Figure 1. Incandescent Lamp

This paper presents energy conservation by energy audit and use of energy efficient lamps. In order to conserve energy and reduce electricity charges, energy audit is done for lighting system used in educational buildings and domestic applications. After comparison of energy efficiency, illumination level and cost of different bulbs, LED (Light Emitting Diode) bulbs are suggested to conserve energy, enhance energy efficiency, and reduce electricity charges. In order to demonstrate the proposed approach, different case studies are considered for energy audit and conservation of energy for the sustainable future. Finally economic analysis of energy saving and investment on LED bulbs and payback period is determined.

In recent years, both electric utilities and customers have experienced increasing costs for electric energy. This is due to escalating costs for fuels that are used to generate electricity as well as the large capital costs for building the new generation units. Addition of new industrial units and population growth are further influencing the power crisis. Careful utilization of available energy will help operational engineers to minimize the power cuts. In this direction, the Energy Audit (EA) will help to understand more about the ways energy is used in any institution/industry and help engineers in identifying the area where waste can occur and scope for improvement [4]. Energy is the capacity of a physical system to perform work. Energy exists in several forms, such as heat, kinetic or mechanical energy, light, potential energy, electrical or other forms. Energy management is defined as the strategy of adjusting and optimizing energy, using systems and procedures so as to reduce energy requirements per unit of output while holding constant or reducing total cost of producing output from these systems [3]. Recently, the concept of energy audit and load management has emerged and it is being applied throughout the world [8]. Energy audit is the verification monitoring and analysis of the use of energy including submission of technical report containing recommendations for improving energy efficiency with cost benefit analysis and an action plan to reduce energy consumption.

A home energy audit and management is a service where the energy efficiency of domestic and commercial buildings is evaluated by a person using professional equipments with the aim to suggest the best ways to improve the efficiency in lighting and costing. An energy audit of a building involves various characteristics of building envelope, including roofs, walls, ceiling, and sky lights. The audit may also assess the efficiency, physical condition, durability of the lamps including conditioning equipments. Some of the greatest effects on energy use are user behaviour, climate, and durability of the lamps. The energy audit and management may therefore include energy billing history from the local utility and is often used to identify cost effective and energy efficient ways to improve the comfort and efficiency of the lamps. In [7], Energy Management and Conservation Strategies are discussed. The advantage of LED lighting for street lighting has been discussed in [5]. Importance of energy conservation, energy management and their opportunities is discussed in [1]. ISO 50001 for Efficient Energy Management System in industries is discussed in [6]. The energy management handbook has been realeased for official reference [2].

The main objectives of this work is to,

The types of lamps available are listed below.

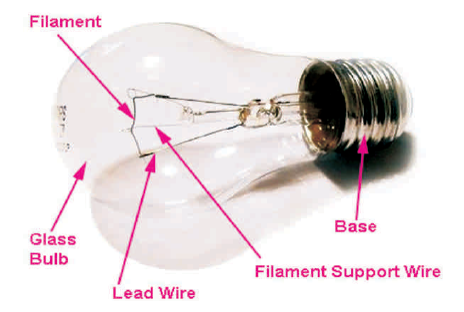

When an object is made hot, the atoms inside the object become thermally excited. If the object is not melting the outer orbit electrons of the atoms jump to higher energy level due to the supplied energy. If the electrons on these higher energy levels are not stable, they again fall back to lower energy levels. During falling from higher to lower energy levels, the electrons release their extra energy in form of photons. These photons are then emitted from the surface of the object in the form of electromagnetic radiation. This radiation will have different wavelengths. A portion of the wavelength is in the visible range, and a significant portion of wavelength are in inferred range. The electromagnetic wave with wavelengths within the range of inferred is heat energy and the electromagnetic wave with wavelengths within visible range is light energy. Incandescent means producing visible light by heating an object. An incandescent lamp works in the same principle.

The simplest form of the artificial source of light using electricity is an incandescent lamp. Here the electric current is flow through a thin and fine filament to produce visible light. The current rises in the temperature of the filament to such extent, that it becomes luminous.

