Figure 1. Bacillus subtilis

The use of bacteria-based self-healing concrete has gained attention in recent years due to its potential to improve the durability and sustainability of concrete structures. This paper provides an overview of the research conducted on the self-healing properties of bacteria-based bio-concrete. The paper discusses the mechanism of bacterial self-healing in concrete, the types of bacteria used in self-healing concrete, and the methods used to introduce bacteria into the concrete. The paper also reviews comparative studies that evaluate the mechanical properties and durability of selfhealing bacterial concrete compared to traditional concrete. The results of these studies demonstrate that the use of bacteria in concrete can improve the self-healing capacity of the material, leading to better mechanical properties and a higher resistance to cracking and freeze-thaw damage. Furthermore, the paper discusses the potential environmental and economic benefits of using self-healing bacterial concrete. The self-healing capacity of the concrete can reduce the need for costly repairs and maintenance of concrete structures, resulting in lower costs and a reduced environmental impact associated with concrete production. Additionally, the use of waste materials as nutrient sources for bacteria can promote the circular economy and contribute to sustainable development. Overall, this paper highlights the promising potential of self-healing bacterial concrete to improve the durability, sustainability, and economic viability of concrete structures.

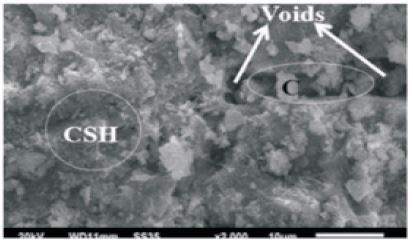

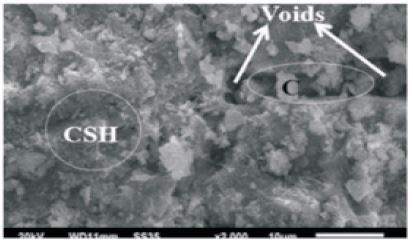

There are several remedies available to solve the problem of cracking in buildings, and bacterial concrete, or self-healing, is one of the more promising solutions. Upon hardening, self-healing concrete fills in or heals cracks due to bacterial reactions in the concrete. When repetitive cycles of dry and wet are performed on small cracks in a structure, they get completely sealed. The width of cracks in the region of 0.05-0.1mm acts as a capillary, allowing water particles to infiltrate through the cracks. These water particles hydrate the unreacted or partially reacted cement, causing it to expand and fill the fissure. However, when the cracks are wider, additional repair work is required. One viable technology being researched and developed is the use of mineralproducing bacteria in concrete. Acid-producing bacteria are used in the self-healing of cracks, and can survive in latent cells for more than 200 years in dry environments. These bacteria act as a catalyst in mend cracks. Some of the bacteria are shown in Figures 1 and 2.

Figure 1. Bacillus subtilis

Figure 2. Bacillus subtilis

Self-healing concrete results from a biological reaction among non-reacted limestone and a calcium-based nutrient, which uses microorganisms to repair the building's cracks (Du et al., 2020). Bacillus microorganisms are used in conjunction with calcium lactate, a calcium supplement. These compounds are mixed into the moist concrete during the concrete preparation process. This bacteria can remain dormant for up to 200 years. When water flows into the fractures within the concrete, the bacteria's spores germinate and begin feeding on calcium lactate while consuming oxygen (Juki et al., 2019). Insoluble limestone is formed from soluble calcium lactate, and the hardening of the insoluble limestone begins, which spontaneously fills the crack without any outside help. Another benefit of this process is that since the microorganisms consume oxygen to turn calcium into limestone, it helps prevent metal corrosion due to fissures. The metal reinforced concrete form becomes more durable as a result. There are two methods for making bacterial concrete, namely: through direct application and by encasing the object with light concrete.

In the direct application method, bacterial spores and calcium lactate are directly mixed into the concrete. The addition of these components does not affect the normal properties of the concrete, and the microorganisms remain dormant until variations in climate trigger their activation. When the microorganisms come into contact with water, they germinate and consume calcium lactate, leading to the formation of limestone and the sealing of cracks in the structure. On the other hand, in the encapsulation technique, the microorganisms and calcium lactate are enclosed in treated clay pellets and added to the concrete mix. About 6% of the clay pellets are added to make bacterial concrete. Although encapsulation is more expensive than direct application, it is a more popular method. When water comes into contact with unhydrated calcium in the concrete, microorganisms act as catalysts to form calcium hydroxide. When calcium hydroxide reacts with carbon dioxide in the air, limestone and water are formed, and the process continues due to the additional water molecule. This self-healing chemical process, also known as bacterial concrete, results in the hardening of the limestone and the plugging of the cracks in the concrete. Overall, the use of bacterial concrete and its self-healing properties can help improve the durability and sustainability of concrete structures, reducing the need for costly repairs and maintenance.

