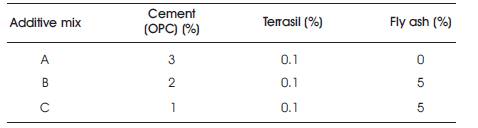

Table 1. Additive Mix

Soil stabilization is a process which permanently changes the physical and chemical properties of soil. Soil stabilization is used to improve the bearing capacity of poor sub grade or sub-base soil to make it suitable to support structures like pavements, railways, foundations etc. Addition of nano particles to natural soil materials are often used to affect soil atomic structure thereby changing its permeability, strength and resistance properties. The addition of Cement (OPC) and terrasil is known to improve the strength of soils. This project primarily deals with the investigation of the strength characteristics of block cotton soil when mixed with a range of proportions of additives such as terrasil, fly ash and cement using CBR and UCC tests. The natural soil was tested according to Indian standards. The soil is classified as CH. Addition of cement and terrasil were based on the guidelines given by the ZYDEX Company. The test results show that the CBR and UCC values are similar for the proportions Cement (OPC) (3%) + terrasil (0.1%) and cement (OPC) (2%) + fly ash (5%) + terrasil (0.1%).

Soil is an important component in any type of civil engineering construction. Developing countries like India need good infrastructure like roadways, railways, buildings, power supplies etc, for their development. India has expansive soils in many parts of the country and it becomes challenging to construct stable structures in such conditions. Thus it becomes imperative to improve the soil properties to make it suitable for accepting structures. One of the ways to improve the soil strength and permeability related properties are to add different chemicals or nano material in different proportion to the soil. Depending upon the sogil type that need to be stabilized and different types of additives are suggested. As the addition of additives to the soil increases the cost of the structures, efforts are constantly made to come up with additives or combination of additives which can improve the soil properties at a lesser cost. Many researchers have worked and continue to work in this field to develop different methods of stabilization techniques, which are economical and practical. By using 0.041% terrasil as stabilizer to CL soil, engineering properties of soil improved and 25% of pavement thickness reduced [1]. Adding 0.02% of zycobond to 0.04% terrasil, and using these combinations of stabilizers to CL soil, the CBR value increased from 6.64% to 12.15% [2]. Addition of 1% PPC to above combination of stabilizers (0.04% terrasil+0.02% zycobond) to CL soil, the CBR value increased from 6.64% to 21.81% [3]. Using 0.07% terrasil + 4% cement as stabilizers to the soil, CBR value increased 8 times, and UCC value improved 613% [4]. The percentage of addition of rough (coarse), fine fly ash improves soil properties and shows clear moisture density relationship. It was found that the peak strength reached by fine fly ash mixture was 25% more compared to rough fly ash [5]. Using Cement individually as a stabilizer to soil, improves soil properties. Adding 2% cement to soil, increases CBR value from 6.67 to 21.82% [6]. Using cement and terrasil as stabilizer for sub grade soil stabilization, affects the Granular sub-base (GSB), Dense Bituminous Macadam (DBM) layers of pavements, which shows that pavement thickness gets reduced [12] . Terrasil was found to be better at reducing permeability than geotextile with a 47.1% in cost reduction [13] .

The main objective of this research was to study the improvement of engineering and index properties of soil when stabilizers (cement, terrasil, fly ash) are added to black cotton soil. Different mix proportions of stabilizers are used. Standard laboratory experiments were conducted to evaluate different mix proportion, thereby helping in choosing the combination and proportion of additives which gives the same or better strength at a lesser cost.

Soil brought from mahabub nagar (district), Jamistapur village.

43 grade Ordinary Portland Cement (OPC) with specific gravity 3, complying with IS: 8112-1989.

It is a Nanotechnology chemical, 100% organic silane. It forms Si-O-Si (glued or joined Together). Nano silicones surfaces in soil by converting water loving Silanol groups to water, by Alkyl Siloxane groups. Terrasil is reported to increase frictional value of soil and decrease soil permeability. It was obtained from ZYDEX INDUSTRY.

It is a by product of thermal power plant, obtained from KBR Transport Company, KPHB, Hyderabad. Specific gravity of fly ash was 2.2.

Soil Specific Gravity (G) was determined by using pycnometer as per guide lines of IS 2720-part 3. The average value of three samples has been taken as the specific gravity of soil.

Grain size distribution was done by using wet sieve analysis and hydrometer analysis as per guide lines of IS2720 part 4.

Liquid limit, plastic limit (Atterberg limits) were determined by using guide lines of IS2720 part5

As per IS2720 part 7 compaction test (standard proctor test) was conducted to find out Maximum dry density and Optimum moisture content of soil.

California Bearing Ratio (CBR) test were conducted to determine the mechanical strength of soil.CBR test were conducted as per guide lines of IS 2720 part 16. The tests were performed on soil with and without stabilizers.

