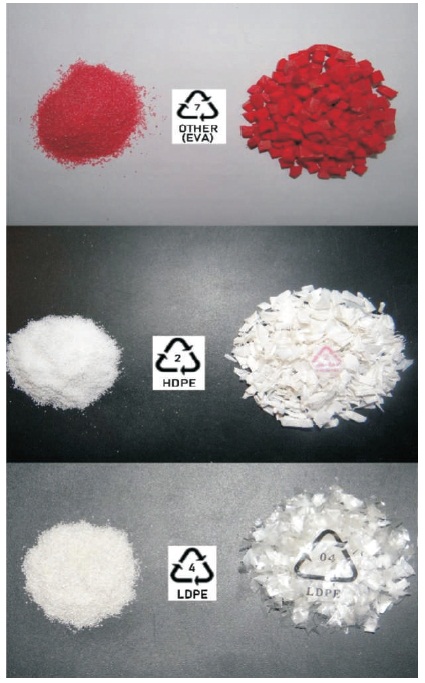

Figure 1. Virgin and Recycled Polymers (Flour and Granules) used in Present Study

Flexible pavements are chosen specially in the high temperature gradient for construction of roads. However, increased volume of traffic, overloading and world climatic changes, have caused widespread problems with the performance of these pavements. On the other hand, the huge amount of polymer is being produced causing menace to the environment. Recycling the waste polymers and using it in road construction have also considerable environmental benefits, such as reduced need for landfill, less pollution of both air and water. The present study was carried out on recycled and virgin polymers with two different sizes (granulate and flour); polyethylene low density (LDPER & V), highdensity polyethylene (HDPER & V), ethylene-vinyl acetate (EVAR & V) were used for modification of pristine bitumen (VG- 30). The outcome of the laboratory standard tests (conventional characterization, storage stability, dynamic viscosity, and resilience) were used in order to choose best-recycled polymer materials and their production. After comprehensive investigations, it has been found that optimum dosage of modified binder with virgin and recycled EVA and LDPE are 3% and 5% by weight, respectively. In case of recycled HDPE, the 3% was determined as an optimum dosage of modifier while for virgin HDPE it is 5%.

Bituminous pavements are broadly used due to its performance and quick construction world wide for construction of rural and urban roads. On the other hand, every year thousands of waste plastics are reversing to the lifecycle while their disposal is practically difficult. Various methods such as use of these materials (waste/recycled polymers) for modification of bitumen are yet to be explored to resolve this problem (Murphy et al., 2001). There are two main regular procedures for modification of bitumen, viz., dry process which involves the waste plastic as aggregate in the mix, this process takes place before adding the bitumen and the second regular method is called as wet process which involves, blending of solid waste plastic and bitumen simultaneously at high temperature (Appiah et al., 2017). This wet method is almost free of trouble (Kalantar et al., 2012).