The authors found that the use of Bacillus bacteria significantly improved the compressive strength of the concrete and reduced crack width, demonstrating the potential of self-healing concrete in improving the durability and service life of concrete structures. Furthermore, a study by Yang et al. (2019) investigated the use of mineral-producing bacteria in self-healing concrete. The authors used a type of bacteria called Sporosarcina pasteurii to produce calcite, a mineral that can fill cracks in concrete. The study showed that the use of this bacteria significantly improved the strength and durability of the concrete, and could also prevent the corrosion of steel reinforcement. Ghosh et al. (2021) explored the use of different types of bacteria in selfhealing concrete, including Bacillus, Pseudomonas, and Lactobacillus. The authors found that all three types of bacteria were effective in producing calcite and improving the strength and durability of the concrete. However, they also noted that the effectiveness of the bacteria was dependent on various factors, such as the type of concrete, environmental conditions, and the concentration of bacteria. These studies suggest that selfhealing bacterial concrete has the potential to improve the durability and service life of concrete structures. However, further research is needed to optimize the use of bacteria in concrete and to evaluate the long-term effectiveness of self-healing concrete in real-world applications.

Vijay and Murmu (2020) examined the effectiveness of Bacillus bacteria in self-healing concrete. The authors showed that the bacteria could effectively seal cracks up to 0.2 mm wide, and that the self-healing process improved the durability of the concrete. Qian et al. (2013) analyzed the effectiveness of various types of bacteria in self-healing concrete. The authors tested Bacillus subtilis, Sporosarcina pasteurii, and Bacillus cohnii and found that Bacillus subtilis was the most effective in producing calcium carbonate and filling cracks. In a more recent study by Zhang et al. (2021), different self-healing techniques, including bacterial self-healing, were reviewed, and their effectiveness in repairing cracks in concrete structures was analyzed. The authors concluded that bacterial self-healing was a promising technique that could be used to repair and extend the service life of concrete structures. Su et al. (2021) experimented with the use of expanded perlite as a carrier for bacteria in self-healing concrete. The authors showed that the use of expanded perlite could significantly improve the survival rate of bacteria in the concrete, and that the self-healing process could effectively repair cracks.

Mechtcherine (2013) investigated different techniques for mitigating reinforcement corrosion in self-healing concrete, and the use of bacteria to be an effective method for preventing reinforcement corrosion and extending the service life of concrete structures. The studies on self-healing bacterial concrete have demonstrated that the use of bacteria in concrete can effectively repair cracks and extend the service life of concrete structures. Although various types of bacteria and carriers have been used in these studies, Bacillus subtilis has been shown to be the most effective in producing calcium carbonate and filling cracks. The use of bacterial self-healing in concrete structures can significantly reduce maintenance costs and improve the durability and sustainability of these structures.

Mors and Jonkers (2019) the use of a calcium lactatebased nutrient system for bacteria in self-healing concrete was evaluated. The authors demonstrated that the nutrient system improved the survival rate of the bacteria and enhanced the self-healing capacity of the concrete. Fernandez et al. (2021) depicted the mechanical properties of self-healing bacterial concrete and traditional concrete. The authors found that the selfhealing bacterial concrete had better mechanical properties and higher resistance to cracking compared to traditional concrete. Luo et al. (2018) evaluated the use of a magnetic field to enhance the self-healing capacity of bacterial concrete. The authors showed that the magnetic field increased the production of calcium carbonate by the bacteria and improved the efficiency of the self-healing process.

Muhammad et al. (2016) examined the use of different concentrations of bacteria in self-healing concrete. The authors found that higher concentrations of bacteria led to a more efficient self-healing process and that a concentration of 107 CFU/mL was the most effective.

Zhang et al. (2021) depict the durability of self-healing bacterial concrete and traditional concrete under freeze-thaw cycles. The authors found that the selfhealing bacterial concrete had higher resistance to freeze-thaw damage compared to traditional concrete.

