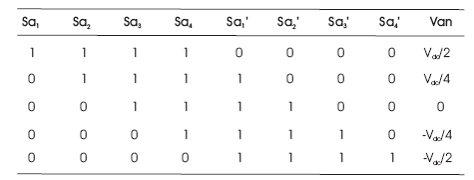

Table 1. Output Voltage Switching State and Magnitude

In the present time, the multilevel inverters gained a large interest by the researchers due to proficient power conversion with multiple voltage steps and consequently improved power quality, higher electromagnetic compatibility, reduced switching losses, and better voltage capability. Generally, the multilevel inverters are widely used in the industries for high power and high voltage applications. The multilevel inverter topology synthesizes a sinusoidal voltage from several levels of voltages obtained from capacitor voltage sources. This paper presents a three phase five level diode clamped inverter fed induction motor drive. The simulation of the model has been done in the latest Matlab/Simulink environment. The proposed simulation model gives efficient results with reduced harmonics in the stator current of the motor. Further, the harmonic analysis of the inverter voltages has also been done. Furthermore, for reduction of significant harmonics, active filter has also been used. This proposed simulation model may be used in many power electronics and drive applications.

From last three decades, it is seen that the industries begun to demand higher power equipment and therefore, the multi-level inverters attracting large attention for power conversion in high-power applications due to their lower harmonics, higher efficiency, and lower voltage stress compared to two-level or three level inverters [2-5, 10-12, 14, 15].

In the multilevel inverter, the sine wave may be approximated to a stepped waveform having large number of steps [9]. The steps are supplied from different DC levels and that is supported by series connected batteries or capacitors. The unique structure of multi-level inverter allows to reach high voltages and consequently lower voltage rating device may be used. As the number of levels increased, the synthesized output waveform contains more steps and produced very fine staircase wave and approached very close to the desired sine wave [11, 13, 16]. It may be easily understood that as induction motor steps are included in the waveform, the harmonic distortion of the output wave decreased and approached zero when the number of levels approached infinity. As a result, multi-level inverter offers a better choice at the high power end because the high volt-ampere ratings are possible with these inverters without the problems of high dv/dt and the other associated ones [20].

The objective of this research paper is to propose a diode clamped five level inverter fed induction motor simulation model and its analysis in the recent MATLAB/Simulink environment. Further, the harmonic analysis of motor parameters through the proposed model has been done. For harmonic analysis, stator current signal of the motor and inverter voltages has been used. Filters have also been used to minimize harmonics up to a significant level. The proposed model may be used in many power electronics and drives applications.

In the past, many researchers proposed three level inverter fed AC motor models, but those models produced large harmonics in the voltages and current. Therefore, these problems are overcome by the analysis of five level diode clamped inverter fed induction motor simulation model.

In this paper, the diode clamped multilevel inverter topology has been discussed in detail due to its advantages over other multilevel inverter topologies. The main focus of this paper is to design five level multilevel inverter that produces less harmonics in the voltage consequently, as a result it may achieve sinusoidal voltage for induction motor with very less harmonics. Therefore, the efficiency of the motor achieved is very high for inverter fed AC drive.

In the past, many researchers published various research papers for multilevel inverter and tried to reduce harmonics in the inverter voltage. Simply, for reduction of harmonics in the inverter voltage, they used more level inverters. But, more level inverters used large number of switches with increasing complexity and cost. Instead of this, they were not able to reduce inverter voltage with great extent as the authors achieved results in this work. Therefore, it is suggested for future researchers does not opt for higher level inverters just rather low level inverters with new idea and may achieve good results.

Basically, three types of multilevel topologies are used. They are as follows,

In this paper, the diode clamped multilevel inverter topology is used for study and simulation. The diode clamped multilevel inverter topology has a number of advantages over other topologies which are as follows [8, 9].

The most commonly used multilevel topology is the diode clamped inverter, in which the diode is used as the clamping device to clamp the DC bus voltage so as to achieve steps in the output voltage [5]. A multi level diode clamped inverter consists of pair of switches and pair of diodes [1]. Each switch pair works in complimentary mode and diodes are used to provide access to mid-point voltage [4].

