Table 1. Trial Mixes of High Strength Self Compacting Concrete using Mineral Admixtures

In this experimental study, attempts have been made to observe the suitability of high strength self compacting concrete slabs of grade M100 with and without Glass and Steel fibers. Experimental investigations were carried out on ultimate load and load deflection characteristics of the slab. Self Compacting Concrete Slabs were cast with varying percentage of steel fibers from 0% to 1.5% and glass fibers of 0% and 0.03% of sizes (S. Sesha Phani, et al., 2015) 1400X1200X100 mm wes cast. These specimens were tested for ultimate load and load-deflection characteristics, and failure characteristics is seen after 56 days curing. It has been observed that, the presence of higher percentages of steel fibers, an improvement in the failure behaviour is seen. Also, with the addition of glass fibers, the load carrying capacity is increased along with the prevention of the development of multiple cracks and micro cracks.

Self compacting Concrete is a solution for the durability problems in concrete structures using which, even the segregation problems can be prevented. In plain Cement concrete, it is highly difficult to achieve an uniform material quality in highly congested reinforced corners of the structures, where it is tiresome to provide steel. The self Compacting Concrete can be compacted in any corner of a formwork, which happens purely by the self weight of the concrete and hence vibration of concrete is not necessary. For building high rise structures by reducing the column sizes and to increase the available space, SCC is used, which is more advantageous in building superstructures of long span bridges, and the bridge decks where durability as well as strength is an important component of the design. By adding hybrid fibers in high strength concrete slabs, the deflection and the load carrying capacity are significantly increased.

To aim of the research work is to study the load-deflection characteristics and ultimate load capacity of High strength hybrid fiber reinforced self compacting concrete slabs of M100 grade concrete.

SCC is attracting engineers and builders all over the because of its advantages like free flow of concrete in congested reinforced elements and its excellent finishing. However, poor tensile strength and fracture properties of conventional concrete are present in SCC. Therefore, the need is felt for the development of SCC composites with enhanced tensile strength, improved fracture toughness and post peak-load deflection response of the flexural members. It is clear from the past that, addition of fibres to conventional concrete improves many of the engineering properties of the conventional concrete. While a number of investigations have been made on the effect of steel fibres on the strength, behaviour of conventional concrete and studies on steel fibre reinforced SCC structural elements such as columns, beams, beam column joints, and slabs. Comprehension studies which involve tensile strength and fracture properties are not available on High strength self compacting reinforced concrete using hybrid fibres(S. Sesha Phani, et al., 2015). Hence, considering the gap in the existing literature, an attempt has been made to understand the flexure behaviour of High strength hybrid fibre reinforced self compacting concrete slabs of M100 grade.

Okumara and Ouchi (2003) [1] made an investigation for establishing a rational mix-design method and selfcompactability.

Ali R. Khaloo and majid, (2015) [2] investigated on the influence of length and volumetric percentage of the steel fibres on energy absorption of concrete slabs with various concrete strengths by testing 28 Small steel Fibre Reinforced Concrete (SFRC) slabs under flexure. Test results indicate that, generally longer fibres and higher fibre content provide high energy absorption. The results are compared with a theoretical prediction based on a random distribution of fibres. The theoretical method resulted in higher energy absorption than that obtained in the experiment. A design method according to allowable deflection is proposed for SFRC slabs within the range of fibre volumetric percentages used in the study. The method predicts resisting the moment–deflection curve satisfactorily.

T. Seshadri Sekhar [3] et al., (2010), studied the effect of glass fibres on glass fibre reinforced self compacting concrete using Alkali- Resistant glass fibres on the strength and behaviour of fibre reinforced SCC structural elements subjected to flexure for various grades of concrete mixes of M 30, M 40.

UdayaKumar et al., (2007) investigated a study on the flexural behaviour of RC slabs reinforced with Glass Fibre Reinforced Plastic (GFRP) rebars. The RC slabs had a width of 500 mm, depth of 100 mm and an overall length of 2200 mm. In all, eight numbers of RC slabs, including control specimens reinforced with High Strength Deformed (HSD) rebars were investigated in the study. The parameters investigated were two types of GFRP rebars and the percentage of reinforcement. The cracking load and loaddeflection behaviour up to the cracking load were almost the same for the RC slabs reinforced with HSD and GFRP rebars. The load carried by the RC slab reinforced with GFRP rebar was only 40% - 50% of the ultimate load of the RC slabs reinforced with HSD rebars at a deflection corresponding to the ultimate load of RC slab reinforced with HSD rebar. However, at a 50 mm deflection, the load carried by RC slab with plain GFRP rebars was nearly the same as the ultimate load of the RC slab with HSD rebar. For the RC slab with ribbed GFRP rebars, it was 10% more than that of the RC slab with HSD rebar.