In the last decades, many researches indicated that the blends of bitumen with recycled polymers result in an enhancement in the flexible bituminous pavement's resistance against cracking and permanent deformations and decreased susceptibility to temperature alteration (Yildirim, 2007; Cong et al., 2013). In terms of deformation properties, recycled plastics, which is used in bitumen modification, can be divided into “plastomers” and “elastomers”. Depending on thermal property, the polymer bitumen modifiers can be either a “thermoset” or “thermoplastic”. In terms of deformation properties and thermal property, the recycled plastics can be “plastomers” or “elastomers” and “thermoset” or “thermoplastic”, respectively (Roque et al., 2005). Thermoplastic Plastomer Materials like Ethyl Vinyl Acetate (EVA), Poly Vinyl Chloride (PVC), Low-Density Poly Ethylene (LDPE), High-Density Polyethylene (HDPE), Poly Propylene (PP) and thermoplastic elastomer materials including Styrene Butadiene Copolymer (SBS) and Crumb Rubber (CR) are used as a bitumen modifier. García-Morales et al. (2006) reported the use of recycled EVA (EVAR), recycled LDPE (LDPER) and CR for modification of bitumen. The authors have found that waste modified polymers made viscosity of the bitumen binder grater at high service temperatures, which consequently leads to have bituminous mix with higher resistance against rutting. Nevertheless, Fuentes-Audén et al. (2008) claimed that the use of recycled PP also had promoted on road performance by increasing the resistance against rutting, thermal fatigue, and cracking. They noticed that due to less workability, incorporation of such a waste material cannot exceed 5% in modified binder. Hussein et al. (2005) studied the influence of polymer like LDPE and EVA, polymer and structure of Polymer-Modified Asphalt (PMA) by rheological technique. The influence of molecular weight of LDPE, vinyl acetate content of EVA, and alkyl acrylate content were investigated and performances are compared. Polymer modification significantly improved the rheological behavior of pristine bitumen. Temperature susceptibility of plain bitumen was decreased in case of EVA and acrylate polymer modification. Casey et al. (2008) have concluded that recycled LDPE and HDPE have more potential for bitumen modification compared with other recycled waste polymers, including Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Chloride (PVC), and Polyethylene Terephthalate (PET) due to their high melting point that causes toxic emission at high temperatures. Furthermore, they noted that 4% (recycled LDPE and HDPE) is the ideal percentage for bitumen modification. This research work aims to evaluate the possible advantages of modifying bitumen binder with various obtainable recycled plastics, which probably leads to improve the physical and chemical properties of the resulting modified bitumen binders that could be used in future bituminous mixtures. The present study carried out to assess the conventional properties, the resilience of modified bitumen, its dynamic viscosity, and storage stability mix-up with several recycled polymers. Additionally, the effect of size of the recycled polymers was also assessed.

In this study, binder VG-30 is used as a base bitumen binder in preparation of all test specimens. Grade of pristine bitumen affects the properties of the modified bitumen especially at low temperatures, whereas the used modifiers do not have significant influence on stiffness at low temperature (Ali et al., 1994). In order to produce new modified bitumen with various recycled polymers, according to the information given by local Indian Shoes and slippers industry (which some of recycled polymers collected from their products for this study), through the literature review it was concluded that LDPE, HDPE, and EVA can be recycled and reused as bitumen modifier (Zhu et al., 2014). Hence, mentioned polymers were nominated for evaluation. All the polymers were obtained and recycled as a modifier material, therefore it is possible to measure the differences in the physical and chemical performances of bitumen modified binders with these polymers in two different particle sizes. Generally, virgin polymer particles mixed with dyes, fillers and other components to produce final products (which changes the efficiency of the recycled polymer for binder modification) with polymers. Therefore, for these particular LDPE, HDPE, and EVA polymers, the comparison of performance between virgin and recycled modified bitumen binders was carried out. In fact, pristine bitumen (VG-30) was modified with recycled and virgin LDPE, HDPE, and EVA. Figure 1 schematically describes the used virgin and recycled modifiers in this research. Polymers used in this study (virgin and recycled) are obtained in a granular form with approximately 5 mm in size. However, for better results all the virgin and recycled polymers were milled in a milling machine as shown in Figure 2 available in the Department of Civil Engineering, Aligarh Muslim University, Aligarh and converted into flour size with the maximum particle size of the 40 mesh (0.425 mm).

Figure 2. Milling Machine with all Components

The process of cryogenic method was carried out in two simultaneous phases including; freezing (with liquid nitrogen in minus 130 for all polymers) and milling (with small balls in the cylinder to shatter the frozen polymers). This method requires less operation time to produce fine mesh size than others and make the materials in much cleaner quality (Mashaan et al., 2012). The different virgin and recycled polymers used in this research are shown in Figures 3 and 4, respectively.

