Figure 1. (a) Fabrication of Merlin, (b) Working with MERLIN

Measurement of road condition in terms of its surface roughness is an important parameter. Assessment of longitudinal profile quality of road surfaces is a commonly considered primary requirement of any newly constructed roads and also in service pavements. Internationally, the riding quality is related to unevenness of pavement surface and quantified in terms of roughness, and is expressed as International Roughness Index (IRI).

There are several low cost, traditional instruments used for measuring roughness of pavements such as Straight Edge, Wedge scale etc. However with the advancement of technology, different sophisticated equipments have emerged, which gives accurate values of unevenness or IRI (Kumar, 2014).

In this study, a low cost device, MERLIN has been fabricated to measure road roughness. Evaluation of roughness of two selected pavements has been made with the fabricated MERLIN and also Reduced Level (RL) values are determined along the same road stretches by using Total Station. Statistical analysis has been carried out on the data collected and regression equations were developed between these two parameters. A comparison between the results of MERLIN and Total Station is made, and suitability of MERLIN as a low cost equipment is investigated with reference to routine evaluation of pavements on short stretches.

Surface roughness in a pavement is a kind of distortion of surface which occurs in a direction perpendicular to its plane, i.e., in the vertical plane. It is an undesirable deviation of the pavement surface compared to its planar surface. It induces vehicle vibrations thereby making the ride discomfortable and travel unsafe. Any neglect of surface roughness may lead to unrealistic, rapid and progressive deteriorations of the pavement causing severe loading effect, long-term cracking and degradation of surface-drainage conditions. Number of experiments and studies have shown that roughness has greater influence on vehicle productivity, running speed, maintenance and tyre damage. Hence, it becomes the responsibility of a Pavement Evaluation Engineer to carry out appropriate measures to prevent this progression of roughness and maintain or retain the service condition of the pavement, with prolonged good riding quality.

Roughness can be determined by different ways such as International Roughness Index (IRI), Ride Number (RN) and Unevenness Index (UI). All of these measurements consider the amount of vertical displacement felt by a car over the section of the road. Generally, higher the number, more the roughness of the road and less, the riding comfort (Sayers and Karamihas, 1996, 1998).

The objectives of the present work are as follows,

Several types of instruments are available for measuring road roughness. To calibrate these instruments and correlate their roughness indices to a standard common scale namely IRI, a programme called International Road Roughness Experiment (IRRE) was conducted in Brazil in 1982.

To overcome the limitations of different indices obtained with different operating speeds as an outcome of IRRE, a standard procedure is recommended for calibrating different equipment and conversion of their output to a standard roughness scale, termed as the International Roughness Index (IRI) (Bennett, 1996).

In India, the roughness is generally measured by fifth wheel Bump Integrator developed by Transport Research Laboratory (TRL) and modified by Central Road Research Institute (CRRI) and the result is reported as Unevenness Index (UI) in mm/km. For arriving at IRI from UI values, the Bump Integrator needs to be calibrated for specific set of parameters using Dipstick Profiler. A typical relation between IRI (m/km) and UI (mm/km) is given as,

IRI = UI/720

The Machine for Evaluating Roughness using Low-cost Instrumentation (MERLIN) is a simple apparatus which is easy to fabricate, operate and maintain. It gives reasonably accurate and reliable results. It was designed by the Transport Research Laboratory (TRL), UK, for direct measurement of roughness of roads in developing countries (Cundill, 1996).

The MERLIN equipment is fabricated in Osmania University as per standards (Figure 1(a)), and it has been used for the roughness evaluation of pavements in selected stretches in Hyderabad.

For the determination of roughness of road surface (Austroads,1999) To determine IRI of the selected pavements 200 numbers of measurements are required to be taken along a test section (Figure 1 (b)). The handles of MERLIN are lifted up, so that just the wheel stays in touch with the road surface and the machine is rolled in forward direction.