UCC (Unconfined Compressive) test was conducted to determine unconfined compressive strength of soil. UCC tests were conducted as per guide lines of IS2720 part 10. UCC tests were also performed on soil with and without stabilizers.

The following three sets of additives were used in the experiment (Table 1).

Table 1. Additive Mix

The experimental results are as given below in the Tables.

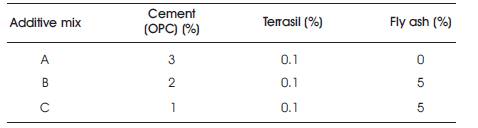

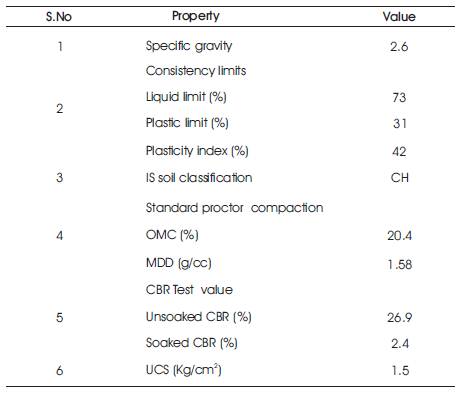

Table 2 gives the properties of black cotton soil before stabilization.

Table 2. Properties of Black Cotton Soil

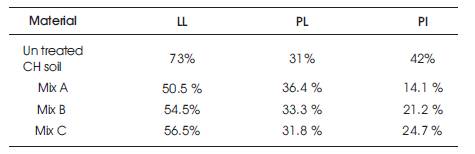

Table 3 gives Atterberg limits of Black cotton soil before and after stabilization.

Table 3. Soil Atterberg limits with and without additives

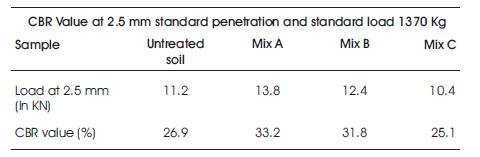

Table 4 gives Unsoaked CBR values at 2.5 mm penetration before and after stabilization.

Table 4. UNSOAKED CBR Test result at 2.5mm penetration

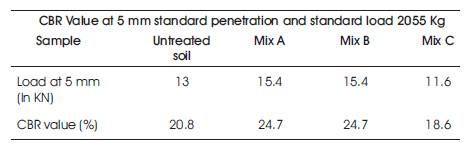

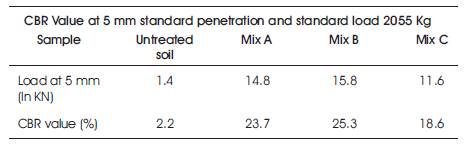

Table 5 gives Unsoaked CBR values at 5 mm penetration before and after stabilization.

Table 5. UNSOAKED CBR Test result at 5mm penetration

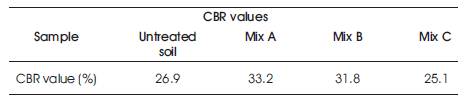

Table 6 gives Final Unsoaked CBR values of before and after stabilization.

Table 6. UNSOAKED CBR Test result

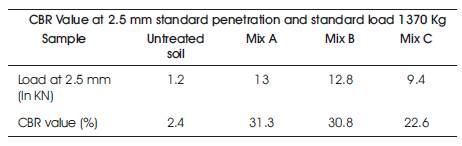

Table 7 gives Soaked CBR values at 2.5 mm penetration before and after stabilization.

Table 7. SOAKED CBR Test result at 2.5 mm penetration

Tables 8 gives Soaked CBR values at 5 mm penetration before and after stabilization.

Table 8. SOAKED CBR Test result at 5 mm penetration

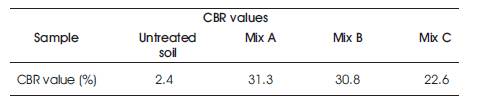

Table 9 gives Final Soaked CBR values before and after stabilization.

Table 9. SOAKED CBR Test result

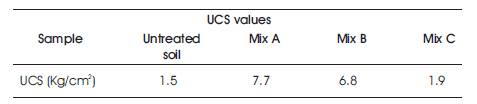

Table 10 gives UCC strength values before and after stabilization.

Table 10. UCS values of soil with and without stabilizers

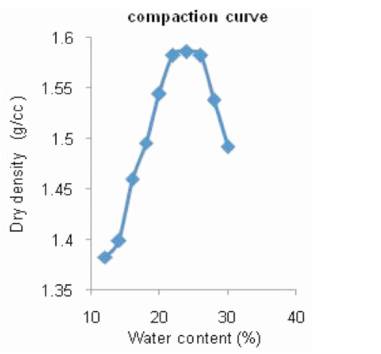

Figure 1 shows Compaction curve of natural soil.

