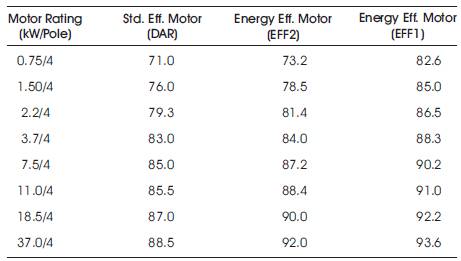

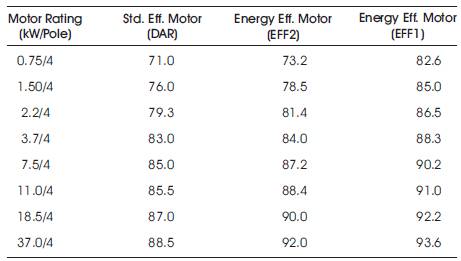

Table 1. Efficiency Comparisons of Standard, EFF2 and EFF1 Motors

In today's power production and utilization scenario, various types of problems are faced such as Depletion of fossil fuel sources, Increase in fuel cost, Deterioration of ecological balance due to carbon emission, Transmission and Distribution losses, Higher energy consumption due to poor efficiency drives and increased demand due to development taking place in many areas of the world which were hitherto undeveloped / under developed. Many of these problems can be addressed by adopting suitable technology resulting in energy saving. 'Energy conservation through Energy Efficiency' is the need of the hour and attempting to achieve this by developing higher efficiency motors with Die-cast Copper Rotor Motor (DCR) Technology. This paper covers the author's experiences so far and provides details of efficiency improvements, Energy saving potential ,case studies in the existing Die-cast Aluminium rotor motor (DAR) with the proposed DCR motor, especially in the industrial and agricultural sectors. This paper also includes some of the general Policy approaches for encouraging electrical energy efficiency.

India is world's sixth largest energy consumer, accounting for 3.4% of global energy consumption. For any country, power is a critical input for economic development and for improving the quality of life. In India, the achievement of increasing installed power capacity from 1,362 MW in 1947 to the current level of over 1,48,265.41 MW as on April 2009 is quite impressive in absolute terms. The total demand for electricity in India is expected to cross 9,50,000 MW by 2030. In spite of this addition in generation capacity, the growth in demand for power has far exceeded the generation capacity augmentation, as a result of which the country is facing both energy and peaking shortages. Based on the demand projections made in the Sixteenth Electric Power Survey, over 1,00,000 MW additional generation capacity needs to be added by 2012 to bridge the gap between demand and supply of power [1]. This would necessitate mobilization of nearly 8,000 billion of investment for additional generation capacity and associated transmission and distribution system in the next decade. So, energy supply projects are highly capital intensive. They have a long gestation period, thereby having a direct bearing on ecology and environment.

Electric Motor systems are the largest industrial loads, on average accounting for more than 70 % of all electricity consumption. Out of this about 30 % to 40 % of electrical energy produced in India is consumed by motorized pump sets employed in agricultural sector. Nowadays, with the increasing emphasis on energy conservation, efficiency values become very important and even dominant for applications in industry. On an average, the energy consumed by a motor during its life cycle is 60-100 times the initial cost of the motor. Therefore efficiency of the motor is of paramount importance both during selection and operation[2]. Even small increase in efficiency improvement can make a big difference in energy savings with accompanying decrease in air contamination. Many of the above problems can be addressed by adopting suitable technology resulting in energy saving. This is achieved by developing higher efficiency motors with Die-cast Copper Rotor Motor (DCR).

