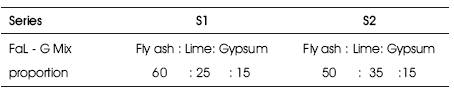

Table 1. Mix Proportions of FaL- G

The rapid increase in the capacity of thermal power generation in India has resulted in the production of a huge quantity of fly ash. The prevailing disposal methods are not free from environmental pollution and ecological imbalance. Large stretches of scarce land, which can be used for shelter, agriculture or some other productive purposes, are being wasted for disposal of fly ash. The production of each ton of cement releases an equal amount of carbon dioxide to the atmosphere. The usage of cement can be reduced by using the other possible cementing materials without compromising the strength and durability. FaL-G, finds extensive application in the manufacturing of building components and materials such as solid bricks, hollow bricks and structural concretes. It is free from conventional cement. FaL-G technology enables production of bricks with a simple process of mixing, moulding and water curing. Due to such appropriate technology apart from economy, conservation of energy and pollution control are also achieved. Housing is a great problem in today's world. The most basic building material for construction of houses is the usual burnt clay brick. A significant quantity of fuel is utilized in making these bricks. Also, continuous removal of topsoil, in producing conventional bricks, creates environmental problems

This paper addresses the technology of making compressed FaL-G mortar blocks with low-calcium (Class F) dry fly ash procured from Raichur Thermal Power Plant, Karnataka as the base material. The cardinal aim is to analyze the experimental data generated to formulate a phenomenological model to arrive at the combinations of the ingredients to produce FaL-G blocks to meet the strength development desired at the specified age irrespective of the age and proportion of the FaL-G mix. The strength data is being further analyzed within the framework of generalized Abrams' law used in concrete technology. Since the blocks are made by static compaction invariably resulting block is in unsaturated state. To describe this state two parameters viz., void ratio and degree of saturation are needed. It is very interesting to note that generalized Abrams' law which is applicable to saturated system is tenable even for analysis of strength development of unsaturated state of compressed blocks when the degree of saturation is maintained constant for all variations in water /FaL-G ratios. How this can be done is elucidated in this paper. The validity of phenomenological model has been examined with an independent set of experimental data generated at reference state and the same set of values are used to find the strength development at any other water –FaL -G ratio and compared with actual values.

In recent times the emission of carbon dioxide into the air is being increasing day by day. Considerable amount of fossils, coal and oil are burnt for different reasons. This weakens the heat–trapping blanket that surrounds the planet, causing global warming. Various alternatives can be considered to protect the planet. The rapid increase in the capacity of thermal power generation in India and abroad has resulted in the production of a huge quantity of fly ash. The prevailing disposal methods are not free from environmental pollution and ecological imbalance. Large stretches of scarce land, which can be used for shelter agriculture or some other productive purposes, are being wasted for disposal of fly ash. On the other hand, the production of each ton of cement releases equal amount of carbon dioxide to the atmosphere. The usage of cement can be reduced by using the other possible cementing materials without compromising the strength and durability. Housing is a great problem in today's world. construction of houses is the usual burnt clay brick. A significant quantity of fuel is utilized in making these bricks. Also, continuous removal of topsoil, in producing conventional bricks creates environmental problems.

FaL-G is the cementitious mixture consisting of fly ash (Fa), lime (L) and gypsum (G) with water. FaL-G technology, developed by Bhanumathidas and Kalidas [2002], is based on two principles namely, that the fly ash-lime pozzolanic reaction does not need external heat under tropical temperature condition, and that the rheology and strength of fly ash-lime mixtures can be greatly augmented in the presence of gypsum. This has dispensed with the need for heavy-duty press and autoclave, and also made the process energy efficient, bringing the activity within the reach of tiny sector entrepreneurs.

As a building material FaL-G is an outcome of innovation to promote large scale utilization of fly ash [Bhanumathidas, and Kalidas, 2003]. It gains strength, like as any other hydraulic cement, in the presence of water and when hardened it remains water tight. Fly ash, lime and gypsum are available in mutual proximity in many regions. An economical alternative to conventional burnt clay bricks will be available, if these materials can be used to make solid bricks and hollow blocks of adequate strength. Lime and gypsum are usually available either from mineral sources or may be procured from industrial wastes.

