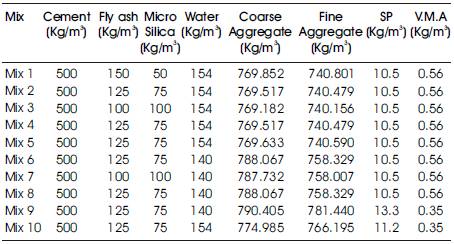

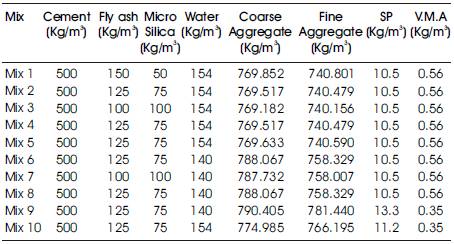

Table 1. Quantities of Materials for 1m3 of High Strength Self Compacting Concrete mixes

In the present investigation a rational mix design is established and self compactability testing methods have been carried out from the view point of making it a standard concrete by using mineral admixtures like micro silica and fly ash for imparting High Strength Self Compacting Concrete. The flow properties of resulting concrete is characterized in the fresh state by methods used for Self compacting concrete, such as Slump-flow, V-funnel and L- box tests respectively. Further the mechanical properties compressive strength, split tensile strength and flexural strength of concrete are examined for High Strength Self Compacting Concrete mix of grade M100.

Self compacting concrete was first developed in 1986 in JAPAN to achieve durable concrete structures. For several years, the problem of the durability of concrete structures in a major topic of interest for construction engineers to make durable concrete structures. Sufficient compaction is needed for conventional concrete that cause segregation. With plain concrete, it is difficult to ensure uniform material quality in heavily reinforced zone where steel is not correctly surrounded by concrete and which finally leads durability problems. The answer to the problem may be a type of concrete, which can get compacted into every corner of a formwork, purely by means of its own weight and without the need for vibrating compaction. Self Compacting Concrete concept was stated that the concrete meets special performance and uniformity requirements that cannot be used as the ingredients of conventional concrete[1-9]].

To design a High Strength Self Compacting Concrete with Mineral Admixtures satisfying EFNARC guidelines.

To study the strength development of High Strength Self Compacting Concrete.

Increasing the concrete strength is always one of the main desires of concrete technology. Since more than 20 years high strength concretes with compressive strength ranging from 50N/mm2 up to 130N/mm2 have been used worldwide in tall buildings and bridges with long spans or building in aggressive environments. Building elements made of high strength concrete are usually densely reinforced. The small distance between reinforcing bars may lead to defects in concrete. If high strength concrete is self-compacting, the production of densely reinforced building element from high strength concrete with high homogeneity would be an easy work. The literature indicates that while some studies are available on SCC, a comprehensive study which involves strength properties are not available for High Strength Self Compacting Concrete. Hence, considering the gap in the existing literature, an attempt has been made to study on the High Strength Self Compacting Concrete.

Ordinary Portland cement of 53 grade having specific gravity was 2.96 and fineness was 3200cm2/gm was used in the investigation. The Cement used has been tested for various proportions as per IS 4031-1988 and found to be confirming to various specifications of are 12269-1987.

Crushed angular granite metal of 10 mm size having the specific gravity of 2.65 and fineness modulus 6.05 was used in the investigation.

River sand having the specific gravity of 2.55 and fineness modulus 2.77 was used in the investigation.

A Viscosity modified admixture for Rheodynamic Concrete which is colourless free flowing liquid and having Specific of gravity 1.01+0.01 @ 250C and pH value as 8+1 and Chloride Content nil was used as Viscosity Modifying Agent.

The Modified Polycarboxylated Ether (BASF GleniumTM B276 SURETEC) based superplasticizer which is pale yellow colour and free flowing liquid and having Relative density 1.10+0.01 at 25oC, pH >6 and Chloride Ion content <0.2% was used as superplasticizer.

Type-II fly ash confirming to I.S. 3812 – 1981of Indian Standard Specification was used as Pozzolana Admixture.

The Micro silica having the specific gravity 2.2 obtained from Oriental Trexim, Private Limited was used in the present investigation.

Quantities of materials required per 1 cum of High Strength Self Compacting Concrete mixes .

Table 1 gives the quantities of material required for various trial mixes of High Strength Self Compacting mixes . The Trail Mixes were carried by verifying the fresh state properties with EFNARC guidelines.

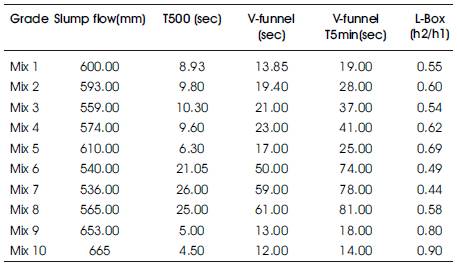

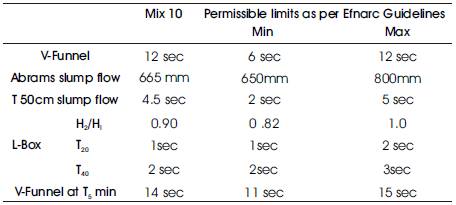

Fresh State properties of High Strength Self Compacting Concrete mixes.

Table 2 provides a summary of the fresh state properties of High Strength Self Compacting Concrete mixes of various trail mixes. As it is evident, the basic requirements of high flowability and segregation resistance as specified by guidelines on High Strength Self Compacting Concrete mixes by EFNARC are satisfied. The Rehelogical properties are maintained by adding suitable quantities of super plasticizers. Table 3 shows the fresh state properties of trail Mix 10 which satisfies the EFNARC guidelines. The test set up are shown in Figures 1 to 3.

