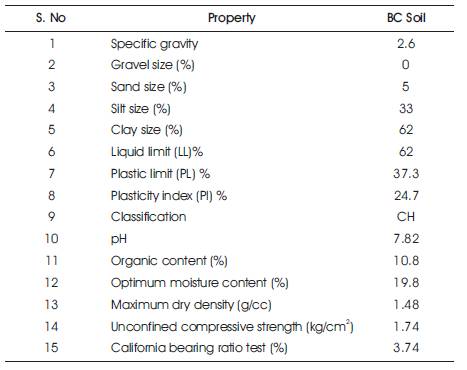

Table 1. Properties of Black Cotton (BC) Soil

To enrich the performance of structures, the stability of underlying soils must be checked. The stability of soil may change due to the discharge of pollutants into water bodies without adequate treatment, which causes momentous changes in the behavior of water, further leading to changes in the pH of water. In the present study, the black cotton soil has been treated with Ordinary Portland Cement (OPC) of 53 Grade and Portland Slag Cement (PSC) with different percentages (3%, 6%, and 9%), and laboratory tests such as Atterberg limits, Compaction, Unconfined Compressive Strength (UCS),California Bearing Ratio (CBR) and Consolidation have been performed. This paper attempts to assess the effect of pH (pH=5, pH=7, pH=9) levels on curing time (7, 14 and 28days) and behavior of cement treated soil. Tests results have shown that there is an increase in Optimum Water Content (OMC) which leads to decrease in Maximum Dry Density (MDD). The UCS and CBR strengths of soil got increased due to the addition of cement, besides that there is a reduction in the compressibility with the addition of cement content which were cured for ages (7, 14 and 28 days).

Generally, industries are the main source for human life and developing countries. Due to the increase in the industrial activities, the waste which has been released from these industries causes enormous changes. In most of the developed countries, among 70% of solid and liquid wastes are dumped into water bodies without appropriate treatment, due to which the ground water is getting polluted. The contaminated water contains heavy metals which creates problems in environment, due to which the pH of water may vary. If pH level of water is < 7, it comes under acidic water and if it is > 7, it comes under alkaline water. Changes in the pH of water may affect the soil which leads to geotechnical problems. The reduction in strength properties may be found because of the mineralogical changes in the behavior of soil. Mostly, expansive soils are the most problematic soils that exert pressure on the foundation or basement, which results in lateral moment of the structure. These soils become sticky when they absorb water, and become hard and brittle when they are in dry state. This can be avoided by improving the properties of soil which further increases its strength, stiffness, etc. To accomplish higher strength, stabilization can be used by adding different additives. In the present study, two different types of cements namely Ordinary Portland Cement and Portland Slag Cement have been used. The technical information about cement treated soil mixtures has been carried out from various research works in the past. Teja et al., (2015) revealed that the maximum dry density decreased with an increase in Optimum Water Content (OMC) with the addition of cement. From the results obtained by using lime and cement, Bekki et al. (2015) concluded that cement treatment is more efficient than lime treatment in improving the values of California Bearing Ratio (CBR). IS 1498 (1970) shows that the unconfined compressive strength increases with increase in the amount of cement content, and for mixtures with 0% cement, the CBR for unsoaked specimens are greater than those of soaked specimens. However, the CBR for soaked specimens are higher than those of the unsoaked specimens. Bahar et al., (2004) shows the investigation of stabilized soil by mechanical means such as chemical stabilization or vibration, and compaction, by using cement. Properties of stabilized sand were evaluated and curing periods with variations in cement content were quantified by Al-Aghbari and Dutta (2005). The compression index (Cc ) for cement treated soils was found to be decreased when compared to the untreated soil samples with an increase in the curing ages, as mentioned by Ho and Chan (2011). In this investigation the effect of acids and alkalis were noted separately by varying pH levels (pH=5, pH=7 and pH=9) and curing time behavior of Black cotton soil, treated with different proportions of OPC and PSC. The behaviour and strength characteristics of soils can be found by performing a series of UCS, CBR and Consolidation tests.

The aim of this research is to establish the effect of acidic and alkaline nature on curing time behavior of cement treated soil.

The black cotton soil which was collected from Medchal Road, Ranga Reddy district, Telengana at the depth of 0.3 m was blackish grey in color. Before conducting the Laboratory experiments, the soil was oven dried and later, the index and engineering properties of soil was determined as per Indian Standards. The properties of black cotton soil are given in Table 1.

