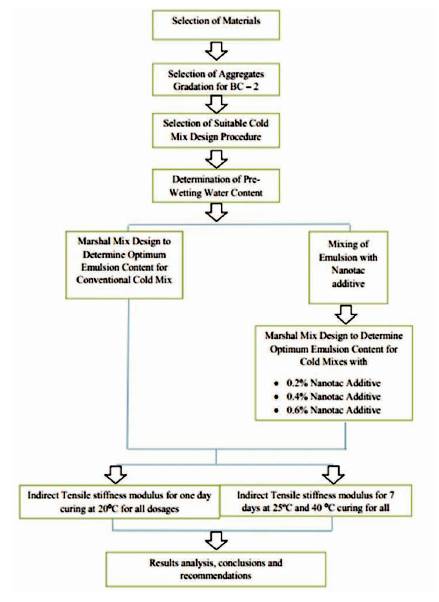

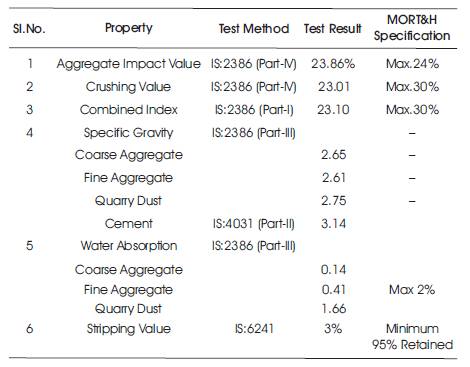

Figure 1. Methodology

Research and application of hot mix is being done on a large scale across the world. In a country like India, Cold mix technology is lagging behind in both research and application fields which is quite observable. In cold mix technology, there is no heating of the aggregates and bitumen which are the prime reason for the environmental pollution as in case of the hot mix technology. Besides environmental problem, cold mix technology is economical as the heating cost of aggregates and bitumen is saved.

The cold mix can be produced using the same hot mix plant. Different agencies and researchers have developed different mix design procedures for cold mixtures with a little change in each of them. The main objective of the present work is to improve the properties of cold mix. For preparation of the mixes, aggregate gradation has been taken as per MORTH specification for BC – 2, emulsion content has been varied regularly from 7% to 10% for dense graded mixes. In the present study, a conventional cold mix Bituminous Concrete (BC) is designed as per asphalt institute manual and is compared with the cold mix bituminous concrete which is prepared with different dosages of liquid additive. The additive is varied in three dosages of 0.2%, 0.4%, and 0.6% and it is added to the bitumen emulsion prior, to mix with the aggregates and mixed with a mechanical mixer for 10 min. For each dosage, optimum residual bitumen content is found out separately by varying emulsion content. From the Optimum Residual Bitumen Content (ORAC), the specimens were made to check the indirect tensile stiffness test at three different curing conditions of, one day curing at 25 oC, seven days curing at 25 oC and 40 oC to check the rate of gain in strength of cold mixes. From the results obtained from the indirect tensile strength after adding the additive, there was a notable increase in one day strength.

The total length of road network in India is over 48.5 lakh kilometers, which is second largest road network in the world. About 90 percent of the total roads are constructed as flexible pavements because of the ease and faster pace of construction over the rigid.

The flexible pavements are constructed from hot mix technology. This technology is most suitable for better pavement performance, but there have been some drawbacks in this technology like degradation of environment, high energy depletion, low output for mix production and increase in carbon footprint, low laying work in rains and cold weather, limited construction period in a year, health and safety hazard to labour. So, there is a need of a technology which has least harm to the environment and also with the ease of construction.

Hence, the cold mix technology comes into picture where there is less emission of gases and ease of mixing and laying in the field. In the cold mix technology, the aggregates are premixed with water as pre-wetting water, thereafter emulsion is added to it in a predetermined quantity then the mix is produced, and then it is transferred to the mould and acts compacted, all the processes are done at room temperatures. Cold mixes in the field can be produced by using hot mix plants and laid and compacted by similar techniques.

The cold mixes prepared from emulsions work similar to that of a hot mix technology and they are considered inferior because of their less satisfactory performance. The major problems associated with the cold mixes are they do not have early strength because of the pre-wetting water, and also require long time to cure to achieve full strength, and they have higher void contents compared to hot mixes. Cold mixes are pre-wetted with water to get a good coating, but the water inhibits proper compaction.

Cold Mixes are affected by a number of parameters, such as emulsion grade, curing time, void content, curing condition, and additives. Many researchers have tried different curing conditions and worked on many additives to enhance the mechanical properties of cold mix. Researchers have extensively worked out with the cement and found satisfactory results, but the initial gain of strength replacing the filler material with cement is still a problem.

