machine has been developed, which is easy to operate and can be used for efficient and effortless harvesting of folder crops.

There are many harvesters available on the market which works on petrol engine, but they are of high cost. After some time of using these expensive harvesters, some mini paddy harvesters are available in the market. Solar energy is an abundant and renewable energy resource. One solar cell can equalize 1.5 W of electrical energy, which is fed immediately.

Solar energy plays an important role in drying agriculture products and irrigation purpose for pumping the well water in remote villages, without electricity. This technology of solar energy can be extended for cutting an agricultural plants such as sugarcane, mulberry plants and paddy.

Paddy is a staple food for Indian people. Fuel based harvesting cost represents a significant portion of total paddy production cost. Harvesting cost per acre land is influenced by many factors including harvesting performance rate per acre, inputs cost like running and labor cost, pesticide cost and cutting weeds. Hence, there is an urgent need for this proposed harvester machine using renewable energy resource.

To design and develop the proposed work, the following literatures have been reviewed. Shinde, et al., (2017) explained and designed a mini harvester to help small scale farmers who are having land area less than 5 acres, by designing a small scale harvester machine to harvest grains very efficiently. This machine has cutting blades which cut crops in scissoring type of operation, and can cut up to two rows of crops. The power unit for this machine is petrol engine of 14.25 HP.

Singh et al., (2016) explained about the problems faced by farmers who work on small fields while harvesting crops as it takes a lot of time, labor and effort to cut the crops manually. To overcome this problem, a lot of ground research has been done in this project wherein various farmers of a village near Gurgaon were met, and their problems were understood. Based on all the findings, a design for a crop cutting machine has been developed, which is expected to help small scale farmers big time. A prototype was also developed.

Kongre et al., (2016a) discussed about the need to concentrate in some situations such as how to increase the productivity and profit, how to reduce the cost and labor efforts, etc. During cropping season, often rains and storms cause considerable damage of standing crops. Rapid cutting of crop gives more time for preparation of land for next crop planting. The usage of machines can help for cutting at proper stage of crop maturity, and also it reduces operation time.

Kongre et al., (2016b) addressed the development and performance of human powered multi crop cutter. They have developed a mechanism for harvesting of crops, which provides easy harvesting in minimum period of time.

Shivashankar et al., (2015) stated that the ultimate aim of agriculture or farming in India is not only limited to growing of crops but also associated with the economic growth of farmers and labors. Small scale farmers frequently face the problem of labor shortage or unable to afford the wages to be paid. These problems prevent the fiscal growth of farmers and ultimately hamper the development of their farmland and family.

Chavan, et al., (2015) discussed about the need to help small-scale farmers to meet an increased demand for local grains, by designing a reaper machine to harvest grains more efficiently. Their research work focused on ease of harvesting operation to the small land holders.

Jadhav, et al., (2015) carried out a realistic experimental approach of solar power to agriculture. This study considered the design and performance analysis of 12 V, 24 W hand held solar powered cutter for paddy. The developed model was performed with two different types of blades in both sunny days and cloudy days. The model operated continously in cloudy day for 3 hours by using 0 stored energy in battery at 27 C temperature.

Aung, et al., (2014) described about a 4GL-120A power reaper, in order to save time constraints and reduce the cost of harvesting operation of rice by mechanization. This paper was studied to recommend the appropriate system for rice harvesting. cutting efficiency, cost economics and percentage of grain losses. The actual cutting width of the reaper was 1.2 m. In this study, performance of power reaper used for rice harvesting was assessed and compared with manual harvesting using sickle.

Handaka and Pitoyo, (2011) explained about the design and development of a commercial lawn mower which had been modified into a rice harvester machine. Modifications that had been made were (1) replacing the cutter blade with a rotary blade; (2) changing the dynamic balance of the harvest machine into a mower type; (3) adding a guider and a propeller; and (4) adding an operator belt. Performance tests on 100 m2 land, with a standard engine for crop harvest showed that, the modified machine had a working capacity of 18-20 hours/ha (where ha-hectare), fuel consumption of 15.0 l/ha, work efficiency of 95%, and weighing of about 10 kg. Price of the machine was in the range of IDR2.5-30 million/unit in 2007.

Solar panel has been used increasingly in recent years to convert solar energy to electrical energy. This energy is stored in battery and it is used to drive the motor. The motor is mounted on the hollow shaft and coupled with circular blade. When the motor turns on, shaft starts to rotate which leads to the rotation of the circular blades (Figure 1). Thus, the paddy crop has been harvested.