Table 1. Properties of Black Cotton (BC) Soil

In the present study, the Ordinary Portland Cement and Portland Slag Cement were purchased from a Cement Company in Hyderabad. The Ordinary Portland Cement (OPC) of 53 Grade is a type of hydraulic cement, which is being used worldwide and Portland Slag Cement (PSC) is an intimate mixture of OPC and granulated slag cement.

In the present study, the chosen black cotton soil was mixed in dry condition with Ordinary Portland Cement (53 Grade) and Portland Slag Cement individually with various percentages (3%, 6%, and 9%).

Various tests were carried out in the laboratory, the index and engineering properties of the soil samples have been determined as per Indian Standard (IS) specifications.

The specific gravity of the chosen soil was determined by using density bottle method, based on IS 2720 (1980a). The Grain size distribution of the soils has been strong-minded as per IS 2720 (1985a) and the soil classification is based on IS 1498 (1970). The casagrande liquid limit apparatus was used to determine the liquid limit of untreated and various soil-cement mixes and plastic limit test has been conducted using rolling thread method as outlined in IS 2720 (1985b). The standard proctor test was conducted to determine the direction of OMC and MDD of the soil according to IS 2720 (1980b). The Organic matter of the chosen soil can be determined using IS 2720 (2010) and pH of the soil can be found using IS 2720 (1997).

The soil sample which was sieved through 425 μ sieve was mixed with various percentages (3%, 6% and 9%) of cement at required OMC. Later, the design mix was compacted in the compaction mould. Further, the sample was ejected from the mould and checked for required dimensions (38 mm diameter and 76 mm height) as per standards. For each cement content, 9 set of specimens have been prepared for chosen soil with Ordinary Portland Cement and Portland Slag Cement, separately. The specimens were wrapped in a polythene cover for one day, and later the specimens were directly immersed in water at 3 different pH levels (pH=5, pH=7, and pH=9) for curing ages of 7, 14, and 28 days.

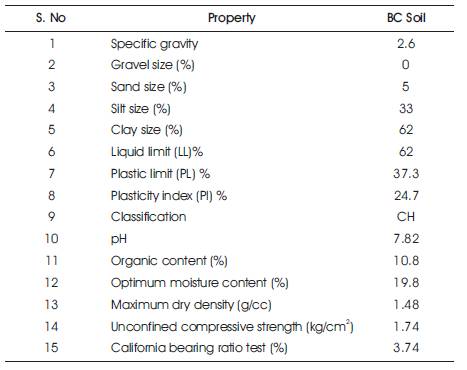

The Unconfined Compressive Strength (UCS) was determined as per IS 2720 (1991) by placing the uncured and cured cylindrical shaped specimens on the base plate. Without any stress application on the sample, the load frame was fixed. Later, by adjusting the dial gauge and proving ring readings are set to zero at a strain rate of 1.5 mm/min; the proving ring readings are noted for regular intervals of dial gauge readings. The UCS specimens under testing is shown in Figure 1.

Figure 1. UCS Specimens Under Testing (a) Before Curing, (b) After Curing

California Bearing Ratio (CBR) test is mostly important for pavements, because the thickness of pavement depends upon CBR value of soil as per Indian Roads Congress (IRC).

The soil-cement mix at optimum moisture content for various percentages (3%, 6% and 9%) of cement was compacted by placing a spacer disc on the bottom of the CBR mould in five equal layers. The excess soil is trimmed off by removing the collar. Later, the spacer disc was removed by reversing the mould by adding of surcharge loads on the top of the soil specimen.

The soil sample was prepared by compacting the design mix in CBR mould. Before performing the test, the porous plate was placed on the of the soil sample along with a filter paper, in addition to surcharge loads. Later, the mould containing soil is engrossed in water at three different pH levels (pH=5, pH=7, and pH=9) for curing period of 7, 14 and 28 days.

The CBR mould is placed on the testing machine and the plunger is brought in contact with the soil sample. The proving ring and dial gauge readings are set to zero. The CBR value can be found as per IS 2720 (2002) at a penetration rate of 1.25 mm/min. The specimen under testing is shown in Figure 2.