Figure 1. (a) Fabrication of Merlin, (b) Working with MERLIN

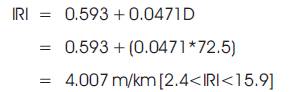

The output result obtained from MERLIN is termed as Dvalue and this value can be used to convert IRI value by using the following equation (Cundill, 1996).

IRI = 0.593+0.0471D

where, 42 < D < 312, 2.4 < IRI < 15.9

IRI - International Roughness Index in m/km

D - Roughness in MERLIN scale measurement in mm

In this study, total station is also used to measure the roughness of pavement surface by conducting levelling survey along the selected stretches at the interval of 2.2 meters. The total station is an electronic theodolite (transit) integrated with an Electronic Distance Meter (EDM) to read slope distances from the instrument to a particular point (Amberg, 1983).

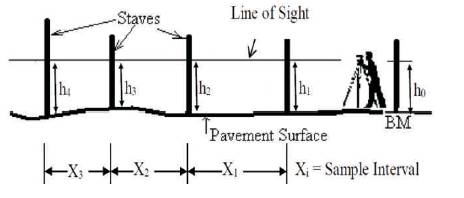

The level difference is calculated from the previous point to the present point (shown in Figure 2), using the following equation.

PLi = HI – Rodi

Figure 2. Measurement of True Profile using Vertical Staff (Rod) and Level, Schematic View

where,

PLi - Profile elevation at ith point, along any selected wheel path,

HI - Height of Instrument (i.e. axis level of the Total Station instrument), with reference to any arbitrary bench mark,

Rodi - Measured reading on the Rod at ith point at an interval of 300 mm.

The Slope for each interval is calculated by,

Slope = (level difference/interval distance)

The Average value of Slope is calculated by,

Average Slope = (Total summation of slopes/ Total number of sections)

The IRI is determined as,

IRI = (Average Slope*1000)

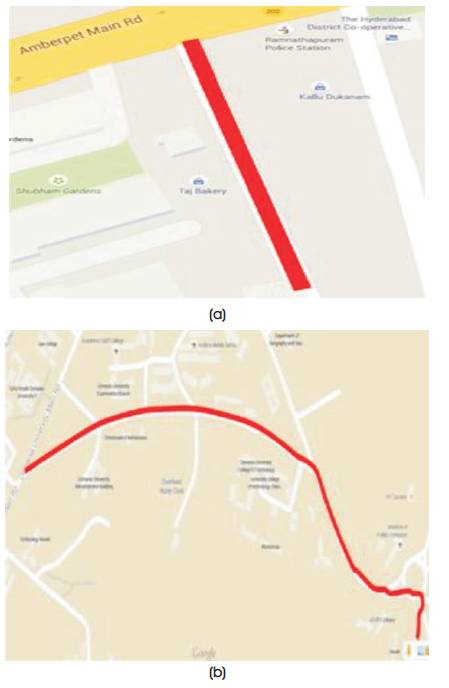

The roughness surveys have been conducted on two stretches in Hyderabad, namely Ramanthapur Road and Osmania University (OU) Road. Figure 3 shows the Google maps of the selected road stretches for the present study.