The objectives of the present study are,

Chavez-Valencia et al. (2007) had done a study on cold mixes and they also indicated that when a solution of polyvinyl acetate emulsion (PVAC-E) was added to bitumen, the results show increment in the compressive strength of the cold mix. Hence, with the addition of the polyvinyl acetate emulsion, pavement could show improvement in resistance to the rutting and fatigue caused by the heavy traffic loads.

Cao and Luo (2015) carried out the study on the demulsification of the emulsion with the addition of the compound emulsifier. From the study it was seen that the formation mechanism of the compound emulsion was better than that of the single emulsifier. The paper also shows the different factors affecting the breaking mechanism of the bitumen emulsion.

S.F. Brown and Needham (2000) carried out an experiment on cement modified bitumen emulsion mixes, the experimental results show that Cement enhances the mechanical properties of bitumen mixes. The results of tests shows improvements in key mechanical properties of fatigue and resistance to permanent deformations with the addition of cement. The work was further carried out and shown that the ultimate stiffness achieved after curing and the rate of stiffness gain increased with increasing OPC content up to 4% level. In this study, the stiffening effects of hydrated lime and cement was shown by Dynamic Shear Rheometer test and the study also show that the filler had a very little influence. Crystalline structure was studied by Electron microscopy to study the fully cured mixtures with and without cement addition. The experimental study show that by addition of cement in the cold mix, there were improvements in key properties like hydration of cement, emulsion breakdown, and also after compaction there is an improvement in the viscosity of binder.

Fu et al. (2009) carried out a study on curing mechanism of foamed bituminous mixes. They have presented curing procedures that are appropriate for the use in project level mix design. The two curing conditions used in the study were specimens that was extruded from the mould immediately after compaction, and curing for 24 hours at 20 oC, and another set of samples were cured for 7 days at 40 oC and they are tested for dry indirect stiffness modulus, then soak the stiffness modulus after one day soaking. The study shows that the addition of the cement improved the curing mechanism of foamed asphalt. The presence of water plays an important role in developing the bond between bitumen and aggregate particles, the curing mechanism was related to interface water content.

In the present study, dense graded bituminous concrete grade – 2 cold mixes were prepared to check the physical characteristics. Selection of aggregate gradation is as per MORT&H (2013) specification for BC – 2 and selection of emulsion is as per IS: 8887 for the dense graded mixes. The selection of the mix design procedure is as per Asphalt Institute manual series – 14 (1997) and specifications as per the MORT&H (2013). The mixes were added with cement to check the improvement in the mix properties and NanoTac (A product of M/s Zydex) was added in the dosage of 0.2, 0.4, and 0.6 to check the suitability of the product in the reduction of emulsion content, improvements in the mix properties and reduction in the curing time. The indirect tensile stiffness was tested at two curing conditions. In the first type, the specimens were extruded from the mould immediately after compaction and cured for 24 hours at 20 oC and another set of samples were cured for 7 days at 25 oC and 40 oC and tested for dry indirect stiffness modulus and soaked indirect stiffness modulus after one day soaking at 25 oC. The overall methodology is represented in Figure 1.

Figure 1. Methodology

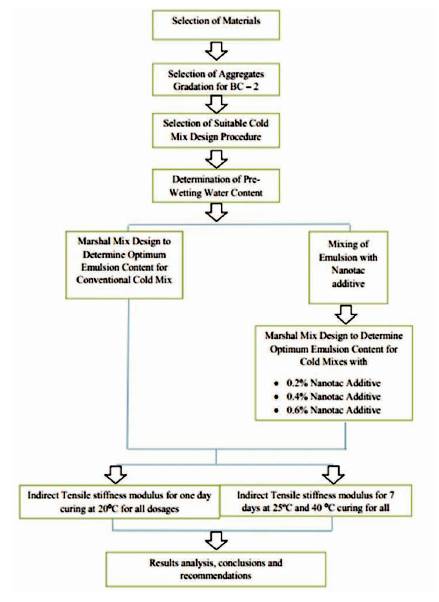

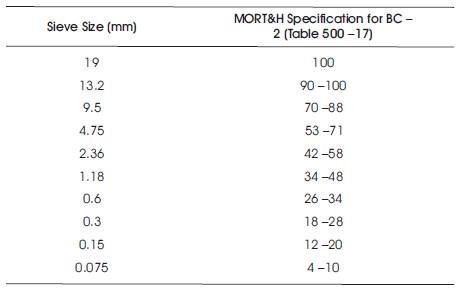

Aggregates used in the present study were collected from Bangalore region. The aggregates were tested in accordance with the specified test methods for testing physical properties. For preparation of cold mixes, the aggregate gradation was taken as per MORT&H (Table: 500 – 17) for BC – 2. The design gradation for the mix is given in Table 1.