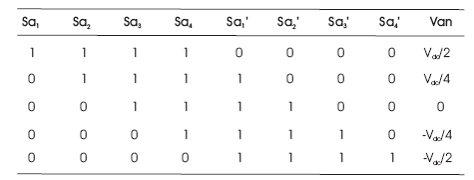

The number of main switches in each topology is equal. Comparing with other types, diode clamped inverters require less number of capacitors, but require additional clamping diodes. Hence the diode clamped multilevel structure is better for high and medium voltage drives which are easily connected to the utility drive. The Diode Clamped Multilevel Inverter typically consists of (m-1) capacitors on the DC bus in which m is the total number of positive, negative, and zero levels in the output voltage. Figure 1 shows a three phase half-bridge five level diode clamped inverter. The order of numbering of the switches for phase a is Sa , Sa , Sa , Sa , Sa ', Sa ', Sa ' and Sa ' and 1 2 3 4 1 2 3 4 likewise for other two phases. The DC bus consists of four capacitors C1, C2, C3 and C4 that act as voltage divider. For a DC bus voltage V , the voltage across each dc capacitor is V /4 and voltage stress on each (Switch) dc device is limited to V /4 through clamping diode. The dc midpoint of the four capacitors 'n' can be defined as the neutral point. Table 1 shows the output voltage levels and the corresponding switch states for one phase of the chosen five levels diode clamped multilevel inverter. The switches are arranged into four pairs (Sa , Sa ') (Sa , Sa ') 1 1 2 2 (Sa , Sa '), (Sa , Sa '). If one switch of the pair is turned ON, 3 3 4 4 the complementary switch of the same pair must be OFF. Four switches are triggered at any point of time to select the required level in the five level diode clamped multilevel inverters.

Table 1. Output Voltage Switching State and Magnitude

Figure 1. A Three Phase Five Level Diode Clamped Multilevel Inverter

In the applications of AC motor drives, the analysis of the common mode voltage is important. It occurs between the neutral point of the star connected motor (node n) to the earth ground (node e); it leads to common mode current. The Shaft voltage and the premature failure of the bearings is mainly the effect of common mode voltage. The simultaneous switching of the series connected devices produces voltage with a high dv/dt at the output terminal of the inverter. The sudden rise in inverter voltage is hazardous to the motor drive application. It is very important to reduce the common mode voltage and limit this voltage within certain bounds. A multilevel inverter can reduce as well as eliminate the common mode voltage. Some approaches to reduce common mode voltage, include four leg inverters, passive filters and dual bridge inverters, but five level diode clamped inverter is the best option to reduce common mode voltage. The causes of common mode voltage are leakage current, bearing current, and bearing failure.

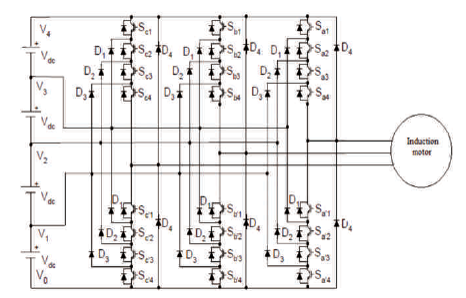

The Pulse Width Modulation (PWM) is the technique of using switching devices to produce the effect of continuously varying analog signals, this PWM conversion generally has a very high electrical efficiency [13]. In controlling either a three phase synchronous motor or a three phase induction motor, it is desirable to receive a perfectly sinusoidal current waveform in motor windings, with relative phase displacements of 120 degrees [15]. The production of sine wave power via a linear amplifier system would have low efficiency, at best 64%. If fast electronic switching devices are used instead of linear circuitry, then the efficiency can be greater than 95%, depending on the characteristics of the semiconductor power switch. The half bridge switching circuit in Figure 2 is given as an example. The switches can be any suitable switching semi conductors [5,13].

Figure 2. Half Bridge Switching Converter

There are various types of Pulse Width Modulation that can be employed. The types have been classified based on method of generation and nature of PWM waveform.

This scheme is popular only for economical inverters for voltage control, as it gives large harmonics at low voltages. It can be implemented online.

The harmonic spectrum of this implementation is superior to all the PWM schemes. It gives the best results with analog control, but is not suitable for online implementation.

The harmonic spectrum is inferior to NSPWM, but it can easily be implemented online as it is governed by simple algebraic equations.

