Table 1. MDD, OMC, Soaked CBR, and UCS of Stabilized Soils

Efficient use of waste materials is a proven solution to the problems associated with their disposal. Fly ash is one such material produced from thermal power plants that requires a huge disposal area and creates environmental problems. Stabilization of weak soils with fly ash not only improves the engineering properties of soil, but also provide answers to the issues of fly ash disposal. This paper reports the results of laboratory investigation carried out on clayey soil stabilized with fly ash and hydrated lime. Effects of lime, fly ash and the days of curing studied on Unconfined Compressive Strength (UCS), California Bearing Ratio (CBR) and compaction parameters of the stabilized soil were also analyzed. An attempt was made for establishing a relationship between the tensile strength and compressive strength of the 56 days cured stabilized mixes. Brazilian Tensile Strength (BTS) of lime-fly ash stabilized soil at 56 days curing varied in the range of 22 to 143 kN/m2 and UCS from 143 to 2172 kN/m2 . Remarkable strength increase indicates that the clayey soils can productively stabilize with fly ash and hydrated lime.

Fly ash is obtained from the combustion of coal in the thermal power plants. It is produced in large quantity in many parts of the world. Annual production of fly ash in India is about 184 million tons per year, and also it increases day-by-day, leading to severe problems of their disposal and environment pollution. However, favourable properties of fly ash such as, low unit weight, high shear strength, low compressibility, insensitive to the moisture variations and pozzolanic properties play an important role in enhancing the engineering properties of soils. This will give an option for reusing fly ash as an industrial waste for improving soft soils performance results in an environment and economic benefit. Additionally, large-scale use of fly ash is possible only in geotechnical applications such as embankment, dam, earthfill, and in road constructions. Investigations related to soil stabilization with fly ash and lime were conducted by few researchers in the past (Sivapullaiah et al. 1995; Ghosh and Subbarao, 2006; Consoli et al. 2007; Sharma, 2012). The present study highlights the effect of stabilizers and curing periods on the compressive strength, bearing ratio and tensile strength of mixes. Also, an empirical equation was developed for estimating the tensile strength from UCS for stabilizing mixes at 56 days curing time.

The soil used was collected from Dighori area of Nagpur, Maharashtra, India. Test results show the specific gravity of soil solids 2.64, liquid limit 60.08%, plastic limit 24.55%, and plasticity index 35.53%. It has sand 8%, silt 38%, and clay 54%. As per IS 1498, the soil is classified as clay, with High Compressibility (CH). The Optimum Moisture Content (OMC), and Maximum Dry Density (MDD) of the soil was found to be 25.32% and 14.26 kN/m3 respectively. Unconfined Compressive Strength (UCS) of soil at OMC is 78.38 kN/m2 and soaked California Bearing Ratio (CBR) value is 2.30%.

Fly ash used in this investigation collected from the Koradi Thermal Power Station, Maharashtra, India belongs to class F according to ASTM C 618. Flyash properties are as follows; specific gravity 2.13, MDD 12.30 kN/m3 , OMC 28.49%, liquid limit 45.95%, and plastic limit 17.43%. Chemical constituents of fly ash determined at Indian Bureau of Mines laboratory on dry weight basis are as follows; SiO2 = 55.58%, Fe2 O3 =3.92 %, Al2 O3 =26.40%, CaO=6.71%, MgO= 0.59%, LOI= 3.68%, and others 3.12%.

Hydrated lime is used to stabilize the soil. The chemical composition of lime on dry weight basis is, SiO2 = 3.60%, Fe2O3 =1.66 %, Al2 O3 =0.14%, CaO = 69.6%, MgO = 1.62%, LOI = 0.88% and others 21.6%.

To study the effect of lime-fly ash on the Compressive Strength, Bearing Ratio and Tensile Strength of Stabilized mixes, on experimental program was carried out in different stages, such as:

During this investigation, Testing work was carried out on the 21 mixes. Fly ash mixed in a dry state with soil, and their weight ratios 10:0, 10:1.25, 10:2.5, 10:3.75, 10:5, 10:7.5 and 0:10 were adopted. The PH test result specifies 6% dose of lime as optimum, however for present experimental program, three lime doses 4%, 6%, 8% were considered on dry weight basis. Test specimens in a set of three are prepared at OMC and cured for 7, 28 and 56 days in desiccators and using gunny bags.

Test confirming to IS 2720 part 7 was conducted on all combinations and the results are tabulated in Table 1. A Marginal decrease in MDD and the increase in the OMC were observed in soil-lime mixes with lime increase, a trend like that is observed by the researchers in the past (Bell 1996; Khelifa 2011). Two possible reasons for MDD decrease, firstly, aggregation of particles due to Base Exchange reaction with lime affects the soil gradation, and Secondly, smaller drop in density is due to the soil particle replacement in a given volume of relatively low specific gravity lime particles (Ola, 1977). An increase in OMC with lime is due to the pozzolanic reaction between the clay and lime. Observations of compaction parameters, OMC and MDD for lime-fly ash stabilized soil mixes are similar to lime stabilization.

Soaked CBR tests performed on the mixes, confirm to IS 2720 part 16. Table 1 shows the test results of soil-lime and soil-lime-fly ash specimens cured and soaked for last four days at the end of the curing period. For lime alone, CBR increases with lime and curing period, however, reduces marginally for 8% lime. An observation indicates flyash dose up to 50% by weight further improves the CBR value of soil-lime mixes but, beyond 50%, the CBR value reduces.

As per IS 2720 part 10 guidelines, UCS test was performed on stabilized mixes. To comprehend the pozzolanic reaction effect on strength, the specimens were cured for 7, 14, 28 and 56 days in desiccators. Table 1 shows the UCS tests results of soil-lime and soil-lime-fly ash mixes at the end of desired curing periods. UCS of lime stabilized soil has increased due to lime availability for pozzolanic reaction. Test results depict that strength increases with a curing period for lime stabilized soils, but with 8% lime, UCS reduces marginally. With higher fly ash doses, UCS of stabilized mix reduces signifying that; fly ash does not contribute in attaining strength to the stabilized mixes.

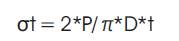

Direct tensile strength measurement test for stabilizing mixes is very difficult to execute, and thus Brazilian Tensile Strength is performed, which is an indirect tensile strength measurement test. Test is conducted as per IS 10082 test procedure on stabilized mixes of 80 mm diameter (D) and 40 mm thickness (t) [D/t ratio two]. Tensile strength is essential to know because the stabilized materials are often subjected to traffic movement, temperature difference, and differential settlement. Equation (1) is the required equation for tensile strength calculation, where P= load at failure, D= specimen diameter, t= specimen thickness;

On the basis of test results, the authors try to develop an empirical relation to estimate BTS from UCS for selected stabilized mixes. Variation of tensile strength with compressive strength is presented in Figure 1 for soil stabilized with fly ash-lime. A good relationship was observed between BTS and UCS from Figure 1, and Least Square Regression technique was adopted for the empirical equation to predict BTS from UCS value for a given mix.