Figure 1. Schematic Diagram

There are two main ways in which solar energy can be harnessed: by the use of Solar Photovoltaic (PV) panels, or by Solar Thermal Systems, which in this report is defined to include Concentrated Solar Power (CSP). Solar PV technologies are often classified as first, second or third generation. The solar panel is shown in Figure 2.

Figure 2. Proposed Solar Panel

First generation technology uses basic crystalline silicon (c-Si). Second generation includes Thin Film technologies, while third generation includes concentrator photo voltaics, organics, and other technologies that are not yet commercialized.

These PV panels are divided into PV cells which convert sunlight directly to electricity, and they are compact and durable, but expensive. They are made of a semiconductor material such as silicon and contains impurities to change the way it conducts electricity, so that the silicon contains a p (positive) section and n (negative) section. The basic design of a PV cell, contains the p-section and n-section sandwiched between metal contacts which are connected to a wire, through which current flows. The anti-reflection coating prevents much of sunlight from being reflected away.

When radiation from the sun hits the PV panel, it makes electrons free (negatively charged particles found inside atoms) from the p-section and the electrons flow to nsection because of the electric field between the p-type and n-type materials (i.e. the junction). These negatively charged electrons get collected at n-section, and as the free electrons are pushed into n-section, they repel each other because they are of like charges.

The dimensions of Solar Photo Voltaic system are as follows:

Length=49 cm, Breadth=32 cm, Area=1586 cm

Solar panel: 20 W, Weight: 2.2 kg, Dimensions: 49 x 32 cm

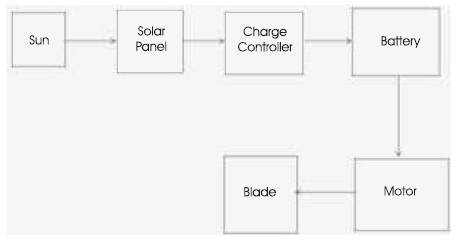

The charge controller is shown in Figure 3. Its dimensions are: Charge controller: 6V/12V, 10 A, Weight: 0.040 g, Dimensions: 6.5 x 5 cm. The proposed charge controller is connected to the part-5 of the design construction is shown in Figure 4.

Figure 3. Proposed Charge Controller

Figure 4. Proposed Design Constructions Layout

The proposed battery specifications are: Battery 12 V, 7.2 A, Dimensions: 15 x 8.5 cm, Weight: 1.96 kg. The proposed battery is placed at the part-5 of the design construction shown in Figure 4.

The proposed motor is shown in Figure 5 and it is placed at the part-1 of design construction, presented in Figure 4.

Figure 5. Proposed Motor

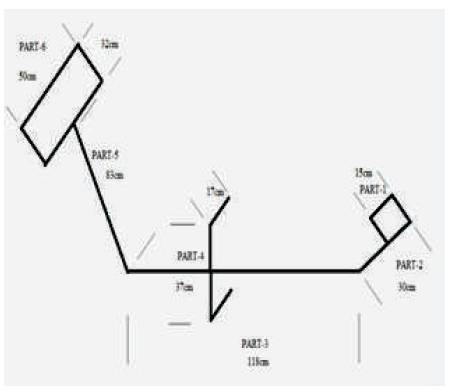

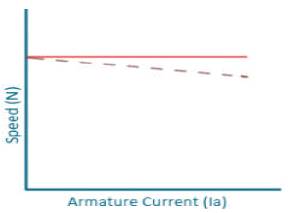

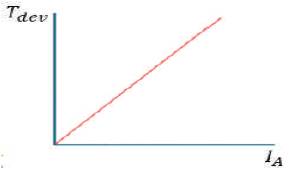

The speed versus armature current characteristics is presented in Figure 6, and Figure 7 shows the torque versus armature current characteristics.

Figure 6. Speed vs Armature Current (N – Ia) characteristics

Figure 7. Torque vs Armature Current (t – Ia) characteristics

Stainless steel contains sufficient chromium to undergo passivation, forming an inert film of chromium oxide on the surface. The proposed blade-1 is shown in Figure 8 and proposed blade-2 is shown in Figure 9.

Figure 8. Proposed Blade-1

Figure 9. Proposed Blade-2

The features of proposed blade-1 are as follows:

Dimensions: 8.5 inch diameter x 1 mm thickness x 32 teeth, Teeth depth: 2 cm, No of teeth=32, Weight: 0.234 g.