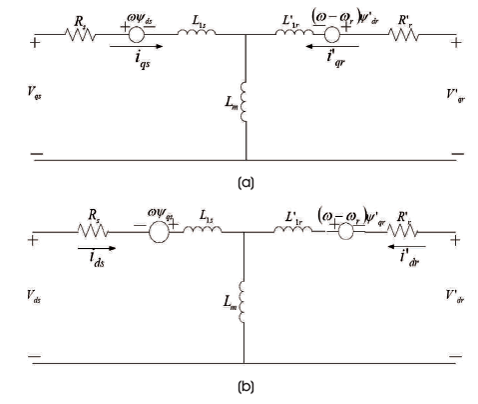

In the present section, the mathematical modelling of an induction motor has been discussed. For three-phase balanced circuits, the d-q transformation reduces three AC quantities in two DC quantities. These two DC quantities are imaginary axis and simplified calculations can be carried out on these imaginary DC quantities for recovering the actual three-phase AC results by performing inverse transformation. The d-q transformation is frequently used to simplify the analysis of three phase induction motor and calculations for control of three-phase inverters. The perphase equivalent diagram of an induction motor for d and q axis is shown in Figure 3.

Figure 3. (a) q-axis Diagram of IM, (b) d-axis Diagram of IM

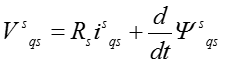

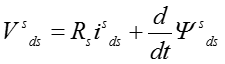

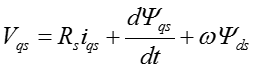

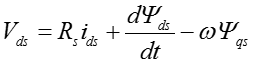

The stator circuit equation of voltage in the stationary reference frame is as follows,

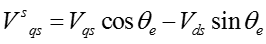

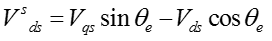

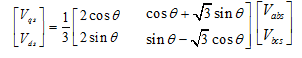

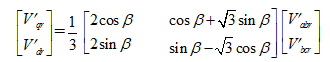

The equations of voltage used in the conversion of rotating reference into stationary reference frame are as follows:

The variable stationary reference frame and the variable rotating reference frame may be expressed by the following equations,

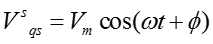

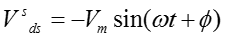

The stator voltage on the q-axis and d-axis are given in equations (7) and (8).

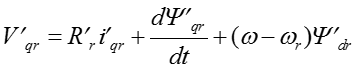

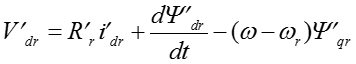

The rotor voltage on q-axis and d-axis are given in equations (9) and (10).

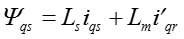

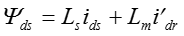

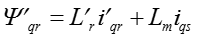

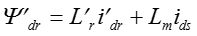

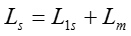

The flux linkages equations are as follows,

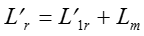

The equations of stator and rotor inductances are as follows,

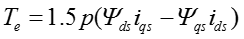

The Electromagnetic Torque is given in equation (17).

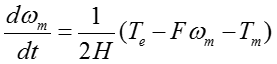

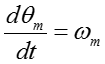

The equations for the mechanical system are as shown below,

The quadrature axis d-axis and q-axis which are obtained form to abc to dq conversion is given as follows.

The following relationships describe the abc-to-dq reference frame transformations applied to the Induction Machine phase-to-phase voltages.

In the preceding equations, is the angular position of the reference frame, while = - is the difference between r the position of the reference frame and the position (electrical) of the rotor. Because the machine windings are connected in a three-wire Y configuration, there is no homopolar (0) component. This also justifies the fact that two line-to-line input voltages are used inside the model instead of three line-to-neutral voltages.

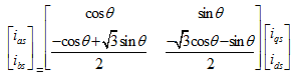

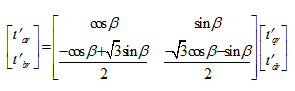

The following relationships describe the dq-to-abc reference frame transformations applied to the Induction Machine phase currents.

where i , i , i are the stator currents in different phases. as bs cs í , í , í are the rotor currents in different phases.