Figure 1 represents different parts of the incandescent lamp. The resistance of the lighting filament conductor changing with temperature means that this incandescent lamp will have non-linear current-voltage curve characteristic. Voltage and current do not follow the simple equation "I=E/R" (with R assumed to be equal to 3 Ω) because an incandescent lamp's filament resistance does not remain stable for different currents.

Figure 1. Incandescent Lamp

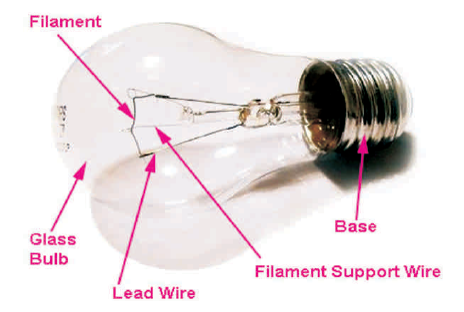

When the switch is ON, full voltage will come across the tubelight through ballast and fluorescent lamp starter. No discharge happens initially, i.e. no lumen output from the lamp. At that full voltage, first the glow discharge is established in the starter. This is because the electrode’s gap in the neon bulb of starter is much lesser than that inside the fluorescent lamp. Then gas inside the starter gets ionized due to this full voltage and heats the bimetallic strip that is caused to be bent to connect to the fixed contact. Current starts flowing through the starter. Although the ionization potential of the neon is little bit more than that of the argon, but still due to small electrode gap high voltage gradient is appeared in the neon bulb and hence glow discharge is started in starter. As voltage gets reduced due to the current causes a voltage drop across the inductor, the strip cools and breaks away from the fixed contact. At that moment a large L di/dt voltage surge comes across the inductor at the time of breaking. This high valued surge comes across the tubelight electrodes and strike penning mixture (mixture argon gas and mercury vapour). Gas discharge process continues and current gets path to flow through the tubelight gas only due to low resistance as compared to resistance of starter. The discharge of mercury atoms produces ultraviolet radiation which in turn excites the phosphor powder coating to radiate visible light. Starter gets inactive during operation of tubelight. Figure 2 represents fluorescent lamp.

Figure 2. Fluorescent Lamp

It is used in domestic and commercial purposes, such as houses, apartments, shops, and schools.

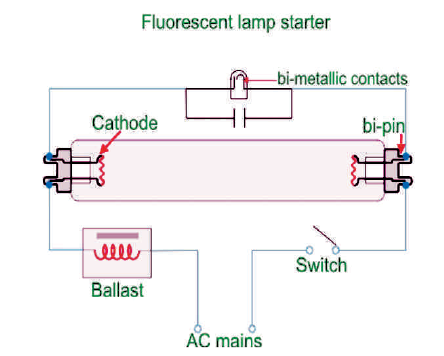

The principle of operation remains the same as in other fluorescent lighting electrons that are bound to mercury atoms are excited to states where they will radiate ultraviolet light as they return to a lower energy level. This emitted ultraviolet light is converted into visible light as it strikes the fluorescent.

CFLs produce light differently than incandescent bulbs. In a CFL, an electric current is driven through a tube containing argon and a small amount of mercury vapour. This generates invisible ultraviolet light that excites a fluorescent coating (called phosphor) inside the tube, which then emits visible light.

It converts electrical energy to radiant energy. They are energy efficient and use better technology as compared to conventional tubelights and bulbs. It has two components,

The ballast circuit takes a 220 V input from external power source and sends a current into the fluorescent tube as output. When power supply is given to the CFL, filament attached with the cathode heats up and emits electrons in the tube. This ionizes the argon and mercury vapour particles. Figure 3 shows different parts of CFL.

Figure 3. CFL (Compact Fluorescent Lamp)

Recessed cans are used in both hospitality and residential setting. A lot of older apartment complexes will have CFLs in the whole apartment.

