Figure 1. Transparent concrete partition wall

The transparent concrete is one of the greatest discoveries in construction world. Nowadays, as theatricality with durability is the major requirement for any structural element, transparent concrete meets both the criteria. The transparent concrete is produced from fine grained concrete and translucent fibers casted in layer. Because of the small amount of fabric and solidity, it is similar to high strength concrete, almost free energy loss and light penetration through optic fibers makes to see light, shadow and colors. So it is highly useful in skyscrapers and for decorative purposes. It is a combination of optical fibers and concrete. A wall made of transparent concrete has the strength of traditional concrete but thanks to an embedded array of optical glass fibers, which lets in the view of the outside world, such as the shadow of trees, or passersby, that are displayed inside the building. It is a bit cheaper and one of the major advantages of this concrete is that it is eco-friendly, aesthetic and saves energy too. As the height of the building increases or there are many skyscrapers within a confined area, use of ordinary concrete which is very dense, make rooms dark which may have ill effects in the building. Hence, transparent concrete can be used which allows light to pass through it. White or colorful illumination elements can be utilized to create special light and color effects. The phenomenon of light transmitting concrete in the form of widely applicable new building materials is accepted.

There are various types of concrete for different applications that are created by changing the proportions of the main ingredients. The mix design depends on the type of structure being built, how the concrete will be mixed and delivered, and how it will be placed to form the structure. Concrete sometimes has a bad reputation as a harsh, rigid, cold-to-the-touch and straight-edged material. Litracon is doing a great deal to change that image of concrete through a score of creative and sustainable applications for their patented lighttransmitting concrete. Filled with optical fibers that run from one end of a poured piece of concrete to the other, these prefabricated blocks and panels effectively transmit light from one side to the other [1]. Colors and light remain remarkably consistent from end to other end, but with a natural variation from the pouring process that actually softens the effects considerably. The fibers can transmit light to over 50 feet and, as they occupy only a small percentage of the total concrete block or panel, they do not significantly affect the structural capabilities of the poured pieces. One could imagine all kinds of artistic as well as functional applications for this new-and-improved form of concrete. Day lighting possibilities abound and all with potentially much lower heat loss and cost and with greater durability. Perhaps, best of all, it puts another broadranging, highly versatile material choice in an architect's or builder's structural tool kit and what designers do with this solid-but-see-through substance ultimately will probably surprise us all. If the concrete is mounted internally in the shape of wall, floor or ceiling panels, artificial light sources can be used to create special effects from an environmental perspective; buildings that use Litracon will require less energy to be lit by day because of the extra natural light. Originally developed by a Hungarian architect in 2001, light-transmitting concrete is produced by adding 4% to 5% optical fibers (by volume) [3]. Light emitting concrete shows amazing possibilities of transformation with light, color and shadow. From an environmental perspective, buildings that use Litracon will require less energy to be lit by day because of the extra natural light.

With over seven billion cubic meters produced each year, concrete is one of the world's most universal building materials. Concrete use has stood the test of time and is a multibillion dollar industry that provides millions of jobs throughout the world. Despite its versatility and popularity, the aesthetic reputation of concrete leaves much to be desired. Common descriptive phrases such as "concrete jungle" do little to increase the desirability of the concrete's aesthetic attributes. However, in a small town in Southern Hungary, a young architect is challenging these negative perceptions. In 2001, Áron Losonczi [5] combined his artistic inspiration, technical innovation and entrepreneurial flair to create translucent concrete building blocks which can transform a solid gray mass into a luminous wall alive with shadows. In 2004, Mr. Losonczi set up Litracon Bt. (Litracon) to market his translucent invention [6].