Seshadri Sekhar, et al., (2013) [5] have presented the mix design for M100 Grade of Concrete.

Annie Peter J., Lakshmanan N, Devadas Manoharan P., Rajamane N.P. and Gopalakrishnan S., (2004) [6] had compared the structural behaviours such as, loaddeflection characteristics, crack-widths, spacing of cracks, number of cracks, crack pattern, ultimate load-carrying capacity, moments-curvature relationship, longitudinal strain in both concrete and steel for Self Compacting Concrete (SCC) and Conventionally Vibrated Concrete (CVC). They observed through SCC. CVC has different modes of compaction, both mixes yielded to similar strength levels at ages of 1,3,7, and 28 day. The UPV readings taken on SCC were similar to those of CVC showing that SCC had flowed through the reinforcement and felled the beam completely without voids, honey combs, etc. The load-deformation behaviour of both SCC and CVC beams were similar up to the peak load stage. Beyond the peak load stage, CVC beams show no drop in load with increased deformation, while SCC beams shows drop in load with increased deformation. While the peak and failure loads were nearly the same for CVC beams, the failure load was nearly 25 percent lower compared to the peak load in SCC beams. Crack widths were within the limits specified by IS 456 at all load stages. The average crack widths of both the types of beams were comparable. The crack spacing of both CVC and SCC were almost the same.

Ganeshan N, Indira P.V and Santhosh Kumar P. T (2005) [7] made an attempt to study the effect of steel fibres on the strength and behaviour of fibre reinforced SCC structural elements subjected to flexure. Twenty beams were cast for this study, out of which two were plain SCC beams without fibres. The variables in this study were aspect ratio (15.25 and 35) and the percentage of volume fraction (0, 0.25, 0.5 and 0.75) of fibres. Based on the experimental investigation, the authors observed that the first crack load and the post cracking behaviour were found to have improved due to the addition of fibres. A marginal improvement in the ultimate strength was observed. The addition of fibres had enhanced the ductility significantly. The optimum volume fraction of the fibres was found to be 0.5 percent.

Ganeshan. N, Indira P.V and Santhosh Kumar P.T (2006) [8] have made an attempt to study the effect of steel fibres on the strength and behaviour of Self Compacting Concrete (SCC) flexural elements. Twenty beams were cast for this study, out of which two were plain SCC beams without fibres. The variables in this study were aspect ratio (0, 15, 25 and 35) and percentage of volume fraction of fibres (0, 0.25, 0.5 and 0.75). First crack load and the post cracking behaviour were found to have improved significantly due to the addition of fibres. A marginal improvement in the ultimate strength was observed. The addition of fibres enhanced the ductility significantly. The optimum volume fraction of fibres for better performance in terms of strength and ductility was found to be 0.5 percent. Experimental values of the ultimate moment were compared with various analytical models. The comparison indicates that Swami and Taan model compares better with the test results than that of the other models.

Ordinary Portland cement of 53 grade having specific 2 gravity 3.02 and fineness 3200cm /gm was used in the investigation. The Cement used has been tested for various proportions as per IS 4031-1988 and found to be confirming to various specifications of IS 12269-1987.

Crushed angular granite metal of 10 mm size having the specific gravity of 2.65 and fineness modulus 6.05 was used in the investigation.

River sand having the specific gravity of 2.55 and fineness modulus 2.77 was used in the investigation.

A Viscosity modified admixture for Rheodynamic Concrete, which is a colourless free flowing liquid and has Specific of 0 gravity 1.01± 0.01 @ 25oC and pH value as 8±1 and Chloride Content nil was used as Viscosity Modifying Agent.

The Modified Polycarboxylated Ether (BASF Glenium B276 SURETEC) based super plasticizer, which is a pale yellow colour, free flowing liquid and has a Relative density of 1.10±0.01 at 25oC, pH >6 and Chloride Ion content <0.2% was used as super plasticizer.

Type-II fly ash confirming to I.S. 3812 – 1981of Indian Standard Specification was used as Pozzolana Admixture.

The Micro silica having the specific gravity 2.2 obtained from Oriental Trexim, Private Limited was used in the present investigation.

