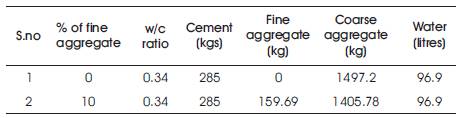

Table 1. Quantities of Material Required per 1 m3 of Pervious Concrete

Conventional normal weight Portland cement concrete is generally used for pavement construction. The impervious nature of the concrete pavements contribute to the increased water runoff into the drainage system, over-burdening the infrastructure and causing excessive flooding in built-up areas. Pervious concrete is a special type of concrete with a high porosity, used for concrete pavement applications that allows water from precipitation and other sources to pass directly through, thereby reducing the runoff from a site and allowing ground water recharge. In order to develop material specification for pervious concrete, it is necessary to conduct testing to evaluate the performance of this new type of high-performance concrete. Pervious concrete is sometimes referred to as “no-fines” concrete. In this study, the fine aggregate is used in various proportions such as 0%, 10% in the mix and the variation in the properties are studied. Properties such as density, void content, compressive strength, are studied for M20 grade by considering the w/c ratio as 0.34 and the design is done based on ACI 522 R10. From these studies, it is observed that the void content got decreased and the compressive strength got increased by the increase in fine aggregate percentage.

Concrete is a homogeneous mixture of cement, aggregate (fine aggregate and coarse aggregate) and water. Now-a-days, special concrete is more preferred in the construction industry. Some of the special concretes are pervious concrete, transparent concrete, high volume fly ash concrete, self compacted and curing concrete because of their special properties which is better compared to conventional concrete. Pervious Concrete is a special type of concrete in which no fine aggregates are used and gravel has been used in place of the fine aggregate. Pervious Concrete is also called as “no-fines” concrete [5,6]. No fines pervious concrete for paving was found that when a small amount of sand was added to the mixture, the compressive strength of the concrete increases gradually. Therefore, it is a mixture of Portland cement, uniform coarse aggregate, with both a small amount of or without fine aggregate and water. Appropriate amounts of water and cementitious material are employed to create a paste that forms a thin coat around aggregate particles, but leaves free spaces between them. Thus, pores are formed in the pervious materials. Water/cement ratios between 0.27 and 0.30 are used routinely with proper inclusion of chemical admixtures and those as high as 0.34 to 0.40 have been used successfully. The relation between strength and water/cement ratio is not clear for pervious concrete because unlike conventional concrete, the total paste content is less than the voids content between the aggregates [8-10]. Fresh pervious concrete is typically stiff with low workability. In order to achieve desired pore structure, proportioning of pervious concrete is commonly carried out using gap graded coarse aggregates and little to no fine aggregates. The range of porosity that is commonly reported for pervious concrete is 15 to 30%, and this depends on the compaction method adopted, in addition to the mixture proportions. However, the strength of the material is relatively low because of its porosity [11]. In recent years, pervious concrete pavements have become increasingly popular as an effective storm water management device in areas that receive frequent and sometimes extensive rainfalls. The most popular application is light traffic volume roadways such as parking lots, residential roads, driveways, and sidewalks. Parking areas properly designed and constructed will last 20-40 years with little or no maintenance. Unlike asphalt, surface ravelling (the loosening of surface aggregates) is common only in the first few weeks after the concrete is laid, and it can be reduced with proper compaction and curing techniques.

Tennis et al. [1] studied the workability parameter and recommended that workability for pervious concrete should be assessed by forming a ball with the hand to established mouldability.

M. Uma Maguesvari and V.L. Narasimha [2] studied the influence of fine aggregate and coarse aggregate quantities on the properties of pervious concrete by considering w/c ratio as 0.34 and aggregate cement ratio as 4.75:1. Fine aggregate was replaced with coarse aggregate in the range of 50 - 100% by weight. Various mechanical properties of the mixes were evaluated. Finally, a relationship between the strength, abrasion resistance, permeability and total void present in aggregate based on angularity number has been developed.

