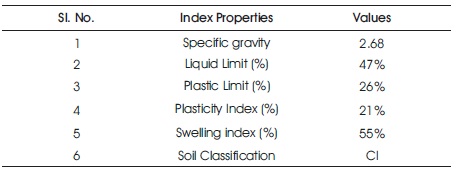

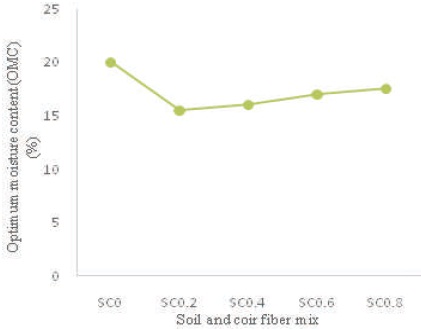

Table 1. Index Properties of Soil

Infrastructure development is important for a developing country like India. Road construction plays a major role in it. Hence, good quality roads are necessary for any type of infrastructure development. Flexible pavements are divided into layers, which consists of subgrade layer (soil as a foundation), sub-base layer, base course layer, and surface course layer (bituminous layer). If any layer becomes unstable or weak, it may lead to failure of the pavement. It is observed that sometimes pavements fail due to low strength of subgrade soil. The subgrade soil is internal part of the pavement. Hence, sound understanding of the properties of soil subgrade is essential for designing a pavement. The properties of soil can be modified by mixing the fiber reinforcements in the subgrade soil. Natural fibers like coir, jute, bamboo have been used to change the index properties of soil. The expansive soil which is also known as problematic soil was selected for the study. Pavement construction on such type of soil is a major problem. In this paper, coir fibres are used as reinforcement and its effects on the various index properties, i.e. Optimum Moisture Content (OMC), Maximum Dry Density (MDD), Unconfined Compressive Strength (UCS), Swell Pressure, and California Bearing Ratio (CBR) are studied. The study also includes effect of percentage reinforcement on the subgrade soil for the pavement design. The pavement design for soil and coir fiber mixture results into decrease of thickness of subgrade layer.

Soil stabilization and/or ground improvement technique is the solution of almost all geotechnical problems. Ground improvement technique has been used as per the requirements of site like, to improve the shear strength, to increase cohesion, to reduce the compressibility, to increase the bearing capacity, to reduce the permeability of soil, to reduce the swelling pressure of soil, etc. Now-a-days, disposing of industrial waste material is a big issue. Some of the industrial waste have potential to be used as a recycled material or as a partial replacement material in construction industry. Industrial waste materials can be used in construction industry, which also solve the problem of its disposal and also modify the properties of soil. Similarly, Geosynthetic and Geotextile materials are also new emerging material that have wide range of applications in case of ground improvement techniques, water retaining structures, embankments, and so on. Bamboo fiber, coir fibre, jute fibre are some of the natural fibres that can be used to stabilize the soil. The construction like embankment, earthen dam, and pavement largely deepens on the soil properties. The subgrade soil is integral part of pavements, which provides support to the pavement. The behaviour of road surface depends on strength of filling material and the sub grade below the same. The pavements are vulnerably affected by change in subgrade soil properties due to water table fluctuation, overloading, flooding, etc. If the subgrade contains expansive soil, it will damage the pavements. Natural fiber like coir or coconut fiber belongs to the group of hard structural fibers. It is one of the commercial products, which is obtained from the shell of coconut. One of the characteristics of coconut coir fiber is that it has elastic nature and without break it can be twisted though it is having deformation. So this coir fiber waste can be used in to modify the index properties of soil and thus it can be effectively discarded. The coir fiber is a natural fiber and it is easily available in coastal region. Due to specific properties of coir fiber it can be used for soil reinforcement purpose as well as to produce coir textile and other coir products, which enhance the soil properties and also it generates the employment as a coir industry.

In this paper, effect of inclusion of randomly distributed coir fiber on compaction parameters, i.e. optimum moisture content and maximum dry density, swelling pressure and strength parameter, i.e. CBR and UCS values are considered for the study. Effect of coir fiber on design of subgrade is also included in the study.