Table 1. Quantities of Materials for 1m3 of High Strength Self Compacting Concrete mixes

Table 2. Fresh Concrete properties of High Strength Self Compacting Concrete Mixes

Table 3. Fresh Concrete properties of High Strength Self Compacting Concrete Mix M 100

Figure 1. Slump flow diameter for High Strength SCC mix of M100 grade

Figure 2. V- Funnel test for High Strength SCC mix of M100 grade

Figure 3. 0 L- Box test for High Strength SCC mix of M100 grade

Strength studies of High Strength Self Compacting Concrete mixes :

Compressive Strength of High Strength Self Compacting Concrete mixes.

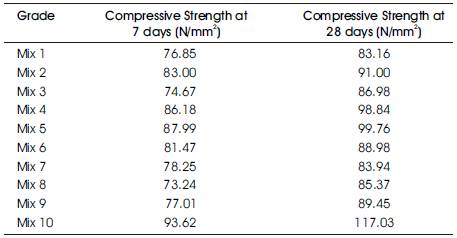

Table 4 gives the compressive strength values of various trail mixes carried out for 7 days and 28 days. The compressive strength of trail mix 10 which is following all the EFNARC guide lines is confirmed to be giving the strength of M 100. Based on this further studies for 56, 90 days has been carried.

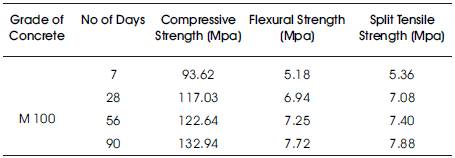

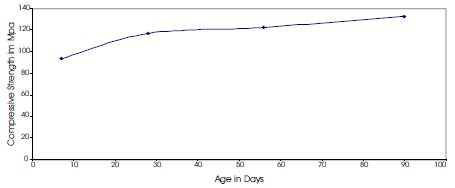

Table 5 gives the Compressive Strength values of High Strength Self Compacting Concrete mixes of M100. These values are observed to be 93.62 for 7 days , 117.03 N/mm2 for 28 days, 122.64 N/mm2 for 56 days and 132.94 N/mm2 for 90 days. These variations are observed in Figure 4. Table 6 gives the variation of 9 to 19 % increase in Compressive Strength of High Strength Self Compacting Concrete mixes of M 100 compared with 28 days Compressive Strength. The Test Set up is given in Figure 5.

Table 4. Compressive strength of High Strength Self Compacting Concrete mixes at 28 days

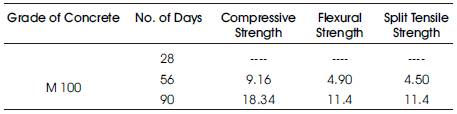

Table 5. Compressive Strength, Flexural Strength and Split Tensile Strength of High Strength Self Compacting Concrete Mix at 28, 56 and 90 days

Figure 4. Variation of Compressive Strength with Age

Table 6. Percentage increase in Compressive Strength, Flexural Strength and Split Tensile Strength Of Self Compacting Concrete in comparison with 28 Days Strength

Figure 5. Testing of High Strength SCC cube of M100 grade in compression testing machine

These results can be explained by the delayed pozzolanic activity of supplementary powder. Initially, cement hydration and the resulting calcium silicate hydrate is the principal source of strength in concrete. But as time progresses, the influence of supplementary powder (Fly Ash) becomes noticeable. Largely pozzolanic in composition, supplementary cementitious materials convert weak calcium hydroxide released by cement hydration into calcium silicate hydrate.

Flexural Strength of High Strength Self Compacting Concrete mixes:

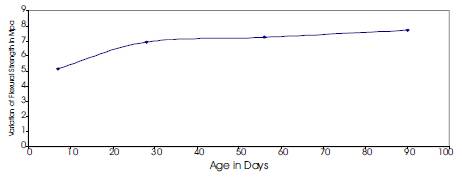

Table 5 gives the Flexural Strength values of High Strength Self Compacting Concrete mixes of M100. These values are observed to be 5.18 for 7 days, 6.94 N/mm2 for 28 days, 7.25 N/mm2 for 56 days and 7.72 N/mm2 for 90 days. These variations are observed in Figure 2. Table 6 gives the variation of 4 to 12 % increase in Split Tensile Strength of High Strength Self Compacting Concrete mixes of M 100 compared with 28 days Compressive Strength. The test set up is given in Figure 7.

Figure 6. Variation of Flexural Strength with Age

Figure 7. Test setup for testing Flexural Strength of High Strength SCC prism of M100 grade

Split Tensile Strength of High Strength Self Compacting Concrete mixes:

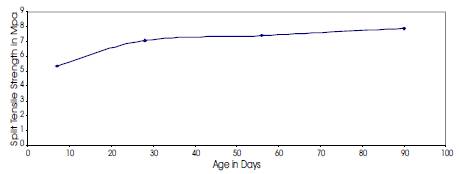

Table 5 gives the Split Tensile Strength values of High Strength Self Compacting Concrete mixes of M100. These values are observed to be 5.36 for 7 days, 7.08 N/mm2 for 28 days, 7.40 N/mm2 for 56 days and 7.88 N/mm2 for 90 days. These variations are observed in Figure 3. Table 6 gives the variation of 4 to 12 % increase in Split Tensile Strength of High Strength Self Compacting Concrete mixes of M 100 compared with 28 days Compressive Strength. The test set up is given in Figure 9.

Figure 8. Variation of Split Tensile Strength with Age

Figure 9. Testing of High Strength SCC cylinder of M100 grade for Split tensile strength