Table 1. Physical Properties of Aggregates

The roadways in India is dominated by flexible pavements and the conventional bituminous mixes proves to be obsolete for the quantum loads exerted by the commercial vehicles which ply on the pavement. Superior quality of pavement is achieved by using superior grade of materials and proper quality control during construction. To modily bitumen, there are many commercially available chemicals which are claimed to be the best in the market to modify bitumen, but only few prove the worthiness. One such commercially available elastomeric pellet VIATOP plus FEP Das Pellet is used in this work and it is evaluated based on laboratory investigation. The rheology of the modified bitumen mainly depends on the percentage of dosage, the mixing temperature, the mixing RPM, and also the mixing process (Dry process or Wet process). The present study is aimed at obtaining the optimum dosage of the elastomeric pellets that has to be added to the neat bitumen, in order to get a superior bituminous mix. The study is conducted on VG-10 bitumen and VG-30 bitumen for both BC Grade-II and DBM Grade-II mixes. Performance studies, such as Indirect Tensile Strength, Moisture Susceptibility, and Repeated load test are done at obtained OBC using Marshall Criteria.

The total road network in India had increase more than two folds since 1990. The demand for transportation is ever growing. The main drawback in the conventional mix is its temperature susceptibility. In order to cater the current day needs of the road transportation sector the quality of the materials needs to be improved, especially bitumen, superior quality which would sustain in heavier load condition and perform well under higher stress levels irrespective of the temperature and climatic conditions has to be used. VIATOP plus FEP Das Pellet is a commercially available bitumen modifier, which can be used to modify binder in both wet and dry condition. This product is a unique pelletized blend of 20% Arbocel ZZ 8/1 and 80% functional additive. The advantages of using this product are excellent resistance towards deformation, improved ageing properties, reduced cracking, improved workability and long storage life.

The objectives of the present study, include

Neil C. Kurtz and Stroup (1992) discuss the conventional Asphalt AC-5 and AC-20 grade asphalt binders were modified with rubber and the following modified asphalts were prepared, AC-5+17% rubber (AC5R), AC-20+Rubber (AC20R) and AC-5+16% Rubber + extender oil (AC5RE). The laboratory research on both static and repeated load were tested at warm temperature, the temperature were maintained at 77 oF and 104 oF. The research was conducted in four phases, first phase dealt with arriving at OBC, second phase dealt with permanent deformation characteristics of asphalt rubber and unmodified bitumen, phase three was about low temperature cracking comparison between asphalt rubber and unmodified bitumen, fourth phase dealt with fatigue characteristics for asphalt rubber and unmodified mixture. The addition of GTR to asphalt mixes exhibited less permanent deformation at higher temperature when compared to unmodified bitumen, this was confirmed with both static and repeated load test.

Gupta and Veeraragavan (2009) compared the fatigue behavior of SBS modified bitumen to that of neat bitumen. 60/70 grade bitumen was used as the neat bitumen and PMB-70 as modified bitumen. A mixing temperature of 180 oC and a compaction temperature of 165 oC were selected for SBS modified mixes. DBM Grade-II is the OBC obtained at 4.5% for neat bitumen and 4.8% for SBS modified. Stability of 18.55 kN was obtained for neat bitumen and 23.50 kN was obtained for SBS modified bitumen. The Retained Marshall Stability, TSR were 71% and 86% for neat bitumen and 89% and 96% for modified, respectively. An increase of 2 to 2.5 times in resilient modulus of polymer-modified mixes was observed as compared to conventional bituminous mix.

Mutiu Akinpelu et al. (2013) decribe polyethylene was considered as polymer additive for the modification of bitumen. Optimum bitumen content was found to be 7%. Polyethylene by weight of optimum bitumen content was added in the five proportions (2.5, 5.0, 7.5, 10, 12.5, and 15%) and tested. 12.5% of polyethylene by weight of conventional bitumen was found to improve stability, air voids and voids of mineral aggregates and reduction in the density compared to other mixes of polyethylene doses.

Nabin Rana Magar (2014) mainly dealt with the use of CRMB manufactured from the waste tyre scrap. The crumb rubber was added at 15% to the weight of bitumen. The research is done on the varying sizes of crumb rubber and the four different sizes of crumb rubber used are coarse (1 mm -600 μm); medium size (600 μm - 300 μm); fine (300 μm-150 μm); and superfine (150 μm - 75 μm). The mixing temperature of bitumen and crumb rubber was maintained at 160 oC and the initial hand mixing time was 3-4 minutes, to achieve the complete blend the mix is mechanically stirred for about 50 minutes while o maintaining the constant temperature of 160 oC. It was observed that the sample prepared using crumb rubber size (0.3-0.15 mm) gave the highest stability value of 1597.64 kg, minimum flow, maximum unit weight, maximum air voids and minimum VMA and VFB % values when compared to other crumb rubber particle sizes.