While doing his Post-Graduate work from 2001 to 2003 in Architecture at the Royal University College of Fine Arts in Stockholm, Sweden, Mr. Losonczi began working with scientists at the Budapest University of Technology and Economics to develop a translucent cement prototype [8]. After returning to Csongrád, Mr. Losonczi completed this first prototype by hand and started demonstrating it at design exhibits throughout Europe. The prototype soon caught the attention of the media and well known architect firms, and Mr. Losonczi's research and development (R&D) focused on refining the product and increasing production capability. The resulting product can be used for interior or exterior walls, illuminated pavement or in art or design projects. Figure 1 shows a transparent concrete partition wall.

Figure 1. Transparent concrete partition wall

Fabric and concrete are alternately inserted into molds at intervals of approximately 2 mm to 5 mm. Smaller or thinner layers allow an increased amount of light to pass through the concrete. Following casting, the material is cut into panels or blocks of specified thickness and the surface is then typically polished, resulting in finishes ranging from semi-gloss to high-gloss. We have used plastic optics fibers which are much cheaper than glass optical fibers and have same properties since it reduces the cost upto 5 times as compared to glass optical fiber, but have disadvantage of less transmitting properties as compared to glass optical fibers [7].

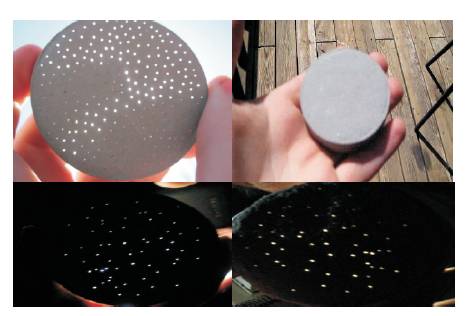

Diffused natural light and sun light provides the full spectrum of colors shining through the LUCEM panels [13]. Depending on the application, artificial light sources can be used for single colors or even special effects creating fascinatingly exclusive potential for floors, walls, ceilings and independently mounted surfaces. For an evenly distributed illumination of transparent concrete panels, a specially developed lighting source can be provided. This transparent Light panel consists of an ultra-flat acrylic panel with two-sided light feeding. This highly efficient and energy saving LED light source is available in white or colored light, with or without color alternating modes. The entire installation light zone is 10mm in thickness. Telling Architectural assists in selecting the best mounting and lighting system to suit the individual project and provides advice upon its application and diversity in use. The illustration of light transmitting concrete self made samples are shown in Figure 2.

Figure 2. Light transmitting concrete self made Samples

Ingredients: 96% concrete, 4% optical fibers

Density: 2100-2400 kg/m³

Compressive strength: 50 -70 N/mm²

Bending tensile strength: 7 N/mm², Flexural strength: > 5 N/mm2

Building material class: A1/A2, non flammable

UV-stability: durable

Finish: polished

Ingredients: 96% concrete, 4% optical fibres

Density: 2100-2400 kg/m³

Compressive strength: 45.7 N/mm²

Bending tensile strength: 7 N/mm²

Finish: polished

Ingredients: 95% concrete, 5% optical fibres

Density: 2100-2400 kg/m³

Compressive strength: 51.3N/mm²

Bending tensile strength: 7 N/mm²

Finish: polished

While there are limited examples of translucent concrete currently in use, some of the potential applications under consideration for implementation include:

Figure 3 depicts some of the areas of application of transparent concrete

Figure 3. Areas of application of transparent concrete

Though expensive production costs will prohibit Light transmitting concrete from transforming cityscapes anytime soon, the company is working to create more affordable translucent concrete products through future licensing deals and large scale production. Light transmitting concreterising popularity in a short time is a testament to its innovation, and if the company can realize this vision, the days of dark, dreary concrete may soon be coming to an end [12]. It is not possible for everyone to use this efficient and amazing concrete. For this purpose we are trying to develop light transmitting concrete which can be afforded by everyone and have same properties as Litracon. So, we used plastic optical fibers instead of glass optical fires which can transmit light upto at least 9 meters which is little less than glass fibers, the effect of the use of plastic fibres instead of glass fibres resulted in little loss in compressive strength of about 5mpa. Besides that, concrete retained all its properties. If more and more buildings begin using this technology, more natural light can be used to light offices and stores [10]. This could lead to huge drops in the amount of electricity used to light buildings, since they'd be naturally lit during the day. Also, people who get exposure to the sun are generally happier and more productive, so that is another reason for businesses to use this light-transmitting concrete. Plastic optical fibers are shown in Figure 4.

