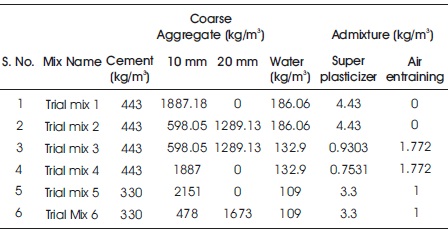

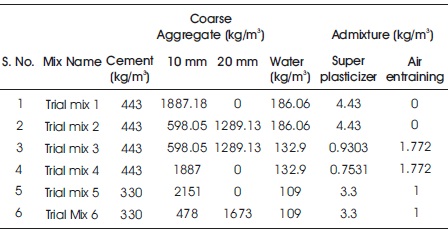

Table 1. Mix Proportions Adopted for Experimental Examination

This research article aims towards alteration in performance of pervious matrix due to variation in hydration kinetics. The effects of Portland cement and their basic constituents, along with hybrid polycarboxylate polymers, CHRYSO Air PL were evaluated. Different ratios of chemical suplimentaries (0.57, 0.61, 1, and 1.30% by weight) along with fluctuating quantities of ingredients was adopted to examine the response of physical and mechanical behaviour. The investigation involves various laboratory testing based on identification of material properties and products. The material (i.e., coarse aggregate) used in the experimentation was tested for water absorption, specific gravity, flakiness and elongation index, and aggregate impact value. Based on the response of materials, the mix design for pervious concrete was sculptured. The profound interpretations were analysed with varying curing techniques, i.e., immersed curing and internal curing. The result implies that the set of trials identified with mix proportions were found to be slightly aided with internal curing technique in mechanical testing. The use of chemical admixture, i.e., hybrid polycarboxylate polymers were found to be responsible for improvement of bonding capability of concrete structure. The compactness between the coarse aggregates and mortar has improved compressive strength capability followed by flexural parameters.

As urbanization is growing rapidly, it is generating impervious surfaces on huge scale thereby minimizing the natural pervious grounds making adverse effect on the environment. The conventional concrete pavement lacks air and water permeability because of which water does not infiltrate underground and results in high runoff. Due to which drainage systems gets overloaded and uncontrolled flooding conditions occur. In addition, because of impervious surfaces soil is not able to exchange heat and moisture with air resulting in high temperature and humidity of the Earth's surface creating greenhouse and hot land effects in city (Yang & Jiang, 2003). The impervious surfaces drop the groundwater level causing settlement of soil and thereby deconstructing various structures. Pervious concrete is the best solution for all these problems.

Pervious concrete matrix is observed to have a uniform medium with continuous fracture, making it a no-fine concrete. The design with high porosities formed irrespective of fluctuation in elementary constituent materials alike to that of the regular concrete mix (Huang, Wu, Shu, & Burdette, 2010). As concrete with its versatile nature diverts it to be in pervious form making it germane for flatwork, with upgrading it to modified form by making it suitable for precipitation of water. The change in the structure of concrete frame not only helps in the deduction of surface runoff of road, but also contributes in prevention on recharging of the groundwater table (Putman & Neptune, 2011; Elango & Revathi, 2017). Pervious with its non-fine medium not only holds good drainage properties, but also found to have noise absorption feature.

The past effort articulates that an attempt have been made to design the pervious concrete pavement with an analysis based on its physical and mechanical responses (Obla & Sabnis, 2015). The referred literature also covers the effort made for the study on analysis of cement paste properties, followed by supplementation of the superplasticizing agent (Chindaprasirt, Hatanaka, Chareerat, Mishima, & Yuasa, 2008). The significant feature of compressive strength is its water cement ratio. Water is the important constituent to produce cement paste, which should have sufficient workability without clogging up all the pores present in pervious concrete. Optimal range for water cement ratio to be considered for achieving good strength and permeability varies from 0.30 to 0.38 (Lian & Zhuge, 2010). Permeability of the porous concrete diverges from 15% to 30%, by volume, and it is totally based on the kind of compaction and the type of the aggregates used (Neithalath, Sumanasooriya, & Deo, 2010).