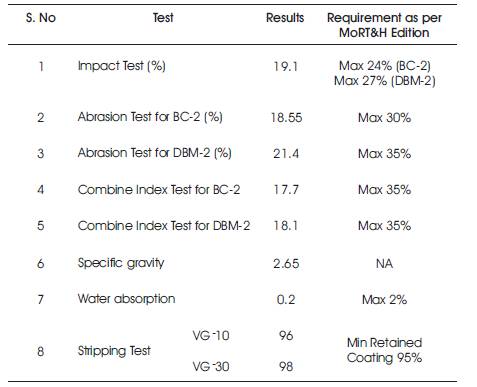

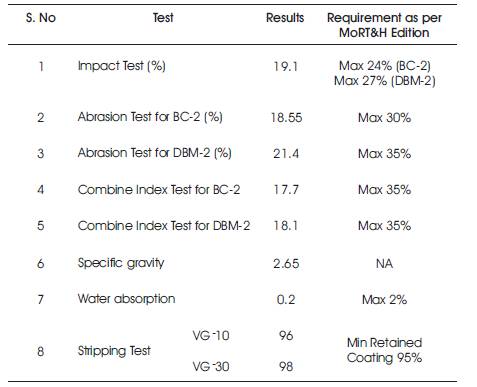

In the research, crushed stone aggregates were obtained from R.N.S. Stone Crusher Plant Jigani in Bangalore, which was used to prepare the BC-II & DBM-II mix specimens and physical properties of aggregate, fulfil the requirements as per MoRT&H 5th revision. The properties of aggregates are presented in Table 1.

Table 1. Physical Properties of Aggregates

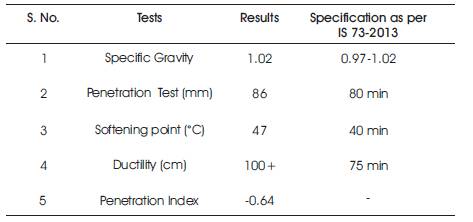

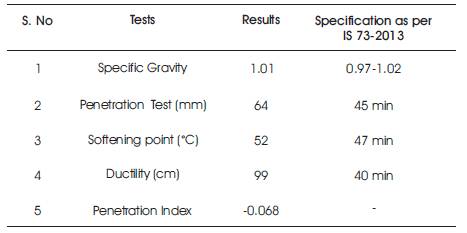

The VG-10 bitumen was obtained from Mathura refinery and VG-30 bitumen from Mangalore refinery. Both the bitumen was tested for their basic properties: penetration value, softening point, ductility and specific gravity, fulfil the requirements as per IS 73:2013. The results are presented in Tables 2 and 3.

Table 2. Physical Properties of VG-10 Neat Bitumen

Table 3. Physical Properties of VG-30 Neat Bitumen

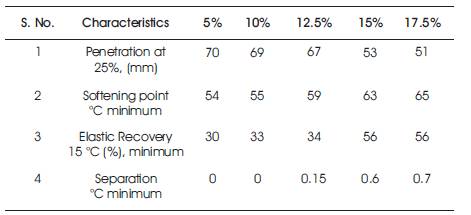

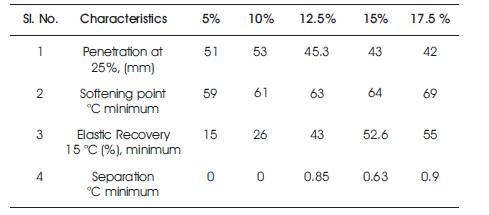

Bitumen (VG-10 & VG-30) is modified by using elastomeric pellets as modifiers at different modification levels (5%, 10%, 12.5%, 15%, and 17.5%). The elastomeric pellets used in the study for binder modification is shown in Figure 1. The wet process is carried out which is recommended to add the VIATOP plus FEP to bitumen, which has previously been heated up to approximately. 180 oC, portion-wise under stirring with a suitable stirrer within 5 minutes to the hot paving grade bitumen at 180 oC. The bitumen is mixed intensively with the stirrer at 200 rpm for a further 4 hours. The bitumen temperature of at least 180 oC for the specified time period must be complied with and checked. The optimum dosage of the elastomeric pellets is determined by comparing the modified bitumen results with the properties of IS 15462:2004 modified bitumen. The results are presented in Tables 4 and 5.

