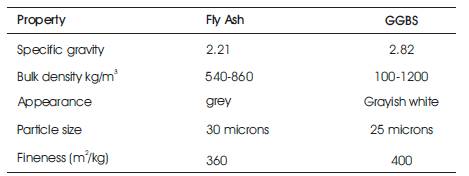

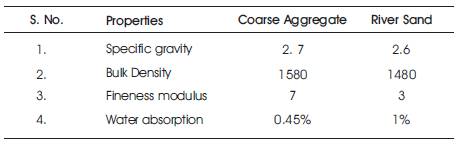

Table 1. Physical Properties of Fly Ash and GGBS

The present experimental work deals with the development of fiber reinforced geopolymer concrete in standard grade of (G40) incorporating polypropylene and basalt fibers. Equal proportions of fly ash and Ground Granulated Blast Furnace Slag (GGBS) were used as binders by replacing cement, active alkaline liquids like Sodium Hydroxide (NaOH) of (12M) Molarity concentration, and Sodium Silicate (Na2SiO3). In this experimental work, polypropylene fibers were varied at 0.25%, 0.75%, 1.25%, 1.75% and maximum up to 2.25%; volume of basalt fibers were kept constant at 0.25%. The detailed study was performed to analyze, how fibers effect in the geopolymer concrete specimens; also Standard increase in the Compressive strength, Split tensile strength was noticed and increase in flexural strength was found to be adequate.

For the past few decades, there has been a smart technological progress within the development of geopolymer applications in concrete industry, where the demand for the special concretes has been doubled as compared to their past. The foremost issue in present trends which is the optimized pollution caused by totally different sources in construction ground. Therefore, the development of alternate green materials has laid an emphasis on the practicing engineers and researchers to work towards the utilization of cementitious mineral admixtures (Lohitha et al., 2016). And, it has gained prominence over the past few decades because of its ability to impart additional performance characteristics. Cement plays a significant role in contribution which was created by emission of pollutants. Corbon-di-Oxide (CO2) which is 75-80% liable for environmental pollution has increased the impact on environmental cycle, as per surveys. The production of one ton of cement emits one ton of CO2 . So, in order to mitigate this effect to some extent, the geopolymer business shows an alternate binder for Portland cement that is well created, easily settles a byproduct created in power coal plants termed as fly-ash that acts as glorious replacement for Ordinary Portland Cement (OPC) (Kumar et al., 2005). The Geopolymer concrete, has two drawback conditions such as the delay in setting time and the necessity of heat curing to gain strength. These two limitations of geopolymer concrete mix was eliminated by replacing cement with fly ash and GGBS, for hardening the geopolymer concrete on the basis of reaction with alkaline liquids (Madheswaran et al., 2013) resulted in geopolymer concrete. In the present investigation, materials like fly-ash and GGBS are chosen as binders. Geopolymer concrete consists of fly ash, fine and coarse mixtures and alkali liquids. Super Plasticizer acts as the water reducer. The incorporation of fibers improves the mechanical and durability characteristics of geopolymer concrete. The types of commonly used fibers are steel, glass, polymeric, carbon, asbestos and different types of natural fibers. The fiber materials like polymeric fibers suchas polypropylene, polyethylene, polyester, fibers are becoming popular these days (Ayub et al., 2014). With nominal lengths of 6, 12 or 18 mm, polypropylene fiber are the ideal solution for concrete mixtures susceptible to plastic shrinkage, as well as cracking. The fibers do not replace the steel reinforcement bars or normal procedures for setting the geopolymer concrete. Solutions like Sodium Hydroxide or Potassium Hydroxide with Sodium Silicate or Potassium Silicate and, fly ash, which contains aluminum and silica, are used which reacts with the alkaline solution to form a desired geopolymer concrete matrix. Impact of mixed fibers in geopolymer concrete improves durability properties and it is more effective on self compacting concrete (Kumar et al., 2014).

The objectives of the present study are,

Primary studies were conducted on geopolymer specimens to check the compatibility of the procured fly ash and GGBS with fibers and the Super Plasticizer. Further, the studies on the geopolymer concrete specimens were carried out using locally available materials.