Pervious concrete mix for road surfacing was prepared considering cement, superplasticizer, silica fumes, coarse aggregates, and steel fibres, resulted void content of 18.8% to 31.9% and densities ranged from 1,890 to 2,034 kg/m3 (Lee, Huang, Chang, & Pao, 2011). Experimental programme was conducted considering the aggregates ranging from 4.75 to 19.5 mm followed by OPC type I and fine aggregates of grading II. The relation between permeability, strength, abrasion resistance, and total voids present in aggregates based on its angularity number was developed (Maguesvari & Narasimha, 2013). The properties of both, i.e., pervious and normal concrete were studied by adopting mix proportions of 1:0.3:5.5 and water-cement ratio of 0.4, and plasticizer as 0.6%, SBR polymer of 0.2% (Mahesh & Lavanya, 2016). The acoustic characteristics and abrasion resistance of pervious concrete was also studied using steel slag and dolomite aggregates and concluded that these characteristics would be improved if only a portion of the aggregate is used (Grubeša, Barišić, Keser, & Vračević, 2019; Vijaya & Sravana, 2016) in the examination observed the density, void content, and compressive strength for M20 grade concrete by considering the w/c ratio of 0.34, which concluded that with decrease in void content, compressive strength of concrete gets increased, However, improvement was observed to be more with increase in percentage of fine aggregates (Eathakoti, Gundu, & Ponnada, 2015) suggested an innovative model that can transport water percolated into the pavement. Different combinations of cement, water, and coarse aggregate with different maximum size and gradation were adopted for trial mixes to arrive at M20 grade concrete.

An innovative method of curing pervious concrete using plastic sheet was carried out to check the abrasion resistance of concrete (Kevern, Schaefer, & Wang, 2009). Super Absorbent Polymer (SAP) was used to reduce the curing time of pervious concrete. The effect of SAP was analysed by compressive and permeability test whose results articulated that the performance of controlled curing and plastic cover technique were almost the same (Kevern & Farney, 2012). The effect of prewetted lightweight aggregates replaced by the conventional aggregate present in pervious concrete was studied on strength, degree of hydration, shrinkage, and freeze–thaw action. The results acquired suggested that internal curing could become a routine for pervious concrete (Kevern & Nowasell 2018).

However, in this research, effort has been made to use hybrid polycarboxylate polymers and CHRYSO Air PL an airentraining chemical admixture for better analysis of the response of pervious matrix. It also involves dual curing techniques, one with immersed nature and other with internal curing technique.

In the present research work, Gujarat Portland cement was used as the binding material, which was added with coarse aggregates, hybrid polycarboxylate polymers, CHRYSO Air PL an air-entraining chemical, and water. The hybrid polycarboxylate polymers used was a superplasticizer adopted from CHRYSO® Delta D630, which is certified through ISO:9000. On the other side, air entraining admixture was also used which follows the guidelines of IS 9103-2007 and ASTM C-260 (American Society for Testing and Materials). The coarse aggregate used in the experimental programme were made available for testing from nearby quarry of Rasayani area, Maharashtra, India. Water used for the preparation of pervious concrete mix was normal tap water suitable for drinking purpose.

The mix proportion design prepared for investigation was set into various trials, which was prepared with combination of six as presented in Table 1. Each trial mix was prepared to identify the response due to variation of material proportions. The alterations made were with quantities of binder material, chemicals used, water content, and a combined ratio of aggregates. The concrete mix prepared in the investigation was as per the guidelines of IS 10262: 2009 and IS 456: 2000.

Table 1. Mix Proportions Adopted for Experimental Examination

In present experimental programme, the analysis of concrete specimens was done with cubes of standard size of 150 x 150 x 150 mm followed by beams with size of 150 x 150 x 700 mm as per Indian standard. Prior to utilisation of moulds, the fitting and gap of fixtures were checked, in order to prevent leakage of the cement slurry.

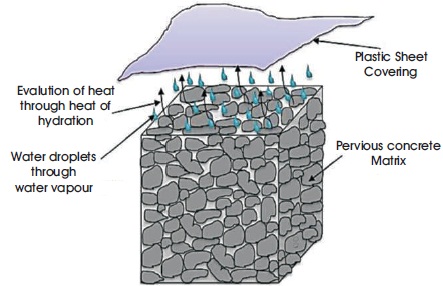

Dual type of curing technique was undertaken to observe the response of pervious specimens. The curing methods used were, i.e., immersed curing method (regular curing) and internal curing. The immersed curing is a regular form of curing method followed with the immersion of specimens in a curing tank with water level above the cubes. However, in the case of internal curing technique, the concrete mould after filling with concrete was covered with the plastic polythene sheet. The duration provided for the curing was the same as that provided for immersed curing, i.e. 7, 14, and 28 days. Internal curing is a process in which the hydration of cement continues because of the availability of water, which is not a part of the mixing water. It is mainly connected to the conversion of evaluation of heat from the concrete, i.e., heat of hydration into water droplets, which could be further utilized by the concrete again. The top layer was covered with plastic sheets, i.e., polythene which can be seen in Figure 1, which is locally available in the market. The covering of plastic polythene done in this investigation helped to entrap the heat, which is evolved from the concrete. However, it is a fact that the addition of cement with water undergoes an exothermic chemical reaction, which is termed as the heat of hydration reaction.

