Figure 1. Waste PET Bottle Granules

An experimental investigation has been carried out to study the feasibility of discarded Poly Ethylene Terephthalate (PET) bottle granules as fine aggregate in concrete. Mechanical strength and temperature studies have been conducted on 162 numbers of standard concrete specimens which are made with or without waste PET bottle granules as per relevant Indian standard code procedure. The waste PET bottle granules have been used as a substituting material in lieu of conventional fine aggregate in concrete ranging from 0 to 100% at an interval of 10%. The mechanical strength studied includes compressive strength, tensile strength and flexural strength at the age of 28 days. Temperature studies have been conducted on concrete cube specimens by exposing it to series of peak temperatures such as 300o C, 600o C and 900o C, to evaluate residual compressive strength. It has been found from test results that substitution of discarded PET bottle granules in place of conventional fine aggregate in concrete reduces compressive strength, tensile strength, flexural strength, residual compressive strength and density of concrete markedly, and the reduction in strength and density increases with increase in PET bottle granules content in concrete. Also, reduction in residual compressive strength increases with increase in temperature for specimens made with and without PET bottle granules in concrete.

Concrete will continue to be the leading construction material all over the world in view of its strength, durability, mouldability and low cost. Cement, fine aggregate (i.e. natural sand), coarse aggregate and water are the basic materials used in the production of concrete. These basic materials are fast depleting due to brisk construction activities and must be preserved for sustainable development of nation. In this direction, a number of attempts have been made in the past to identify appropriate alternate/substitute materials that can be used either partially or fully for making concrete without compromising concrete quality. Some of the substitute materials identified includes: (i) fly ash, silica fume, metakaolin, waste glass powder, rice husk ash, etc, for cement [9], [17], [24], [25], [29], [31]; (ii) crusher stone dust, copper slag, bottom ash, discarded PET bottle flakes, etc, for fine aggregate [3], [4], [6], [8], [19] , [26], [28], [30] and (iii) Broken tile waste, ceramic waste, brick bats etc, for coarse aggregate [7], [10], [18], [21], [22]. In India, approximately 40 million tons of solid waste is getting generated annually and is increasing at the rate of 1.5 to 2% every year. Plastics constitute 12.30% of total solid waste generated and is mostly from discarded PET bottles [26]. The discarded PET bottles are non-decaying waste material and will remain in earth for thousands of years by polluting environment. In addition, the non-decaying waste PET bottles contaminate soil and ground water, and also affect growth of vegetation on the surface of earth. Disposal of waste PET bottles is a rapidly growing problem and effective utilization of this waste alleviates both disposal and environmental problems to a great extent. Hence, in this present study an attempt has been made to explore the possibility of using waste PET bottle in the construction industry.

In the construction industry, discarded PET bottles are being used either by filling empty PET bottles with suitable filler materials and using them for construction of temporary/small scale structures, partition/non-loading bearing walls in buildings, as a filler material in the construction of flat roofs, etc. [2], [5], [20] or by grinding discarded PET bottles into smaller size fibers/pellets/flakes and using them as a substitute material for fine/coarse aggregate in concrete. Few studies conducted in the recent past by various researchers on strength and other engineering properties of concrete using waste PET bottle as a substitute material for traditional fine/coarse aggregate in concrete is presented.

In the study conducted by Sahil Verma and Sahil Arora [27], waste PET bottle fibers were used as a substitute material for sand in concrete. Compressive strength of concrete was found at the age of 7, 14 and 28 days after replacing 0, 2, 4 and 6% of sand by waste PET bottle fibers and found that the compressive strength of concrete increased up to 2% substitution level and beyond this level the strength of concrete decreased.

In the work of Nabajyoti Saikia and Jorge de Brito [23] three types of recycled PET aggregates viz. coarse flakes (PC), fine fraction (PF) and plastic pellets (PP) were used instead of sand in concrete. Compressive, tensile and flexural strengths of concrete were found at 7, 28 and 91 days using different replacement levels of 0, 5, 10 and 15% and observed that the development of strength of concrete containing all three types of PET aggregates is similar to conventional concrete, though this incorporation lowered strength of the resulting concrete. However, early strength gain (i.e. 0 to 7 days) relative to strength determined after 91 days of curing for most of the concretes containing PET aggregates is higher than that observed for conventional concrete. Also, incorporation of PET aggregates in concrete increases toughness behaviour of concrete. For a given amount of PET addition, the order is PC > PF > PP, which indicates that adding large flake PET aggregates can have more effect on the improvement of toughness behaviour of resulting concrete than concrete with other two types of fractions.

