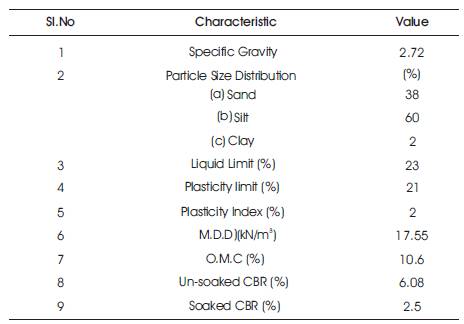

Table 1. Properties of Soil Used

Development of an adequate network of roads, especially in remote rural areas is of vital importance for the socioeconomic development of a country. Search is being made to find alternative materials, for use in pavement construction. Fly ash, lime and cement are the commonly used materials for soil stabilization. Geosynthetics, Geotextiles and Geo-grids are also used nowadays in roads for subgrade improvement in road construction. This paper presents the laboratory CBR test results conducted on sandy soil mix with fly ash for unreinforced and reinforced cases. The reinforcement was done using geogrids in layers at different depths in CBR mould. The fly ash was varied from 15% to 35% in sand sample. All the tests were conducted at Optimum moisture content (OMC) and maximum dry density (MDD) of mixes. The results of California Bearing Ratio (CBR) tests have shown considerable improvement with the use of reinforcement. The maximum increase in CBR value with Geo- grid was observed with the 2 layers of Geo-grid use. The increase in value of CBR was from 6% for virgin soil to 13% with use of geogrids.

Development of an adequate network of roads, especially in rural areas is of vital importance in the socioeconomic development of villages in a country. However, development of a large network of roads by traditional means and techniques require heavy financial investments. Engineers are continually faced with maintaining and developing pavement infrastructure with limited financial resources. Traditional pavement design and construction practices require high-quality material for fulfillment of construction standards. In many areas of the world, quality material is unavailable or in short supply. Due to these constraints, engineers are often forced to seek alternative design using substandard materials, commercial construction aids, and innovation design practices. Concrete or asphalt pavement cannot be constructed on weak soil, because in this case, the pavement will be easily cracked. As sub grade soil function is to transfer applied loads from pavement to the layer beneath, it should have a sufficient load carrying capacity. There are a lot of places all over the world where clayey soil can be found. Design and construction of pavement over this weak and expansible kind of soil is quite challengeable and problematic for geotechnical engineers.

One category of commercial construction aids is geosynthetic. Geosynthetics include a large variety of products composed of polymers and are designed to enhance geotechnical and transportation projects. Geosynthetics, as applied to flexible pavement systems, have been widely used in recent years. Geosynthetic reinforcement is typically placed in the interface between the aggregate base course and the subgrade.

Geosynthetics perform at least one of five functions: separation, reinforcement, filtration, drainage, and containment. Search is being made to find alternative materials, preferably locally available low grade ones for use in pavement construction, which results in sizeable economy without compromising with the engineering performances of the structure.

Normally, in construction of Highways for filling purpose, locally available soil is used. But, the soil from agricultural land is becoming unavailable due to environmental and mining issues so that availability of soil is short and costly. Due to this short supply, sub standard materials are used for innovative design which are required for maintaining the standards.

One of the innovative techniques is to use fly ash in subgrade for highways, flyover project construction. The flyash being silty soil, has low bearing capacity. Therefore, geogrids are used in conjunction with flyash for improving the bearing capacity and CBR value of mix. The present paper explores how the geo-grids are beneficial for subgrade with the use of flyash.

Rao et. al (1989), Shetty and Shetty (1989), Rao and Raju (1990), Cancelli et. al (1996), Gopal Ranjan and Charan (1998) have done pioneer work in CBR studies for fiber reinforced soils. The results of series of laboratory CBR tests (soaked and unsoaked) on silty sand reinforced with randomly distributed polypropylene fibers showed significant improvement. The increase in CBR was observed to be 175% and 125% under soaked and unsoaked conditions, respectively with addition of 3% fibers (by weight).

Benson and Khire (1994) showed that there is an increase in CBR and secant modulus of sand when cut pieces of waste milk jugs are used for reinforcing. Motanelli et.al (1997) and Perkins and Ismeik (1997) analyzed the results of a full scale pavement test conducted on several reinforced sections by use of geogrids in saturated silty clay soil having the CBR value of about 1% to 8%. The test results showed that the multi layer geogrids provide the best base reinforcement results for sub base soil having CBRs equal to 3% or lower. No major differences were found between different single layer integral geogrids. The higher tensile modulus geogrids have shown better contribution at CBRs 3% or lower. The percent reduction of rutting between reinforced and unreinforced sections, increases with reducing the sub grade CBR, for all geosynthetics. The traffic improvement factor for road service life increases for deep allowed ruts, lower CBR values and lower pavement structural number. Kumar et. al (1999) studied engineering properties of silty sand reinforced with fibers.

Bergado et. al (2001) conducted CBR tests on soft weathered clay overlain by compacted sand. The specimens were reinforced by geotextile with different stiffness between clay and sand. The results showed that using geotextile in soil increases the bearing capacity. By increasing loading speed and geotextile stiffness, the load value increases in certain strain. (i.e. CBR value increases). Gosavi et. al (2004), Mittal and Shukla(2001) investigated the strength behavior of black cotton soil reinforced with randomly mixed geogrid woven fabric and fiberglass. CBR value of black cotton soil was 4.9% without geogrid. Soaked California Bearing Ratio test results show considerable increase in the CBR value for black cotton soil after use of reinforcement. CBR value of black cotton soil increases 42% to 55% when 1% woven fabrics and fiberglass, respectively are added randomly. The rate of increase in CBR value with 2% addition of fibers is less and the absolute value of CBR still decreases with more addition of fibers.