Figure 1. VIATOP Plus FEP Pellets

Table 4. VG 10 Bitumen was Modified with VIATOP Plus FEP Fibers

Table 5. VG 30 Bitumen was Modified with VIATOP Plus FEP Fibers

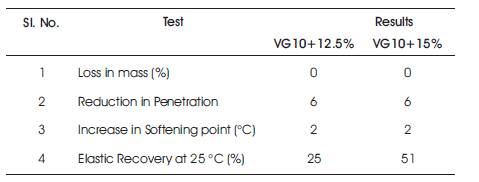

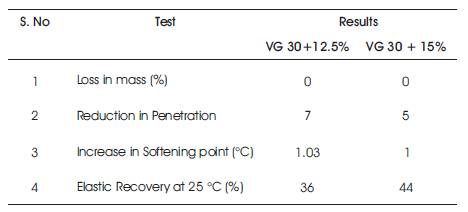

Thin Film Oven Test (TFOT) conducted as per ASTM-D 1754- 97 on different binders to evaluate the effect of ageing on Elastomeric Pellets modified binders developed in the present investigation. The results are presented in Tables 6 and 7.

Table 6. Thin Film Test Results of Modified Binder

Table 7. Thin Film Test Results of Modified Binder

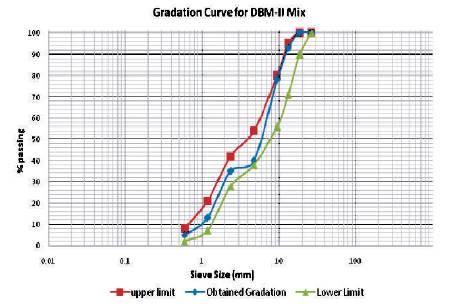

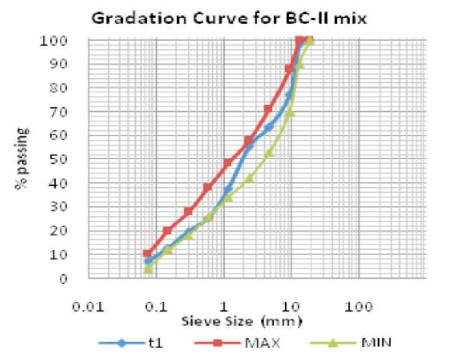

As per the specification of MoRT&H 5th revision the gradation of aggregate for DBM-II and BC-II mix is obtained by Rothfutch's method. The results are presented in Tables 8 and 9. The gradation curves are shown in Figures 2 and 3, respectively.