Figure 2. CBR Specimen under Testing

The test specimens were prepared by compacting the soilcement mixture with different cement percentages (3%, 6% and 9%) in standard proctor compaction mould at obtained optimum moisture content on non-treated and cement treated soils. After completion of compaction, the specimens were extracted from the compaction mould as per the required dimensions (2 cm height and 10 cm diameter) and excess soil was trimmed off. The consolidation ring containing soil sample was placed in the consolidation cell, by providing porous stones on top and bottom of the specimen along with a filter paper, which was placed between the porous stones and specimen. Now, the consolidation cell is adjusted in a suitable position in the loading device.

The consolidation test was carried out according to IS 2720 (1965) at a pressure increment of 0.25, 0.5,1.0 and 2.0 kg/cm2 by varying pH levels (pH=5, pH=7 and pH=9). For each load increment, the corresponding dial gauge readings are taken using time (minutes) sequence of 0.00, 0.25, 1.00, 4.00, 9, 16, 25, 36, 49, 64, 81, 100 and 1440.

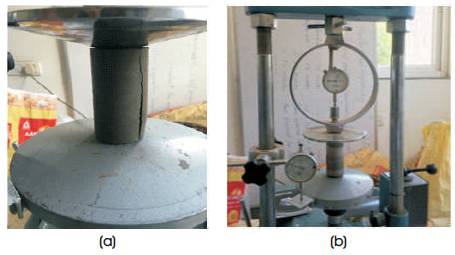

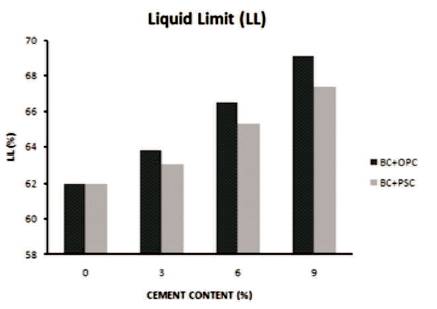

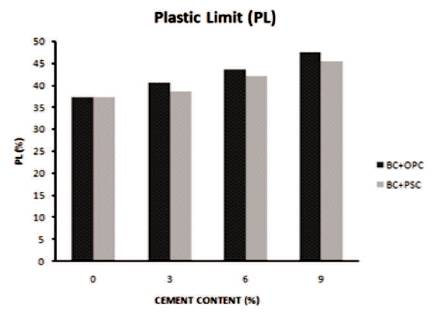

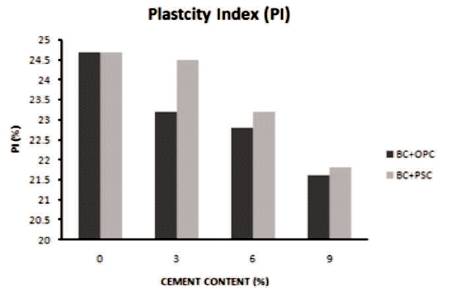

The Liquid Limit (LL) and Plastic Limit (PL) of black cotton soil increases with increasing cement contents, and a decrease in the Plasticity Index (PI) was found, with the increase in the cement contents. Figures 3 and 4 show the variation of Liquid Limit and Plastic Limit of black cotton soils respectively, when treated individually with OPC and PSC. Figure 5 shows the variation of Plasticity Index of black cotton soils, when treated with OPC and PSC individually.

Figure 3. Variation of Liquid Limit of Black Cotton Soil when treated with Ordinary Portland Cement (OPC) and Portland Slag Cement (PSC) Individually

Figure 4. Variation of Plastic Limit of Black Cotton Soil when treated with Ordinary Portland Cement (OPC) and Portland Slag Cement (PSC) Individually

Figure 5. Variation of Plasticity Index of Black Cotton Soil when treated with Ordinary Portland Cement (OPC) and Portland Slag Cement (PSC) Individually