In a study by Mohammadnezhad et al. (2022), the use of a waste material, specifically ground granulated blastfurnace slag, as a nutrient source for bacteria in selfhealing concrete was evaluated. The authors showed that the use of this waste material as a nutrient source improved the survival rate of the bacteria and enhanced the self-healing capacity of the concrete. Overall, these studies demonstrate the potential of self-healing bacterial concrete to enhance the durability and sustainability of concrete structures. Different techniques, including the use of nutrient systems, magnetic fields, and waste materials, have been used to improve the selfhealing capacity of the concrete. The results of comparative studies, as shown in Table 1, suggest that self-healing bacterial concrete has better mechanical properties and higher resistance to cracking and freezethaw damage compared to traditional concrete.

Bacteria have emerged as an exciting new tool in the field of concrete technology. By using specific strains of bacteria, it is possible to create bioconcrete that has superior durability and self-healing properties. The bacteria are used to produce calcium carbonate, which acts as a cementing agent, helping to fill in cracks and prevent further damage.

Several bacteria have been used in bioconcrete, including Bacillus sphaericus, Bacillus subtilis, Bacillus cohnii, and Sporosarcina pasteurii. One of the most commonly used bacteria in bio-concrete is Bacillus sphaericus. This bacterium is particularly well-suited for concrete applications because it can survive in harsh, alkaline environments. It produces calcium carbonate as a by-product of its metabolic processes, which helps to strengthen and repair the concrete.

Bacillus subtilis is another popular choice for bioconcrete. This bacterium is known for its ability to form durable spores that can survive in a variety of conditions. Like Bacillus sphaericus, it produces calcium carbonate as a by-product of its metabolism, making it an excellent candidate for bio-concrete applications. Bacillus cohnii is a lesser-known bacterium that has also been used in bio-concrete. It is particularly effective at producing calcium carbonate, making it an attractive option for researchers looking to create more durable and resilient concrete structures (Jena et al., 2021).

Finally, Sporosarcina pasteurii is a bacterium that is particularly well-suited for bioconcrete applications. This bacterium has the unique ability to produce calcium carbonate at a rapid rate, which helps to accelerate the healing process in damaged concrete. By harnessing the unique properties of these microorganisms, it is possible to create concrete structures that are more durable, longerlasting, and better able to withstand the challenges of the modern world.

The mechanism of bacteria-based self-healing involves the activation of dormant bacteria cells in the concrete matrix by moisture and nutrients. The activated bacteria then start to metabolize and produce calcium carbonate, which fills the cracks and pores in the concrete, and ultimately restores its strength and durability.

The use of bacteria for self-healing concrete represents a revolutionary approach in the field of construction materials. This innovative technology involves the incorporation of specific strains of bacteria into the concrete matrix, which can respond to environmental triggers and stimulate the healing process in the concrete. The mechanism of bacteria-based self-healing involves the activation of dormant bacteria cells in the concrete matrix by moisture and nutrients. The bacteria are typically encapsulated in microcapsules or added to the mix as spores, which remain dormant until favorable conditions arise. When the concrete cracks or sustains damage, moisture and nutrients penetrate the cracks and trigger the activation of the dormant bacteria cells.

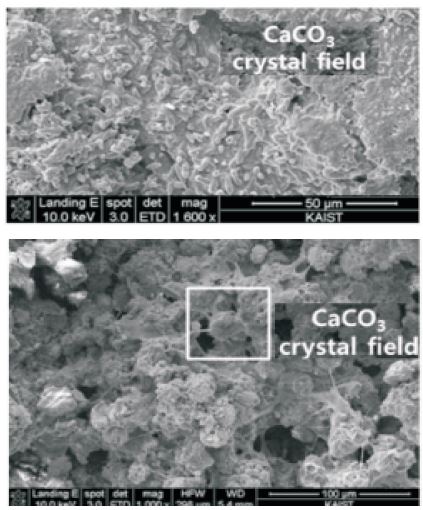

Once the bacterial cells are activated, they start feeding on the available nutrients in the concrete matrix and convert them into calcium carbonate through a process called bio-mineralization. This process involves the conversion of soluble calcium ions and carbonate ions into solid calcium carbonate, which fills the cracks and pores in the concrete, improving its strength and durability. The calcium carbonate acts as a natural adhesive that binds the concrete together and prevents further damage.