Figure 2. Gradation Curve of Aggregates For DBM-II Mix

Figure 3. Gradation Curve of Aggregates For BC-II Mix

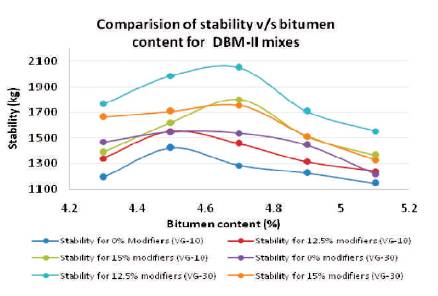

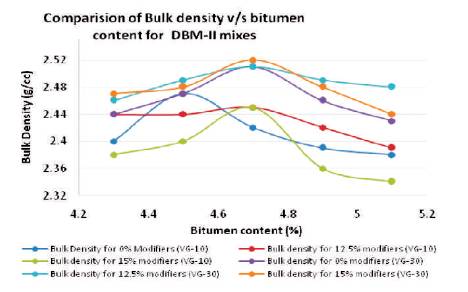

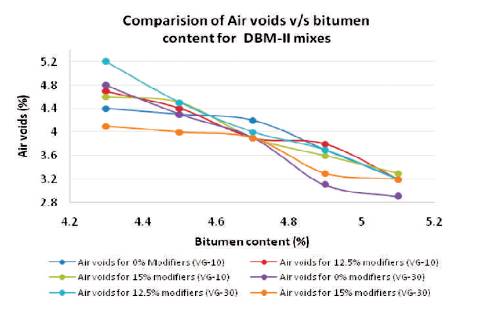

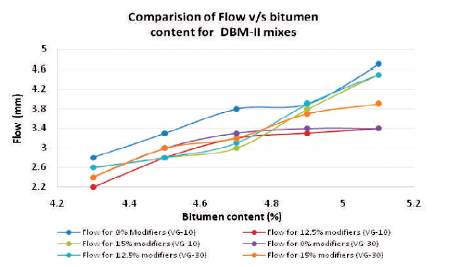

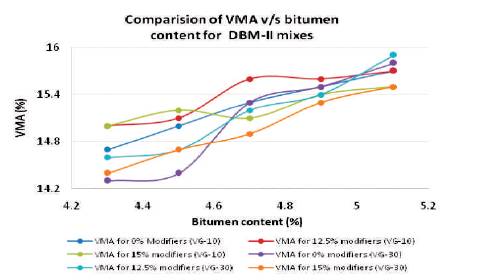

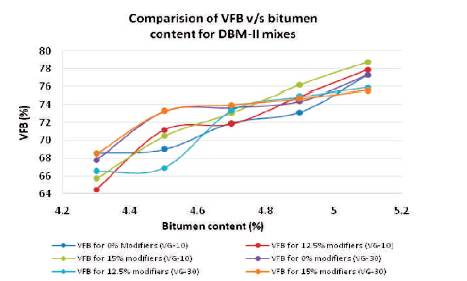

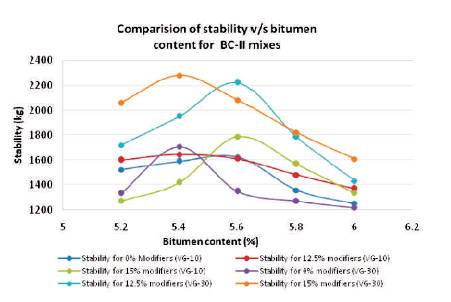

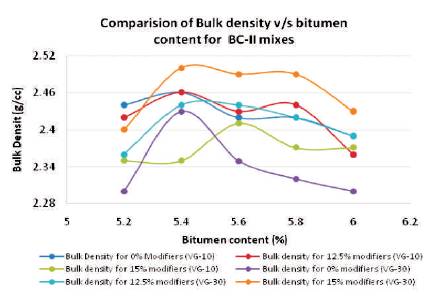

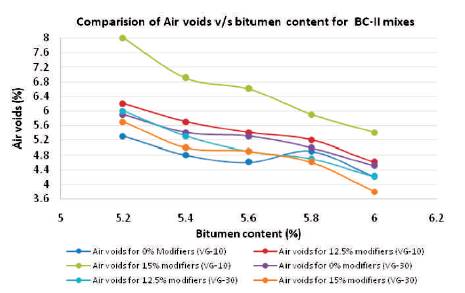

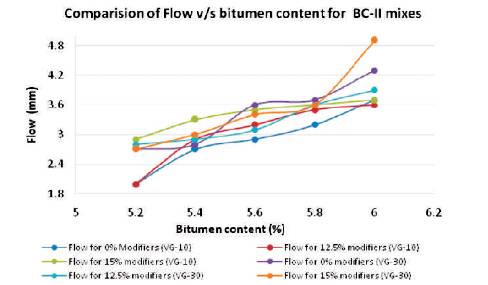

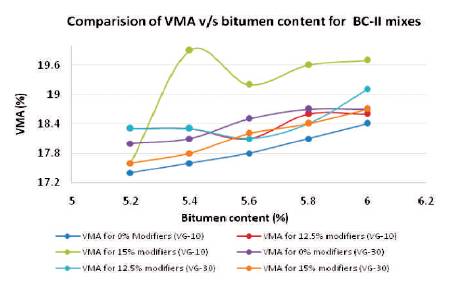

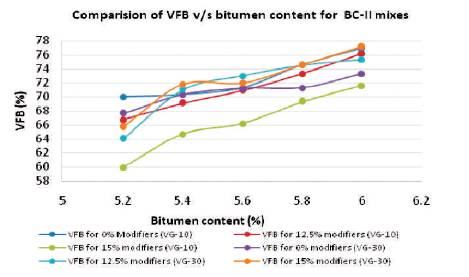

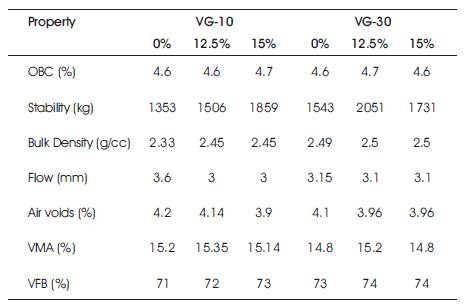

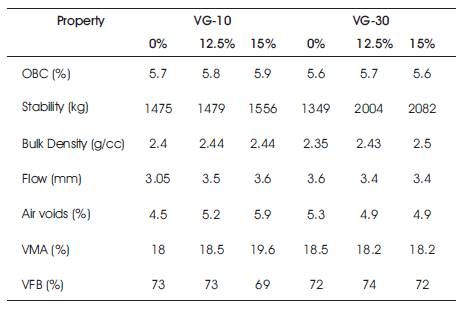

As per the specification of ASTM D-1559-96, Marshall Mix designs of DBM-II and BC-II with neat and modified binders are obtained. The results of marshall properties, such as stability, bulk density, air voids, flow, VMA and VFB, respectively for DBM-II and BC-II neat and modified bituminous mixes by varying the percentage of binder (VG- 10 & VG-30) are presented in graphs as shown in Figures 4- 15. The Marshall properties at OBC for DBM-II and BC-II neat and modified bituminous mixes satisfy the requirements as per MoRTH 5th revision and IRC: SP: 53-2010 and are presented in Tables 10 and 11.

Figure 4. Comparison of Stability v/s Bitumen Content for DBM-II Mixes

Figure 5. Comparison of Bulk Density v/s Bitumen Content for DBM-II Mixes

Figure 6. Comparison of Air Voids v/s Bitumen Content for DBM-II Mixes

Figure 7. Comparison of Flow v/s Bitumen Content for DBM-II Mixes

Figure 8. Comparison of VMA v/s Bitumen Content for DBM-II Mixes

Figure 9. Comparison of VFB v/s Bitumen Content for DBM-II Mixes

Figure 10. Comparison of Stability v/s Bitumen Content for BC-II Mixes

Figure 11. Comparison of Bulk Density v/s Bitumen Content for BC-II Mixes

Figure 12. Comparison of Air Voids v/s Bitumen Content for BC-II Mixes

Figure 13. Comparison of Flow v/s Bitumen Content for BC-II Mixes

Figure 14. Comparison of VMA v/s Bitumen Content for BC-II Mixes

Figure 15. Comparison of VFB v/s Bitumen Content for BC-II Mixes

Table 10. Summary of Marshall Properties at OBC for DBM-II using Pellets Dosage (with 12.5% & 15%) by Weight of Binder (VG-10 and VG-30)