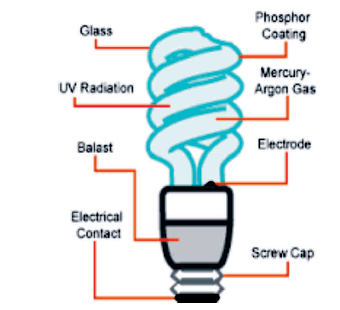

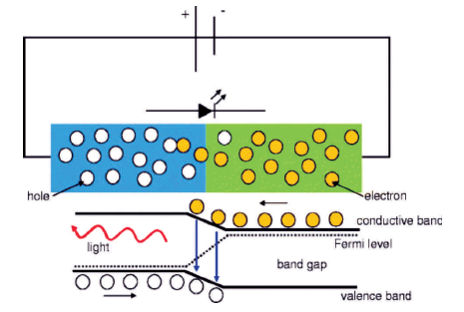

A LED consists of two semiconducting material, i.e. p-type material and n-type material. By connecting these two types of materials, a p-n junction forms. When p-n junction is forward biased, the majority carriers either electrons or holes start moving across the junction.

As shown in Figure 4, the electrons start moving from n region and the holes start moving from the p region. When they moved from their regions they start to recombine across the depletion region. Free electrons will remain in the conduction band of energy level while holes remain in the valence band of energy level. The Energy level of the electrons is high than holes, because electrons are more mobile than holes, i.e. current conduction due to electrons are more. During the recombination of electrons and holes, some portion of energy must be dissipated or emitted in the form of heat and light.

are more mobile than holes, i.e. current conduction due to electrons are more. During the recombination of electrons and holes, some portion of energy must be dissipated or emitted in the form of heat and light.

Figure 4. LED Lamp

The phenomenon into which light emitted from the semiconductor under the influence of electric field is known as electro luminescence.

Always remember that the majority of light is produced from the junction nearer to the p-type region. So diode designing is done in such a way that this area is kept as close to the surface of the device to ensure that the minimum amount of light is absorbed. Figure 4 represents LED lamp.

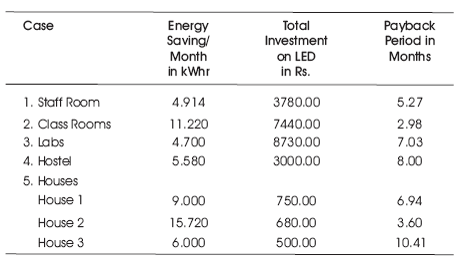

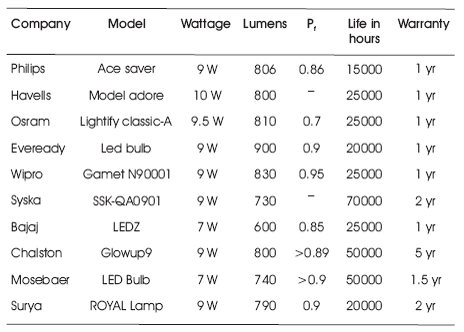

Tables 1 and 2 show the various manufacturers of LEDs and comparison of specifications of different lamp.

Table 1. Different Manufacturers of LED Lamps

Table 2. Comparison of Specifications of Different Lamp

Number of staff rooms = 17

Total number of tubelights used = 21

Average power consumption per tubelight = 36 W

Total number of hour operation per day = 7 h

Total energy consumption per day

= 7*36 = 252 Wh

= 7*36 = 252 Wh

Total energy consumption per month

= 252*26 = 6552 Wh (1FL)

= 252*26 = 6552 Wh (1FL)

For same lighting 15 W LED & 9 W LED

= 9*7*26 = 1638 Wh

= 9*7*26 = 1638 Wh

Savings = 6552 - 1638 = 4914 w = 4.914 kW

Savings per month = 4.914 * 6.95 = 34.15

Total savings = 21*34.15= 717.19

Payback period = Total investment/Total savings

= 3780/717.19

= 3780/717.19

= 5.27 months

= 5.27 months

3.1.2 Classroom

Total number of classrooms = 4

Number of FL = 24

Number of EFL= 8

Total = 32

Average power consumption per tubelight

= 40 W & 36 W

= 40 W & 36 W

Total number of hour operation per day = 16 h

Total energy consumption per day

= 12 * 40 = 480 (FL)

= 12 * 40 = 480 (FL)

= 4 * 36 = 144 (EFL)

= 4 * 36 = 144 (EFL)

Total energy consumption per month

= (480+144)*26 = 16224 W (1FL)