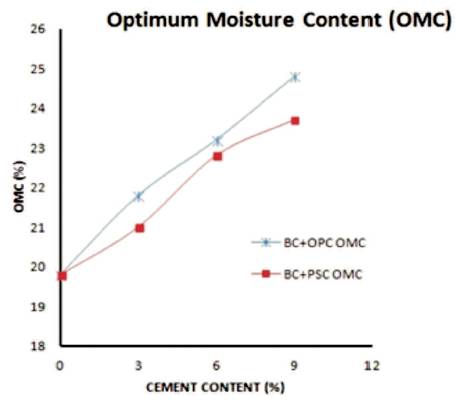

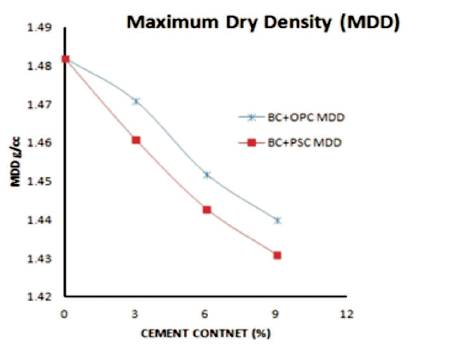

The increase in the addition of cement decreases the maximum dry density and increases the corresponding values of optimum moisture content. Figures 6 and 7 show the variation of Optimum Moisture Content and Maximum Dry Density of black cotton soils respectively, when treated individually with OPC and PSC.

Figure 6. Variation of OMC of Black Cotton Soil treated with OPC and PSC Separately

Figure 7. Variation of MDD of Black Cotton soil treated with OPC and PSC Separately

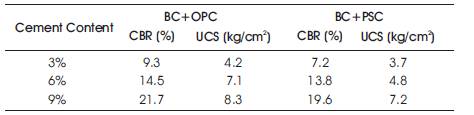

The Unconfined compressive strength and California bearing ratio values increase when black cotton soil is treated with Ordinary Portland Cement and Portland Slag Cement individually, with increasing cement content. Table 2 shows the UCS and CBR values of Black Cotton (BC) soil treated with OPC and PSC.

Table 2. UCS and CBR values of BC Soil treated with OPC and PSC

The effect of curing time for 7, 14, and 28 days with varying cement contents (3%, 6%, and 9%) were studied. The strength of soil-cement mixes has been increased with the curing ages. This gain in strength may continue for years which further increase the UCS and CBR values. The UCS and CBR specimens at the time of curing are shown in Figures 8 and 9.

Figure 8. UCS Samples at the Time of Curing

Figure 9. CBR Samples at the time of Curing

Figures 8 and 9 shows the Curing of UCS and CBR specimens when BC soil is treated with OPC and PSC under different pH levels (pH=5 (Acid), pH=7 (Neutral) and pH=9 (Base)).