In the investigation carried out by Zainab Z. Ismail and Enas A. AL-Hashmi [32], recycled waste plastic was used as fine aggregate in concrete. Waste plastic of fabriform shapes was used as a partial replacement material for natural sand and the various replacement levels considered are 0, 10, 15 and 20%. Test results indicated that the introduction of waste plastic of fabriform shapes arrested the propagation of micro cracks in concrete. However, other engineering properties like strength, workability and density of concrete decreased as the waste plastic content in the concrete increased at all ages of testing (i.e. 3,7,14 and 28 days).

Adel Sadeghifar and Mohammad Reza Sohrabi [1] studied compressive and tensile strengths of concrete using crushed PET bottle waste of 0 to 5 mm size as a replacement material for fine aggregate and 5 to 20 mm size as a replacement material for coarse aggregate in concrete. The various replacement levels considered are 0, 5, 10 and 20%, and strength and other engineering properties of concrete were evaluated at 28 days. The study indicated that incorporation of PET bottle waste of both sizes in concrete reduced density, specific gravity and compressive strength. Nevertheless, tensile strength of concrete increased, when PET bottle waste of 0 to 5 mm was introduced as a replacement material for sand in concrete.

The work of K.Ramadevi and R. Manju [26] investigated strength properties of hardened concrete by replacing traditional fine aggregate with waste PET bottle fibres. The various replacement levels considered are 0, 0.5, 1, 2, 4 and 6%. Compressive and tensile strengths of concrete samples made with waste PET bottle fibres indicates increase in strength with increase in plastic aggregate content in concrete up to 2% replacement level. Beyond this level (i.e. at 4 and 6%), these strengths decrease. However, flexural strength of concrete samples made with waste PET bottle fibers is increased with increase in PET bottle content from 0 to 6%. But beyond this level, the incorporation of PET bottle fibers might decrease the flexural strength because the strength obtained remains almost same at 4% and 6% replacement levels.

Some of the past research works encourage the use of consumed PET bottle in construction industry either as a sand-substitution aggregate in cement concrete or as a building material for construction of non-load bearing walls in buildings and appears to offer low-cost lightweight material. It would also help to resolve solid waste management problems created by plastics production. Hence, in the present study, the use of waste PET bottle granules has been investigated as a sand-substitution material in concrete and substitution levels ranging from 0 to 100% at a constant interval of 10% have been considered. Test results obtained in this investigation are presented and discussed in this paper.

Following materials were used in the present experimental investigation:

53 grade Ordinary Portland Cement (OPC) having a specific gravity of 3.15, fineness (on 90 micron sieve) of 3.5%, soundness of 1.5 mm and conforming to requirements of IS:12269 [12] .

Locally available natural fine aggregate (i.e. river sand) having a specific gravity of 2.6, fineness modulus of 2.37, bulk density of 17.26 kN/m3 and conforming to grading zone - II as per IS: 383 [13].

Crushed granite coarse aggregate of 12.5 mm maximum size having a specific gravity of 2.64, fineness modulus of 7.20 and bulk density of 16.92 kN/m3.

Potable water available in the college premises having a pH value of 7.8 and conforming to requirements of water for concreting and curing as per IS: 456 [14].

Waste PET bottle granules (obtained by grinding discarded PET bottles) having a maximum size of 4.75 mm, specific gravity of 2.43, fineness modulus of 6.70 and bulk density of 9.74kN/m3 . Figure 1 shows waste PET bottle granules obtained after grinding discarded PET bottles and Figure 2 shows PET bottle grinding machine.