Figure 1. Internal Curing Technique

In this reaction, when C3S and C2S react with water, i.e., H2O it forms C-S-H gel and Ca (OH) and evolve heat from it. This 2 evolved heat is entrapped by the polythene and converted into moisture. This moisture in the form of water droplets gets collect over the polythene and fall back on the concrete surface that can also be seen in Figure 1. These water droplets help to provide water to the concrete after hydration reaction, so that the concrete can get sufficient compressive strength.

The evaluation of properties of materials such as aggregate was done using a specific gravity test and water absorption test on aggregate, which are followed by flakiness and elongation index and impact value test. However, the fresh state of the pervious mixture was identified for its workability using slump cone apparatus test. In case of analysis of the mechanical response of pervious concrete, compression test and the flexural test were adopted.

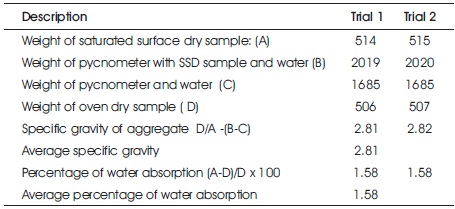

Specific Gravity and Water Absorption tests were carried out on the coarse aggregate of 10 mm and 20 mm as per IS 2386 Part III (Reaffirmed 1997). Its result articulates that the average specific gravity for aggregates is 2.81 and the average percentage of water absorption is 1.58%, which is necessary for preparing a mix design. Table 2 in the following section shows the results for specific gravity and water absorption test with standard formula calculations. However, the average specific gravity obtained after the trials was 2.81, where as the average water absorption found was 1.58. According to IS 2386 (Part 3), the specific gravity should range from 2.5 to 3 and water absorption should range from 0.1 to 2.0%

Table 2. Specific Gravity and Water Absorption Test Result

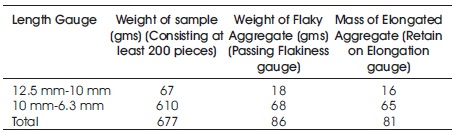

Flakiness index and elongation index are important terms to be determined as the flaky and elongated particles lower the workability of concrete mixes.

Table 3 shows the result of the flakiness index and elongation index. As per the numerical model presented in Shetty (1982) and the guidelines of (IS 2386 Part I (Reaffirmed 2002) the flakiness and elongation index were calculated, which observed to be with value 12.7 and 11.96. It is articulated as per Indian standard that combined flakiness and elongation should not exceed 40%, which is observed to be satisfied in this effort. However, the obtained values of indexing make the resultsuitable for experimentation.

Table 3. Flakiness Index and Elongation Index Result

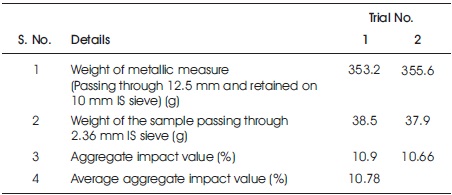

The toughness response of coarse aggregate was examined using impact value test as per the guidelines presented in (IS 2386 Part IV Reaffirmed 2002). The outputs obtained from the investigation reveals that the aggregate impact value obtained in both trials are 10.9% and 10.66%, which can also be examined in Table 4. However, the average impact value achieved is 10.78%. According to IS 2386 (Part 4), aggregate impact value should not exceed 30% for wearing surfaces. Therefore, the results obtained satisfies Indian Standard requirements.

Table 4. Impact Value Test Results

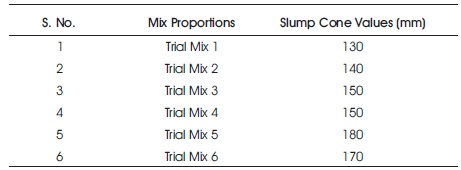

Slump cone apparatus was considered for the examination of workability of concrete. Conduction of test was done according to specifications mentioned in IS code. The results varying slump values were noted for different water-cement ratios. Slump cone test was performed on fresh concrete to calculate the workability; the result obtained is presented in Table 5. It is observed from the obtained slump values that Hybrid polycarboxylate polymers were mainly responsible for enhancing the flow value.