The soil used in this investigation is local soil of DCRUST campus, Murthal, Sonipat. The soil samples were taken from 1.0 m below ground surface so as to avoid vegetation problem. According to Indian Standard of Soil Classification, the soil is medium to low compressibility Silt. The properties of the soil are as shown in Table 1.

Table 1. Properties of Soil Used

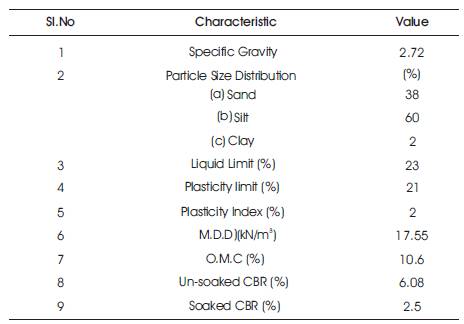

Fly ash was collected from the Thermal power plant of Panipat. The sample was screened through 2mm sieve to separate out the foreign and vegetative matters. The collected samples were mixed thoroughly to get the homogeneity. The properties of flyash are given in Table 2.

Table 2. Properties of Flyash Used

For the study, Geo-Grid were procured from Soma Isolex Workshop Pvt. Ltd, Karnal, Haryana, India.

CBR test was performed as per the guidelines of Indian Road congress (IRC) IRC: SP: 72-200 and IS 2720.

The general steps are as follows: Take about 4.5 to 5.5 kg of Fly ash soil mix. Now add the required water quantity and mix it with soil. Fix the extension collar and the base plate to the mould. Insert the spacer disc over the base. Place the filter paper on the top of the spacer disc. Compact the mix soil in the mould using either light compaction or heavy compaction. For light compaction, compact the soil in 3 equal layers, each layer being given 55 blows by the 2.6 kg rammer. Place geogrid layers horizontally at specified distance in single, double and three layers on the soil mix. Remove the collar and trim off soil. Turn the mould upside down and remove the base plate and the displacer disc. Weigh the mould with compacted soil and determine the bulk density and dry density. Put filter paper on top of the compacted soil (collar side) and clamp the perforated base plate on to it. After this, observe load v/s penetration value.

The mechanical behavior of soil and Fly ash mixture was examined, through the use of Proctor Compaction tests and California Bearing Ratio tests, in which the effect of compaction, water content, density, curing time for percentage of fly ash and lime were studied. Three series of tests were conducted. Fly ash was varied from15%, 25% and 35%. Each series of 9 samples were prepared. One sample contained 3 specimens. All the laboratory tests had been conducted in triplicate to obtain average results and also to check reproducibility.

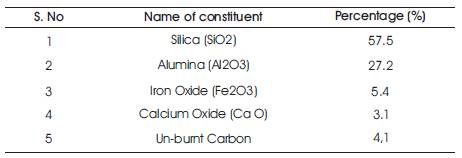

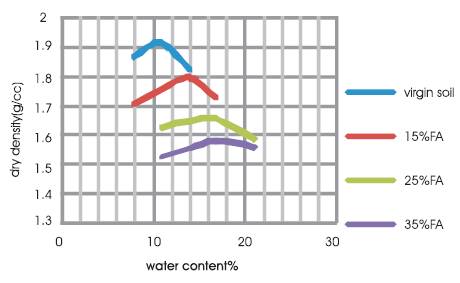

The variations of Dry density with different percentages of soil in combination of fly ash are presented in Figure 1. It was observed that with mixture of 15 % fly ash and 75% soil quantity addition, the maximum dry density decreased from 19.05 kN/m3 to 17.7 kN/m3.When the flyash percentage increases to 25%, density decreases to16.47 kN/m3.Further, increase in the lime percentage from 25% to 35% density reduced to 15.6 kN/m3. Fly ash is a light weight material as it consists of a large amount of hollow semi spheres, and it is being used as a replacement material in the soil mixes. The corresponding OMC of the three mixes were 13.5%, 16% and 17.1% respectively.

Figure 1. Results showing maximum Dry density curves

The increase in optimum moisture content with the increase in percentage of flyash occurs due to the fact that lime reacts with mineral of soil to form a tough water insoluble gel of calcium silicate which cements the soil particles.

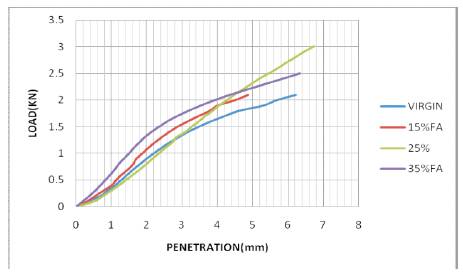

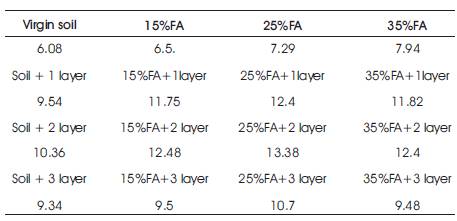

CBR tests were conducted on virgin, and reinforced soil with a single, double and three layers of geo-grid (Figure 2 and Table 3). The samples were made maximum dry density (MDD) and corresponding optimum moisture content was achieved from standard proctor tests.

Figure 2. Results of CBR Tests with one layer of Geogrid

Table 3. Results of CBR Tests