Figure 1. Waste PET Bottle Granules

Figure 2. PET Bottle Grinding Machine

In the present experimental work, a concrete of M30 grade was considered. Mix design for the above grade of concrete was carried out as per IS 10262 guidelines [11] and the mix proportion obtained was 1: 1.33: 2.81: 0.45 (cement: sand: coarse aggregate: water) with a cement content of 425.78 kg/m3 of concrete. Using the above mix proportion, a total of 162 number of standard size concrete specimens were cast with and without waste PET bottle granules to evaluate:

(i) mechanical strength by conducting compressive strength, tensile strength and flexural strength tests, and

(ii) temperature effect by exposing to different levels of elevated temperature such as 300o C, 600o C and 900o C.

During casting, fine aggregates in concrete were removed, and in its place, waste PET bottle granules were substituted. Various substitution levels considered in the present study are 0, 10, 20, 30, 40, 50, 60, 70, 80, 90 and 100%. Different test specimens cast include 33 number of 100 x 100 x 100 mm size cubes for 28 days compressive strength; 33 number of 150 mm diameter and 300 mm long size cylinders for 28 days split tensile strength; 33 number of 100 x 100 x 500 mm size prisms for 28 days flexural strength and 63 numbers of 100 x 100 x 100 mm size cubes for temperature studies at 300o C, 600o C and 900o C (i.e. 21specimens for each temperature). Table 1 shows detail of specimen cast in the present study using various combinations of sand and waste PET bottle granules in concrete. In order to protect electric furnace from possible damage due to melting of PET bottle granules during temperature studies, specimens containing 70% and higher dosages of PET bottle granules were not considered (vide Table 1).

Before casting, machine oil was smeared on inner surfaces of moulds. Concrete was mixed for about two minutes in a tilting type laboratory mixer machine until uniform mix was obtained and it was poured into the moulds in three layers of equal height. Each layer of concrete was compacted for about 30 seconds in a table vibrator and finished using a trowel. The specimens were allowed to dry at room temperature for about 24 hours in a well-ventilated shed. Air-dried specimens were removed from moulds and were cured under water in a curing tank for 28 days. For strength studies, water-cured specimens were taken out of curing tank just before test, surface dried and then tested for compressive, tensile and flexural strengths. Compressive and flexural tests were conducted by following IS 516 code procedure [15] whereas split tensile test was conducted by following IS 5816 code procedure [16]. A compression testing machine of 2000 kN capacity was used to conduct compression and split tension tests, an universal testing machine of 400 kN capacity was used to conduct flexure test. For temperature studies, water-cured specimens were taken out of curing tank and air-dried for a period of about one week in a well-ventilated shed at room temperature under normal environment. This was done to avoid possible explosion of specimens when heated at elevated temperature. Air-dried specimens were exposed to a series of peak temperatures at 300o C, 600o C and 900o C in an electric muffle furnace for 2 hours duration. These peak temperatures were reached by increasing temperature at the rate of 10oC per minute. After heating it to the above peak temperatures for specified duration, the specimens were allowed to cool naturally to room temperature and then tested for residual compressive strength. An electric muffle furnace of 1000o C capacity was used for temperature studies. Figures 3a to 3d show snapshots taken during testing of specimens reported in this study.

Figure 3. Snapshots of Specimens during Testing

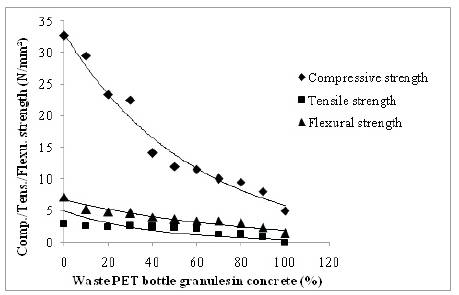

Results of strength and temperature studies for specimens made without waste PET bottle granules (i.e. control specimens), and for specimens made with waste PET bottle granules are presented in Table 2. Besides, unit weight (i.e. weight per unit volume) results for specimens which are made with and without waste PET bottle granules are also presented in the table. The results reported is the average of three specimens. The results presented in Table 2 are also illustrated in Figures 4 to 6 for quick and better understanding of the results. The effect of substitution of waste PET bottle granules in place of fine aggregate in concrete on strength, temperature studies and unit weight are discussed in the succeeding sections.

