Figure 1. Diagram of the Design Process of the Pahl and Beitz Model (Pahl et al., 1996)

At present, designers usually carry the responsibility to select adequate materials for their designs, and without supportive expert knowledge in materials, there will be chances that wrong choices are made inevitably in material selection, which leads to product failures. The aim of this paper is to determine the enhancement of design decisions in the material selection process with the history of material application failures in order to find out what information should be provided for designers so that a well-informed decision can be made on the material selection. From the literature survey conducted, material selection should be considered early and in all stages of the design process so that designers can identify suitable range of materials earlier thus narrowing their choice of material when the design concept is developed. Designers should explore the opportunity to manipulate the intangible characteristics of materials to deliver the desired sensation or emotion to users. The history of material application failures were often not recorded or made available to designers, which explained why poor decision were made in material selection. In order to overcome this problem, a reference library of possible material application failures may be linked to an automated knowledge based material selection system which can include a pro-active warning mechanism that alerts the user when a failure history was discovered with the selected material.

Product failure is not an uncommon occurrence which may be due to various factors causing the product to fail. Product designers should be aware of the potential causes of failure and try to design a robust and reliable product where possible. One of the important factors which can help to avoid the product failure would be through selecting suitable materials for the components. By doing so, the product's design intent can be successfully expressed as well as the requirements of the design specification can be fulfilled.

The implementation of the history of material application failure was considered here and how this may be used to enhance the design decision in material selection is the main focus of this paper. The aim is to discover and reveal the role of material selection in the design process, the most important factors that a designer should consider when selecting a product and how the failed history of material application had been effective in changing the design decision in material selection.

In order to explore the topic in detail, a literature review was used to provide readers a general understanding of the topic around material selection and its involvement in the design process, which should also cover how the history of material failures can be used to inform the future designs, and what information should be provided to designers with regards to the history of material failures.

Two case studies were used to demonstrate the current material information provided in the Cambridge Engineering Selector (CES) software with suggested improvements, with explanation to inform readers what improvement options were available and how the decision in material selection could be enhanced through learning about the history of material application failures.

The result and findings from the literature survey and case studies were analysed in the discussion and possible future research options were suggested.

A key question was devised in order to guide the research process:

Could a reference library of material application failures enhance design decisions?

The following research topics were used to guide the research process:

Through addressing the research topics listed above, a background understanding of the material selection process and its relationship to design could be established. The factors for consideration for designers when selecting a material should be revealed. By exploring ways through which designers obtain their knowledge on materials, this should identify the existing source of material knowledge for designers and other possible ways that extra knowledge can be obtained.

This paper also aimed to reveal the influence of the history of material application failures in design decision changes, and how this information should be presented to designers.

Finally, the justification for recommendation of the CES software to designers to aid the material selection process was presented to show how this can help designers make informed design decisions in material selection.

In order to help readers and designers understand the importance of material selection in the design process, illustrated diagrams of the design process by different authors were presented in this section, which were used to demonstrate the flow of the design process, how and when the material selection is involved.

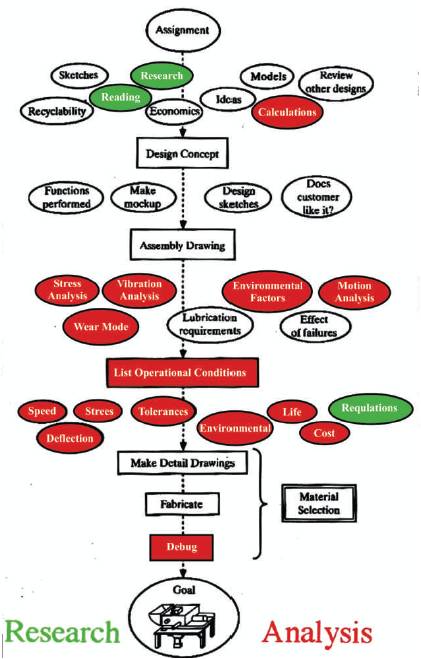

With regards to the design process, the Pahl and Beitz Model (Pahl et al.,1996) was an important starting point for readers to understand how the design process was carried out. Design activities involved at all three main stages in the design process (Conceptual, Embodiment, and Detail design) were clearly identified and the key tasks associated with each stage were presented. It suggested that the design process involved frequent upgrade and refinement of the design concept at each stage (Figure 1).

Mangonon (1999), Ashby and Johnson (2010) and Cross (2008) have agreed on this concept as an exemplar design process as it was cited in their respective publications. This is an important concept which the designer should take into consideration when designing as it was found to be a well-accepted concept referred to by the acknowledged authors mentioned above.

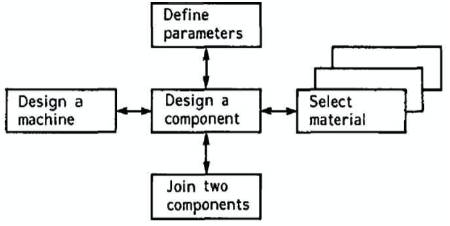

Starting from a materialist's point of view, Budinski's concept of design strategy involved a lot of analysis and there was relatively little research required in the design process. This would mean that designers may have difficulties obtaining expert knowledge from the main sources suggested, such as reading and research activities. A strong disadvantage of this idea would be that the material selection would require an established design concept with known dimension, specification with assembly drawings before material selection can take place, which meant if any problems associated with the material such as supply and cost arises, the design concept may have to be refined, hence consuming extra time and resources. An illustrated diagram of Budinski's concept is presented in Figure 2 for clarification.