Phosphogypsum is an important by-product of phosphoric acid fertilizer industry. It's chemical formula is CaSO4 .2H2 O and contains some impurities such as phosphate, fluoride, organic matter and alkalies. Approximately 5 million tons of phosphogypsum is produced each year in India [ Singh and Garg 1997]. Cementitious binder, FaL-G, finds extensive application in the manufacturing of building components and materials such as bricks, hollow bricks and structural concretes. FaL-G technology enables production of bricks with a simple process of mixing and water curing. Due to such appropriate technology apart from economy, conservation of energy and pollution control are also achieved [Sunil Kumar 2002].

Fly ash bricks are used in multi-storeyed apartment houses for non-load bearing purposes in making curtain and partition walls of these houses. Use of fly ash bricks in this type of construction is meant mainly to achieve economy and make profits. The domestic buildings in the category of low or middle-income groups mostly have single or twostoreyed dwelling units. Therefore, not only the cost effectiveness but also the strength and durability of fly ash bricks are very important for them. The FaL-G blocks require no skilled labour and can also be moulded in to any shape and size depending upon the requirements. FaL-G bricks with suitable phosphogypsum content have better resistance to strong sulfate environments [Sunil kumar 2002].

A general study conducted on M30 strength of neat FaL-G has indicated that 1.5 times of its dosage by weight, as against OPC, keeping the other aggregate same, renders a mortar or concrete of parallel grade strength. A Study on workability for M15 grade concrete has not shown any slump, unlike OPC. The additional 50% input of FaL-G cement might have rendered relatively better cohesion for wet concrete to show this phenomenon. Hence a different approach to study workability of FaL-G concrete has to be developed. Even at low workability, this can be considered as roller compacted concrete.

FaL-G can replace OPC in many avenues. The reinforcement behavioral studies in reinforced FaL-G cement concrete (RFCC) are in progress but the postulations indicate that the constituent of FaL-G is1.5 times more than OPC by weight, which in other words is 3 times by volume of account of two to one ratio in densities, and the specific area of cement matrix is relatively larger in RFCC than in RCC. Thereby reinforcement is more closely coated with cementitious gels and more safely ensured for water impermeability to veto the chances of corrosion. However FaL-G is a weak abrasive product and hence may be avoided on high abrasive prone areas, till its abrasive resistance is virtually improved. It is cheap in cost; transportation cost can be reduced by decentralizing the FaL-G cement activities.

Fly ash-based brick and cement are far superior in engineering properties over their conventional competitors. This knowledge needs to be disseminated globally, more so in second and third world countries, through tangible technical explanations (Bhanumathidas and Kalidas 2003). Although results of FaL-G bricks and hollow blocks were promising, the technology could not be implemented due to initial consumer resistance in adapting to new materials. Ambalavanan and Roja (1996) in their study of FaL-G bricks utilized waste lime and gypsum with fly ash. They have observed that in most cases the use of waste lime does not give technically desired results and some improvement is needed to increase the strength of FaL-G bricks. The treatment to be given to waste lime increases the cost of FaL-G bricks significantly as compared to conventional bricks, which is hindering the commercialization of this new material. Some researchers have reported that there is fall in strength in FaL-G composites at later age. This aspect should be considered in the field application of FaL-G products. For wider application of FaL-G bricks and hollow blocks in the housing sector, extensive research is further needed. There are no methods of predicting FaL-G composites except as reported by Radhakrishna [2010].

In conventional compressed cement blocks, the strength development is sensitive to water- cement ratio at constant degree of saturation. The mix follows the Abrams' and Bolomey's Laws. Does the strength development in FaL-G is of the same pattern as in Portland cement blocks? Does the same laws, such as Abrams' [1918] and Bolomey's [1927] are of use in the analysis of strength data? Can a phenomenological model be advanced for assessment of the combination of ingredients to meet a specified strength development? The cardinal aim of this study is to address and examine these issues.