Figure 3. Used Virgin Polymers (Flour and Granules Size)

Figure 4. Used Recycled Polymers (Flour and Granules Size)

The primary process of assessment involved the incorporation of recycled and virgin polymers, in the pristine bitumen, in their granular dimensions. The objective of present work was to distinguish whether the dimensions of the prepared recycled waste polymers are the most suitable for blending of bitumen modification process. Hence eliminating prices of extra processing of the recycled polymers or the better requirements of high shear mixers, among other. With the hypothesis that with smaller polymer particles they can be, digest in pristine binder with less energy (including rotation of higher shear mixer and lesser time for digestion).

In order to make fair comparison, produced modified binders were made under the identical conditions for both recycled and virgin polymers, in order to complete digestion of polymers in the pristine binder and making a homogeneous blend, after adding a modifier in the pristine binder, with concentration of 1.0% - 7.0% of virgin and recycled LDPE, HDPE, and EVA polymers by an increment of 2% by weight of pristine bitumen and the mixture was vigorously stirred for 60 minutes at 170 and 3000 rpm (Singh et al., 2014). Moreover, the required amount of modifier is gradually added in binder to prevent agglomeration of modifier in the binder, for homogeneity of the mix and the modified blends are passed through sieve 100# American Society for Testing and Materials (ASTM). Physical characteristics of different modified bitumen were evaluated in order to observe which polymer in what percentage can be under specified limitation of Indian standard as well as which polymer has more influence in the pristine bitumen (VG-30), particularly recycled waste plastics (LDPE, HDPE, and EVA) modifiers. In addition, by measuring and consequently evaluating the physical properties of all modified bitumen binders, the advantage of size reduction in recycled and virgin polymers can be obtained. Initially, classic tests including softening point, penetration, and elastic recovery tests were done for evaluating the performance of pristine and modified bitumen samples. In next phase, the rotational dynamic viscosity test was carried out in order to specify mixing and compaction temperatures as well as comparing the viscosity of modified binders. Ultimately, the storage stability was investigated, by measuring the difference in softening point of the top and bottom sides of samples.

This test were performed using the ring-and-ball apparatus in the laboratory by immersing in distilled water in the range of 30 to 80 oC as per ASTM D36. In addition, through results of Softening point test, the temperature, which has major impact on the resistance against permanent deformation, can be obtained. In another word, the result indicates that at temperature the bitumen mixture (with this binder) will be at risk of rutting. Therefore, the test was performed to judge the improvement in characteristics of modified bitumen binders.

The Penetration test was carried out as per ASTM D5 for measuring the consistency of bitumen binder. Therefore, by specifying the test value it can indirectly be concluded that the stiffer bitumen binders almost have lesser fatigue resistance. In India, the classification of bitumen binder is generally based on penetration value test. In this test method, the most important part of the apparatus is needle (must be made from tempered stainless steel and fully hardened), which penetrates perpendicularly into a bitumen blended under standard condition of time (5 ± 0.1s), weight load (100 g), and temperature (25 ± 0.1 the outcomes reported in 0.1 millimeters).

According to IRC: SP: 53-2010, the elastic recovery test for modified bitumen binders were carried out at 15 oC. The capacity of materials, which elastically absorb energy of materials is called resilience. Using Bitumen binder with greater elastic recovery value, probably leads to have higher resistance against fatigue failure in bituminous mix. it is mainly because of the ability of elastic material which has a high tolerance for absorbing and transferring energy even after applying a high number of traffic loads on the pavement. In this method, ductility machine must be stopped travelling as soon as the machine's distance indicator reached to 100 mm under the condition of 15 oC with a speed of 50 mm/min. The elongated sample must be split up at the midpoint into two equal parts with scissors. After 60 minutes, the length of the remerged samples was noted by placing a pulled cut half of the piece return into the point, where the fixed and moving half of test samples toughing each other in order to record the distance between recombined samples.

