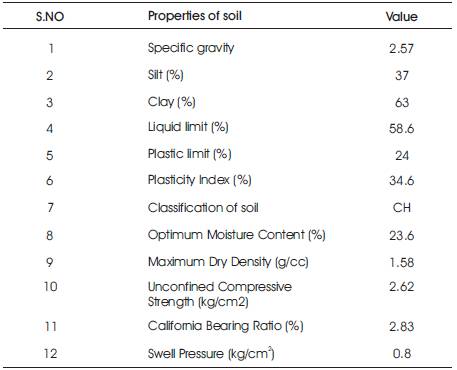

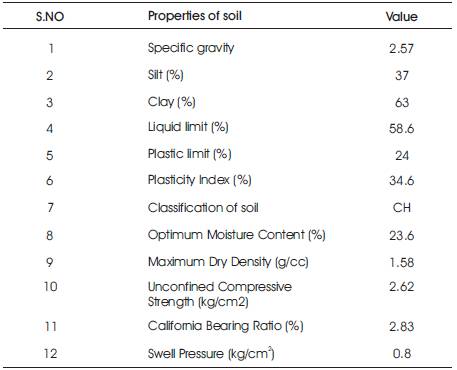

Table 1. Properties of BC Soil Used

This paper presents the heave behaviour of expansive clay reinforced with Synthetic-fibres. Expansive clay is common to many parts of central and southern India, as well as elsewhere in the world. It has caused significant structural damage to an alarming number of buildings, particularly light weight structures and pavements. The pressures generated by swelling of clay can be devastating to the foundation if not managed properly. The expansive potential of soil varies dramatically from one season to another at any site due to the change in moisture content, which is the driving force in swell/shrink cycle. In this study, research has been carried out to study the effect of Synthetic-Fibers (Polypropylene and Polyester fibers) in curbing the swelling tendency of expansive clays. The behavioral changes in the soil samples were determined using One Dimensional swell-consolidation tests. In addition, the strength characteristics of the soil were also determined using Unconfined Compressive Strength (UCS) tests and California Bearing Ratio (CBR) tests for varied range of percentages of Synthetic-Fibers induced (i.e., from 0.2% to 0.8%). The swell-consolidation and strength parameters of soil are accomplished for varied Synthetic-Fibers and it is observed that the swell pressure has decreased by addition of fibers where as the voids ratio has increased on addition of Synthetic- fibers. The UCS and CBR of the soil have increased by increasing the proportion of fibres.

Expansive clay is a type of clay formed of light weight aggregate with a rounded structure, with inside porous and outside harder layer. Expansive clayey soils, commonly known as Black Cotton soils in India occupy about one fifth of the entire land area of our country [7]. It is prone to large volume changes directly related to variations in moisture content. In wet season, the clay swells and in dry season, it can shrink and form cracks. Also these foundations may undergo swelling upon wetting which is due to seasonal moisture variations [2]. These volume changes result in deep cracks in dry season, resulting in cracks in foundation and structure, leading to heavy losses to national economies. The annual cost of damage caused due to expansive clays are estimated at £150 million in the UK, $1000 million in the USA and many billions of pounds worldwide [1].

In practice, expansive clays undergo volume change when they come into contact with water due to the presence of clay minerals such as illite, kaolinite and montmorrillonite. Therefore these clayey particles tend to absorb more and more water and expand in volume due to swelling phenomenon and if the swelled soil strata loose the absorbed and adsorbed water and gets dry, the shrinkage phenomenon comes into picture which results in extensive cracking [9]. Examples are longitudinal and transverse cracks in pavements, cracks in foundations and brick work of buildings, in canal lining and in floor slab of structures like reservoirs due to drying shrinkage of expansive soils in summer [8].

These volume change behaviors can be shown in terms of swell-shrink capacity of clays. The proportion of these clay minerals may directly affect the behavior of expansive clays. In order to study the volume change behavior of expansive clays, many researchers have performed different swell-shrink tests and swell consolidation tests. This drastic change in volume of expansive soils results in poor quality of construction works or post-construction as they have low shear strength and high compressibility [4] . Due to the swell-shrink tendency of expansive clays, heave and cracking in foundations and structures have been prominently observed. Avoiding these soils may not be possible practically because around 3% of the world's land area and 20% of India's land area is covered with expansive soils [6].