The fly ash used in this investigation was procured from RTPS, Raichur, Karnataka. The Class F fly ash collected was stored in airtight containers. The ash is characterized to assess the physical and chemical characteristics. The specific gravity of the fly ash was found to be 2.4. The reactivity of ashes obtained from Lime reactivity test as per IS 1727-1967 was found to be 7.47 MPa. It can be seen that the fly ash conforms to requirement of grade-I fly ash as per IS 3812- 1981. Soundness of pozzolana cement mix was obtained from Le-Chatelier apparatus in conformity with IS 1727- 1967 and IS 4031-1968. The results of the soundness test indicate that the soundness is very less and hence does not disqualify mortars with the ash.

Chemical analysis conducted on the ash indicate that the ash conforms to the requirements of IS:3812 (Part-I)-2002. It is observed that content of SiO2+Al2O3 is 88 percent for the ash against minimum of 70 percent stipulated in IS:3812(9)(Part-I)-1981.

The XRD study confirms the presence of crystalline phases of Quartz and Mullite present in matrix of alumino silicate glass. SEM study of the ash indicates that almost all the particles are spherical and smooth. Some of them are smooth spheroids of size 1-5μ, with the majority being less than 3μ in size.

Locally available raw lime stones were crushed into powder and sieved through 1mm sieve. The lime powder containing less than 1mm particles in unslaked form was used to make the compressed blocks. The specific gravity of the lime was 1.39.

Commercially available fertilizer gypsum was used in the investigation. The specific gravity of the gypsum was 1.2. Tap water and locally available fine aggregates in saturated surface dry condition of specific gravity 2.58 were used to prepare FaL-G mortar.

Required quantities of fly ash and fine aggregate were mixed in dry condition. Then weighed quantity of lime and gypsum were added to the dry mix and was mixed further to get dry homogenous mixture of FaL-G. The measured amount of water was then added and mixed till the homogenous mix was obtained. The fresh FaL-G mortar was used for casting the specimens. Static compaction device was used in the experimental program for compacting the cylindrical specimens for the required densities. The diameter and height of the specimen are 36mm and 72mm respectively.

The specimens were made so that the mix contains constant degree of saturation of 45%. The mix proportion of the FaL-G mix is indicated in Table 1. The compressed FaLG cylindrical specimens were then kept in the humidity cabinet at 250C at 95 percent humidity till they were tested for compression in triaxial machine.

Table 1. Mix Proportions of FaL- G

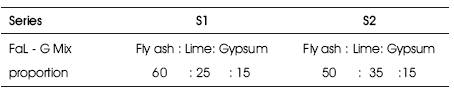

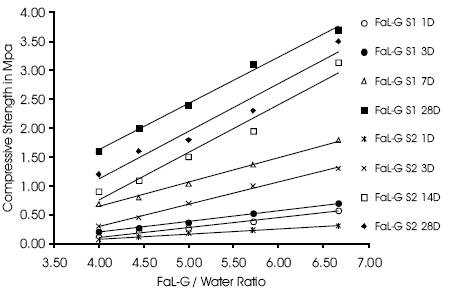

The results of compressive strength test are indicated in Figure 1. The results indicate that as the water – FaL-G ratio increases, the strength of the FaL-G compressed blocks decreases which is in accordance of Abrams' law. This is true at all the ages and mix proportions of FaL-G. The strength of the blocks increases with age. There is no appreciable change in compressive strength with the decrease of fly ash and increase of lime content.

Figure 1. Variation of strength with water/ FaL-G ratio

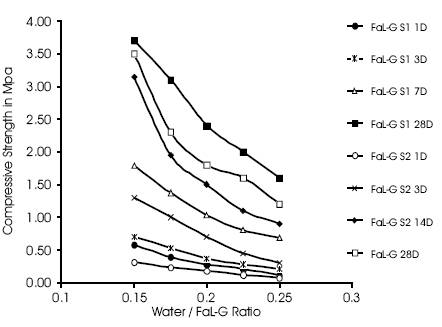

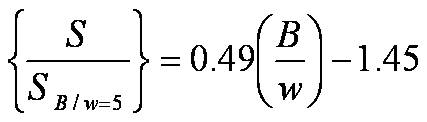

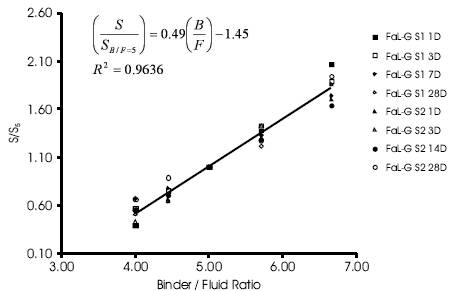

At all the ages, the strength development is in accordance with Bolomey's law as indicated in Figure 2. Further the strength values were generalized taking reference strength data at FaL-G / water ratio at 5. The resulting phenomenological model is as under.

with the correlation coefficient being 0.96.