Viscosity is a property of liquid and semi-liquid material, which refers to internal friction, and it is a measure of resistance to flow. In present study, the dynamic viscosity of all samples was carried out using a “rotational viscometer” according to ASTM D4402. The viscosity measurements were made at 110 oC, 135 oC, 150 oC, and 175 oC for both pristine and modified bitumen blends with virgin and recycled of EVAR&V, HDPER&V, and LDPER&V in both flour and granules sizes. The speed and torque were used in the test machine (Brookfield viscometer) to determine the viscosity of the binder in centistokes (cSt) unit, a conversional factor is required to convert it to pascal seconds (Pa.s). As per machine guideline spindle, Number 27 was used for the temperature 135 up to 200 with the speed of 20 rpm. The obtained Viscosity values are matched with Indian standard codes (IRC: SP: 53-2010, IS 15462:2004, or IS 73:2013) as required.

The storage stability test was carried out according to IRC: SP: 53-2010 (Indian Roads Congress, Standard specification). Through this test, compatibility of waste and virgin modified binders with pristine bitumen as well as optimum of each modifier in modified binders can be determined. In this test, molten modified blends were poured into standard tube of aluminum with 13.67 cm height and 2.54 cm diameter. After filling, the sealed tubes were located perpendicularly in an oven at 163 ± 5 for 2 days ± 4 h, thereafter putting them in a freezer for 4 h at 6.7. Finally, aged tubes were equally divided into three parts.

Blends, which were in top and base parts of tube were tested for their softening point temperature. Storage stability of modified binders can be acceptable if the difference of softening point values of top and low parts of tested tubes are below three for plastomeric polymers. Otherwise, it can be considered as phase separated blend.

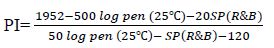

Using equation (1), the Penetration Index (PI) was determined by substitution of the test result values of penetration and softening point. The penetration Index measures the alteration of the binder's consistency with temperature. The PI value ranges from (-3) to (+7) for high and blown low temperature susceptible bitumen, respectively. Lower PI value indicates the quicker changes of bitumen viscosity as the temperature changes.

Table 1 shows the results of whole characterization tests that took place for modification of binders with various virgin and recycled polymers. According to their fundamental properties (penetration value and softening point) and resilience based on the specified limitation in Indian codes, the most appropriate amount of each types of polymers were determined. The physical properties of the pristine binder (bitumen VG-30) used for preparation of all modified binders are also shown. In order to assess the efficiency and influence of the different polymers, particle size and time (for digestion process) is applied in this research.

Table 1. Physical Properties at Various Percentage of Virgin and Recycled Polymer (EVAV&R, HDPEV&R & LDPEV&R)

Increasing softening point values is related to two main parameters; first the compatibility of the modifier with pure binder and second the softening point of the modifiers itself, i.e., whatever the softening point of modifier is, it is higher than the pristine bitumen while it has good digestion with bitumen it will increase the softening point modified blend. It can be seen from (Table 1) the softening point increased with increase in percentage of modifiers and the similar results were reported by (Appiah et al., 2017, Yu et al., 2011). It was found that the effect of EVAV (in both flour and granular forms) on softening point are higher than that of EVAR, which indicates more digestion (compatibility) with the bitumen while LDPEV and HDPEV results have minor difference with LDPER and HDPER in softening point values. As it was expected, in terms of effect of size of modifiers in softening point's results, slight changes was observed. However, softening points of all flour size modifiers, illustrate higher softening point compared to granules size. Modification of VG30 bitumen with 7% of EVAR&V, HDPER&V, and LDPER&V (modifiers) in flour form, exhibited the softening point values increase up to 69.2 & 74.6 oC, 68.6 & 72.5, and 66.5 & 69.5, respectively. According to IS: 15462-2004, LDPE (modifiers) in flour form exhibited the softening point R&V values increase up to 69.2 & 74.6 oC, 68.6 & 72.5, and 66.5 & 69.5, respectively. According to IS: 15462-2004, softening point values above 60 of plastomeric modified bitumen is considered as PMB-40. Hence, based on the softening point results, VG 30 bitumen modified with 3% and more percentage of EVAR&V and HDPER&V and 5% and 7% of LDPER&V fall in the grade of PMB 40.

