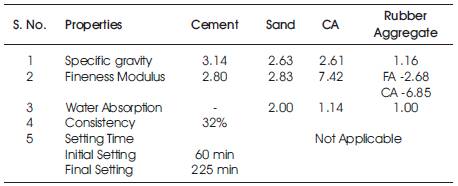

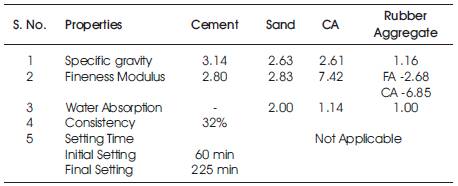

Table 1. Material Properties

Recent investigation accounted that more than one billion tyres are scrapped annually throughout the world, as we know rubber materials are durable, flexible and elastic which are the basic properties required for manufacturing of tyre that itself engender critical problem of managing when it become waste. When waste tyre is dumped into the land it takes 100 years to decompose and it enmesh water which behaves as best breeding grounds for insects and produce health hazards to the human society. While charring, tyres produce toxic gases and generates pollution to the environment. To alternate the aforesaid methods, the tyre wastes are tried as replacement material in concrete either as fine or coarse aggregate by volume batching but no researcher suggested the optimal usage of this waste tyre rubber. The current research investigates the optimal consumption of shredded rubber and truck tyre rubber in concrete called in the name of Rubbercrete. A total of 72 cubes, cylinders and flexure beams of M20 and M25 grade concrete were cast and tested for the combined replacement of both fine and coarse aggregates simultaneously with that of shredded rubber and truck tyre rubber chiseled into nominal size of coarse aggregate by 2, 4, 6 and 8% in concrete by weigh batching. The test results were compared with 18 numbers of conventional specimens and it was identified that 6% of replacement performs better in compressive strength, split tensile strength and flexural strength and hence it is being an optimal replacement.

Modern development in transportation produced large number of vehicles creating enormous amount of waste tyres. The discharge of waste tyre rubbers is expensive and the continuously decreasing numbers of landfills generates stockpiling. Stockpiles of this non-degradable waste tyre rubber leads to reduction of water table and causes drought. Combustible nature of tyres lead into fire which is hard-hitting to extinguish due to geometry of tyres,and the runoff creates hazardous pollutant into ground water. Tyres offer attractive breeding grounds for pests such as mosquitoes which can be the vectors for the transmission of life threatening diseases to humans. Hence sustainable use of waste tyres becomes the major problem to the society. One of the largest potential factors of waste tyre management is utilizing it into construction, but usages of waste tyre rubber in civil engineering projects are currently very low. Topcu (1995) reported that a general reduction in the physical and mechanical properties of rubberised concrete made by using scrap tyres was observed. About 50% decrease in cylinder and cube compressive strengths, 64% decrease in tensile strengths was observed in concrete mixed with fine rubber aggregate. On the other hand, using coarse rubber aggregate caused decreases up to 60% in cylinder compressive strengths and up to 80% in cube strength and up to 74% in tensile strength. Toutanji (1996) conducted experiments to investigate the effect of the replacement of coarse aggregate by rubber aggregate. Four different contents of rubber aggregate with a maximum size of 12.7 mm were used to replace the coarse aggregate at 25, 50, 75 and 100% by volume. The researcher discovered that the incorporation of the rubber aggregates in concrete produced a reduction in compressive strength of upto 75% and a significantly smaller reduction in flexural strength of upto 35%. The reduction in both strengths increased with increasing the rubber aggregate content. The researcher observed that the specimens containing rubber aggregate exhibited a ductile mode of failure as compared to the control specimens. While examining the available literatures the replacement of waste tyre rubber was carried out either with fine aggregate or coarse aggregate, that too by volume batching. Therefore an attempt is planned that to replace both fine and coarse aggregate with that of shredded rubber and truck tyre rubber chiseled into nominal size of coarse aggregate simultaneously by 2, 4, 6 and 8% (by equal combination of fine & coarse rubber aggregates) in concrete by weigh batching.

Rubbercrete is a concrete consisting of cement, river sand, metal and rubber aggregates (Figure1) and their properties are tabulated in Table 1.

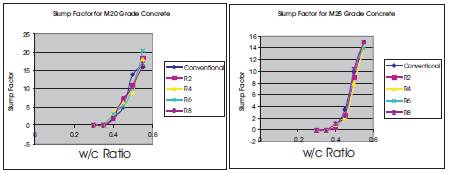

Workability refers to the mobility or flow ability of concrete experimented by slump test. The slump test was carried out for M20 & M25 grade concrete with combined replacement of fine rubber and coarse rubber compared with conventional concrete to identify appropriate water cement ratio.

From the Figure 2 it has been recognized all the rubbercrete might behaved very close to the flow of conventional concrete. Hence it is ideal to make use of water-cement ratio as 0.50 for M20 Grade and 0.45 for M25 Grade concrete.

