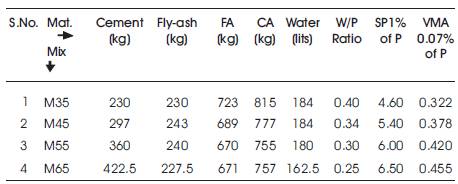

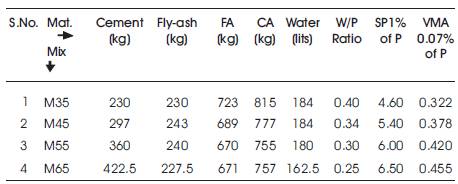

Table 1. Mix proportions for SCC mixes

This paper presents an experimental study on the durability properties of steel fiber reinforced self compacting concrete[3, 14]. Experiments were conducted to study the effect of steel fibers on weight loss (in acidic and alkaline environment) and permeability of steel fiber reinforced self compacting concrete (SFR-SCC) [5]. The variables considered were grade of concrete (M35, M45, M55 and M65) and fiber content (0, 0.5 and 1 percent). The ordinary Portland cement and fly-ash[6] were used as the main ingredients. It was observed that the weight loss reduced and chloride ion penetration increased with the increase in the value of fiber content, further, it was also noticed that the value decreases with the increase in the value of compressive strength of SCC.

In recent years many researchers have established that the use of supplementary cementitious materials like fly-ash, blast furnace slag, silica fume, metacolin, rice husk ash etc can improve various properties in fresh[10] and hardened states of concrete[12,13], as well as curb the rise in construction costs.

Self compacting concrete[4, 11] was developed in Japan by Okamura in the late 1980s to be mainly used in highly congested reinforced concrete structures in seismic region and to overcome the problem of shortage of skilled labourers for the efficient compaction of concrete. Self compacting concrete in general contains a large volume of powder materials, a super-plasticizer and viscosity modifying admixtures. The high powder content is often supplemented by mineral admixtures such as fly ash, slag etc. The use of mineral admixtures could increase the slump flow[10] of the concrete mixture without increasing its cost. The use of fly ash[6] also reduces the demand for cement, fine fillers and sand that are required in self compacting concrete. Moreover, the incorporation of fly ash also eliminates the need for viscosity enhancing chemical admixtures. The lower water content of the concrete leads to higher durability, in addition to better mechanical integrity of the structure. Also the use of fly ash improves rheological properties[10] and reduces thermally induced cracking of concrete due to the reduction in the overall heat of hydration.

This paper outlines the results of research project aimed at producing and evaluating the durability performances of self compacting concretes[7] incorporating randomly distributed steel fibers. The main objective of the present investigation was to study the durability performances of self compacting concretes over a wide range of concrete strengths with varying dosages of fibers. The durability properties[15] were investigated through micro structure related properties of concrete such as, permeability[5] and weight loss due to chemical attack[1,2].

A durable concrete is the one that performs satisfactorily in the working environment during its service period. Review of literature indicates that durability of SCC largely depends upon the type of mineral admixtures used. Increased risk of drying shrinkage of SCC is likely due to the rich powder content and lower coarse aggregate content in SCC. Though lot of literature is available on durability parameters, an attempt has been made to study and report about the effect of fiber content and water powder ratio on the permeability and weight loss (due to chemical attack) of fly ash based SCC.

Ordinary Portland Cement (OPC) of 53 grade confirming to IS: 12269 – 1987 was used for the present experimental investigation. The specific gravity, compressive strength and the specific surface area of the cement were noted to be 2.9, 54N/mm2 and 3200cm2 /gm respectively.

Clean river sand conforming to IS 383:1970 was used. The specific gravity and the fineness modulus were noted to be 2.40 and 2.932 respectively.

Crushed granite coarse aggregate of particle size passing through 12.5mm and retained on 4.75mm sieve having “rounded” shape and confirming to IS: 2386 – 1963 was used for the present investigation. The specific gravity and the fineness modulus were noted to be 2.60 and 6.048 respectively.

Potable tap water free from any injurious amounts of oils, acids, alkalies, sugar, salts and organic materials available in the laboratory with pH value of 7.0±1 and confirming to the requirements of IS: 456 -2000 was used for mixing concrete and curing the specimens as well.

The fly-ash confirming to IS: 3812 – 1981 was used in the present investigation. The specific gravity and the fineness were noted to be 2.25 and 5770 cm2/gm respectively.