In-order to gainfully utilize these soils for construction purposes, they are being stabilized using different additives such as fly-ash, cement, lime, rice husk ash etc., and a combination of these, and also some ground improvement techniques such as stone columns, sand columns, geo-synthetic reinforcements have been used. Research has been carried out regarding how these stabilization techniques affect the strength, swelling and shrinkage behavior of expansive soils. Soil which is made up of discrete particles is not bonded together properly [3]. In order to offer proper bonding, researchers in recent years have used discrete and randomly distributed fibers in different proportions to these soils in-order to enhance their strength and improve their volume change behavior [5] .

The Geo-Fibre reinforcement, because of its better economy offers an improved alternative to chemical stabilization. This study focuses on the performance of expansive soils reinforced with Geo-Fibers such as polypropylene and polyester fibers. The aim of this study is to understand and analyze the comparative behavior of expansive soil when reinforced with two different synthetic fibres namely Polypropylene (PP) and Polyester and to draw relevant conclusions to enable improvement in the behaviour of expansive soils.

It is also proposed to examine how the different parameters such as Maximum Dry Density (MDD), Optimum Moisture Content (OMC), Swell Pressure, Voids ratio and Compression Index vary due to the addition of varied proportions of Polypropylene and Polyester Fibers to Black Cotton (BC) soil by conducting relevant tests.

The soil sample for this research is collected from the agricultural land near Medchal Highway, RR District of Telangana state, India. Table 1 represents the properties of BC soil.

Table 1. Properties of BC Soil Used

Recron 3S polypropylene and polyester fibers have been used as reinforcing materials for the soil selected. The fibre length is 12mm. Recron 3s fibre is specially used as a reinforcement additive which toughens and strengthens the soil by resisting swelling and shrinkage cracks. The polypropylene and Polyester fibres have very high tensile strength. It also offers good bonding with the mix due to its dimensional stability. Figures 1 (a) and 1 (b) show polypropylene and polyester fibers.

Figure 1(a). Polypropylene Fibers of Length 12mm

Figure 1(b). Polyester Fibers of Length 12mm

The fiber percentages used are 0.2%, 0.4%, 0.6% and 0.8% by weight of the soil mass. Laboratory tests such as Standard Proctor's test, One Dimensional Swell- Consolidation test, Unconfined Compressive Strength test and California Bearing Ratio test have been conducted for different soil-fibre mixes in order to assess the behavior of expansive clays in both the cases.

The objective of this test is to find out the OMC and MDD of the soil sample and for the soil reinforced with polypropylene and polyester fibres mixed in different proportions.

The soil samples were prepared according to Indian Standards [10]. The dia. of compaction mould is of 10cm and height is 12.5cm. The compaction was done in three layers with 25 blows per each layer using 2.6kg hammer under a height of fall of 31cm. The soil sample was mixed with trial moisture contents and for different fibre percentages.

The soil samples prepared as above by varying the proportions of the two types of Fibres are tested for different moisture contents, and the moisture content at which maximum dry density has been attained is considered as the Optimum Moisture Content.

The objective of this test is to determine the swell consolidation parameters such as swell pressure, voids ratio and compression index for different pressure increments.

One dimensional swell consolidation tests have been conducted for varying fiber additions. The samples are prepared as per “IS: 2720-41 (1977) - Measurement of swelling pressure of soil” [11] and “IS 2720-15(1965) - Determination of consolidation properties” [12] .

The samples are prepared using Proctor compaction mould in three layers at the rate of 25 blows for each layer with Optimum Moisture Content obtained according to the percentages of fibre additions. Then the oedometer rings are inserted into the compacted soil and extracted with soil. The oedometer ring is of 2cm thick and of 6cm dia. The specimens of fibre reinforced soil are prepared with the addition of 0.2, 0.4, 0.6 and 0.8% of polypropylene and polyester fibres. Figure 2 represents the sample placement in Oedometer ring (or) Consolidation ring.