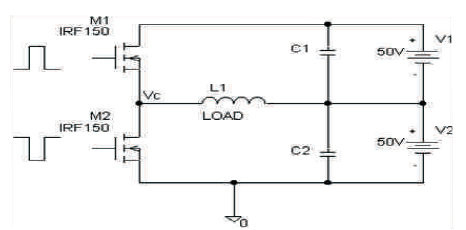

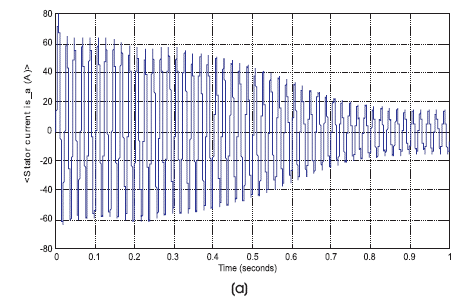

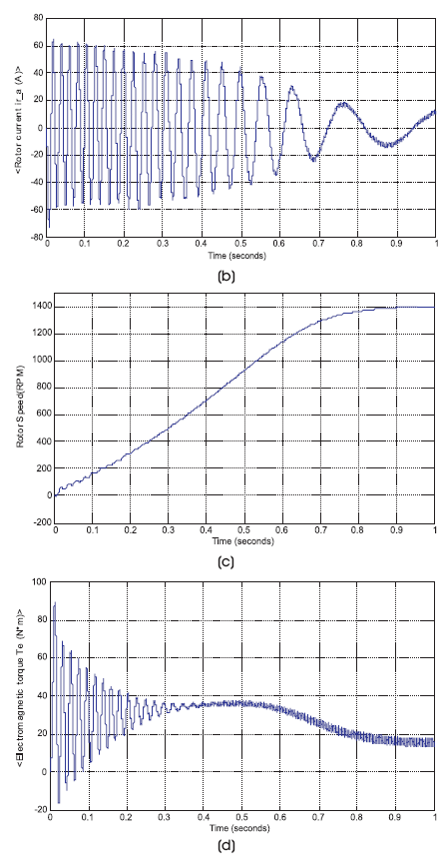

In this section, the five level diode clamped with sinusoidal pulse width modulated control inverter fed squirrel cage induction motor has been simulated in the latest Matlab/Simulation environment. The rating of the three phase induction motor is 3 hp, 220 V, and 1400 rpm. The induction motor can be operated in both modes either motoring or generating. The mode of operation depends on the sign of mechanical torque. For motoring mode operation, the load torque is positive and for generating mode operation, load torque is negative. The nominal mechanical load torque is set 15 N-m.

The rotor of the motor is kept short-circuited for simulating the effect of squirrel cage. For simulating the effect of smoothing reactor, the stator leakage inductance is set twice to its actual value. The smoothing reactor is placed between the inverter and the motor. The speed set point of the motor is 1400 rpm. The motor's inertia is used to prevent noise from appearing in the speed. The bus selector block contains 21 multiplexed signals of the motor. But, in this paper only four useful motor signals have been chosen for analysis purpose. Inverter signals have also been used for analysis purpose and discussed in the next section. The complete diode clamped five level inverter fed induction motor drive model is shown in Figure 4. The stationary reference frame has been used to convert input voltages to the dq reference frame and output currents dq reference frame to abc reference frame.

In this section, the results of the motor and inverter signals analysis has been done.

5.1 Simulation Result Analysis of Motor Signals

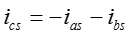

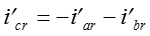

This section presents simulation result analysis of induction motor signatures and it has been done in the latest Matlab simulation environment. The simulation results in symmetrical or balanced supply (or called healthy mode) motor condition of the motor are shown in Figure 5. Four motor signals have been considered for analysis purpose. These are stator current, rotor current, rotor speed, and electromagnetic torque. For standstill operation, the slip of the motor is set 1 with nominal load torque 15 N-m. It has been observed that all used motor parameters have been reached in the steady state condition after 0.9 s. The model has been simulated only for 1 s for clear visualization of transient characteristics of the motor.

Figure 5. Induction Motor Signals in the Balanced Condition, (a) Stator Current, (b) Rotor Current, (c) Rotor Speed, (d) Electromagnetic Torque

In the present time, the stator current signal has widely been used for health monitoring or condition monitoring of the induction motor and called motor current signature analysis technique. Therefore, further, the harmonic analysis of the stator current parameter has been done. From the harmonic analysis result, it has been observed that the stator current signal contains less harmonics as compared to three level inverter. The three and two level inverters have been discussed in [18, 19] or extensively available in the previous literatures.