Table 1. Adopted Gradation for the Cold Mix BC–2 [8]

In the present study, the filler used was cement of OPC grade – 43. Specific gravity of cement was found out be 3.14.

The Binder used for the preparation of mix was slow setting – 2 of cationic type. The emulsion was collected from Tikitar Company. The residual bitumen content of the emulsion was found out to be 62%. The other tests for the emulsion was carried out as per IS: 8887 and are tabulated in Table 2.

Table 2. Physical Properties of Aggregates

NanoTac is a Nano chemical used for cationic bitumen emulsions introduced by M/s Zydex industries. It forms alkyl siloxane (Si-O-Si) bonds to create bitumen loving aggregate surface. The use of NanoTac is mainly in the tack coats to improve the bond strength at lower bitumen contents, setting time and eliminates debonding due to moisture susceptibility.

The main objective of the Cold mix design is to produce a bituminous mix by proper proportioning of various components to achieve –

JMF for the blend is,

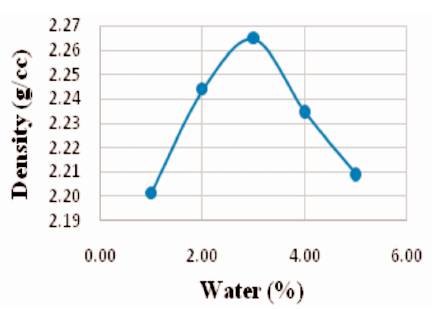

Figure 2. Relation between Water Content and Density

Table 3. Determination of Pre-wetting Water Content

Marshall Properties of cold mixes for BC – II for following variations were determined in the laboratory and results were analyzed.

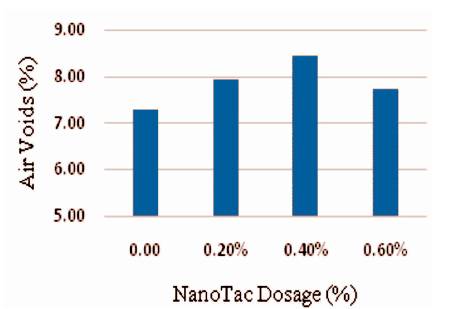

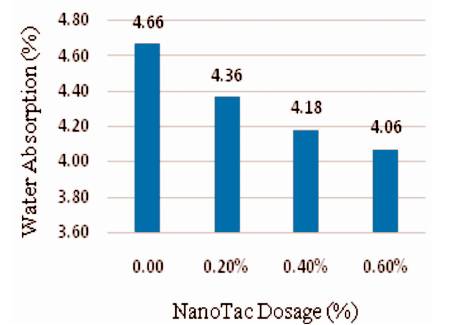

The above mixes were in agreement with specifications from the MORT&H 5th revision as given in Tables 6, 8, 10, and 12, except the air voids which were above the limits for all the mixes.

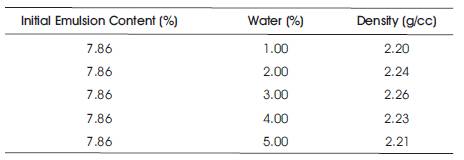

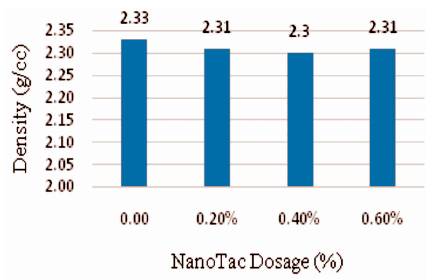

Figure 3. Comparison of Stability at different NanoTac Dosages

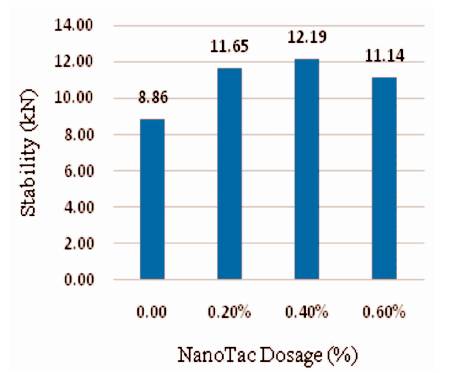

Figure 4. Comparison of Density at different NanoTac Dosages

Figure 5. Comparison of Air Voids at different NanoTac Dosages

Figure 6. Comparison of Water Absorption at different NanoTac Dosages

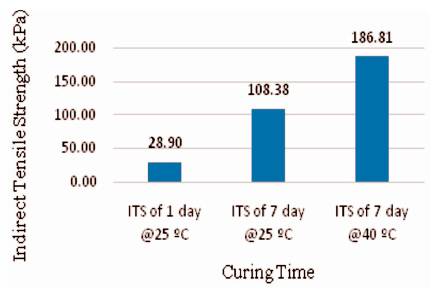

Figure 7. Relationship between Indirect Tensile Strength and different Curing Conditions for Conventional Cold Mix