= (480+144)*26 = 16224 W (1FL)

For same lighting 15 W LED & 9 W LED

= 15* 12 *26 = 4680 = 4.68 kWh

= 15* 12 *26 = 4680 = 4.68 kWh

=9 * 4 *26 = 936 = 0.936 kWh

=9 * 4 *26 = 936 = 0.936 kWh

Savings = 16224 - (4068+936)

= 11220 = 11.22 kWh

= 11220 = 11.22 kWh

Savings per month = 11.22 * 6.95 = 77.98

Total savings = 32 * 77.98 = 2495.3

Payback period = Total investment/Total savings

= 7440/2495.3

= 7440/2495.3

= 2.98 months

= 2.98 months

Total number of labs = 4

Number of FL = 38

Number of EFL = 38

Average power consumption per tubelight

= 40 W & 36 W

= 40 W & 36 W

Total number of hour operation per day

= 4h (FL) & 3h (EFL)

= 4h (FL) & 3h (EFL)

Total energy consumption per day

= 40*4 = 160 (FL)

= 40*4 = 160 (FL)

= 36*3 = 108 (EFL)

= 36*3 = 108 (EFL)

Total energy consumption per month

=40*4*26 = 4.16 kWh

=40*4*26 = 4.16 kWh

= 36*3*26 = 2.808 kWh

= 36*3*26 = 2.808 kWh

Total = 6.96 kWh

For same lighting 15 W LED & 9 W LED

=15 * 4* 26 = 1.56 kWh

= 9*3*26= 0.70 kWh

Total = 2.26 kWh

Savings = 6.96 - 2.26 = 4.7 kWh

Savings per month = 4.7 * 6.95 = 32.66

Total savings = 38*32.66 = 1241.2

Payback period = Total investment/Total savings

= 8730 / 1241.2 = 7.03 months

= 8730 / 1241.2 = 7.03 months

Total Saving of the Dept= 4453.69/-

Capital Investment for LED =

For 9 w= 40 *180 = 7200 (9W)

For 15 w = 51*250 = 12750 (15W)

TOTAL CAPITAL INVESTMENT= 19950

Payback Period = Total Capital Investment/Total Saving of the Dept

= 19950/4553 =4.48 months

= 19950/4553 =4.48 months

Total number of tube lights used = 12

Average power consumption per tube light = 40 W

Total number of hour operation per day = 6 h

Total energy consumption per day = 6*40

= 240 Wh

= 240 Wh

Total energy consumption per month = 240*30

= 7200 Wh

= 7200 Wh

For same lighting 15 W LED & 9 W LED

= 9*6*30 = 1620Wh

= 9*6*30 = 1620Wh

Savings = 7200 - 1620 = 5580 w = 5.580 kWh

Savings per month = 5.580 * 6.95 = 38.78

Total savings = 38.78*12= 465.37/year

Payback period = Total investment/Total savings

= 3000/375 = 8 months

= 3000/375 = 8 months

Total number of tube lights used = 3

Average power consumption per tubelight = 40 W

Total number of hour operation per day = 12 h

Total energy consumption per day = 40*12

= 480 Wh

= 480 Wh

Total energy consumption per month = 480*30

= 14.4 kWh

= 14.4 kWh

For same lighting 15 W LED & 9 W LED

= 15*12*30 = 5.4 kWh

= 15*12*30 = 5.4 kWh

Savings = 14.4 - 5.4 = 9000 Wh = 9 kWh

Savings per month = 9*4 = 36

Total savings = 3*36 = 108

Payback period = Total investment/Total savings

= 750/108 = 6.94 months

= 750/108 = 6.94 months

Total number of tube lights used

= 2 (FL) & 1 (EFL)

= 2 (FL) & 1 (EFL)

Average power consumption per tubelight

= 40 W & 36 W

= 40 W & 36 W

Total number of hour operation per day

= 8h (FL) & 12 h (EFL)

= 8h (FL) & 12 h (EFL)

Total energy consumption per day

= 8 * 40 = 320 Wh (FL)

= 8 * 40 = 320 Wh (FL)

= 12 * 36 = 432 Wh (EFL)