The glass fibres are of Cem-FIL Anti-Crack HD with the modulus of elasticity 72 GPA, Filament diameter 14 microns, Specific Gravity 2.68, length 12mm and having the aspect ratio of 857.1. For kilogram, the numbers of fibres are 212 million.

In the present investigation, round crimped steel fibres of 30 mm length and diameter of 0.50 mm with aspect ratio as 60 are procured. The Volume fraction percentage is 0.50,1.0,1.50 and Ultimate Strength is 840 To 1250 Mpa.

Glass fiber reinforced with crimped steel fibers of high strength, high performance Self compacting concrete slabs by varying the percentage of steel fibers from 0% to 1.5% and glass fibers of 0% & 0.03% of sizes 1400x1200x100 mm were cast with reinforcement of 8mm diameter HYSD bars with a spacing of 200mm c/c on each direction of the slabs. A total of 8 specimens were cast and these specimens were cured in water for 56 days and tested for ultimate load, deflections and failure characteristics under one third point loading.

The following table gives the quantities of material required for various trial mixes of high strength self compacting concrete using mineral admixtures (Table 1). The Trail Mixes were carried by verifying the fresh state properties with EFNARC guidelines (S. Sesha Phani, et al., 2015).

From the following table, the authors could observe the basic requirements of high flow ability and segregation resistance as specified by the guidelines of EFNARC are satisfied. Table 2 shows the Fresh Concrete properties of High Strength Self Compacting Concrete Trail Mixes with Compressive strength values (S. Sesha Phani, et al., 2015).

Table 2. Fresh Concrete Properties of High Strength Self Compacting Concrete Trail Mixes with Compressive Strength Values

From the above results it can be observed that the ultimate flexural strength is observed in a slab having 0.5%, 1% and 1.5% steel fibers.

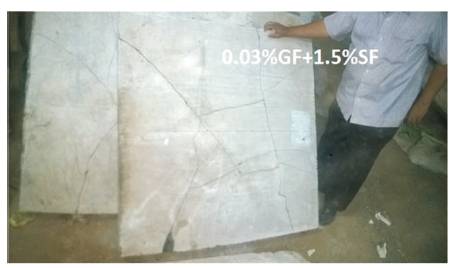

The variation of high strength self compacting concrete slabs with and without hybrid fibers are given in Figure 1. From the Figure and the observation of cracks it can be seen that the load carrying capacity of hybrid fiber reinforced concrete slabs are on a high side when compared with slabs without Glass fibers. It can be also noted that the presence of glass fibers in glass fiber reinforced high strength self compacting concrete slabs is not much advantageous with respect to ductility. The load carrying capacity of high strength self compacting concrete slabs with glass fibers at 0.03% is greater than the slabs without glass fibers. However, development of multiple cracks and micro cracks is prevented with the use of glass fibers. Due to the presence of higher percentage of steel fibers, the formation of cracks has been delayed considerably. Hence in the present study, it may be concluded that the presence of steel fibers has helped in imparting more ductility and better cracking behavior. This is effective in high strength self compacting concrete slabs due to the better fiber - matrix bond. The Failure patterns are shown in Figures 2(a),2(b) and 2(c).

Figure 1. Load Deflection Characteristics of High Strength Hybrid Fiber Reinforced Self Compacting Concrete of M100 Grade

Figure 2(a) Failure pattern of High Strength Hybrid Fiber Reinforced Self Compacting Concrete Slabs of M 100 grade with 0.03% Glass Fibers and 1.5% Steel Fibers

Figure 2(b). Failure pattern of High Strength Hybrid Fiber Reinforced Self Compacting Concrete Slabs of M 100 grade with 0.03% Glass Fibers and 1.5% Steel Fibers

Figure 2(c). Failure pattern of High Strength Hybrid Fiber Reinforced Self Compacting Concrete Slabs of M 100 grade with 0.03% Glass Fibers and 1.5% Steel Fibers

The load carrying capacity of high strength hybrid fibre reinforced self compacting concrete slabs of M100 grade is greater than that of zero percentage hybrid fibre HSSCC of M100 grade. The presence of glass fibres in glass fibre reinforced high strength self compacting concrete slabs is not much advantageous with respect to ductility. Due to the presence of higher percentage of steel fibres, the formation of cracks has been delayed considerably. Hence in the present study, it may be concluded that the presence of steel fibres has helped in imparting more ductility and better cracking behavior. The ultimate flexural load of the slab with steel fibre reinforced increases with the percentage of steel fibres. Load carrying capacity of hybrid fibre reinforced concrete slabs are on the higher side when compared with slab without Glass fibres.