The penetration values are decreasing significantly, as the concentration of modifier increases. However, Airey (2011) indicated that the improvement in modified blends temperature susceptibility resistant characteristics, i.e., for pristine VG-30 bitumen mixed with all polymers (EVAR&V, HDPER&V, LDPER&V), the penetration value dramatically decreased. Among the recycled modifiers, EVAR seems to be more effective than other two mentioned modifiers in terms of reduction of penetration value. The same findings were reported by (Murphy et al., 2001). Again, the modified binders with LDPER&V and HDPER&V (flour and granular size) have almost identical characteristics in terms of penetration results. The modified blends with LDPER&V (granular and flour size) illustrated the maximum penetration values, which implies a lower potential of recycled LDPE for alteration in this property of the pristine binder. The penetration value for pristine bitumen VG-30 is 66, which on modification with 1% - 7 % EVAV, HDPEV and LDPEV in flour size the penetration value reduced from 49- 107%, 27-82%, and 15-67%, respectively. For recycled flour size with same percentages of modification with EVAR, HDPER, and LDPER, the penetration values decrease from 29-73%, 19-74%, and 6-42%, respectively (Table 1). Comparison of the percentage indicated that virgin polymers have more compatibility (digestion) with pristine bitumen than recycled one, due to addition of dyes and some of the processes that were made during the production of these polymeric materials. According to IS 15462: 2004 and IRC SP 53: 2010 penetration values 30–50 of plastomeric thermo plastic-modified bitumen is considered as PMB 40. Hence, based on their penetration results, VG-30 bitumen modified with 3 and more percentages of EVAR&V, 5% and 7% of HDPER&V and LDPER&V fall in the grade of PMB 40.

The elastic recovery values are given in (Table 1). It is recognized that the elastic recovery values are increased with increase in percentages of all type of modifiers. Elastic recovery values of pristine VG 30 blend is very lower than elastic recovery of modified bitumen specimens prepared with those aforementioned modifiers. The bitumens modified with virgin and followed by recycled EVA gives the maximum rate of elastic recovery as compared to bitumens modified with LDPER&V and HDPER&V as expected. The elastic recovery, modified with powder size are higher than the blends modified with granulate form. According to IS 15462: 2004, the minimum specified elastic recovery limit for PMB 40 is 30%, which is satisfied for both EVAR&V after addition of 1% while for another two plastomeric thermoplastic modifiers (HDPER&V and LDPER&V), those mix could be considered as PMB 40 after 3% and more addition of modifiers (Table 1). The findings are in the line with (Ameri et al., 2011; Jain et al., 2011)

The storage stability behavior of polymer-modified binders, which has to be used for construction of flexible pavement has a very significant role, i.e., this behavioral property demonstrate the degree of compatibility or amount of digestion of used materials as a modifier with base binder (bitumen). Therefore, the storage stability were assessed in accordance with IS 15462: 2004 and IRC: SP: 53-2010 through the difference in the softening point temperature of top and base samples of each tube. As per IS 15462: 2004, the maximum specified difference in softening point temperatures for all plastomeric thermoplastic modifiers including all PMB's grades must be less than or equal to 3, which has to be fulfilled before acceptance of any modified bitumen as a PMB grade. Based on the results of storage stability test it was observed that, the optimum virgin and recycled content for the modification of VG 30 binder with EVAV&R and LDPEV&R are 3% and 5%, respectively. In case of recycled HDPE modifier content, the storage stability criteria was satisfied for 3% and lower content of both flour and granular forms since the higher value of modifier increased the physical properties (Table 1) of the modified blend of 3% has been chosen. Whereas, for virgin HDPE, 5% of modifier was preferred (Table 2). Costa et al. (2013) have reported the similar results. It is found that modifiers with lower surface area and higher density have lower storage stability compared with the modifiers with higher surface area and lesser density. A prominent example of these points is the comparison of rubbers modifiers with each other, HDPE vs LDPE in this study. The storage stability test results that is performed at varying virgin and recycled polymer content is presented in Table 2.