The proportion of coir fiber was 1-2% increment in the strength and stiffness of soil. The triaxial test on soil and coir fiber mixture results in improvement of stress–strain behaviour of soil by adding coir fibers in the soil, deviator stress at failure can increase up to 3.5 times over plain soil by fiber inclusion. Engineering properties of soil durability, volume stability, and strength can be improved by soil stabilization through optimum use of coir fibers concluded by Babu and Vasudevan (2008). An experimental study on fly ash and coir fiber proved that the CBR value can be increased due to fly ash and coir fiber mix of proportion 15%, 1.5%, respectively. This improvement in CBR value can reduce the pavement thickness and ultimately it can save the cost and material. This is due to composite waste material, which changes the brittle behaviour of the soil to ductile behaviour explained by Ramesh and Kumar (2009). Experimental study like swelling pressure tests, consolidation test, and three-dimensional (3D) shrinkage strain tests were performed on the coir pith and short coir fiber mix, which reduces the swell index and compressibility characteristics. The consolidation test results show that for combined treatment of coir fiber and coir pith, the coefficient of consolidation increased 6.3 times. The use of optimum percentage of coir pith and coir fiber reduced the volumetric swell strain by 42%. The recommendation based on experimental study state, that the coir waste can be used for a reinforcing action to solve the volume change of expansive soil concluded by Jayasree, Balan, Peter, & Nisha (2015). Based on the experiment study on soft soil using coir pith (0-3%) and coir fiber (0-1%), the Optimum moisture content, maximum dry density, and static triaxial test and CBR characteristics were determined and the test results showed that the stabilization with coir waste had significant effect on the compaction, elastic modulus, and CBR characteristics. The CBR value was increased by 4.6 times for soil, coir fiber, and coir pith mixture. The E-value for the combined treatment increased from 7.92 MPa to 9.66 MPa given by Peter, Jayasree, Balan, & Raj (2016). Due to important characteristics of coir fiber and coir pith though as a waste material can be used in construction field. It can create cost effective and sustainable solution. The use of coir products can generate the employment through coir industry.

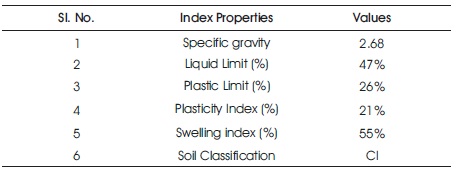

A series of experimental investigations was performed in order to study the effect of coir fibre reinforcements on various properties. The coir fibers are biodegradables and natural material. Though the decomposition rate of coir fiber is slow, it can be coated with kerosene or some suitable chemicals to prevent its early decomposition. The coir fibers are cut in a length of 0.5 cm and distributed randomly in the soil by taking different percentage of dry weight of soil. The soil samples were collected from the Agricultural University, Junagadh. The index properties of soil are given in Table 1. The soil and coir fiber mixture are denoted as SCX, where X represents, the percentage of fibre content for analysing its effect, i.e. SC0 (unreinforced soil) SC0.2, SC0.4, SC0.6, and SC0.8 were considered in this study. Standard proctor test as done to analyse effect of fibre on maximum dry density and optimum moisture content of the soil as per IS: 2720 part (VII). UCS test and CBR test are done to check the effect of fibre content on strength of subgrade soil as per IS: 2720 (Part-X) and IS 2720 (Part-XVI). Swelling pressure test was done to check the effect of coir fiber on swelling pressure as per IS: 2720 (Part. XII). Figures 1 and 2 show coir fibers and soil-coir mixture, respectively. California Bearing Ratio (CBR) is widely used as an indicator to measure the strength of subgrade soils. CBR value determined using both laboratories as well as field approaches. The expansive soil exerts pressure on the pavement, so to study the inclusion of coir fiber on the swelling pressure was studied. Table 2 shows the results of the variation in different properties with increase in percentage of coir fiber. This is a similar study which was done by Rangwala et al. (2017) conducted for silty sand using jute fiber.