Fly ash corresponding to (ASTM Class F) with a specific gravity of 2.3 was used in the current study. Kakatiya Thermal Power Station is located near Chelpur village in Warangal district of the Indian state of Telangana. The Power Plant is one of the coal based power plants of Telangana State Power Generation Corporation Limited (TSGENCO). The Physical and Chemical properties of fly ash and GGBS are presented in Tables 1 and 2, respectively.

Table 1. Physical Properties of Fly Ash and GGBS

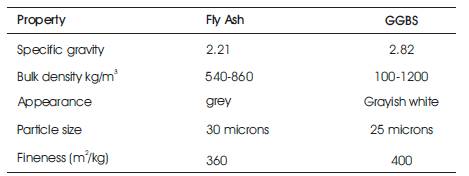

Table 2. Chemical Composition of Fly Ash and GGBS

Ground Granulated Blast Furnace Slag (GGBS) produced in thermal industries by quenching molten Iron Slag (a byproduct of iron and steel-making) from a blast furnace in water or steam to produce a glassy, granular product which is then dried and ground into a fine powder. The chemical composition of the slag varies considerably depending on the composition of the raw materials in the iron production process. The Silicon-aluminate impurities from the iron ore and coke are combined in the blast furnace with a flux, which reduces the viscosity of the slag. In case of pig iron production, the flux consists mostly of a mixture of limestone and forsterite, in some cases, of dolomite.

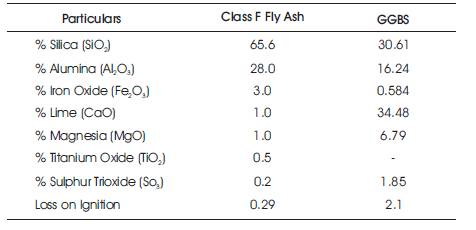

The aggregates used in this study were obtained locally from Hyderabad. Coarse aggregate used in the study was crushed granite aggregate with a maximum aggregate size of 20 mm and specific gravity of 2.7.

The fine aggregate used was River sand with a specific gravity of 2.6. The properties of aggregates are shown in Table 3.

Table 3. Properties of Aggregates

Polypropylene fiber shown in Figure 1(a) is a synthetic carbon polymer which is produced as a continuous monofilament with circular cross section. Polypropylene fiber with 0.0075 diameter, 12 mm length, Aspect Ratio(L/D) is 1600 and 0.91 g/cm3 density were used. Polypropylene fibers are tough, but with low tensile strength and modulus of elasticity. The role of polypropylene fibers in geopolymer concrete is to reduce crack width. These types of fibers are usually recommended for Plastic shrinkage reinforcement in concrete. It helps in uniform distribution throughout the concrete mix and gives excellent finishability. The properties of polypropylene fibers are represented in Table 4.

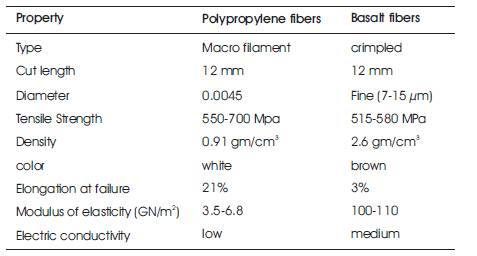

Table 4. Properties of Fibers

Basalt is a volcanic rock which can be chopped into small particles, forming continuous or chopped fibers. Basalt fibers are shown in Figure 1(b) which possess a high working temperature, and a good resistance to chemical attack. These fibers are mostly used in a wide range of applications such as strengthening of soils, construction of highways, bridges and industrial floors, retrofitting activities such as retrofitting and rehabilitation of structures (Ayub et al., 2014). The major role of basalt fibers in geopolymer concrete is to improve tensile strength, where they also have a high elastic modulus that results in excellent specific strength which is three times which of the steel. It has a similar chemical composition as glass fiber, but has better strength characteristics. Unlike most glass fibers, it is highly resistant to alkaline, acidic and salt attack which makes it a good candidate for concrete, bridges and high rise structures (Amuthakkannan et al., 2013).