Table 5. Result for Slump Cone Test

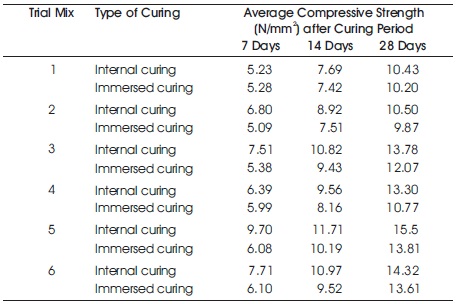

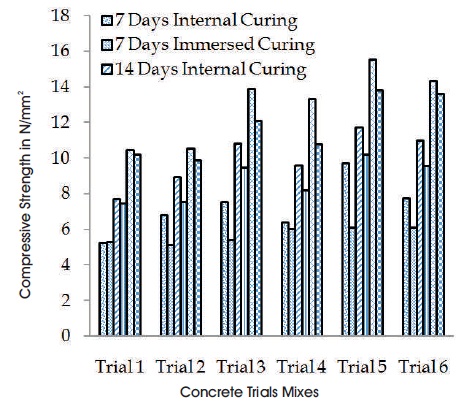

The investigation of strength parameter for concrete mixes was analyzed using uniaxial compression test apparatus, which were determined after 7, 14, and 28 days of curing. The identification of strength properties was checked for both curing technique, i.e., internal and immersed curing, which can be seen in Table 6 while the graphical representation can be seen in Figure 2. The output reveals that the compressive strength of concrete was found to be enhanced with all the trials at all the curing stages, but the crowning attained in case of internal curing was with fifth trials, i.e., 15.50 N/mm2. However, in the case immersed curing technique, the strength parameter was observed with a peak at 13.81 N/mm2. As per the mix profile, the alteration as compared to other mix trial was mainly based on the proportion of cement and aggregates, which was also offered with slight variation in water and chemical suplimentaries. The improved compactness in mortar of fresh concrete improved the strengthening and holding of aggregates resulted in improved stability towards pervious structure.

Table 6. Compressive Strength by Internal and Immersed Curing Method

Figure 2. Graphical Representation of Compression Parameters for Both Internal and Immersed Curing

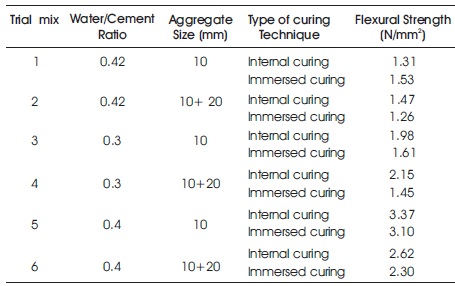

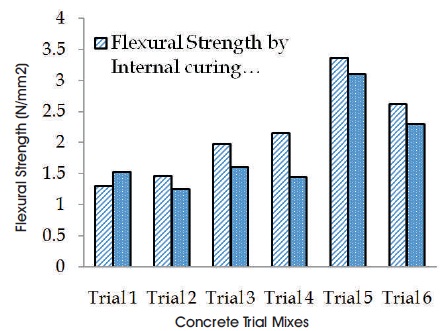

In this investigation, the effort was taken towards the analysis of the behaviour of pervious concrete by the flexural test. The response in case of the flexural test was identified using a third point loading method over the beam. The output obtained from the test is presented in Table 7, which covers both internal and immersed curing techniques results. Figure 3 shows the graphical representation of all the flexural results, which articulates that trial 5, was observed to be at peak in both curing techniques.

Table 7. Output of Flexural Strength by Internal and Immersed Curing Method

Figure 3. Graphical Representation of Flexural Parameters for both Internal and Immersed Curing

However, the comparison between both figures of trial 5 of flexural gives a higher pole towards internal curing, which is found to be similar in case of compressive strength analysis. On the other side, the result of immersed curing is nearly the same, but with 0.27 N/mm2 margin. The improved structure of fresh concrete was observed to have developed higher strength due to the effect of Hybrid polycarboxylate polymers. However, the flexural response due to voids of pervious concrete is observed to be non-supportive, resulting in a low improving response.

The research study conducted based on the identification of response of various concrete mixes has been observed with different figures and parameters. The conclusions that can be formed based on the results are presented in this section.

The pervious concrete matrix prepared with various fluctuations in quantities of the material was observed with marginal results, which was made to a deep identification with dual curing techniques. The results based on compression parameters were found to be upgraded due to alteration in trial mixes, which were approximately more than 48% in trial 5 when compared with trial 1 in internal curing. Similarly, in case of immersed curing, the hike of more than 35% was observed by trial 5, when compared with trial 1. The improved compactness in the mortar of fresh concrete improved the strengthening and holding of aggregates resulted in improved stability towards pervious structure.

The flexural output of pervious concrete were also found to be benefited in a similar manner as that of a compression test, but with low response. The flexural values reveal that the increase in strength parameters was more than double when compared between first and fifth trial mix. However, it was also observed that in both tests, that may be compression or flexural, the figures of internal curing technique were slightly exceeding than the immersed curing technique. The use of Hybrid polycarboxylate polymers improved the binding stability of pervious skeleton, which was found to be improving the flexural capability of pervious concrete.