Figure 2. Variation of strength with FaL-G/water ratio

A phenomenological approach is one by which the combination of parameters would be done within the basic framework of a law. The use of this model needs an input of experimental data of a single trial to account for the synergy between different constituents of a given set of materials. If any one or in combination the ingredients of a set changes for the new set, the new input data is to be generated again to use the phenomenological model to obtain the corresponding water–cement ratio to arrive at the appropriate mix proportions in order to meet the specific strength and workability requirements. This exercise is identified as 'Re-proportioning Method'. This is akin to making adjustments to the trial mix until the specified requirement is met with. Instead of repeated laboratory trials, introducing the experimentally determined reference strength value and making simple calculations result in desired results. This is a rapid exercise and has further potential to determine the parameter that would provide a wide spectrum of mixes that would have potential to develop strength over a desired range for a given set of materials. In an earlier investigation further analysis has been done of extensive data generated for British method of mix design, Design of normal concrete mixes, published by the Department of environment [1988]. By considering the strength S, at water -cement ratio of 0.5, S0.5 , as the reference state to reflect the synergy between different constituents of concrete, the relation between the compressive strength and free water cement ratio has been generalized.

This has resulted in a relationship of the form Nagaraj and Zahida Banu, [1996]

It is now intended to examine as to how far in similar lines it is possible to formulate the phenomenological model for assessment of strength development at different water / FaL-G ratios at different age with similar reference strength data within the range of value of FaL-G/water ratio considered in this investigation. Inverse of water / FaL-G ratio of 0.2 i.e. FaL-G/water ratio of 5.0 is considered as reference for normalization of respective compressive strength for FaLG/ water ratios of different series of experiments. This chosen value of FaL-G/water ratio is arbitrary. There is no other significance. The resulting functional relation is graphically shown in Figure 3. This is the phenomenological model for assessment of compressive strength in FaL-G Blocks.

Figure 3. Generalised Data with the phenomenological model

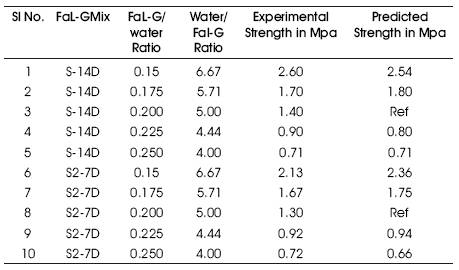

To use this relation for a given set of materials the strength developed at a specified age for a FaL-G –water ratio of 0.2 is to be determined. Using this as an input parameter in the equation, the FaL-G water ratio for any other strength desired can be calculated using the phenomenological model. A separate series of experimental data was generated to examine the predictions made by the use of phenomenological model.

From each of these sets, the compressive strength at reference FaL-G/ water ratio is taken into consideration in the denominator of the left hand side of phenomenological equation, and strength developed at other water/FaL-G ratios are calculated and tabulated for comparison with experimental values Table 2. There is very close match between the Experimental and Predicted values reinforcing the applicability of phenomenological model. With more data being generated for still wider range of FaL-G / water ratio the scope of this phenomenological model can still be further enhanced.

Table 2. Comparison of Experimental and Predicted Strength Data

The following concluding remarks can be made from this comprehensive study.

This paper is respectfully dedicated to Late Prof. T.S. Nagaraj, Former Distinguished Professor, RV College of Engineering & Former Adjunct Professor, University of Massachusetts- Amherst, USA, Former Professor Emeritus of Indian Institute of Science, Bangalore. for his valuable guidance and inspiration

The authors thank the authorities of RSST, Dr. B S Satyanararayana, Principal, RVCE, Bangalore, for encouragement and Dr. B C Udayashankar, Head, Department of Civil Engineering, RVCE Bangalore, for extending facilities to carry out the research work at RVCentre for Alternative Construction Materials and Technologies (RV-CALTech), RVCE, Bangalore.