Figure 1. (a) Polypropylene Fibers, (b) Chopped Basalt Fibers of Length 12 mm

The sodium sillicate solution pellets used is shown in Figure 2(a).

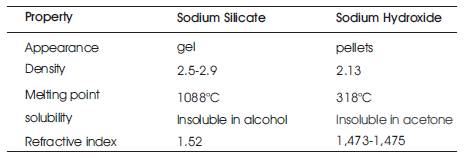

Sodium Sillicate usually known as "water glass" or “liquid glass”, is well- known due to its commercial and industrial applications. It is mostly composed of oxygen-silicon polymer bockbone lodging water into molecular matrix pores. Geopolymer Concrete treated with a sodium silicate solution helps in reducing the porosity in most products such as geopolymer concrete. This substance involves a combination of Sodium Carbonate (Na2CO3) and Silicon Dioxide (SiO2) under conditions sufficient to melt 2 both the reactants. The properties of sodium silicate are presented in Table 5.

Table.5 Properties of Alkaline Liquids

Sodium hydroxide is also known as caustic soda; it is a harmful base and an alkali substance which helps binding the loose aggregates together to form geopolymer concrete paste. In this present experimental investigation, 12 Molarity concentration of Sodium Hydroxide (NaOH) solution is prepared by mixing 480 grams of pellets and addition of water of up to one liter. This solution is prepared 24 hrs earlier and then introduced into geopolymer concrete matrix, where the pellets of 98% of purity were used. The properties of Sodium Hydroxide are also presented in Table 5. The Sodium hydroxide pellets used in Alkaline solution are shown in Figure 2(b).

Figure 2. (a) Na2SiO3 Solution, (b) NaOH Pellets used in Alkaline Solution

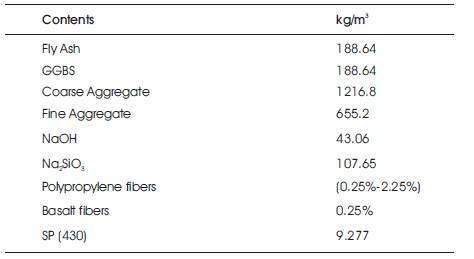

Since there are no codal provisions available for the mix design of geopolymer concrete, the density of Geopolymer concrete was assumed to be 2400 kg/m3 and other calculations were made based on the density of concrete as per the design given by Lloyd and Rangan (2010). The combined total volume occupied by the coarse and fine aggregates was assumed to be 78%. The ratio of alkaline liquid to binder is 0.40. The major difference between geopolymer concrete and cement concrete is the binder. The silicon and aluminum oxides in the fly ash and GGBS react with the alkaline liquid to form the geopolymer paste, that binds the aggregates to form the geopolymer concrete. Generally in normal concrete, the coarse and fine aggregates occupy about 75% to 80% of the mass of geopolymer concrete. This component of geopolymer concrete mixtures can be designed same as the ordinary portland cement concrete. The compressive strength and the workability of geopolymer concrete depends on the proportions of materials, that are responsible for the manufacturing of the geopolymer paste (Kumar, 2016).

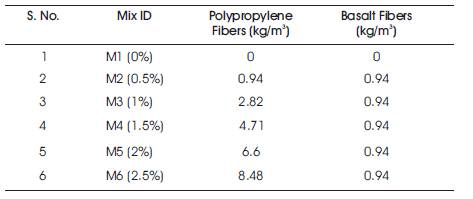

The role and influence of the aggregates are considered tobe the same as normal concrete. The mass of combined aggregates can be chosen between 75% and 80% of the mass of the geopolymer concrete for G40 grade. The performance of geopolymer concrete mixture depends on the strategy of mix. In order to meet these performance criteria, it depends on the alkaline liquid-to-fly ash ratio, water-to binder ratio by mass, water to geopolymer solids ratio by mass, admixtures used and the curing temperature. The mix design data is shown in Table 6 for all mixes, where polypropylene and basalt fibers were varied for every mix.