The proposed blade-2 is connected to the motor of part-1 of the design construction shown in Figure 4. The features of the proposed blade-2 are as follows:

Diameter: 8 inches, Dimensions: 8 inch diameter x 2.5 mm thickness x 80 teeth, Teeth depth: 0.5 cm, No of teeth=80. Carbon steel material with 2.5 mm thickness with Tungsten Carbide Tipped (TCT) circular blade used for cutting tree branches upto 4 inches is also used for cutting paddy and wheat. This blade model is compatible with brush cutters. It is weather resistant and is of weight 330 grams.

Electronic wires used for connecting is often categorized by the insulation. The proposed copper wire is shown in Figure 10.

Figure 10. Proposed Connecting Wires

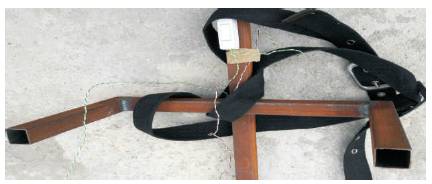

The proposed handling belt is shown in Figure 11 and it is connected to the part-4 of the design construction shown in Figure 4. The Belt length is 2.004 m. The proposed control switch is also connected at the part-4 of the design construction shown in Figure 4.

Figure 11. Proposed Handling Belt and Control Switch

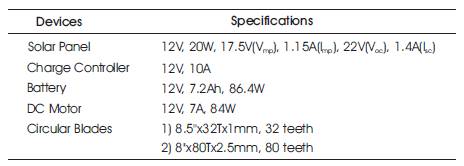

Design consideration of the proposed paddy cutter using solar energy, its main peripheral devices and specifications are given in Table 1.

Table 1. Specifications of the Components

A PV system design and sizing process passes through various two stages depending upon the level of details used in components sizing. The proposed design construction is shown in Figure 4.

The overall design can be divided into the following five stages: The top view of the real time design, the top view of the real time design (at motor), the side view of the real time design, the side view of the real time design (at motor) and the front view of the real time design, which are presented in Figures 12 to 16 respectively.

Figure 12. Top View of the Real Time Design

Figure 13. Top View of the Real Time Design (at Motor)

Figure 14. Side View of the Real Time Design

Figure 15. Side View of the Real Time Design (at Motor)

Figure 16. Front View of the Real Time Design

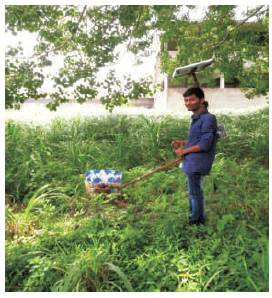

The real time verification of the performance has been verified successfully for various crops, which are shown in Figures 17 to 20.

Figure 17. Weeds Cutting

Figure 18. Grass Cutting

Figure 19. Paddy Harvesting

Figure 20. Paddy Harvesting Testing

The design construction features are as follows:

The various parameters were measured with different sizes of paddy using proposed blade, tests were carried out and the test results were estimated. The results show that, the time required to cut plant stem is less, motor used here consumes less current, is small in size, light in weight and portable, and the torque provided is sufficient for cutting agricultural plants.

The designed machine is not only used for harvesting the paddy crop but also used for trimming the tree, i.e. cutting the grass of thickness 0.8 cm with blade-1, cutting the weeds of thickness 0.35 cm and 0.65 cm with blade-2, and also cutting the grass of thickness 0.8 cm with blade- 2. The field test has been successfully verified.

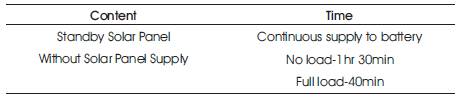

At no load, the battery works continuously for 1 hour and 30 minutes. At full load, the battery works continuously for 40 minutes.

The battery works continuously when the solar panel is connected. The battery takes 2 hours to get fully charged. The proposed battery ’s performance test results summary is as shown in the Table 2.

Table 2. Battery Service Test

At no load, the motor draws 3.5 A of current and at full load, the motor draws 7A of current. The machine is designed at low cost and its operation is simple. It can be easily operated manually by one person. It takes less time to harvest the crop when compared to traditional methods. It is easily transportable. No running cost is required and no maintenance cost and pollution.

The performance analysis of the proposed design and development of paddy rice cutter using solar energy has been examined for various crop varieties with various circumferences. It has been found that it reduces operation time, possesses low initial cost and almost no running cost. It is simple to operate, easy to carry out, does not contribute to any greenhouse effect and has low weight. Finally, it can be concluded that, the proposed one can be suitable for multicrop harvesting. It is economical for farmers, with very low maintenance cost, high efficiency and no running cost. Also, it can be used in all the seasons.