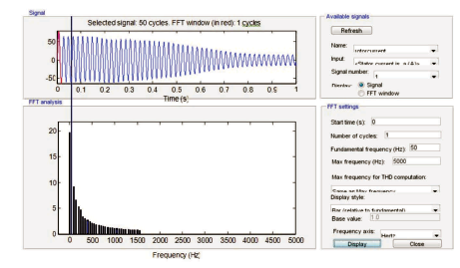

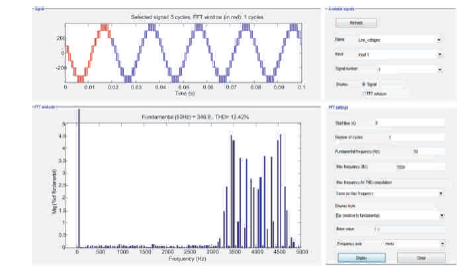

From Figure 6, it may be observed that the total harmonic distortion in the motor current is only 15.98% for inverter fed induction motor and it is in the permissible range of adjustable AC drives.

Figure 6. Harmonic Analysis of Motor Stator Current Signal

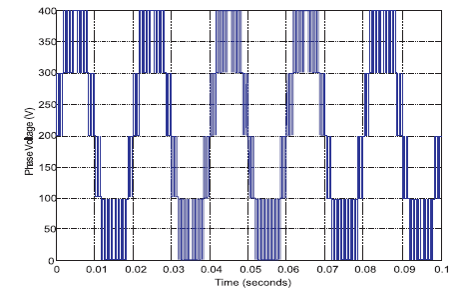

The output voltage of the inverter is shown in Figure 7. The authors have achieved an efficient result of the output voltage of the inverter for five level inverter fed induction motor drive. The switching sequence of the diode clamped inverter has been discussed in the previous section.

Figure 7. Waveform of Phase Voltage

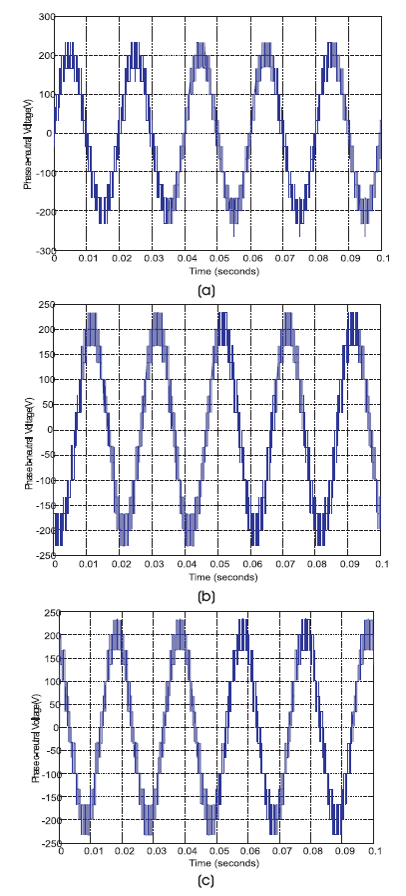

The phases a, b, c with neutral terminal voltages are shown in Figure 8. It may be observed that all the voltage waveforms are displaced 120 degrees. Therefore, an efficient three phase sinusoidal waveform for operation of the induction motor in the efficient way with less harmonics is obtained.

Figure 8. Waveforms of Phase a, b, and c with Neutral, (a) Phase a with Neutral, (b) Phase b with Neutral, (c) Phase c with Neutral

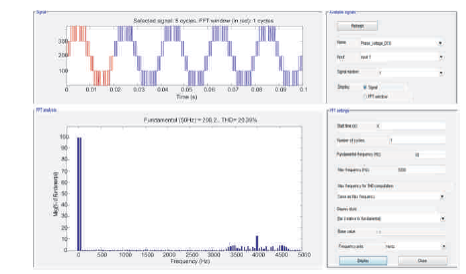

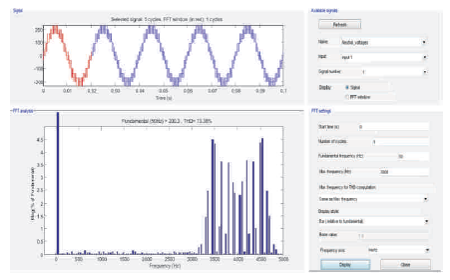

The harmonic analysis has also been done for inverter voltages. Earlier, it has been observed that the three level inverter contains harmonics in the output voltage approximately 65-145 percent [6, 7, 17-19]. But, if we use five level inverter then the harmonics has been reduced significantly. In this case, the authors have achieved only 20.39% harmonics in the inverter output voltage and it is shown in Figure 9.