Table 6. Mix Design Data

The mass of combined aggregate is assumed as 0.78% of the mass of concrete i.e. 0.78 x 2400 = 1872 kg/m3.

Let us consider the mass of coarse aggregate as 65%, then the mass of coarse aggregate = 65/100*1872 = 1216.8 kg/m3.

Let us consider the mass of fine aggregate as 35%, then the mass of fine aggregate = 35/100*1872=655.2 kg/m3 Mass of Fly ash and alkaline Liquid = 2400-1872 = 528 kg/m3.

Considering Alkaline liquid to Binder ratio as 0.40,

Mass of fly ash = (528)/(1+0.40) = 377.28 kg/m3.

Considering the ratio of sodium hydroxide to sodium silicate as 2.5,

Mass of Sodium Hydroxide is given by,

28-377.28=150.72 kg/m3

(150.72/1+2.5)=43.06 kg/m3

Mass of sodium silicate solution is given by,

150.7- 43.06=107.65 kg/m3.

The mass of Sodium Hydroxide Solution (NaOH) is given by,

12 X 40 (molecular weight) = 480 grams. 480 grams of sodium hydroxide solids per one liter of sodium hydroxide solution consists of 44.44% of pellets (solids) and 63.5 % of water. The water content present in the NaOH solution is observed as 63.5%.

The mass of NaOH solution is given by,

Mass of solids = (44.44/100) x 43.06=19.1 kg.

Mass of water = (43.06-19.1) =23.96 kg.

In Sodium Silicate Solution (Na2SiO3) the water content present observed as 63.5%.

Mass of Water = (63.5/100) x (107.65): 68.38 kg.

Mass of Solids = (107.65 – 68.38): 39.27 kg.

Total mass of water is given by,

Mass of water in Na2SiO3+ NaOH solution= (68.38+23.96) = 92.34 kg.

Total mass of solids is given by,

Mass of solids in NaOH + Na2SiO3+ mass of fly ash= (19.1+39.27+377.28) = 435.56 kg.

Ratio of water to geopolymer solids is given by,

(92.34) / (435.53) = 0.21.

Geopolymer concretes can be prepared by using the following conventional techniques used, same as in the steps of cement concrete. In the laboratory, the constituents were mixed together in a pan mixer for about four minutes. The aggregates were prepared in saturated surface dry condition (Ayub et al., 2014; Kumar et al., 2005). The alkaline liquids preferred in this experiment for the geo polymerization are Sodium Hydroxide (NaOH) and Sodium Silicate (Na2SiO3). 12 Molarity of sodium hydroxide solution is taken to prepare different mixtures. The sodium hydroxide is available in the form of pellets and flakes are mixed with the distilled water and prepared prior one day before casting. The Sodium silicate is added to the dry materials, just before casting and the mix is continued for four minutes. The fresh geopolymer concrete was cast and compacted by the usual methods same as OPC concrete (Balachandra and Bhosle, 2013; Ramanujee, 2014). The ratio of the composition of FA+GGBS was varied suitably. The primary objective for performing the trial and error procedure was to obtain the desired compressive strength and reduce crack width of specimen, when subjected to the axial loading. The secondary objective was to achieve a good cohesive mix with good workability (slump of 75 to 100 mm) (Ayub et al., 2014). The proportions of fibers, super plasticizer and binder materials play a major role in setting of geopolymer concrete. The specimens cast were demoulded after 24 hours and then subjected to heat curing at 60 degrees. The mix contents of geopolymer concrete and Fiber proportion mixes are shown in Tables 6 and 7 respectively.

Table 7. Fiber Proportions for Various Mixes

A concrete is said to be workable if it is easily transported and placed well compacted and finished without any type of segregation. Workability is a property of freshly mixed concrete, where the concrete is a mixture of cement, aggregate, water and admixture, and super plasticizer.