Ghafoori and Shivaji Dutta [3] studied the physical and engineering characteristics of no fines concrete for various concrete mixtures under various compaction energies. They reported that strength properties mainly depends upon the mixture proportions and compaction energies. They also reported that when the aggregate to cement ratio was increased, the compressive strength of pervious concrete was decreased.

Praveenkumar Patil and Santosh M Murnal [4] studied the effect of w/c ratio and aggregate size on the strength properties of pervious concrete. The property of pervious concrete by replacing cement by fly ash is also studied. They reported that the compressive strength of pervious concrete increases as the water/cement ratio decreases up to optimum w/c ratio of 0.38 with increase in volume of paste. The optimum replacement of cement by fly ash is found to be 20% in the study.

JCI [7] presents certain standards and formula for determining Void Content and Density of Hardened pervious concrete.

To study the properties of pervious concrete for pavements such as Void content, Density, and Compressive strength. The study is carried out with variation in fine aggregate percentages (0%,10%).

Ordinary Portland Cement of 53 grade of ultratech having specific gravity of 2.9 was used in the investigation. The cement used has been tested for various physical properties and found to be confirming to various specifications as per IS:12269-2013.

Crushed aggregate of 20 mm and 10 mm produced from local crushing plants were used. The aggregates were tested for their physical and chemical requirements such as gradation, specific gravity, bulk density, etc in accordance with IS:2386-1963.

The locally available sand is used as fine aggregate in the present investigation. The sand is tested for various properties like specific gravity, bulk density, water absorption, etc.

Locally available water is used and the water to cement ratio is taken as 0.34 for the study.

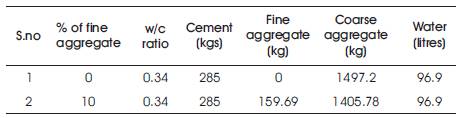

Mix design is carried out based on ACI 522 R10. Table 1 gives the quantites of material required for 1 m3 of pervious concrete. Table 2 gives the mix proportion ratio which is used for the study.

Table 1. Quantities of Material Required per 1 m3 of Pervious Concrete

Table 2. Mix Proportion Ratio

In the present study, American Concrete Institute reported by ACI Committee 522R-10 design code is utilised for M20 grade concrete. Figure 1 shows the structure of pervious concrete.

Figure 1. Pervious Concrete Structure

A procedure for producing initial trial batches for pervious concrete is shown as follows. The b/b0 method applies absolute volume concepts. The b/b0 method for designing a pervious concrete mixture can be broken up into a series of eight steps:

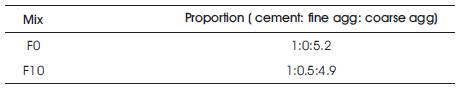

Total void content and density experiement was conducted in accordance with ASTM C1754. Cubes of specimen of size 100 mm were prepared for each mix and the void content was tested from reference [7].

where,

At = total void content of porous concrete,

M1 = buoyant mass of the saturated specimens in water,

M2 = dry mass in the air for 24 hours,

V = total volume of specimens, and

ρw = density of water

Compressive strength test were conducted in accordance with ASTM C39. Cubes of specimen of size 150 mm were prepared for each mix as shown in Figure 2. After 24 hours, the specimens were demoulded and cured in water for 28 days until testing. The strength value was reported as the average of the samples.

Figure 2. Cube Under Compression Testing Machine

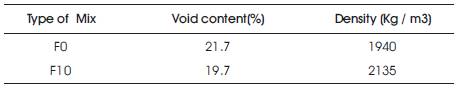

From Table 3, the void content was observed to be 21.7% for 0% fine aggregate and it was decreased when fine aggregate in the mix was increased. Similarly, the density was observed to be 1940 kg/m3 for 0% fine aggregate and it was increased when fine aggregate in the mix increased.

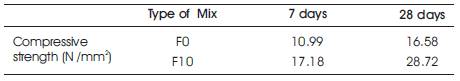

From Table 4, the strength properties was observed to be increased by addition of fine aggregate in mix.

F0 = 0% fine aggregate, F10 = 10% fine aggregate.

Table 3. Void Content and Density

Table 4. Strength Properties at 7 and 28days