Figure 2. Sample Placement in Oedometer Apparatus

These specimens are tested using oedometer equipment and the variations in swelling pressures and consolidation parameters such as swell pressure, voids ratio and compression index for varied fibre proportions of black cotton soil are studied and analyzed. The pressure increments used were 0.25, 0.5, 1 and 2kg/cm2 for consolidation test. The swell pressure value can be obtained from load versus voids ratio curve. The load corresponding to initial voids ratio denotes Swell pressure of the specimen. The calculations have been done using Change in voids ratio method, and the void ratio, swell pressure and compression index have been analyzed for different proportions of Polypropylene and Polyester fibres. The oven dried Oedometer ring specimens are displayed in Figure 3.

Figure 3. Oven Dried Oedometer Ring Specimens

The objective of this test is to determine the unconfined compressive strength of the soil reinforced with varying proportions of Polypropylene and Polyester fibres.

The unconfined compressive strength test is used as a speedy and cost effective method for obtaining the approximate compressive strength of a cohesive soil. The soil passing through 425μ sieve is mixed with varying proportion of polypropylene and polyester i.e. (0.2%, 0.4%, 0.6% and 0.8%) compacted for their Optimum Moisture Contents. Samples were shaped in a mould with a length of 76mm and an inner diameter of 38mm.

The unconfined compressive strength test is conducted in accordance with IS: 2720 part X – 1991 [13] and the specimen is placed on bottom plate of loading device and is adjusted so as to make contact with the specimen. The force is applied in order to produce an axial strain rate of 0.5 to 2 mm/min to the specimen until shear failure occurs, or until a vertical deformation of 20% is reached. Displacement is measured by strain gauge. Finally unconfined compressive strength is calculated based on failure load and corrected area. Figure 4 shows the UCS specimen under testing.

Figure 4. CBR Specimen Under Testing

The objective of this test is to determine the load required to produce a specified penetration for soil reinforced with different proportions of polypropylene and polyester fibres.

California Bearing Ratio tests have been conducted using a cylindrical mould on specimens compacted in five layers at their OMC which has been determined by Standard Proctor's Test. The CBR test samples have been prepared with different proportions of polypropylene and polyester fibers i.e. (0.2%, 0.4%, 0.6% & 0.8%) in accordance with IS: 2720 part XVI – 1987 [14].

The CBR test apparatus with a loading frame of capacity five tones provided with proving ring and a dial gauge reading to 0.01mm is used. The soil sample is placed on bottom plate of the loading device and the base plate. Annular surcharge weight equal to the intensity of the base material and of the pavement is placed to prevent upheaval of soil. Load is applied at a strain rate of 1.25 mm/min. Penetration is measured by strain gauge. Load is recorded at different penetrations up to 12.5mm. The CBR value is expressed as a proportion of the actual load causing a penetration of 2.5 mm. The greatest value of load calculated for penetrations at 2.5 mm has been recorded as the CBR. Figure 5 shows the Expansive clay specimen tested under CBR apparatus.