Binding wire commercially available in the local market was used as fiber in the present investigation. The diameter of the wire was found to be 0.925mm and a constant aspect ratio of 40 was used throughout the work.

The modified polycarboxylic ether based super plasticizer which is yellowish in color and free flowing liquid with relative density 1.09±0.01 at 250C, pH value as 7.0±1 and chloride ion content less than 0.2% was used as super plasticizer.

An admixture which is colorless free flowing liquid having specific gravity of 1.01±0.01 at 25 degree Celsius, pH value as 8.0±1 and chloride content nil was used as viscosity modifying agent.

Mix proportions [8, 11] for M35 to M65 grades of SCC are arrived based on the trials and same are presented in Table 1.

Table 1. Mix proportions for SCC mixes

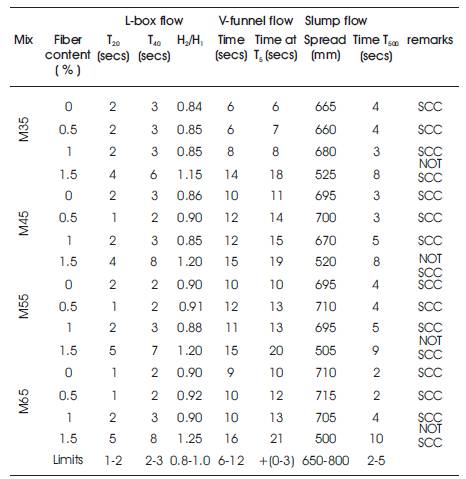

The following tests were conducted to characterize the workability properties[10] of SCC for the final acceptance of the SCC mix proportions.

Slump Flow TestThe slump flow is used to assess the horizontal free flow and the filling ability of SCC in the absence of obstructions. It is recommended to maintain slump flow value as 650 to 800 mm.

T50cm Slump Flow Test:This test is used along with slump flow test to assess the flowability of SCC.

V-Funnel Test:This test is used to determine the filling ability, flow-ability and segregation resistance of SCC.

L-Box Test:This test assesses the flow of concrete in the presence of reinforcement obstructions.

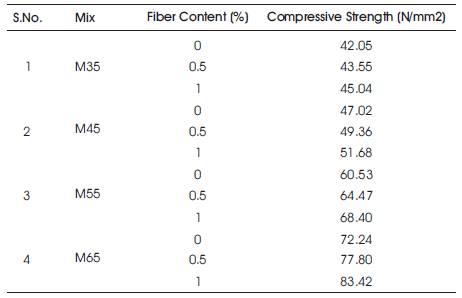

Compressive strength[9] is defined as the ability of the material to resist compressive stress without failure. After the required period of curing the cube specimens of 100mm size, they were removed from the curing tank and cleaned to wipe off the surface water. The specimen cubes were tested in accordance with IS:516-1969. The testing was done on a digital type Compression Testing Machine (CTM) of 2000 kN capacity.

The chloride ion present in the concrete can have harmful effect on concrete as well as on the reinforcement. In the first case, chloride ion penetration results in concrete swelling. This causes slight reduction of concrete strength. In the second case, presence of chloride ions near the reinforcement steel makes it vulnerable to corrosion.

The chloride permeability test was conducted to assess the concrete quality as per ASTM C 1202. The apparatus consists of a regulated D.C. power of 60 volts which can be adjustable to ± 10% by an adjustable potentiometer. The digital LCD display indicates the voltage available across the concrete specimen under test. The whole setup is electrically operated. Besides, current flowing through each diffuser cell can be monitored by microcontroller with LCD display. The current readings are noted down automatically by the microcontroller.

The diffuser cells are made up on non-corrosive chamber as per the standards with a thickness of 50mm and of 150mmx150mm size. The outer groove is machined for 103mm diameter for a depth of 6mm to keep the sample specimen in its place. The inner groove is fixed with a mesh brass sheet and a brass mesh which will terminate through a copper lead to the external terminal for easier power connections. Cylindrical disc shaped concrete test specimen 100mm dia X 50mm thickness cut from a cylinder with 100mm dia X 200mm height are used for chloride permeability studies as per ASTM C-1202.