Table 11. Summary of Marshall Properties at OBC for BC-II using Pellets Dosage (with 12.5% & 15%) by Weight of Binder (VG-10 and VG-30)

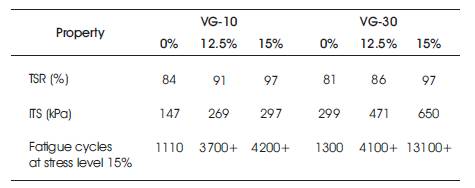

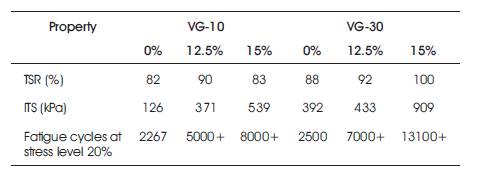

Performance tests, such as ITS, TSR, and repeated load fatigue test were conducted on the different mixes of DBMII and BC-II at OBC.

Tables 12 and 13 describe the results of the performance tests.

Table 12. Performance Properties at OBC for DBM-II using Pellets Dosage (with 12.5% & 15%) by Weight of Binder (VG-10 and VG-30)

Table 13. Performance Properties at OBC for BC-II using Pellets Dosage (with 12.5% & 15%) by Weight of Binder (VG-10 and VG-30)

The ageing properties on the modified binder indicates that the binder is very less affected by ageing which proves that the modified bituminous mixtures will yield higher shelf life.

The Marshall properties of VG-10 & VG-30 bituminous mix in unmodified and modified condition were tested. The results obtained for these mixes adhere to the specification of MoRT&H 5th revision.

The stability of the modified binder shows immense improvement over neat binder. This is due to the increase in stiffness of binder with the addition of modifier to the binder.

The flow value increases for the all the mixes as the bitumen content increase. The obtained flow value is in the range of 2-4 mm for the unmodified bitumen and 2.5-4 mm for modified bitumen as per the requirement of MoRT&H 5th revision.

The air voids decreases as the bitumen content increases for all the mixes. The air voids that vary from 3-5%. 4% air voids is taken as reference value for the calculation of OBC.

The results revealed that the modified binder mix has more tensile strength when compared with conventional binder mix irrespective of the dosage.

The mix should have Tensile Strength Ratio of minimum 80% to satisfy the moisture susceptibility criteria.

Flexure test is done in order to determine the number of repetitions of load the pavement can bear without failure. The study is conducted at 15% stress level.

The modified binder samples took more repetitions of load compared to the neat binder samples and did not fail.