Figure 5. CBR Specimen Under Testing

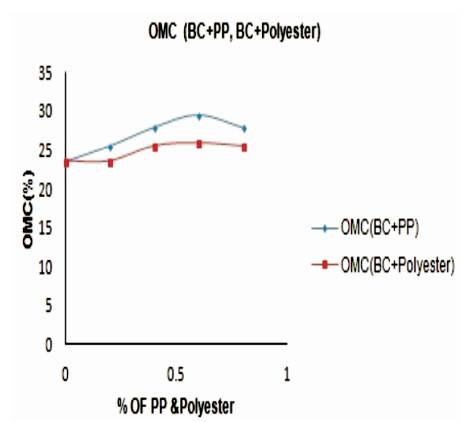

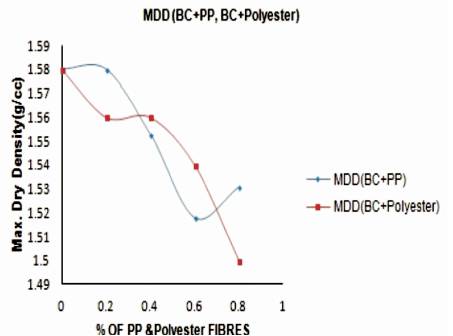

The compaction characteristics of black cotton soil reinforced with fibers have shown slight increase in their Optimum Moisture Contents (OMC) and decrease in Maximum Dry Densities (MDD). Increasing the fibre content has shown increase in their OMC and decrease in MDD for both polypropylene and polyester fibers. The OMC obtained for polypropylene fibers is significantly high when compared to the OMC obtained for polyester reinforced soil.

The significant variations of OMC and MDD for polypropylene and polyester reinforced soil are shown in Figure 6 and Figure 7.

Figure 6. Variation In OMC of Soil Reinforced with Polypropylene Fibres and Polyester Fibres

Figure 7. Variation of MDD for Polypropylene and for Polyester Fibre Reinforced Soil

The results indicate that due to the addition of fibers, the weight of the soil is replaced by fibers to some extent, which in turn reduced the MDD of fiber reinforced soil.

Compared to Polyester fiber additions, polypropylene fibre reinforced soil has shown significant variation in OMC of BC soil.

One dimensional swell consolidation tests have been conducted for black cotton soil reinforced with varying proportions of fibre to enhance the behaviour of the soil, and the tests results have shown a significant improvement in swell pressure, voids ratio and compression index.

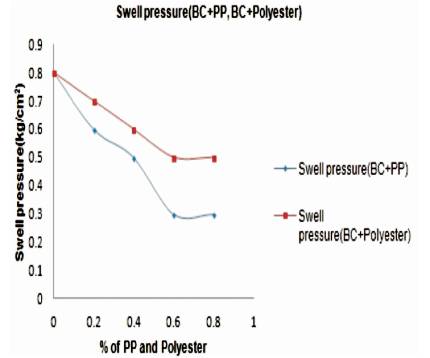

The test results have shown a reduction in swell pressure due to increase in fibre proportions

The comparative graphs for varied proportions of Polypropylene and Polyester fibre reinforced soil have been shown in Figure 8.

Figure 8. Swell pressure Variations for BC Soil Reinforced with Polypropylene and With Polyester Fibers

The Swell pressures have been reduced from 0.8 kg/cm to 2 0.3 kg/cm on addition of 0.8% Polypropylene fibers and to 2 0.5 kg/cm on addition of 0.8% Polyester fibers.

This indicates that, due to the addition of fibers there is significant reduction in swell pressure of expansive clay. As the fibers are added to the expansive soil, the inbuilt capacity of fibers to bind soil particles together helps the expansive soil to reduce its swelling tendency and there by swell pressure of the fiber reinforced soil.

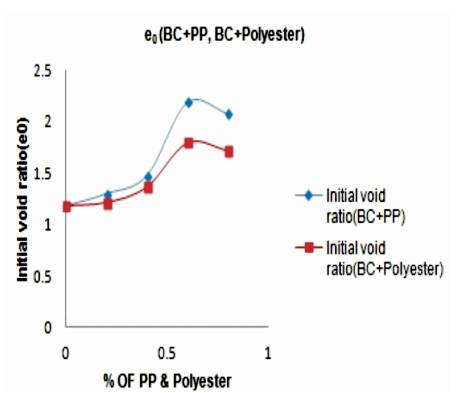

The comparative change in Initial voids ratio (e0) for PP and Polyester fibre reinforced soils have been demonstrated in Figure 9.

Figure 9. Alteration of Initial void ratio (e0) for BC soil reinforced with PP and Polyester fibers

From the test results obtained, the initial void ratio of BC soil reinforced with Polypropylene and polyester fiber proportions indicate that, the Initial void ratio has been increasing with increase in the proportions of Synthetic fibres up to 0.6% and for 0.8% addition; the initial void ratio has been reduced for both Polypropylene and Polyester fibers.