Figure 4. Plastic optical fibers

The test which was conducted in the laboratories has given the following results:

The compressive strength of Light transmitting concrete comes between 50-70 N/mm2 which is equal to the strength of the ordinary concrete and it has the property to transmit light upto 15 meters [2]. If the percentage of the optical fibres increased, then the strength of the concrete starts decreasing, so we can use 4-7 % of optical fibres for the light transmitting concrete. Only fine aggregates are used because if we use coarse aggregates it may destroy the optical fibres and change their properties. In theory, a wall structure built out of the light-transmitting concrete can be a couple of meters thick as the fibers work without any loss in light up to 20 m. Load-bearing structures can also be built from the blocks as glass fibers do not have a negative effect on the well-known high compressive strength of concrete. Transparent concrete achieves maximum effect when used in an environment with a high degree of light contrast, such as this illuminated table in a dimly lit room. Light transmitted by the optical fibres is due to the phenomena of total internal reflection due to which light passes from the optical fibres and make the concrete translucent. Glass fibers are very costly and thus the cost of the light transmitting concrete also increases which make it too expensive for everyone to use it. Light transmitting concrete is eco friendly and resistant to fire. The transmission of light in light transmitting concrete is shown in Figure 5. The glass fibers lead light by points between the two sides of the blocks. Because of their parallel position, the light-information on the brighter side of such a wall appears unchanged on the darker side. The most interesting form of this phenomenon is probably the sharp display of shadows on the opposing side of the wall. Optical fiber itself consists of several inner layers, including the core, which transmits the light waves, and the cladding around it. The cladding is made of a material which has a lower refractive index than the core. This means that for light to pass from the core out through the cladding, it would have to slow down. Instead, the light waves take what might be called the path of least resistance by reflecting only in the core through the length of the fiber, to then be visible at the other end. This means that optical fiber can be bent around corners or in a spiral shape and still only emit light at the end of the fiber.

Figure 5. Transmission of light in Light transmitting Concrete

Translucent concrete is made by mixing optical fibers into the traditional concrete formula. The optical fiber strands constitute only 4 to 5 percent of the volume of the mixture, and the low percentage allows this green construction material to retain all the strength of conventional concrete. Thickness of the optical fiber can vary, resulting in more or less light transmission, allowing a range of applications. Optical fibers are highly efficient, and regardless of the thickness of the concrete, lose no light conductivity. Colors can even be used, creating a variety of possible effects. The concrete is made with 4% glass optical fibres so you can see shadows, colors and light through it. The glass optical fibres allow light to pass through the concrete no matter how thick or thin it is. The pattern is random and, so you can get some amazing effects with colored lights. It can be used as a structural component to a building or as an architectural feature, or in landscaping. Three colors are available in white, grey and black. The use of Light transmitting concrete can reduce the pollution and also gives a better appearance to the structures. It provides same strength with more natural light and durability. By using plastic optical fibers the light transmission may decrease but it becomes cheaper so that it can be used by all class of people and can be used widely. One of the first demonstration projects in Stockholm was to light sidewalks at night. Now people are thinking about increasing visibility in dark subway stations with the material. And there are several potential safety applications being discussed, such as lighting indoor fire escapes in the event of a power failure or illuminating speed bumps on roadways at night. Surely, as many people see its potential, light-transmitting concrete will become more and more visible. If more and more buildings begin using this technology, more natural light can be used to light offices and stores. This could lead to huge drops in the amount of electricity used to light buildings, since they'd be naturally lit during the day. Also, people who get exposure to the sun are generally happier and more productive, so that is another reason for businesses to use this light-transmitting concrete.