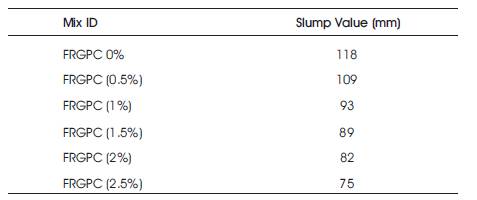

The mold chosen for slump test is a frustum of cone, which is 300 mm (12 inches) of height. The base is 200 mm (8 inches) in diameter and it has a smaller opening at the top, of 100 mm (4 inches). The base is placed on a smooth surface and the container is filled with concrete in three layers, whose workability is to be tested. The results are presented in Table 8. The Slump cone test variation for all mixes is shown in Figure 3.

Figure 3. Slump Cone Test Variation for all Mixes

Table 8. Slump Test Results

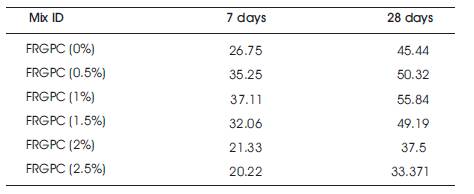

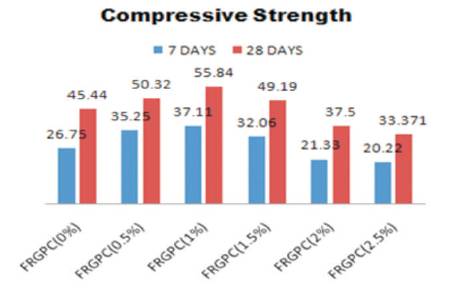

Compressive strength is the most important property of a concrete. The specimens were tested on 2000 kN as per IS: 10086-1982. The geopolymer concrete mixes were formulated in such a way that the fibers were varied replaced partially with 0.5%, 1%, 1.5%, 2%, 2.5%. Fly Ash and GGBS were included in the mix at equal volumes. The incorporation of fibers yields the highest strength in the tests. The geopolymer concrete with the addition of 0.75% of polypropylene fibers and 0.25% of basalt fibers yields the highest strength, and the control mix without the addition of fibers, results in relatively lower strengths which are still above the desired 40 MPa. The increase in the compressive strength, could be attributed to the fibrous nature of polypropylene and basalt fibers. The compressive strengths of all cubical specimens were evaluated at the end of 7 and 28 days as shown in Table 9. The compressive strength variation of all mixes is shown in Figure 4 (Kumar and Ramujee, 2017).

Table 9. Compressive Strength Results

Figure 4. Compressive Strength Variation for all mixes

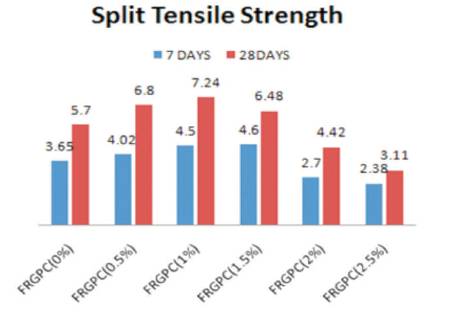

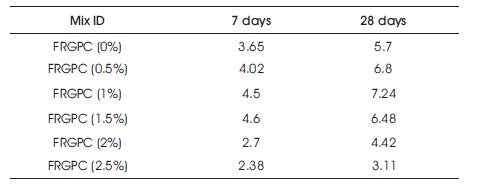

The variation of split tensile strength measured at the end of 7 and 28 days of curing is as shown in the Figure 5. The specimens were tested on 2000 kN as per IS 5816-1999. The increase in split tensile strength of the geopolymer concretes was observed with the inclusion of 0.75% dosage polypropylene and 0.25% basalt fibers. The addition of 2.25% of polypropylene and 0.25% of basalt fibers in geopolymer concrete matrix has shown a decrease in tensile strength in comparison to another percentage of dosage, but it still performs better in comparison to Normal Concrete. The results of split tensile strength tests are shown in Table 10.