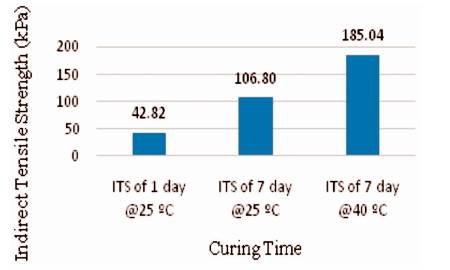

Figure 8. Relationship between Indirect Tensile Strength and different Curing Conditions for 0.2% of NanoTac Additive

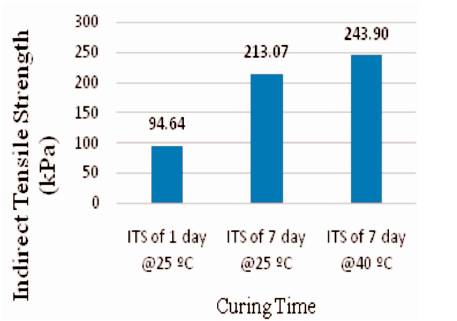

Figure 9. Relationship between Indirect Tensile Strength and different Curing Conditions for 0.4% of NanoTac Additive

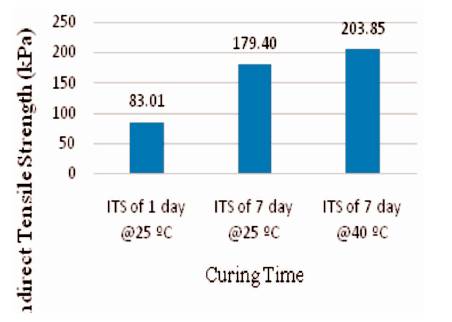

Figure 10. Relationship between Indirect Tensile Strength and different Curing Conditions for 0.6% of NanoTac Additive

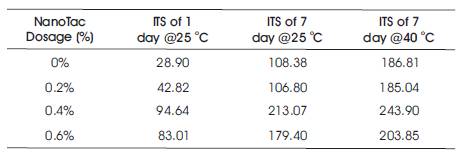

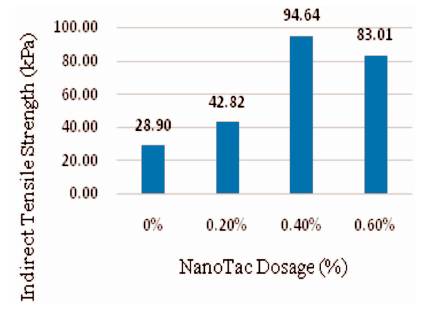

Table 4. Results of Indirect Tensile Strength Test at Different Curing Temperatures

The experimental results reported in this paper have focused on developing an improved understanding of the role of Nano chemical in enhancing the mechanical properties of bitumen emulsion mixtures for structural layers in roads.

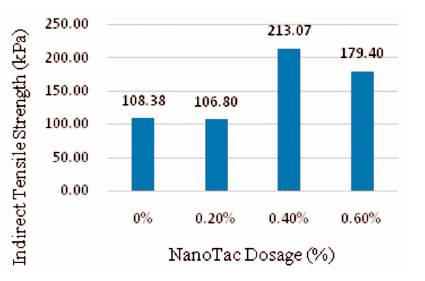

Figure 11. Graph Showing Relationship between Indirect Tensile Strength and different NanoTac Additive for 1 Day Curing at 25 oC

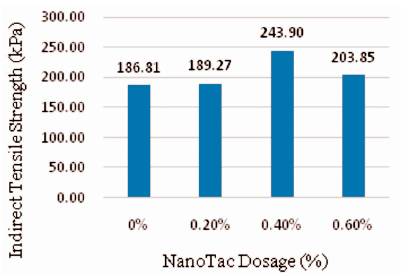

Figure 12. Relationship between Indirect Tensile Strength and different dosage of NanoTac Additive cured for 7 Days at 25 oC

Figure 13. Relationship between Indirect Tensile Strength and different dosage of NanoTac Additive cured for 7 Days at 40 oC