= 12 * 36 = 432 Wh (EFL)

Total energy consumption per month

= (320+432) * 30= 22560 Wh

= (320+432) * 30= 22560 Wh

= 22.56 kWh

= 22.56 kWh

For same lighting 15 W LED & 9 W LED

= 15 *8*30= 3600 Wh

= 15 *8*30= 3600 Wh

= 3.6 kWh (FL)

= 3.6 kWh (FL)

= 9 *12*30= 3240 Wh

= 9 *12*30= 3240 Wh

= 3.240 kWh (EFL)

= 3.240 kWh (EFL)

Savings = 22.56 - 6.84 = 15720 Wh

= 15.72 kWh

= 15.72 kWh

Savings per month = 15.72 * 4 = 62.88

Total savings = 3*62.88= 188

Payback period =Total investment/Total savings

= 680/188 = 3.6 months

= 680/188 = 3.6 months

Total number of tube lights used = 2

Average power consumption per tubelight = 40 W

Total number of hour operation per day = 8 h

Total energy consumption per day

= 8*40 = 320 Wh

= 8*40 = 320 Wh

Total energy consumption per month

= 320*30 = 9600 Wh

= 320*30 = 9600 Wh

= 9.6 kWh

= 9.6 kWh

For same lighting 15 W LED & 9 W LED

= 15*8*30 = 3600 Wh

= 15*8*30 = 3600 Wh

Savings = 9600 - 3600 = 6000 Wh = 6 kWh

Savings per month = 6 * 4 = 24

Total savings = 2*24= 48

Payback period = Total investment/Total savings

= 500/48 = 10.41 months

= 500/48 = 10.41 months

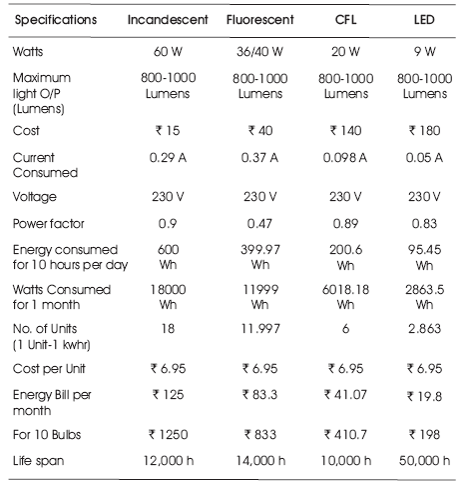

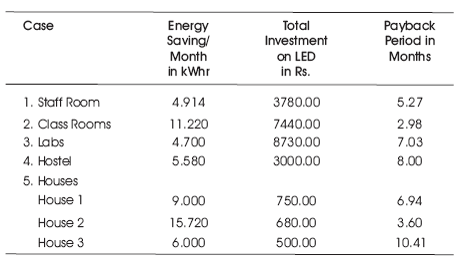

From the case studies, it is observed that the energy can be saved after energy audit and use of LED bulbs. Table 3 below shows comparison of energy saving, investment and payback period of different case studies considered.

Table 3. Comparison of Energy Saving, Investment and Payback Period

The outcome of this work benefit both consumers and utilities.

Now-a-days, there is a need of conserve energy for future sustainable development. The energy audit and energy management help both utilities and consumers.

The power factor of the LED is ≈ 0.9. This will reduce the reactive component of the current drawn by the supply main will reduce, which in turn reduces the transmission losses, even though the initial cost involving by replacing Fluorescent Lamps by LEDs and a very little time for payback with reduction of electricity bill.

The outcome of energy audit and use of energy efficient bulbs in lighting system is a considerable scope of electric energy conservation, reduction of electricity bill for domestic and commercial customers, and enhancement of energy efficiency. This in turn helps the utilities to maintain quality of the power, reliability, and security of the supply system as a whole. With the analysis of different case studies, it is proved that in lighting system, LED having low wattage is the most efficient lamp compared with other lamps and also save energy without compromising the illumination level. At the end the economic analysis and payback period is calculated and some recommendations were suggested.

The authors wish to thank the authorities of SDM College of Engineering, & Technology, Dharwad, Karnataka, India for providing the necessary arrangement to carry out this work.