Figure 5. Split Tensile Variations

Table 10. Split Tensile Strength Results

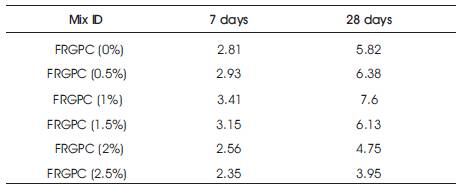

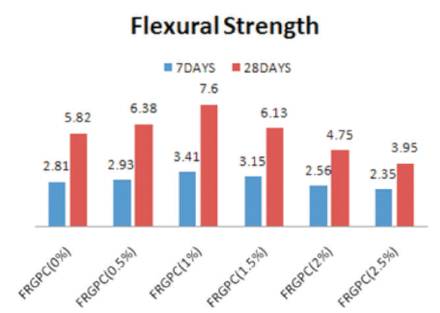

Flexural strength is also known as bending strength or fracture strength. It is a mechanical property which is defined as a material's ability to resist deformation under load or stress in a material just before it is yielded in a flexure test. The flexural strength of 100*100*500 mm beams wastested as per IS: 516-1959. The increase in flexural strength of geopolymer concrete specimen observed with the incorporation of 0.75% dosage of polypropylene and 0.25% of basalt fibers, is same as compressive and split tensile strength. The decrease in flexural strength was relatively low in comparison with normal geopolymer mix with the addition of mixed fibers. The difference in flexural strength measured at the end of 7 and 28 days at heat curing of 60 oC for 24 hrs is shown in Table 11. The variations is flextural strength is shown in Figure 6.

Table 11. Flexural Strength Results

Figure 6. Flexural Strength Variations

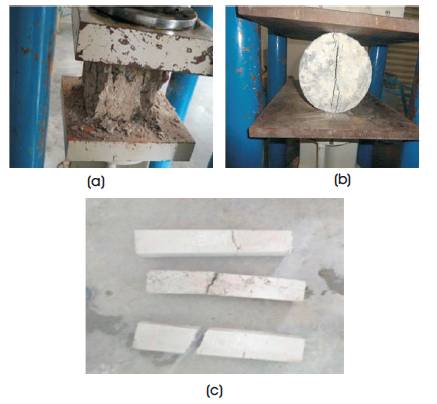

The failure pattern observed during compression test, split tensile strength test, and flexural strength test are shown in Figure 7.

Figure 7. Typical Failure Pattern observed during (a) Compression Test, (b) Split Tensile Strength, (c) Flexural Strength

Use of binder's fly ash GGBS in equal proportions had shown good increase in Split Tensile and Flexural strength of fiber reinforced geopolymer concrete better than compressive strength. Addition of mixed fibers to geopolymer concrete enhanced its mechanical properties. The decrease in water content favors the formation of geopolymerization process, which demands the requirement in increase of concentration of Sodium hydroxide and Sodium silicate. Therefore, increase in concentration of NaOH results in increase of compressive strength. Hence 12M can also be recommended. Dosage of polypropylene and basalt fibers has decreased crack width of specimens compared to the control mix. It has been observed that the excessive workability of concrete has been decreased with the addition of Basalt and Polypropylene fibers. It was found from the study failure pattern of the specimens (Figure 7) that, the formation of crack width is more in the case of the geopolymer concrete without addition of fibres than with addition of fibers in geopolymer concrete. Nearly 22% of increase in compressive strength was noticed with comparison to, with and without additions of fibers at the end of 28 days (Table 9). In Split tensile strength the increase was noticed as 27% for optimal mix (Table 10). Whereas, in flexural strength, the increment observed was nearly 31% with respect to control and optimal mix (Table 11). From the experimental results, it can be considered that an incorporation of 1% fibers performed better in comparison to other mixes of geopolymer concrete.

The behavior of geopolymer specimens of optimal mix which gains high strength among all mixes when immersed in acidic solutions such as H2SO4 and HCL at 5% concentration can be studied further. The Abrasion Resistance of optimal mix condition obtained i.e. at 1% of fiber dosage can also be studied and the regression analysis can be run using MS Excel.