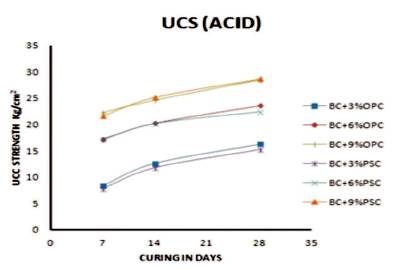

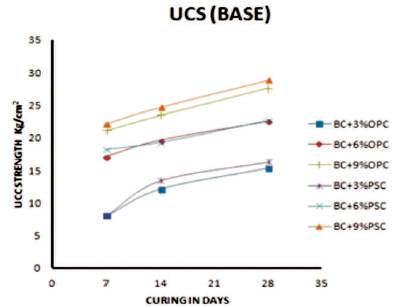

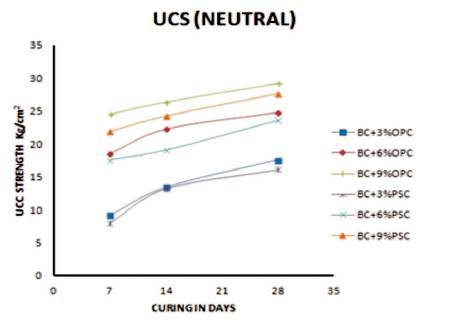

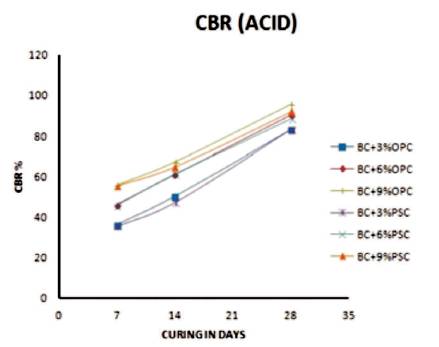

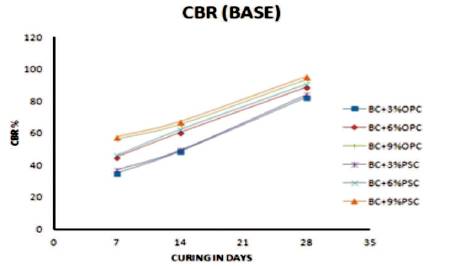

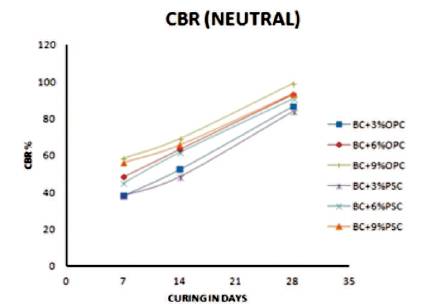

The UCS and CBR strengths of black cotton soil increases with an increase in curing periods/days. The black cotton soil when treated with Ordinary Portland Cement and Portland Slag Cement separately in acidic solution (pH=5) for 7, 14, and 28 days gives best results for Ordinary Portland Cement when compared to Portland Slag Cement. The black cotton soil when treated with ordinary Portland Cement and Portland Slag Cement separately in (pH=9) base for 7, 14, and 28 days gives best results for Portland slag cement when compared to ordinary Portland cement. The black cotton soil when treated with Ordinary Portland Cement and Portland Slag Cement separately in neutral solution (pH=7) for 7, 14, and 28 days gives best results for Ordinary Portland Cement when compared to Portland Slag Cement. Figures 10-12 show the variations in the Unconfined Compressive Strength of black cotton soil, treated with cement (OPC, PSC) for curing ages of 7,14 and 28 days in acidic, base and neutral solutions respectively. Figures 13-15 show the variations in the California Bearing Ratio of black cotton soil, treated with cement (OPC, PSC) for curing ages of 7,14 and 28days in acidic, base and neutral solutions respectively.

Figure 10. The Variations in the Unconfined compressive Strength of Black Cotton Soil Treated with Cement (OPC, PSC) which were Cured under Different Acid (pH=5) for Curing Ages of 7,14 and 28 Days

Figure 11. The Variations in the Unconfined Compressive Strength of Black Cotton soil Treated with Cement (OPC, PSC) which were Cured under Different Base (pH=9) for Curing Ages of 7,14 and 28 Days

Figure 12. The Variations in the Unconfined compressive Strength of Black Cotton Soil Treated with Cement (OPC, PSC) which were Cured under Different Neutral (pH=7) for Curing Ages of 7,14 and 28 Days

Figure 13. The Variations in the CBR Values of Black Cotton Soil Treated with Cement (OPC, PSC) which were Cured under Different Acid (pH=5) for Curing Ages of 7, 14 and 28 Days

Figure 14. The Variations in the CBR Values of Black Cotton soil Treated with Cement (OPC, PSC) which were Cured under Different Base (pH=9) for Curing Ages of 7,14 and 28 Days

Figure 15. The Variations in the CBR Values of Black Cotton Soil Treated with Cement (OPC, PSC) which were Cured under Different Neutral (pH=7) for Curing Ages of 7, 14 and 28 Days

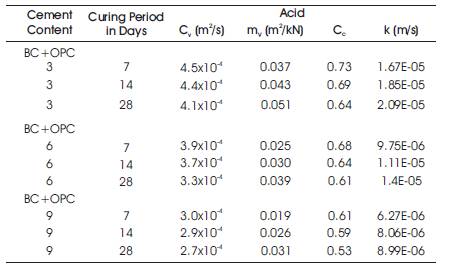

When black cotton soil is treated with ordinary Portland Cement and Portland Slag Cement separately under different pH levels (pH=5, pH=7 and pH=9), the coefficient of consolidation and compressibility decreases with the increase in the cement contents and curing ages. Whereas, on the other side, the coefficient of volume compressibility and permeability increases with curing ages and decreases with the addition of cement content. The permeability of black cotton soil decreases with the increase in cement content and increases with the increase in curing ages. This is due to the decrease in the voids present in the soil particles because of the increase in the cement content, which improves the bonding between the cement and soil particles.

Table 3 shows the variation in consolidation parameters such as coefficient of consolidation (Cv ), coefficient of volume compressibility (mv ), Compression Index (Cc ), coefficient of permeability (k) with the effect of Acid (pH=5) and curing time when Black cotton soil treated with OPC.