Figure 3. Study Roads (a) Ramanthapur Road, (b) OU Road

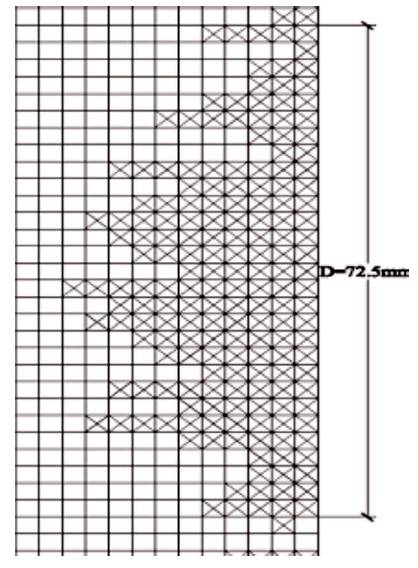

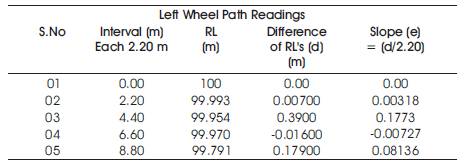

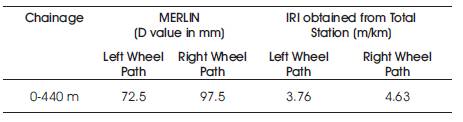

Sample MERLIN survey sheet is shown in Figure 4, and the details of roughness measurement by MERLIN on Ramanthapur Road at chainage (0-440 m) is presented in Table 1.

Figure 4. Sample Merlin Data Sheet obtained on Ramanthapur, along Left Wheel Path

Table 1. Sample Data at Ramanthapur Road using MERLIN

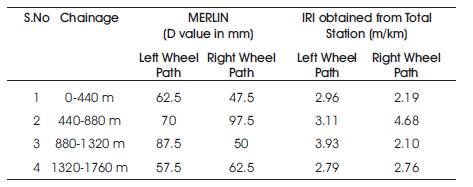

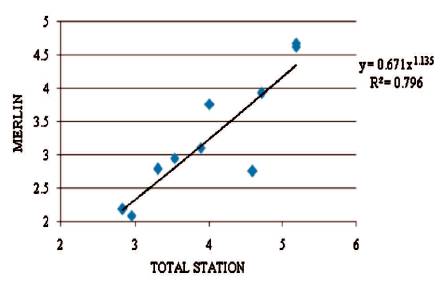

By using MERLIN and Total Station, two selected stretches, Ramanthapur road and OU road have been evaluated for roughness measurement, and the two test data are compared (Wang, 2006). The summary of the survey results obtained from MERLIN and the IRI converted values of the two study sections i.e., Ramanthapur Road and OU Road are presented in Tables 2 and 3, respectively.

Table 2. Summary of Ramanthapur Road

Table 3. Summary of OU Road

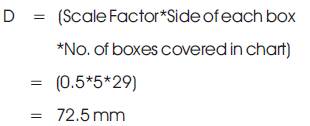

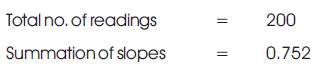

A sample calculation of conversion of MERLIN D-value to IRI value, and Total Station Slope value to IRI value for Ramanthapur road, along its left wheel path at chainage 0-440 m is presented below.

The value of D = 72.5 mm [42 < D < 312]

The International Road Index (IRI) is calculated by using equation (2).

By using equation (5),

By using equation (6),

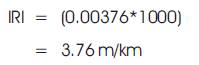

Statistical regression analysis is carried out to correlate the results obtained from these two devices (Perara and Kohn, 1994). The obtained regression model with the scattered diagram is presented in Figure 5.

Figure 5. Regression Model between MERIL D-value and the total Station Slope Value

The IRI values obtained from standard calibration equations as recommended by TRL (Cundill, 1996) and the IRI values obtained from the present regression model are calculated, and a comparison of IRI values from the two instruments is presented in Table 4.

Table 4. Comparison of IRI Values Obtained from the Two Instruments

The following are conclusions drawn from the present study,

As a summary of the above remarks, MERLIN is found to be a low cost and good equipment for measuring the unevenness of the road surface. Fabrication of MERLIN is simple, it is easy to work with and data can be collected in a short duration. Also, one person is enough to collect data using this device. On the other hand, fabrication of Total Station needs a lot of science and skill. Collecting data with Total Station is a laborious process and consumes more time.

Based on the above study, it is recommended that MERLIN can be fabricated locally at low cost and used in the roughness measurement of pavements, mainly in the developing countries where other costly equipments are not readily available. The procedure adopted and the methodology described in this paper can be implemented even for calibration of high speed equipments, used for measurement of pavement roughness.