Figure 9. Harmonic Analysis of Inverter Output Voltage

The harmonic analysis of line voltage has also been done and shown in Figure 10. The harmonics in the line voltage also achieved very less.

Figure 10. Harmonic Analysis of Line Voltage

The harmonic analysis of phase - neutral terminal has also been done observed that less harmonics is produced and shown in Figure 11.

Figure 11. Harmonic Analysis of Neutral Voltage

In the next section, the active filter has been used to reduce harmonics in the inverter voltages.

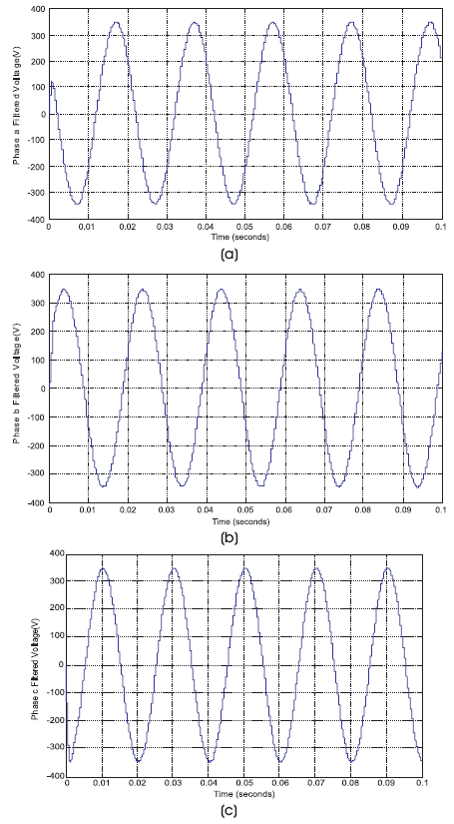

For elimination of these harmonics, the authors have used an active filter. After observing the waveforms, they have obtained efficient sinusoidal signals in the phase voltages which is shown in Figure 12.

Figure 12. Filtered Waveforms of Voltages, (a) Phase a, (b) Phase b, (c) Phase c

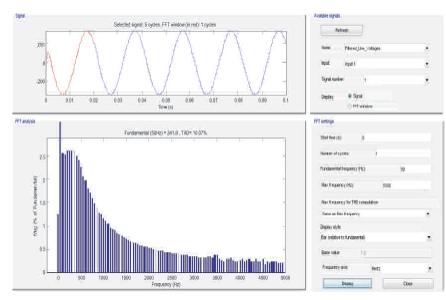

Further, the harmonic analysis of this filtered signal has been done and it is observed that the further reduction of harmonics can be done as shown in Figure 13.

Figure 13. Harmonic Analysis of Filtered Voltage Signal

In this paper, harmonics in the inverter voltages was tried to minimize with the proposed simulation model, but in the inverter fed induction motor drives, some harmonics will be present. If one wants to remove these harmnoics also, they will have to move for higher level. But, if one moves for the higher level then complexity and cost of the system will be increased.

In this paper, an accurate dynamic transient model of five level diode clamped inverter fed induction motor with SPWM control has been done. The transient analysis of the induction motor and inverter has been done. In this paper, the harmonics produced in the inverter voltages has been eliminated by the proposed model. In future, proposed model will be used in many power electronics and drives applications, such as health monitoring of the induction motor and inverter. Furthermore, this model has given excellent results for current and inverter voltages with reduced harmonics. Further, the analysis and comparison may also be done by different pulse width modulated inverter techniques. The detailed recommendation for multilevel inverter fed motor models is given in [19-20].

In the paper, the five level diode clamped inverter fed induction motor with SPWM control has been proposed and analyzed. The main aim of this research paper is to propose an accurate dynamic transient model for inverter fed induction motor drive. By this proposed simulation model, the transient behavior of the induction motor and inverter has been analyzed. Therefore, in this paper, analysis of five level inverter fed induction motor is done with minimized harmonics. Finally, it has been concluded that the proposed simulation model gives efficient results and may be used in many applications of power electronics and drives.