Table 1. Material Properties

Figure1. Rubber Aggregates (Fine & Coarse)

Figure 2. Slump Chart for M20 & M25 Grade Concrete

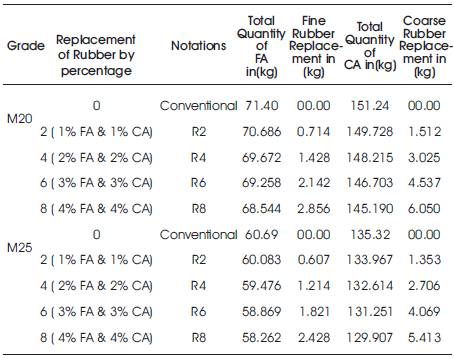

Mix design was carried out as per Indian Standard Code Method (IS 10262 – 2009) for the test specimen. Two different grades namely M20 and M25 grades were adopted in this study. The mix proportion adopted in this investigation for M20 grade is 1:1.43:3.03 whereas for M25 grade, the ratio used is 1:1.21:2.71.

The test specimens were cast in two different mix proportions of M20 & M25 Grade by weight with water cement ratios of 0.50 and 0.45 respectively. The sizes of the specimens are as follows: cube 150 x 150 x 150 mm, cylinder 150 x 300 mm and beam mould 100 x 100 x 500 mm. The moulds were placed on an even surface and the materials were mixed in mixer machine. First coarse aggregate, fine aggregate and their respective replacement of rubber aggregates (Table 2) were added and mixed thoroughly in a dry condition then cement and water was added to get fresh concrete mix. Compaction was done for all the specimens using vibrating table. The mould is striped after 24 hours. The test specimens were cured for 7 days, 14 days & 28 days in a curing tank.

Table 2. Rubber Replacements with Fine & Coarse Aggregate

The compressive strength is measured by breaking cube specimen and split tensile strength is measured by placing a cylindrical specimen horizontally between the loading surfaces in compression testing machine. Compressive strength test results are primarily used to determine the characteristic compressive strength of the concrete specimen and split tensile strength gives nearly equal direct tensile strength. Flexure testing machine shown in Figure 3 is used for testing the beam specimen which is placed in such a manner that the load is applied to the uppermost surface as cast in the mould, along two lines spaced 20 cm apart. The flexural strength is expressed as the modulus of rupture.

Figure 3. Compression, Split Tensile & Flexural Strength Test Setup

A total of 90 cubes, cylinders and beams were cast with M20 & M25 mix for this study with 2, 4, 6 & 8% of replacement of waste tyre rubber with combination of both fine and coarse aggregate and compared with the conventional concrete specimen.

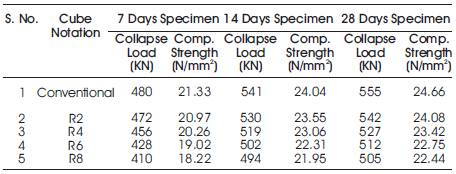

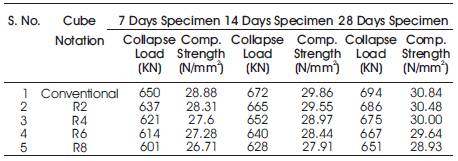

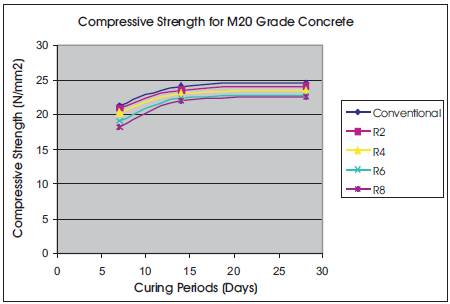

The compression test is carried out with cube specimen to find out the compressive strengths of conventional and rubber replaced concretes using compression testing machine and the results are tabulated in Tables 3 & 4.

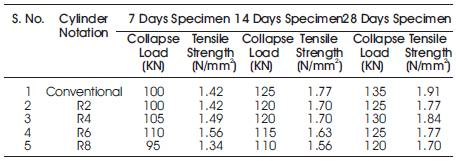

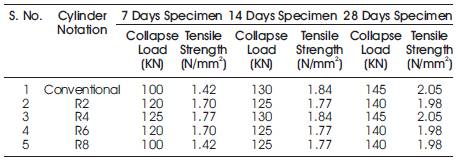

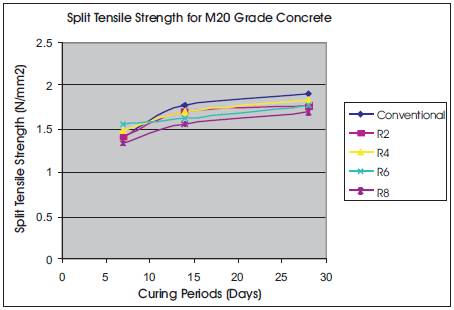

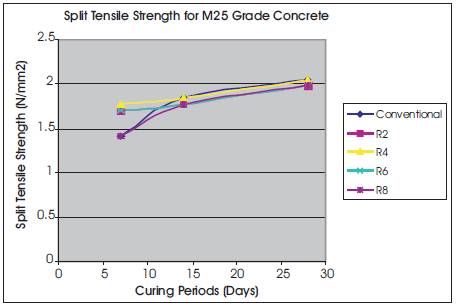

The split tensile test has been carried out and comparative results of conventional and rubber replaced concretes are tabulated in Tables 5 & 6.