Figure 1. Water content v/s Dry density graph

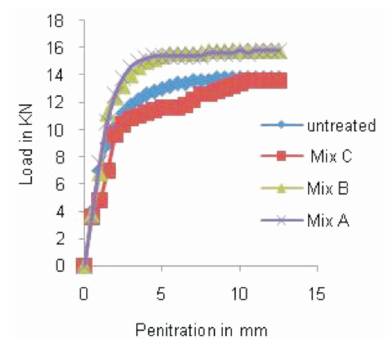

Figure 2 shows Unsoaked CBR values Comparison graph before and after stabilization.

Figure 2. Load v/s Penetration graph

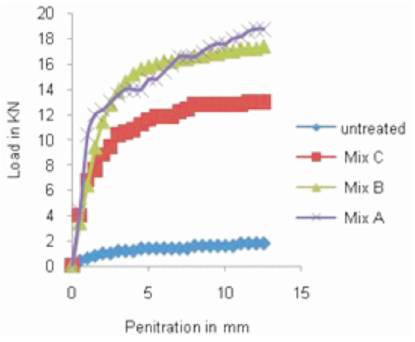

Figure 3 shows Soaked CBR values Comparison graph before and after stabilization.

Figure 3. Load v/s Penetration graph

Dry density relation is found using standard proctor test for untreated soil. From the graph OMC is 20.4% and MDD 1.58 g/cc.

The MDD and OMC values were used to calculate the optimum dosage of terrasil as per zydex protocol.

Using additives LL decreased and PL increased. Mix C Liquid limit value decreased more compared to Mix A and Mix C. Plastic limit increased more for Mix A compared to Mix B and Mix C. Similarly Plasticity Index value decreased more for Mix A compared to Mix B and Mix C.

The Unsoaked CBR value at 2.5mm penetration was similar for Mix A and Mix B. Unsoaked CBR value at 2.5mm penetration was similar for Mix C and untreated soil.

The Unsoaked CBR value at 5mm penetration was same for Mix A and Mix B. Unsoaked CBR value at 5mm penetration of Mix C is less than untreated soil CBR value.

The Unsoaked CBR value at 2.5 mm penetration is more than the 5mm penetration. So 2.5 mm penetration values were taken as Unsoaked CBR values of respective tests.

Variation in Unsoaked CBR values for different mix proportions (Mix A, Mix B, Mix C and Untreated soil) are shown in below graph

The Soaked CBR value at 2.5 mm penetration was similar for Mix A and Mix B. Soaked CBR value at 2.5 mm penetration for Mix C was found to be less than Mix A and Mix B but greater than untreated soil.

The Soaked CBR value at 5 mm penetration was similar for Mix A and Mix B. Soaked CBR value at 2.5 mm penetration for Mix C was found to be less than Mix A and Mix B but greater than untreated soil.

The soaked CBR value at 2.5 mm penetration is more than the 5mm penetration. So 2.5mm penetration values were taken as soaked CBR values of respective tests.

Variation in Soaked CBR values for different mix proportions (Mix A, Mix B, Mix C and Untreated soil) are shown in below graph.

UCS values were greater and similar for Mix A and Mix B .Mix C, UCS value was slightly greater than untreated soil.

When significant reactions take place, the soil stabilization occurs. Those reactions are hydration, carbonation, ion exchange, pozzolona action etc. These reactions occur when cement, fly ash, and lime are mixed with soil in the presence of water.

Due to hydration process free lime occurs, and ion exchange predeceases positively charged calcium ions on surface of clay particles. This action decreases the plasticity of soil either by decreasing LL and increasing PL or decreasing PL and increasing LL, depending upon additive.

After these reactions, pozzolona action takes place. In this process alumina and silica present in clayey soil react with free lime in the presence of water, and it forms cementitious gel. This cementitious action gives strength to soil.

Here we added fly ash (class F), cement (OPC) and terrasil to soil. Cement, Fly ash formed cementitious properties and Terrasil formed Si-O-Si (Siloxane bond), water proofing surface. Due to this action strength increased, and soil particles bonded closely by filling pore spaces.

Due to all the above reactions and their results, the plasticity index of soil decreased by decreasing LL and increasing PL. CBR and UCC strength values increased.

Based on experimental results and discussions it can be concluded that:

In conclusion, Additive Mix A and additive Mix B were good in strength and similar, but economic point of additive Mix B is best, because in additive Mix B we are decreasing 1% cement compared to additive Mix B and using 5% fly ash. Fly ash is a by product cheaper than cement. The stabilization of soil soil-cement-fly ash-terrasil is very useful as sub grade or sub base material due to increased CBR value.

Our Sincere thanks to Dr.P.N. Singh, Professor of Civil Engineering Department, VNR Vignana Jyothi Institute of Engineering and Technology and Prashanth M.G. for their support and encouragement. Also we would like to thank Head of Department of Civil Engineering, VNR VJIET, and Geotechnical faculty for their valuable support.