As it is widely known, the conductivity of copper is about 40% higher than aluminium. By using DCR to replace the traditional DAR, an improvement in motor efficiency can be expected. Based on copper rotors, super efficiency or ultra efficiency motors can be produced, especially in the area of small size motors. Motors can reach a higher level of efficiency in the same size by using copper rotors. For example, motor efficiency can be improved from EFF2 to EFF1 or from EPACT to NEMA Premium. This can be accomplished by a resign of the motor to take advantage of the characteristics of copper rotors and receive a maximum improvement in motor efficiency. The usage of DCR motor can reduce financial cost of industrial sector such as the cost of motor maintenance and cost of buying a new motor because it has long life span[3]. Therefore, DCR motors can save a substantial amount of money in the long run and reduce electricity bill. A considerable literature has been published in the past few years on the benefits to the performance of the induction motor by using copper as the conductive material in the rotor[4-7].

The paper is organized into the following sections; Section 1 describes the case studies conducted in the textile sector to analyze the energy saving potential of DCR motors. Section 2 describes the results of efficiency improvement in submersible pump sets by utilizing DCR pump sets and Section 3 presents a brief study about the general policy approaches for encouraging energy efficiency.

By merely replacing the DAR by DCR (without changing the other parameters), the efficiency of the motor were proven to improve by 1.6% in 37.0 kW motor and 9.4% in 0.75 kW motor. Improved efficiencies obtained by using DCR in the existing designs are given in Table 1 for the certain popular ratings used in the Industrial sector. The test method for the above motors are of IS 12615:2004 and the test conditions are 3 Phase, 415 V, 50 Hz. This table also shows the efficiency comparisons of Standard, EFF2 and EFF1 Motors. By simply changing the standard efficiency motor with EFF1 (DCR) motor, the efficiency improvement is found by 11.6% in 0.75 kW motor and nearly 5% in 37.0 kW motor. The efficiency values are subject to tolerance as per IS 325.

In an industry, majority of the motive loads use squirrel cage induction motor as the driving element. Most of the motors used in industry are oversized, even when proper sized motors are used, they are not loaded to their full capacities. This results in poor efficiency which leads to more energy consumption and energy cost[8]. Therefore improvement of efficiency of the motor must be a part of any comprehensive energy conservation effort. This conservation is possible by using energy efficient motors in place of a standard motor. It should be noted that the replacement of a standard with a DCR motor isn't likely to have much influence on motor power factor. On an average, we can expect a power factor improvement of less than 1%. In any event, power factor correction is easily achieved by adding external capacitors. Oversized motors will require greater starting currents and operate with a lower power factor than motors that are closely matched to load. The higher power factor reduces the currents in the cables supplying power to motor and this reduces cable loss, improving the system efficiency sometimes by even 2 %. Sometimes this allows even a lower cable size saving tremendously on capital costs. Saving is also made by reducing capacitors required to improve power factor.

Table 1. Efficiency Comparisons of Standard, EFF2 and EFF1 Motors

In order for a company to reduce its energy costs, it needs to evaluate how it uses energy. The energy audit defines where and how much energy can be saved. These figures are then translated into a potential monthly saving, i.e. this is the reduction in energy costs possible. One of such study has been carried out in the Exhaust motor of spinning department of textile mill in India as textile industry is one of the largest industrial sectors. The test results of various parameters measured are given in Table 2. Relative costs are summed up for each rating as per the present research (which needs further verification and work). The existing oversized 'Crompton' make 15 kW/20 HP motor is replaced by a proposed 'Orbitto' make DCR motor of 9.3kW/12.5 HP, which is comparatively low. In case of speed is concerned, the existing motor is rotated at 1440 RPM and the proposed DCR motor has rotated at 1458 RPM (Due to its low slip) during loaded condition. The Crompton motor used ND160L type of frame whereas on the other hand 160M frame size is used in the 'Orbitto' motor. The rated current taken by the existing motor is 27.6 A and the proposed motor is 16.5 A only. The average load current taken by the existing and proposed motors are 18.49 A and 16.5A respectively.