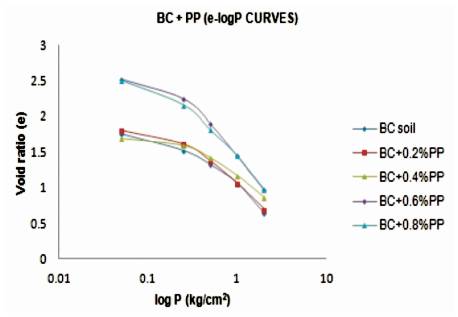

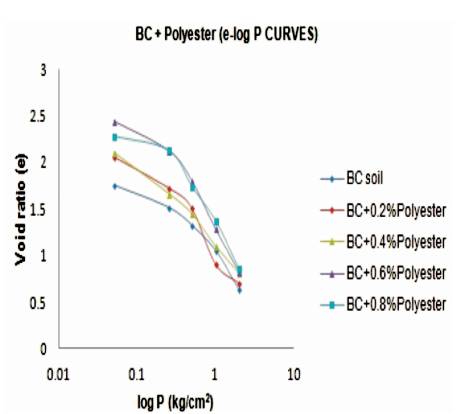

The change in voids ratio due to pressure increments for varying polypropylene and polyester fiber proportions are shown in Figure 10 and Figure 11.

Figure 10. Change in void ratio for corresponding load increments of BC soil reinforced with PP proportions

Figure 11. Change in void ratio for corresponding load increments of BC soil reinforced with Polyester fibers

As the pressure increments were added, the void ratio was decreasing for varying polypropylene and polyester fiber proportions. This implies that as the load on the specimen increases, the voids in the specimen decrease due to expulsion of water from voids.

In one dimensional swell consolidation test, due to the load increments applied for oedometer rings, the height of the specimen has been reduced accordingly.

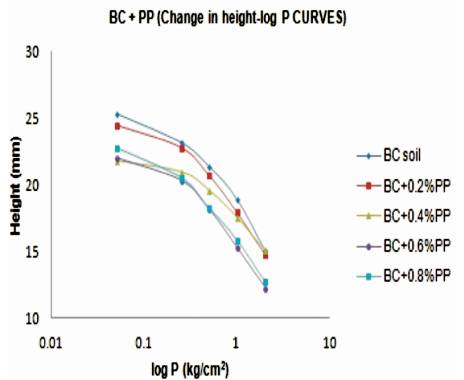

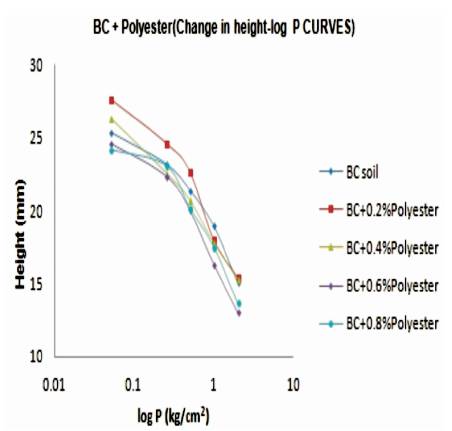

The change in height of specimens for various pressure increments of BC soil reinforced with polypropylene and polyester fiber proportions were shown in Figure 12 and Figure 13.

Figure 12. Alteration of heights for corresponding pressure increments of BC soil reinforced with Polypropylene fiber proportions

Figure 13. Alteration of heights for corresponding pressure increments of BC soil reinforced with Polyester fiber proportions

The increments in loads and increase in proportion of Polyester fibre resulted in a reduction of void ratio. Due to the reduction in void ratio, the height of the specimen has also been reduced significantly. This can be explained as, the voids in the specimen when reduced; the water absorption of the soil will also get reduced which in turn tends to a decrease in height when pressure increments are added to the specimen.