Table 2. Storage Stability Test Results Based on (LDPEV&R , LDPEV&R, & HDPEV&R) in Flour and Granular Size

The viscosity measurements were made at 110 oC, 135 oC,150 oC, and 175 oC for all modified and pristine bitumen, which are modified with EVAR&V, LDPER&V, and HDPER&V. The results are illustrated in Figures 5-7. In addition, Figures 5 through 7 correspondingly show the effect of virgin and recycled EVA, LDPE, and HDPE as modifiers on viscosity of pristine (VG 30) and modified bitumen with 1%, 3%, 5%, and 7% at different temperatures. In the present study, the dynamic viscosity of all samples was carried out using a “rotational Brookfield viscometer” according to ASTM D4402. According to the test results, the viscosity of bitumen-modified blends increased with increase of additional virgin and recycled modifier and decreased with the further temperature in the same additional percentage of modifier (Chen et al., 2003), i.e., at the temperatures above 150 oC, the viscosity of bitumen reduced and bitumen blend behaves as a fluent liquid. Comparing the results (in terms of increasing the viscosity) revealed that EVAV&R modifier are more effective than the same content of other modifiers in this study (Costa et al. (2013) have found that viscosity of EVA are more HDPE and LDPE, especially at 130 oC. As per SHRP's specifications to ensure pump capability at the hot mix bitumen plan, the viscosity of unaged bitumen blend should be less than 3. According to this limit, the viscosity of bitumen modified using both Virgin and Recycled EVA with 1 and 3% of flour and granules sizes were lower than 3 Pa.s at 135 oC. Whereas, in case of LDPE and HDPE, this limited value has been passed after 5% additional of the modifiers at the desired temperature. Since the storage stability of recycled HDPE with 5% in both (flour and granules) sizes could not be in the specified range consequently in Figure 6, the 3% recycled and 5% of virgin viscosity of the HDPE modified bitumen have been shown.

The Penetration Index (PI) was determined by using Equation (1). The penetration Index measures the alteration of the binder's consistency with temperature. The PI value generally ranges from −3 and +7. The one, which has less tendency toward the negative values is more susceptible to temperature and vice versa, i.e., Lower PI value indicates the quicker changes of bitumen viscosity as the temperature changes. Bitumen generally used for road construction contains a PI value between -2 and +2. Bitumen with PI less than -2 usually charecterized by high brittleness and bitumen with PI more than +2 are charecterized by less brittleness at low temperature. Penetration Indices values for pristine bitumen (VG30) and modified blends (with VG-30 using different percentage of virgin and recycled EVA, LDPE, and HDPE) are given in (Table 3). According to the test results and statement of other researchers (Sadeque & Patil, 2014), the PI values of bitumen modified blends were improved with increase of additional recycled or virgin modifiers. Comparing the results (in terms of increasing the PI values) revealed that EVAV followed by EVAR in flour and granules form are more effective than the same content of other modifiers. This is because of compatibility enhancement that is due to chemical reactions between the pristine bitumen and virgin and recycled polymer. It is concluded that modified bitumen equal or lower, 3% EVAV&R and 5% for both HDPEV&R and LDPER&V were considered as optimal dosage based on PI values.

Table 3. Penetration Index Values at Various Percentage of Virgin and Recycled Polymers (EVAV&R, HDPEV&R and LDPEV&R) in Flour and Granules Size

Use of various types of recycled and virgin polymers in granular and flour form in the modification of bitumen was assessed in the current study to evaluate the potential of utilizing recycled one in bituminous mixtures for their valorization.

Recycled and virgin EVA, HDPE, and LDPE all in granular and flour form were studied. Comparison of physical characteristics of modified bitumen with 1% - 7% in case of EVAR&V, HDPER&V, and LDPER&V polymers with increment of 2% demonstrated that, the better properties with lower quantity (which satisfied the limit values of Indian standard codes) of the modifier were achieved. In fact, the following conclusions were found.

The authors would like to acknowledge due to material support given from Transportation and Highway Engineering section of Civil Engineering and Petroleum Studies Departments of AMU University.