Figure 1. Surface texture of laterite blocks before dressing and after dressing

Utilization of laterite soil as building material has become a source of concern to all due to its effect on the social, economy and environment factors. Rising population in developing nations like India has led to the demand and effective utilization of these gifted materials in construction of houses, roads and others. This paper is aimed at examining the properties of laterite soil for sustainable buildings. Hence in this experimental investigation, an attempt has been made to study the suitability of laterite soil in the preparation of compressed laterite bricks with the addition of different percentages of cement. Dry compressive strength, wet compressive strength and water absorption were found out on the prepared specimens. The results show that the compressed laterite bricks of laterite soil with 7% addition of cement possess the maximum compressive strength with less absorption of water.

Over the past 40 to 50 years, there has been an increasing interest in the use of stabilized compressed earth blocks for residential construction [5]. They maximize the use of locally available materials; require relatively simple construction methods, whilst offering favourable thermal and acoustic insulation properties [6]. Environmental benefits include reduced energy consumption in production and a lessening demand for non-renewable resources [8, 12]. Earth building is not a characteristic only of the Third World [9]. Earth walled houses can be found in France, Germany, New Zealand and in some regions of Australia about 20% of the houses are built with walls of unfired earth [10,11] . In western countries, thousands of luxury earth homes have been built in the last few decades. These have showed the feasibility of this material as a natural building material 13. The strategy will have the potential to reduce costs, conserve energy, and minimize waste. On the other hand, unfired clay materials provide a sustainable and healthy alternative as a replacement to conventional masonry materials [1, 12].

Laterite stone blocks have been used for masonry purposes in many tropical regions where they are readily available. In the western coastal regions of India, the abundance of laterite had been utilised for the construction of permanent structures, which includes monuments like forts, temples, churches and residential buildings. Laterite being locally available, cost effective, energy efficient and environment friendly building material in the Malabar region of Kerala and Dakshin Kannada and other parts of Karnataka, makes it a material of choice for the present day constructions. The use of mobile rotary saw machine for laterite quarrying, since 1993, resulted in large-scale production and use of laterite ashlars, in the construction industry. In spite of the advent of many new materials, laterite continued to be the predominant masonry material in the Malabar region of Kerala and coastal Karnataka [7, 9].

This paper was aimed at examining the properties of laterite soil for the production of sustainable and suitable building material.

The main aim of this experimental investigation was to stabilize the laterite soil by using different percentage of stabilizer and to check suitability of the same for construction purpose.

The disturbed laterite soil was collected from the laterite quarries of Hosanagar, Chandragutti, Thyagarti and Anandapura of Shimoga district, Karnataka. The residue (disturbed) laterite soil available after dressing of natural laterite building blocks was used. It was reddish brown in nature and classified as A-2-7(0) using AASHTO soil classification system and GP by the United soil classification system [Figures 1 and 2]. The physical and chemical properties of tested laterite soil are given in Tables 1and 2.

Cement used in this investigation was Ordinary Portland Cement (OPC-43 grade), which satisfies the requirements of IS: 8112-1989 specifications [2]. The physical properties of tested cement are given in Table 3.

Ordinary potable water free from organic content, turbidity and salts was used for mixing and for curing throughout the investigation.

Figure 1. Surface texture of laterite blocks before dressing and after dressing

Figure 2. Residue laterite soil available after dressing and passed through 4.75mm IS sieve for production