Table 1. Index Properties of Soil

Figure 1. Coir Fiber

Figure 2. Soil and Coir Fiber Mix

Table 2. Index Properties of Soil and Coir Fiber Mixture

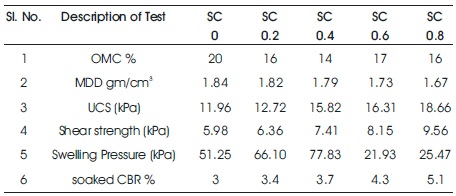

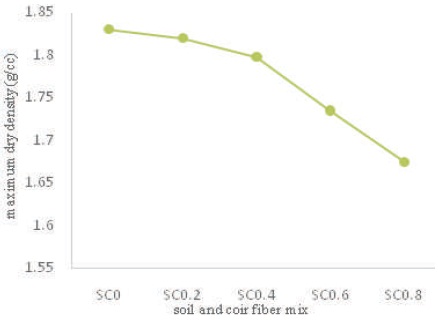

Standard proctor's test gives optimum moisture content and maximum dry density for a given soil. Variation of optimum water content at different fibre content is as shown in Figure 3. Variation of maximum dry density at different fibre content is as shown in Figure 4. It can be observed from Figure 3 that there was a sudden decrease in OMC with the addition of 0.2% coir fibre, but the OMC increases afterwards. Due to addition of coir fiber in soil, initially the soil and coir fiber mix requires less water to achieve maximum dry density. After that the OMC value will increase which implies that as the coir fiber increases water absorption capacity of soil and coir fiber mix also increases. Optimum moisture content increases with an increase in fibre content. Maximum dry density reduces with an increase in fibre content. This may be due to the fact that the fiber content is taken as percentage weight, which will affect significantly on the volume of soil and coir fibre mix. Moreover it was also observed that the reduction in MDD decreases with an increase in the fibre content.

Figure 3. Optimum Moisture Content of Soil and Coir Fiber Mix

Figure 4. Maximum Dry Density of Soil and Coir Fiber Mix

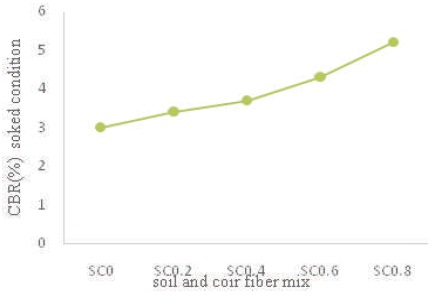

A series of CBR test has been done with variation in fibre content. CBR test for soaked condition was done on the sample with a given fiber content at corresponding OMC and MDD, utmost care has been taken for getting up to 95% of MDD for the soil prepared for the CBR test. For expansive soil, as per IRC-37 recommended that it is necessary to study field moisture density relationship under the same number of roller passes at different water content. Recommended moisture content should be 1-2 per cent wet of optimum moisture content and a minimum density corresponding to 95 per cent of the standard proctor density should be attained in the field.

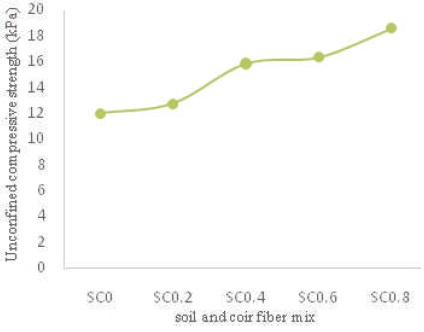

Cylindrical UCS samples of virgin soil and coir fiber soil mix have been tested for different percentage of coir fiber. The UCS was increased with increase in percentages of coir fiber as shown in Figure 5. The California Bearing Ratio (CBR) and UCS test were performed out on soil and coir fiber mix for different percentage of coir fiber by taking the suitable value of dry density and moisture content as per standard proctor test. The CBR test was performed for soaked condition, where the specimens were soaked in water for 96 hours and tested to evaluate the strength in the worst subgrade condition. Variations in CBR ratio for the addition of coir fibers are shown in Figure 7. The increase in strength is due to the fact that coir fiber acts as reinforcement material, which is responsible to increase the CBR strength. The cylindrical specimens were prepared for UCS test and the unconfined compressive strength for unreinforced soil and soil-coir fiber mix are given in Figure 5. The UCS increases due to the coir reinforcement.