Both the motors have produced exhaust CFM value of 52000 Cubic Feet per Minute. But the energy consumed by these motors are found to be 12.8 kWh and 11.11 kWh respectively. The main advantage of DCR motor is energy saving. It saves 39.10 units of energy per day, which comes 1173 units per month. This leads to saving of  5278.50. per month. The initial purchase cost of the proposed EFF1 motor is

5278.50. per month. The initial purchase cost of the proposed EFF1 motor is  25119.00. But the pay back period of proposed motor is found to be 4 months and 22 days.

25119.00. But the pay back period of proposed motor is found to be 4 months and 22 days.

Table 2. Efficiency Comparison in Exhaust motor of Spinning Department

Similarly, a case study was carried out in the centrifugal blower load, which is available in the textile relax dryer unit given in Table 3. Both the existing motor and proposed DCR motor have the capacity of 7.5 HP. The speed of the above motors are 1440 RPM and 1460 RPM respectively. The average energy consumption per hour of the existing motor is 0.786 kWh higher than that of the DCR motor. The energy consumption of existing and EFF1 motor is 30,956.64 kWh per Annum and 20,052.00 kWh per Annum respectively. The annual energy saved for the proposed EFF1 motor is 4904.64 kWh higher than that of the existing Standard efficiency motor. By using this DCR motor, taking the energy charge of  4.70. per unit, then total saving in cost of energy is found that

4.70. per unit, then total saving in cost of energy is found that  1920.98/ per month and

1920.98/ per month and  23051.80 per annum. The initial cost of the DCR motor is higher than the existing motor by

23051.80 per annum. The initial cost of the DCR motor is higher than the existing motor by  4403. But the recovery period of this excess cost and recovery period of full cost of the motor is found to be 2.6 months and 7.67 months respectively.

4403. But the recovery period of this excess cost and recovery period of full cost of the motor is found to be 2.6 months and 7.67 months respectively.

Table 3. Efficiency Comparison in Textile Relax Dryer Centrifugal Blower Load

Agriculture Demand Side Management promises immense opportunity in reducing the overall power consumption, improving efficiencies of ground water extraction and reducing the subsidy burden on the states without sacrificing the service obligation to this sector. It also presents a promising prospect of targeting subsidy to the beneficiary farmers. In terms of electricity saved, given that most of the pilot projects as well as other studies, project potential savings of 45 - 50% by mere replacement of inefficient pumps, the overall electricity savings (from 20 million pumps) is estimated at 62.1 billion units annually.

The first electric motor in India was manufactured in Coimbatore in 1930 and thereafter the motor pump industry expanded rapidly there. Today 60% of India's requirements of domestic and agricultural pump sets are made in Coimbatore. The Southern India Engineering Manufacturers Association (SIEMA), which is established in 1952, has 215 members, most of tham manufacture motors and pumps of various types. Indian pumps are made according to the specifications of the Bureau of Indian Standards (BIS). Besides Coimbatore, Ahmedabad, Baroda, Calcutta and Dewas are the other places where agricultural pump industries are situated [9].

Individual farmers purchase agricultural pumps through local dealers with the help of a loan (new purchases onlyfrom the Regional Rural Bank (RRB)). The National Bank for Agricultural and Rural Development (NABARD) re-finances loans for RRB and approves the loans for pumps confirming to standards by BIS. Local dealers and rewinders (also the mechanic) influence the purchase and make brand recommendations to the farmer. The electrician from the local State Electricity Board (SEB) also makes brand recommendations to the farmer. The farmer depends on the pumps for water supply. They require quick response for service and repair. Local electricians or mechanics provide this service and act as brokers at the time of new purchases. The dealer act as a technical consultant to the farmer, who has no technical knowledge. Dealer and electrician alliances exist to influence purchase decisions.