Table 3. Variation in Consolidation Parameters (Cv , Mv , Cc , k) with the Effect of Acid (pH=5) and Curing Time when Black Cotton Soil Treated with OPC

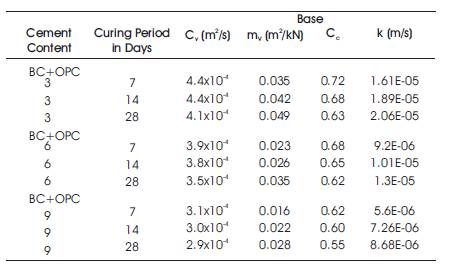

Table 4 shows the variation in consolidation parameters (Cv , Mv , Cc , k) with the effect of Base (pH=9) and curing time, when black cotton soil is treated with OPC.

Table 4. Variation in Consolidation Parameters (Cc , Mv , Cc, k) with the Effect of Base (pH=9) and Curing Time when Black Cotton Soil Treated with OPC

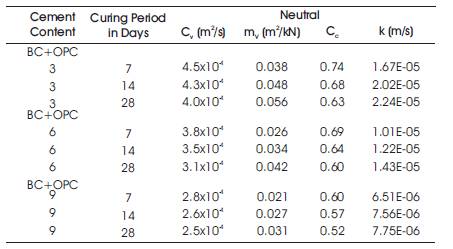

Table 5 shows the variation in consolidation parameters (Cc , Mv , Cc , k) with the effect of Neutral (pH=7) and curing time when black cotton soil is treated with OPC.

Table 5. Variation in Consolidation Parameters (Cc , Mv , Cc, k) with the Effect of Neutral (pH=7) and Curing Time when Black Cotton Soil Treated with OPC

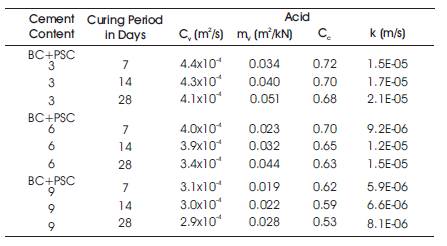

Table 6 shows the variation in consolidation parameters (Cc , Mv , Cc , k) with the effect of Acid (pH=5) and curing time when black cotton soil is treated with PSC.

Table 6. Variation in Consolidation Parameters (Cc , Mv , Cc, k) with the Effect of Acid (pH=5) and Curing Time when Black Cotton Soil Treated with PSC

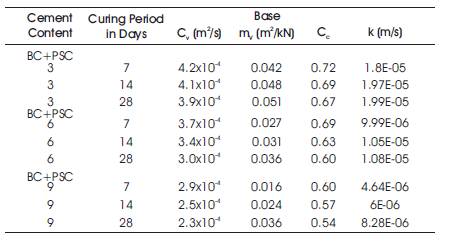

Table 7 shows the variation in consolidation parameters (Cc , Mv , Cc, k) with the effect of Base (pH=9) and curing time when black cotton soil is treated with PSC.

Table 7. Variation in Consolidation Parameters (Cc , Mv , Cc, k) with the Effect of Base (pH=9) and Curing Time when Black Cotton Soil Treated with PSC

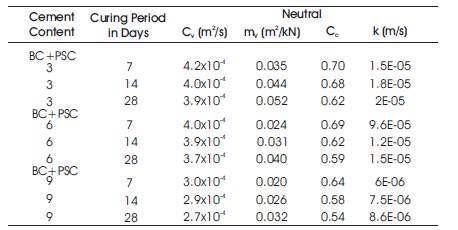

Table 8 shows the variation in consolidation parameters (Cc , Mv , Cc, k)with the effect of Neutral (pH=7) and curing time when black cotton soil is treated with PSC.

Table 8. Variation in Consolidation Parameters (Cc , Mv , Cc, k) with the Effect of Neutral (pH=7) and Curing Time when Black Cotton Soil Treated with PSC

The authors would like to thank the Principal of VNR VJIET and Dr. A. Mallika, Professor and Head of the Department of Civil Engineering for providing all facilities required for the completion of this research successfully and also they express their sincere gratitude to the management authorities for their continuous support, patience, motivation, enthusiasm and immense knowledge towards completion of this research.