The NaCl solution with a concentration of 2.4M is filled in one of the two diffusion cell chambers while in another chamber 0.3M NaOH solution is taken. The chloride ions were forced to migrate through the centrally placed vacuum saturated concrete specimen under an impressed DC voltage of 60 volts. The chamber containing NaOH solution is connected to the positive terminal of the 60 volts DC supply and the chamber containing NaCl solution is connected to the negative terminal of the DC supply. The diffuser cells are attached in such a way that they would accommodate both the solutions of NaOH and NaCl approximately 250ml by volume.

The technique is based on the principle that charged ions, - such as chloride (Cl ), will be accelerated in an electric field towards the pole of opposite charge. The ions will reach terminal velocity when the frictional resistance of the surrounding media reaches equilibrium with the accelerating force. This is the basis of electrophoresis, which is utilized in many chemical and biological studies.

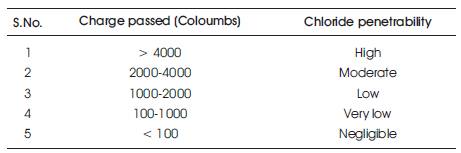

A DC power supply is used to apply a constant voltage between the copper screen and the steel reinforcement. The total current flowing between the mesh and the reinforcing bar over a period of six hours is then measured. The total electric charge (in coulombs) is computed (indicating the degree of resistance of the specimen to chloride ion penetration) and can be related to the chloride ion permeability[5] of the concrete as per ASTM C 1202-94 assessment criteria as shown in Table 2.

In addition, the resistivity or conductivity can also be determined from the initial current reading, since the resistance of the disc can be calculated immediately from Ohm's law

R = V/I

Where 'R' is resistance, 'V' is voltage and 'I' is current.

The resistivity is determined from:

Resistivity = RA/l

Where 'A' is area of the disc and 'l' is thickness of the disc.

The durability of SFR-SCC was tested for resistance against mineral and organic acids[1] such as hydrochloric acid, sulphuric acid[2], and sodium sulphate. The response of chemical attack on various grades of concrete was studied by observations on loss in weight. For conducting these tests, concrete cubes of size 100mm x 100mm x 100mm were cast. The cubes thus cast were immersed in water for 28 days for curing. After that they were immersed in 5% solution of hydrochloric acid, 5% solution of sulphuric acid and 10% solution of sodium sulphate for different periods of 28, 56 and 90 days, and deterioration was observed by recording loss in weight.

Table 2. ASTM C 1202-94 assessment criteria on RCPT results

The results of the workability tests on fresh concrete, compression test on 100mm size cube, chloride ion penetration in SFR-SCC mixes and weight loss analysis due to chemical attack are presented in Table 3, Table 4, Table 5 and Table 6 respectively. The results are also presented by means of graphs and charts as shown in Figure 1 to Figure 4.

The mix proportions for M35 to M65 grades of SCC are arrived based on the workability tests carried out as per the guidelines given in EFNARC. In all the four mixes used herein for investigation purpose, the quantities of VMA and SP adopted are 0.07% and 1% of powder content respectively. The quantity of fly ash used is in the range of 227 – 243 kg per cubic meter of concrete.