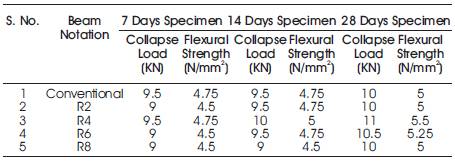

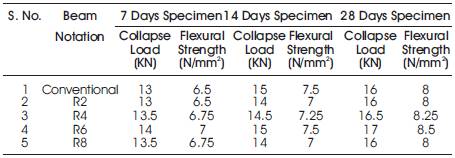

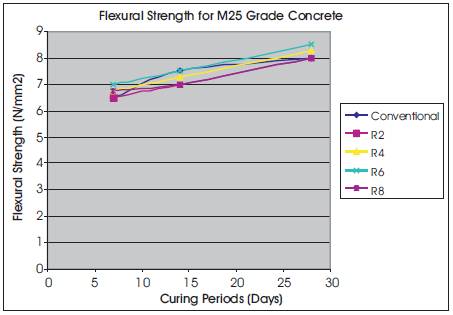

The beam specimens are tested in flexural testing machine to compare the results of conventional and rubber replaced concretes and the results were tabulated in Tables 7 & 8.

Table 3. Results of M20 Grade Concrete Average Compressive Strength

Table 4. Results of M25 Grade Concrete Average Compressive Strength

Table 5. Results of M20 Grade Average Split Tensile Strength

Table 6. Results of M25 Grade Average Split Tensile Strength

Table 7. Results of M20 Grade of Average Flexural Strength

Table 8. Results of M25 Grade of Average Flexural Strength

Figures 4 & 5 give comprehensible indication that all the percentages of replacement provide a gradual and strong increment in compressive strength,and the smooth nature of all the compressive strength curves proves it. From Figures 4 & 5 it is clearly found that all the replacements achieve more than 90% of compressive strength compared to conventional concrete on both M20 & M25 grades. Further it clarifies that when rubber replacement increases, the compressive strength of concrete decreases. Accordance with the comparison of split tensile strength (Figures 6 & 7), in M20 grade all the percentages of replacements confirms 90% strength compared with conventional concrete specimen. In M25 grade concrete all the replacements confirms 97% achievement of strength compared with conventional concrete. The flexural strength comparison in Figures 8 & 9 in both the grades 2 & 8% replacements shows equal strength to conventional concrete. But 4 & 6% replacement establishes higher strength than that of conventional concrete in both the grades.

Figure 4. M20 Grade Concrete Compressive Strength

Figure 5. M25 Grade Concrete Compressive Strength

Figure 6. M20 Grade Concrete Split Tensile Strength

Figure 7. M25 Grade Concrete Split Tensile Strength

Figure 8. M20 Grade Concrete Flexural Strength

Figure 9. M25 Grade Concrete Flexural Strength

With the back ground of the illustrations the authors come to know that 10% of compressive strength gets reduced due to the 8% of replacement of rubber aggregates in both grades. Accordance with the higher grades the performance of the rubber aggregates gradually increases that will be identified while comparing compressive strength and split tensile strength of M20 and M25 grade concrete. In flexure strength all the replacements shows exceptionally better performance with that of conventional concrete. Accordance with the graphical representation it is very clearly known that combined replacement of waste tyre rubber aggregate with that of fine and coarse aggregates shows gradual and strong improvement in all the above mentioned graphs in both grades of concrete in all the requisite strength. But by specific reference from the tables and graphs replacement of 6% proves exceptionally well in all the respective strengths and achieves higher flexural strength than the conventional concrete proving its ductile behaviour.

Based on the above mentioned discussion the following conclusions are made.

1. Increase in rubber percentage decreases the compressive and split tensile strength but increases the flexural strength to some extent.

2. 10 % of compressive and split tensile strength gets decreases while replacing 8% of fine & coarse aggregate by waste tyre rubber wastes on both M20 & M25 grades.

3. Curing period has been found to increase the strength of both the grades.

4. 6% combined replacement of waste tyre rubber by both fine and coarse aggregate in concrete is the adequate and optimal replacement. Hence it is suggested to use 6% replacement by weigh batching.