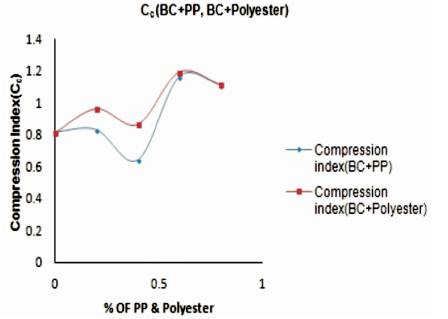

The Compression Index (Cc ) values obtained for fibre reinforced soil are displayed in Figure 14.

Figure 14. Alteration of Cc for BC soil reinforced with Polypropylene and Polyester fibers of varying proportions

The Compression Index values obtained from one dimensional swell consolidation test indicate that with an increase in proportion of fibers, there is no specific trend observed in Compression Index values.

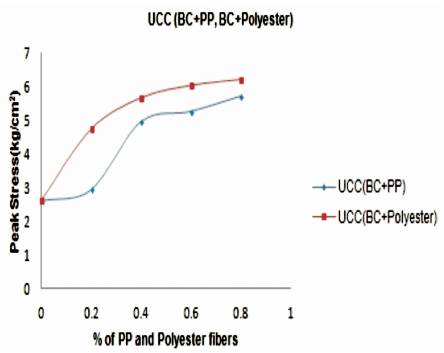

A series of Unconfined Compressive Strength tests have been performed on BC soil reinforced with Polypropylene and Polyester fibre of varying proportions. The test results indicate that the Unconfined Compressive Strength of soil reinforced with varying proportions of Polyester fibres is higher when compared to the soil reinforced with Polypropylene fibre of varying proportions. In spite of low proportions of fibre additions, the enhancement of strength properties was comparatively higher.

The comparative strength results for proportions of fibre reinforced soil are shown in Figure 15.

Figure 15. Alteration of qu for PP and Polyester Fibre Reinforced Soil

The above figures clearly indicate the enhanced qu value for Fibre reinforced soil.

As the fiber proportions were increased, the soil particles were bonded close and because of high bonding between soil particles, the intermolecular attractions increase. The shear failure took place after a long time from the appearance of crack. This indicates that, the fibers are not only strong in tensile strength but also strong in compressive strength. So we can say that, fiber reinforced soil proved to be a best alternative for increasing strength characteristics of BC soil.

Also it has been observed that, Polyester fiber reinforced BC soil has shown significant improvement in Unconfined Compressive Strength when compared with Polypropylene fiber reinforced BC soil.

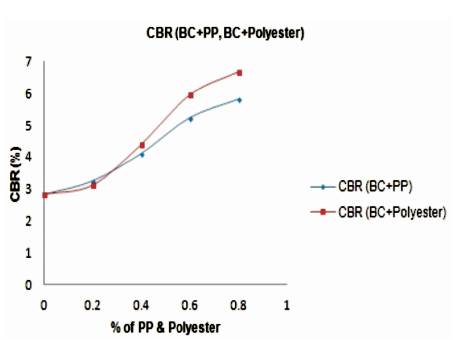

The California Bearing Ratio tests have been performed for varied fiber proportions on BC soil. The test results have been displayed in Figure 16.

Figure 16. Alteration of CBR values for BC soil reinforced with PP and Polyester fibers

The chart shows comparison of CBR values for varying proportions of polypropylene additions. The CBR values have been increasing with increased fiber proportion additions.

It is observed that the CBR values obtained for PP fiber reinforced BC soil are less when compared to the CBR values for Polyester fiber reinforced BC soil for the same proportions of addition.

From the above study, it is concluded that:

We convey our sincere gratitude to Dr C.D. Naidu, Principal, VNR VJIET, Bachupally, Hyderabad, India for providing us the opportunity of conducting this research.

We further convey our sincere thanks to the Head of the Department of Civil Engineering, Prof A. Mallika, VNR VJIET, Bachupally, Hyderabad, India for her constant guidance in carrying out this research.

We convey our gratitude to G Kondala Rao, Chief Engineer, APUFIDC, Govt. of AP for his valuable suggestions in improving the paper.