Table 3. Properties of fresh concrete

Table 4. Compression test results of SFR-SCC mixes

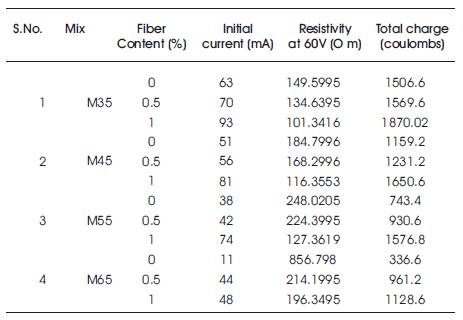

Table 5. Rapid chloride penetration test results of SFR-SCC mixes

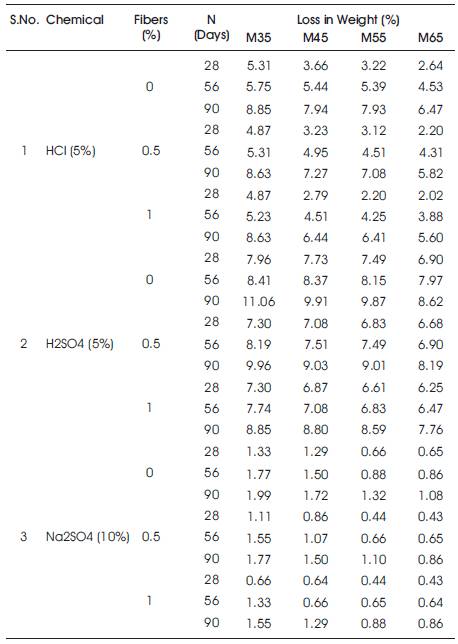

Table 6. Weight loss results of SFR-SCC mixes

Table 3 gives the results of various tests conducted on fresh concrete mixes to assess the self compacting properties. The concrete with a maximum of 1 percent fiber content exhibits all the properties of SCC. It was noticed that the fibers that are long and large fractious were found to ball up during the mixing process. The process called 'balling' affects the workability and strength characteristics of concrete. The concrete with 1.5 percent fiber content was tested for SCC properties and a clear blockage in L-box test and V-funnel test were noticed. Further, a segregation of materials was observed in slump flow test also.

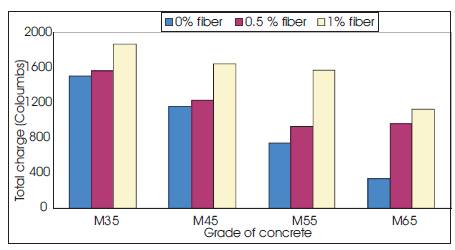

Figure 1 Rapid chloride penetration test results of SFR-SCC mixes

Accelerated chloride permeability test was conducted on the specimens of SFR-SCC mixes. The total charge passing in 6 hrs as a measure of the chloride permeability is presented in Table 5. The results are also presented in Figure 1. The chloride ion permeability limits suggested by ASTM C 1202 are shown in Table 2 and the experimental results were compared with these limits. It can be seen that all the mixes showed less than 2000 Coulombs total charge passing and these were assessed as “low” chloride permeability concretes as per ASTM C 1202 – 94 assessment criteria. This clearly indicates that the high volume fly ash self compacting concrete mixes performed much better with respect to chloride penetrability.

The resistivities calculated by considering the initial current at 60V potential also followed a reverse trend with an increase in replacement percentage of fly ash. From Table 5, it can be seen that as initial current increases, the total charge increases and with increased resistivity, the total charge decreases.

The chloride ion penetration depends on the chloride binding capacity of the constituent materials. Usually chlorides penetrate in concrete by diffusion along water paths or open pores. Some of these chlorides can react with the cement compounds, mainly tricalcium aluminates (C3A), forming stable chloro-complexes. The excess chloride that is free leads to the initiation of the corrosion process. The presence of fly ash leads to an increase in the amount of C3A due to the higher amount of alumina present in the mix and to an increase in the content of calcium silicate hydrate that is found in the pozzolanic reactions. Thus, the chloride binding capacity of concrete tends to increase with fly ash addition and consequently less free chloride is available to initiate the corrosion process.

It was noted that the chloride ion penetration increases with increase in fiber content and decreases with strength of the concrete. The decrease in penetration is mainly due to increase in powder content and decrease in water powder ratio.

The percentage loss in weight of SFR-SCC mixes due to chemical attack[1,2] is noted and is reported in Table 6. It is noted that the loss in weight in 5%HCl, 5%H2SO4 and 10%Na2SO4 varies from 2.02 – 8.85%, 6.25 – 11.06% and 0.43 - 1.99% respectively. It is observed that the percentage loss in weight increases with respect to contact period and decreases with increase in fiber content. The SFR-SCC will lose its weight when it comes in contact with the acidic and alkaline solutions. The loss is reduced by increasing the fiber content of SFR-SCC. The gypsum that is formed due to the reaction of acidic and alkaline solutions with hydrated cement gets washed out easily, resulting in loss in weight of the SFR-SCC. However, it was noted that the addition of fiber content decreased the loss.

1. The mix maintains self-compactability for fiber content up to 1% with an aspect ratio (of fibers) of 40.

2. The chloride ion penetration decreases with the strength of the mix and increases with the fiber content. For SFR-SCC mixes of M35 and M45 grades with 0%, 0.5% and 1% fiber content, the chloride ion penetration is noted to be 'low' as per the assessment criteria. For SFR-SCC mixes of M55 and M65 grades with 0% and 0.5% fiber content, the chloride ion penetration is noted to be 'very low' whereas it is noted to be 'low' at 1% fiber content.

3. In acidic and alkaline solutions, the weight loss decreases with increase in the fiber content. The weight losses are, 2.02 – 8.85%, 6.25 – 11.06% and 0.43 – 1.99% in 5%HCl, 5%H2SO4 and 10%Na2SO4 respectively.