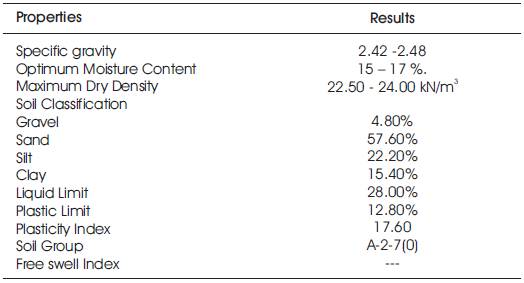

Table 1. Physical Properties of Laterite soil

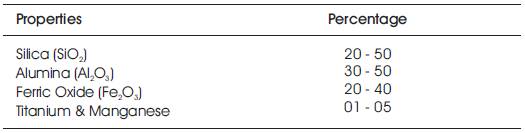

Table 2. Chemical Properties of Laterite soil

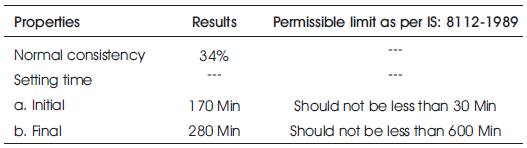

Table 3. Physical Properties of Ordinary Portland Cement-43 grade

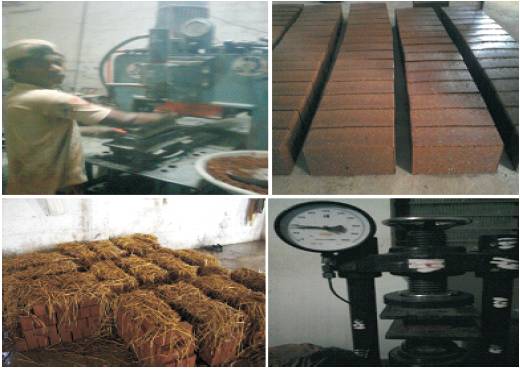

For the production of pressure moulded laterite brick, 4 kg of laterite soil was taken for each brick. Based on the size of mould, soil was spread on clean and flat hard surface. To this, known percentage of stabilizer (cement) was added on weight basis followed by thorough hand mixing to get uniform mix. Finally potable water (calculated as per optimum moisture content) was added to the dry mix by sprinkling. Soil was mixed with water gently but quickly and care was taken to avoid formation of lumps in it during mixing. Entire mixing was carried out in an enclosed area and nearer to the compressing device, to avoid the evaporation of moisture content in the mix and to maintain the workability of wet mix. As soon as the wet mixture was prepared, the homogeneous mix was transported to compressing machine for pressing. The wet mix was placed in known size of the mould and compressed through hydraulic pressure. After compaction, the mould was taken out from the machine by ejection process. Further, brick was lifted carefully from the mould base plate and placed in an open dry place. Since the bricks are not burnt and as it has less initial handling strength, extra care was taken while lifting, placing and stacking of the bricks.

The Hydraulic press paver block and brick making machine was used for the production of bricks. The bricks produced will be having uniform dimension of 230mm x 100 mm x 75mm. A net load of 10 tonne was applied over cross sectional area of 23000 mm2 of the brick. Since there was a constant compaction effort on all the bricks, there was less variation in strength characters of bricks that are produced and is the expected advantage of this research work. Because of heavy compaction, the difficulty of brick ejection from the mould may occur due to generation of suction pressure at the corners of mould [Figure 3].

Figure 3. Production of laterite stablized soil bricks, curing and testing

The curing method used in this investigation was “Hay curing”. The paddy straw was spread over bricks, such that it completely covers them. The bricks were cured by sprinkling water gently on straws, thrice a day. The curing was continued for 7, 14, 21 and 28 days based on testing [Figure 3].

The following tests were conducted on pressure moulded laterite bricks:

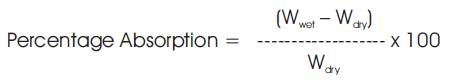

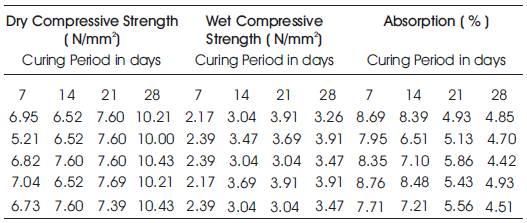

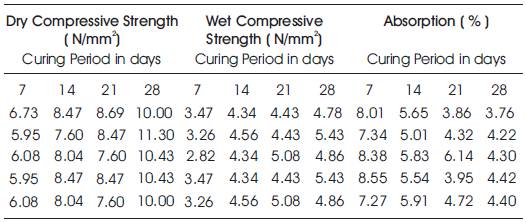

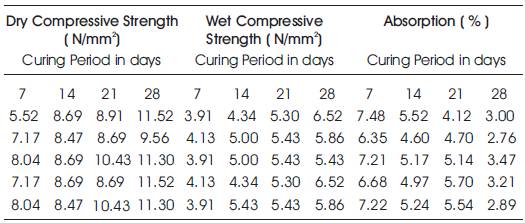

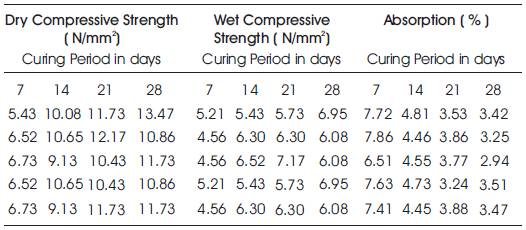

The bricks were dried in sunshine for 2 to 3 days, to remove moisture content inside the bricks completely for dry compression test. To conduct wet compression test, completely dried bricks were immersed in water for a duration of 24 hours. The bricks were removed from water and the wetted surface was wiped out cleanly for test. For each average result, five bricks per set were taken and the bricks were tested for compression as per IS: 3495 (Part 1) 1992 specification [3] on each specimen. The test results are tabulated in Tables 4 to 10.

The dry weight (Wdry) of the bricks was taken and then it was immersed completely in clean potable water for 24 hours. After 24 hours, the bricks were removed from water and the wet surface was wiped out with a clean cloth and the weight was taken (Wwet) as per IS: 3495(Part 2)-1992 specification. The absorption was given by the relation,

Five bricks per set were taken and the average of five results was considered as 'Water absorption' of the bricks. The results are tabulated in Tables 4 to 10.

Based on the experimental investigation, the following observations and discussions were made in comparison with conventional burnt bricks.

Table 4. Compressive strength and water absorption test results of compressed laterite soil bricks (A4) with the addition of 4% of cement for various days of curing

Table 5. Compressive strength and water absorption test results of compressed laterite soil bricks (A5) with the addition of 5% of cement for various days of curing

Table 6. Compressive strength and water absorption test results of compressed laterite soil bricks (A6) with the addition of 6% of cement for various days of curing

Table 7. Compressive strength and water absorption test results of compressed laterite soil bricks (A7) with the addition of 7% of cement for various days of curing

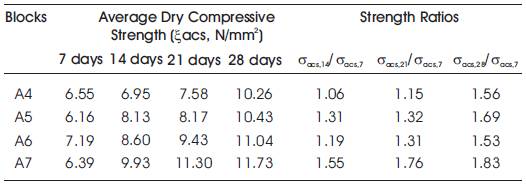

Table 8. Average dry compressive strength and strength ratios test results of compressed laterite soil bricks for various percentage of cement and days of curing

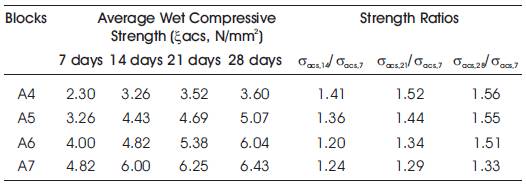

Table 9. Average wet compressive strength and strength ratios test results of compressed laterite soil bricks for various percentage of cement and days of curing

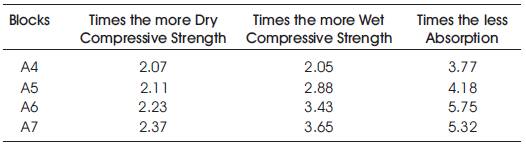

Table 10. Test results of compressed laterite soil bricks in comparison with conventional bricks

Based on the experimental investigations, the following conclusions can be drawn in comparison with conventional burnt bricks.