Another factor driving the lack of interest in energy efficient motors is the heavily subsidized power tariff for the agricultural sector in India [10]. Power supplied for agriculture use is not metered, but charged on the basis of connected load, hence no incentive for efficiency. So, the poor farmer has no interest for investing huge money for purchasing the costly Pump set even though it is energy efficient. Subsidized or free power situation largely pampers this mind-set to go for slightly costly efficient pump set. Hence the authors have tried and succeeded in decreasing the cost of the submersible pump set, by decreasing the core length of DCR without sacrificing the overall efficiency level stated by IS 8034:2002[11-12].

Agricultural structures are not recognized as a major issue in India, however, resolution is highly political. The Central Electricity Regulatory Commission (CERC) and respective state electricity regulatory commissions are expected to address tariff rationalization issues and changes are expected. These changing conditions will drive the market towards increased motor efficiency[13].

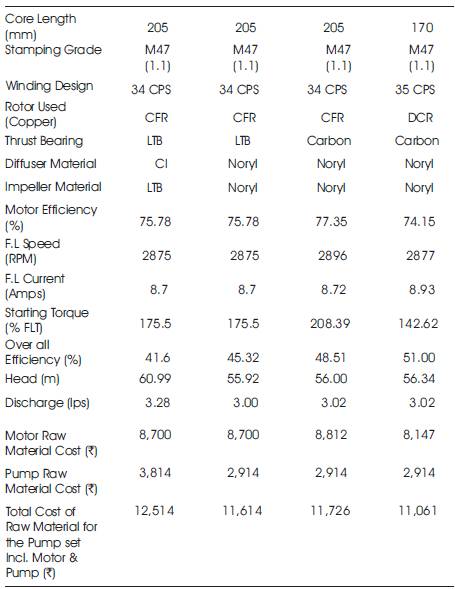

In India, the overall efficiency of a 5HP, 2 pole, 8 stage, and 150Ø mm borehole submersible pump set with existing Copper Fabricated Rotor (CFR) motor is 45% and above [14]. But the features suggested in the proposed technique using DCR, under data set 4 of the Table 4, should be able to improve the overall efficiency to around 51% and even a little more. For the purpose of improving the efficiency of the pumps, a “Standard Pump” was chosen whose details of performance and raw material costs are shown in data set 1 of Table 4. While only 4 data sets are given in Table 4, the large number of tests and assembly/manufacturing combinations were tried and the 4sets are just milestones in the development process. This project is aimed to improve the over all efficiency of the submersible pump set together with the reduction in manufacturing cost. So, to achieve these goals variety of diffuser/impeller combinations are tried, which overlap in terms of discharge, and those combinations, which render the same discharges in different, pipe diameters. This would go a long way in conserving lot of energy and at the same time bringing the cost of production lower than what is prevailing now. In the data set 2, using Noryl impeller and Diffuser has improved the overall efficiency by about 4% points and the more appropriately designed combination should render much more improvements. The use of carbon thrust bearing in the motor has improved the overall efficiency by about 3% points. The DCR used in data set 4 has contributed about 2% improvements in the overall efficiency. Under data set 4 in Table 4, it has been achieved a reasonably optimized design giving a higher efficiency at the lower cost of the submersible motor portion. In short it should be pointed out that an improved pump set consuming 25% less power has been achieved at 90% of the cost of the conventional CFR pump set under reference. As one could see, the efficiency improvements obtained are quite substantial meaning a reduction of 25% in the energy consumed. This project is extended to all ratings and models in vogue should considerably save energy through not necessarily 25% noticed here, but at least 10 to 15% conservation should be possible. The overall cost of the pump sets shown in Table 4 are bill of material costs and is taken on at the end of February 2009.

Table 4. Various parameter values of 5 HP / 8 Stage, 415 V, 2-Pole, Three phase, 50 Hz, 6”Submersible Pump motors

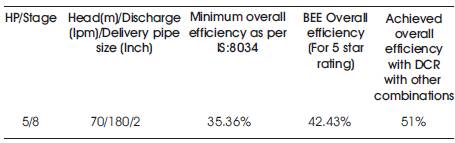

As per IS:8034, the minimum overall efficiency of 5HP, 8 stage submersible pump sets having a head of 70 m and discharge of 180 lpm is 35.36%. The overall efficiency for getting 5 star rating as per Bureau of Energy Efficiency (BEE) recommendation is 42.43%. But utilizing the DCR with other combinations the overall efficiency is increased by 51%, as given in Table 4&5. Table 6 shows the comparison of cost saving opportunities in 5HP/8 stage submersible Pump set with proposed DCR and existing system.