Figure 5. Unconfined Compressive Strength of Soil and Coir Fiber Mix

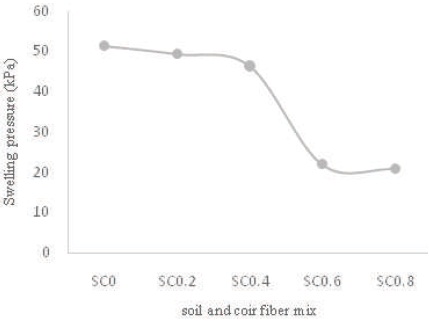

Figure 6. Swelling Pressure of Soil and Coir Fiber Mix

Figure 7. CBR of Soil and Coir Fiber Mix

The swelling pressure was decreased with increase in percentage addition of coir fiber as shown in Figure 6. The decrease in swelling pressure may be due to the addition of coir fiber. The pore water pressure can be easily dissipated due to the mixture of soil and coir fiber.

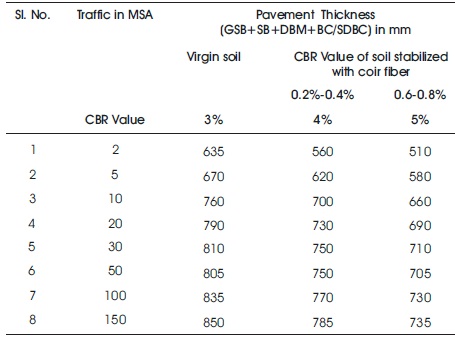

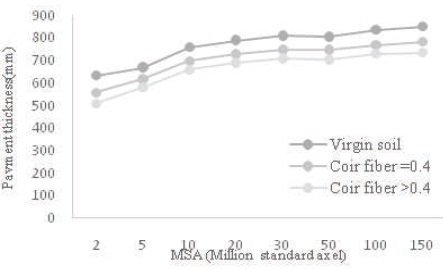

The pavement design is done as per IRC 37:2012 using the design charts as given in the code. Table 3 mentions the thickness of the pavement required for the stabilized soil and unreinforced soil. It can be seen from the table that as the CBR value increases with the increase in percentage of coir fiber pavement, thickness decreases accordingly. However, for design of pavement soaked CBR values are considered as per IRC 37:2012. Hence the stabilized soil requires less pavement thickness, thus making the pavements sustainable and more economical.

Table 3. Pavement Thickness and CBR Value

According to the Indian road congress IRC 37:2012, The subgrade soil forms the foundation of a pavement as per IRC 37:2012. The parent soil, replaced soil, or modified soil, which is immediately below the pavement having 500 mm thickness is most important layer as a subgrade layer. The select soil forming the subgrade should be compacted to a minimum 97% to avoid rutting due to densification over time. As seen from the graph in Figure 7, unreinforced soil was originally unfit to be used as a subgrade material as it has soaked CBR value of around 3%. Any soil having a CBR of minimum 8% or above can be used for traffic of 450 commercial vehicles per day. Use of expansive clay is not allowed for subgrade construction for heavily traffic road. Generally, the soil is replaced if the soil is expansive soil and which increases the cost of construction of embankment due to replacement of material. Once the soil was stabilized with coir fibers the CBR value can be increased. Addition of coir fibers in the range of 0.4%, 0.6%, and 0.8% increased the soaked CBR value of soil to 3.7%, 4.3 %, and 5.2%, respectively. Figure 8 shows the decrease in pavement thickness with increase in coir fiber content. Hence such soil which was stabilized with coir fibers can be used for road embankments. However, expansive soil mixed with admixtures like lime and/or flyash along with the coir fiber will give better results as per the study done by Ramesh and Kumar (2009); Shreyas (2017). However, In case of expansive soil buffer layer or blanket course can be provided additionally to deal with its shrinkage and swell behaviour.

Figure 8. Pavement Thickness and Percentage of Coir Fiber

In this study, the experimental investigation was done to analyse the effect of coir fiber on strength, compaction and swelling behaviour of soil. An effect of randomly distributed coir fiber pavement subgrade was attempted in this study. It was observed that the fibre content significantly affects the parameters under consideration, i.e. optimum moisture content, maximum dry density, UCS, and CBR values. In general, it observed that MDD decreases with an increase in fibre content, while OMC, UCS, and CBR values increase with an increase in fibre content.

Design of subgrade and the thickness of pavement is then done using data obtained from the experimental study. Effect of fibre content on the thickness of pavement subgrade was analysed. It was observed that the pavement thickness reduces significantly with an addition of reinforcement in the subgrade soil. This technique can be used for rural road infrastructure, where heavy traffic is not available.