Figure 4. Plot of Strength Versus PET Bottle Granules

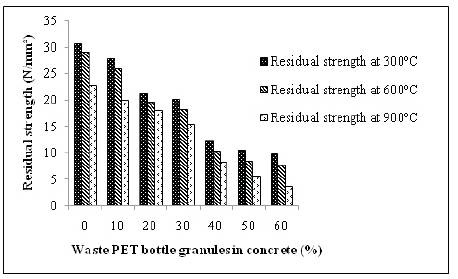

Figure 5. Plot of Residual Strength Versus PET Bottle Granules

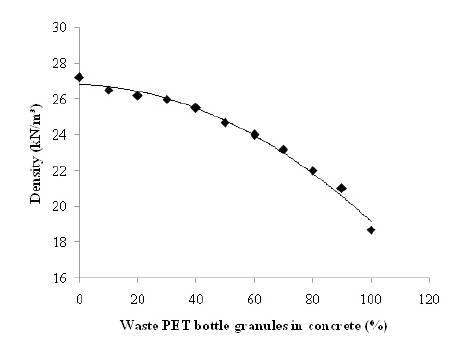

Figure 6. Plot of density versus PET bottle granules

A close observation of test results given in Table 2 indicates that, substitution of waste PET bottle granules reduces compressive, tensile and flexural strengths of concrete. The reduction in strength may be attributed to lack of adequate bond between cement matrix and granules of waste PET bottles. The reduction in compressive, tensile and flexural strengths at 50% substitution level is 63.19%, 21.95% and 50%, respectively. Similarly, the reduction in compressive, tensile and flexural strengths at 100% substitution level is 84.66%, 97.57% and 80.55%, respectively. This indicates that, the possibility of producing concrete by substituting granules of discarded PET bottles as fine aggregate in concrete either partially or fully without compromising the quality of concrete is not feasible.

It can be observed from test results given in Table 2 that substitution of waste PET bottle granules reduces residual compressive strength of concrete at 300o C, 600o C and 900o C. The reduction in residual compressive strength might be due to the reason cited above i.e. poor bond between cement paste and granules of waste PET bottles. The reduction in residual compressive strength at 30% substitution level is 34.43%, 37.37% and 32.60% at 300o C, 600o C and 900o C, respectively. Similarly, the reduction in residual compressive strength at 60% substitution level is 67.87%, 73.36% and 84.14% at 300o C, 600o C and 900o C, respectively. This indicates that, the quality of concrete gets affected markedly due to rise in temperature as well as substitution of waste PET bottle granules in concrete.

It can be seen from test results given in Table 2 that substitution of waste PET bottle granules reduces density (i.e. unit weight) of concrete. This is due to the fact that density of waste PET bottle granules is 9.74 kN/m3 and density of sand is 17.26 kN/m3 . This shows that, density of waste PET bottle granules is 43.67% which is lower than density of sand. Thus, the substitution of low density PET bottle granules in concrete leads to reduction in density of concrete. The reduction in density of concrete at 50% and 100% substitution levels are 9.19% and 31.25%, respectively. Therefore, it is evident that, substitution of low density waste PET bottle granules in place of conventional fine aggregate in concrete, causes considerable reduction in density of concrete, and makes the concrete light-weight.

Based on the experimental investigation conducted in this study, the following conclusions can be drawn

i. Substitution of PET bottle granules in place of conventional fine aggregate in concrete reduces strength and density of concrete in a marked manner. The reduction in compressive strength, tensile strength, flexural strength and density at 50% substitution level is 63.19%, 21.95%, 50% and 9.19% respectively, and the corresponding value at 100% substitution level is 84.66%, 97.57%, 80.55% and 31.25% respectively.

ii. Quality of concrete gets affected considerably due to rise in temperature as well as substitution of PET bottle granules in concrete. The reduction in quality is measured in terms of residual compressive strength, for the temperature of 300o C, 600o C and 900o C at 30% substitution level is 34.43%, 37.37% and 32.60% respectively, and the corresponding values at 60% substitution level is 67.87%, 73.36% and 84.14% respectively.

iii. From this investigation, it is evident that it is not feasible to produce concrete without affecting its quality by substituting discarded PET bottle granules in conventional fine aggregate in concrete and utilization of waste PET bottle granules in concrete is not an effective way for solving disposal and environmental problems associated with discarded PET bottles.