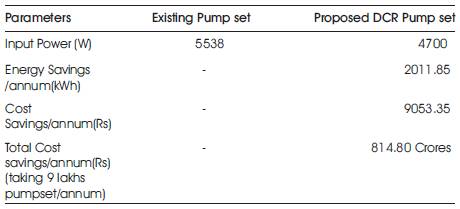

The input power consumed by an existing BEE 5 star rating, (overall efficiency 42.43% ) pump set is 5538 Watts and the proposed DCR Pump set with overall efficiency of 51% is only 4700 Watts. i.e., reduction in input power is 878 Watts. Therefore, the total savings for the period of 2400 Hours per annum is 2011.85 Units. The annual cost saving is  9053.35. It is inferred that by simply substituting the DCR Pump set for the 9 lakhs pump sets, then the total cost saving per year is

9053.35. It is inferred that by simply substituting the DCR Pump set for the 9 lakhs pump sets, then the total cost saving per year is  814.80 Crores.

814.80 Crores.

Table 5. Comparison of overall Efficiency of 5 HP / 8 Stage, 415 V, 2-Pole, Three phase, 50 Hz, 2”Submersible Pump motors

Table 6. Comparison of Cost Saving Opportunities in 5 HP/8 Stage Submersible Pump set

Energy efficiency is a fundamental element in progress towards a sustainable energy future. As global energy demand continues to grow to meet the needs and aspirations of people across the globe, actions to increase electrical energy efficiency will be essential. Some of the general Policy approaches for encouraging electrical energy efficiency are given below:

Governments should promote energy efficiency and support energy-efficient technologies like DCR Technology through their own purchasing policies and practices.

Governments should consider supporting energy efficient technologies directly by implementing policies that encourage investments in high-efficiency products and equipment. Examples may include tax credits and accelerated depreciation for energy efficient equipment (DCR Motor).

Government should consider increasing its support to the private and public sectors for research and development of energy-efficient technologies. Government sponsored research programs have aided the development of such products as DCR motors; energy savings and product selection software. When successful, research and development can be a good investment of taxpayer rupees.

Number of technologies show great promise for costeffectively improving the efficiency of electricity use. For each technology, we describe the potential benefits of improving efficiency and discuss policies to encourage technology development and dissemination.

This paper describes the Enhancement of Energy Efficiency in Squirrel Cage induction motors using DCR Technology, especially in the industrial and agricultural sectors. The results shows for the same output power, by merely replacing the existing motor with DCR motor (without changing the other parameters), the efficiency of the motor is increased by nearly 9% points in the lower capacity motors. If the rating of the machine is high, the incremental difference in efficiency of DCR motor is narrowed down. The case studies conducted in the textile sector and agricultural sector shows that the energy saving potential by utilizing DCR motor is high at the same time the payback period of the motor is less. In today's rising power shortage, it is one of the solutions of energy efficiency initiative and energy conversion of the induction motor by using DCR technology. Apart from energy savings, the DCR motor also reduces the production of greenhouse gases and pushes down the total environmental cost of electricity generation. Therefore the adoption of these motors can give immense benefits to the user as well as the country and the global environment[15]. Finally some of the general policy approaches for encouraging electrical energy efficiency are also presented.

The authors would like to thank the management of Karpagam College of Engineering, M/s Megala Machine Works India Ltd and M/s Challenger pumps (P) Ltd, Coimbatore,Tamilnadu, India., for their infrastructure and testing facilities provided to complete this research work.