The bacteria-based self-healing process is a sustainable and eco-friendly solution that reduces the need for costly and time-consuming repairs. Unlike traditional repair methods that require the removal of the damaged concrete and the addition of new material, the bacteriabased self-healing process repairs the concrete from within, without the need for any human intervention. This significantly reduces the cost and time required for repairs and increases the lifespan of concrete structures. The use of bacteria for self-healing concrete is a promising technology that has the potential to revolutionize the construction industry. By harnessing the natural abilities of bacteria to produce calcium carbonate and repair damaged concrete, we can create more durable and sustainable concrete structures that can withstand the test of time. With further research and development, this technology can be expanded to other construction materials and become a standard practice in the industry.

Several factors can affect the self-healing properties of bio-concrete, including the type and concentration of bacteria used, the moisture content of the concrete, and the availability of nutrients. The curing temperature and the pH of the concrete can also influence the rate and effectiveness of self-healing.

The self-healing properties of bio-concrete depend on several factors that influence the activation and growth of bacteria, as well as the bio-mineralization process that leads to the production of calcium carbonate.

Understanding these factors is essential for optimizing the performance of bio-concrete and achieving long-lasting self-healing properties. One critical factor affecting the self-healing properties of bio-concrete is the type and concentration of bacteria used. Different strains of bacteria have varying abilities to produce calcium carbonate and withstand the harsh conditions of the concrete matrix. Bacillus sphaericus, Bacillus subtilis, Bacillus cohnii, and Sporosarcina pasteurii are among the most commonly used bacteria in bio-concrete, but the optimal strain and concentration depend on the specific application and environmental conditions.

The moisture content of the concrete is another critical factor that affects self-healing properties. The bacteria require a certain level of moisture to become active and start producing calcium carbonate. If the concrete is too dry, the bacteria may remain dormant, and self-healing may not occur. On the other hand, if the concrete is too wet, the bacteria may become diluted, and the concentration of nutrients may decrease, leading to reduced self-healing effectiveness. The availability of nutrients is also essential for the growth and activity of the bacteria. The bacteria require a source of carbon, such as sugars or organic acids, to fuel their metabolism and produce calcium carbonate. The availability of nutrients depends on the composition of the concrete and the environmental conditions. The addition of nutrients, such as urea, can increase the self-healing effectiveness of bio-concrete.

The curing temperature is another factor that can influence the self-healing properties of bio-concrete. Higher temperatures can accelerate the growth and activity of the bacteria, leading to faster self-healing. However, excessive heat can also damage the bacteria and reduce their effectiveness. Therefore, optimizing the curing temperature is critical for achieving the desired self-healing properties. The pH of the concrete is also essential for the self-healing properties of bio-concrete. The bacteria thrive in alkaline environments, and the pH can affect the solubility of calcium ions and carbonate ions, which are essential for bio-mineralization. Therefore, maintaining an appropriate pH is crucial for the growth and activity of the bacteria and the production of calcium carbonate. Optimizing these factors is critical for achieving long-lasting self-healing properties and realizing the potential of bio-concrete as a sustainable and durable construction material.

Based on the research papers reviewed, the strength of self-healing concrete samples increased when compared to control samples, and there was a reduction in water absorption in samples containing microorganisms. Currently, researchers are primarily focused on developing bacterial concrete, which can enhance concrete durability, mechanical strength, and permeability. Bacillus cereus at concentrations up to 106 cells/ml has been found to produce the most significant increase in compressive strength, up to 50%, while S. pasteurii has been observed to achieve an 80-85% reduction in water absorption after 28 days of curing, compared to standard concrete samples (Maheswaran et al., 2014).

Previous studies have shown that while some bacteria can be harmful to human health, others, such as Bacillus sphaericus, Bacillus pasteurii, Bacillus subtilis, and Bacillus flexus, have no negative effects on human health and possess a higher ability to precipitate calcite, making them ideal bacteria for developing bacterial concrete. Bacterial concrete is expected to have a longer lifespan than conventional concrete, which may create new job opportunities for professionals. The cost of bacterial concrete can increase by up to 30% compared to ordinary concrete, depending on the type and concentration of bacteria used. However, the use of bacterial concrete can ultimately save on maintenance costs. The cementation process for bacterial concrete is simple and convenient.

Currently, researchers are highly interested in developing bacterial concrete, as it has been observed to make concrete more durable, mechanically strong, and permeable. Research conducted to date suggests that using Bacillus cereus in concentrations up to 106 cells/ml can lead to a 50% increase in compressive strength, and after 28 days of curing, S. pasteurii results in a noticeable decrease in water absorption and is 80-85% stronger than the standard concrete sample.