Figure 2. Diagram showing Budinski's Design Strategy (Budinski and Budinski, 2005) found in (Warnes, 2014)

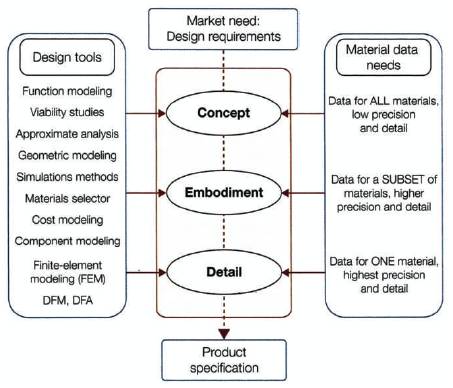

A contrasting view to Budinski's design strategy was suggested by Ashby (Ashby, 2011). His view proposed that material selection should be considered at every stage of the design process which, at each stage would require different level of detail in the information provided to the designer. Instead of considering the material selection at a later stage in the design process, it was also considered early at the conceptual stage which would allow designers to obtain information on all materials, therefore increasing the designer's awareness of the possible materials that he or she can design with. As a result, this would promote new or creative ideas due to increased flexibility and would enable a material based design approach. This idea does not only allowed materials to be considered at an early stage, it also enabled other material related factors, such as costs, processing methods, geometrical limitations to be considered earlier in the design process reducing the time spent refining the design concept as suggested in Budinski's idea. Ashby's concept is illustrated in Figure 3.

Figure 3. Diagram of Ashby's Design Procedure (Ashby, 2011)

As one of the founders of the Granta Design and the CES Selector (Granta Design, 2014d), Ashby suggested that material selection should be considered as a major part in all stages of the design process, and he recognised that the nature of the data required for each stage is different. This idea was also supported in the works of Dieter (2000) and reviewed by various authors ( Dieter et al., 2009; Mangonon, 1999), although they share the same view with this approach on material selection within the design process, for other materials such as ceramics, the material selection should be considered early enough as it may affect the outcome of the product due to factors such as thermal expansion, and therefore there was no agreeing point to where the material is selected in the design process (Bamkin and Piearcey, 1990).

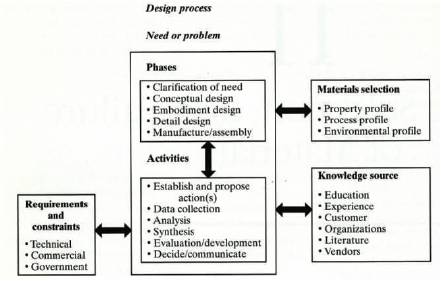

All three authors mentioned above (Ashby, Bamkin, and Mangonon) posed a similar view on material selection (Figures 4 and 5) that it should be a process carried out in parallel as well as other design activities, such as concept development, evaluation, and analysis of the design concept. As the design was continuously refined, more details on the requirements of the design were established therefore this enabled more requirements for the material in greater depth, thus restricting the numbers of suitable materials, making material selection easier at later stages of the design process.

Figure 4. Mangonon's Idea of Material Selection in the Design Process (Mangonon, 1999)

Figure 5. Bamkin's Diagram of the Design Process (Bamkin and Piearcey 1990)

Through considering material selection in the early stages of design, this should allow flexibility in the design, where new materials may be considered to influence the design of the product. The list below shows three forms of design with examples as suggested in, which could be applied through early considerations of material selection in the design process (Ashby, 2011):

Offers new, unique combinations of properties that enables original design. Examples were transistors made of high purity silicon and optical Fibre (Heywood, 1973) made by high purity glass.

This offered incremental advance in performance through refining the working principle. Examples: Carbon fibre rackets instead of wooden rackets for sports ( Tennis Rackets UK, 2014; International Tennis Federation, 2014) using polymers instead of metals for the housing of household appliances ( Encyclopaedia Britannica, 2014; Wallender, 2014).

Depending on the nature of the material used, some products such as ceramics would require detailed information to be available to designers before the embodiment stage because of the possible processing issues. Therefore, there should not be a strict statement to where material selection is involved in the design process as this varies with materials. The design process of a component was not systematic, and other inter-related activities, such as evaluation and refinement of the design concept continued at the same time (Bamkin and Piearcey, 1990). It was important that designers take into consideration of material selection early in the design process to ensure that they do not restrict themselves to using a single class of material; instead they can be encouraged to experiment and conduct tests with different materials at the conceptual stage in order to obtain a good understanding of the material and its properties. Doing so may help to reduce the chances of finding an unsuitable material causing future problems such as failures arising from processing and fabrication (Mangonon, 1999).

When a designer is required to make a decision on the material used for a part, it is important to understand how the material selected can fulfil the design intent and requirements for the part. The decision making on any material selection methods relied on suitable material information (including properties and characteristics) being available to designers (Edwards 2014). To help designers gain a basic knowledge about materials, their properties and characteristics, a comprehensive list of material information can be found in the works of Askeland et al. (2011):

It is important that designers understand the language and terminology used in materials science as well as the materials' characteristic properties, how they are measured and processes of each class of materials (Askeland et al., 2011). The Product Design Specification is directly linked to material selection, especially in the product's performance, costs, and user requirements, therefore the following factors should be considered when choosing a material (Rodgers and Milton, 2011).

Through generating a list of desirable qualities and requirements, these factors could be matched up against the properties of a range of materials, hence re-interpreting the design intent in technical design which could involve setting numerical values and limits for the material selection that forms part of the technical design.

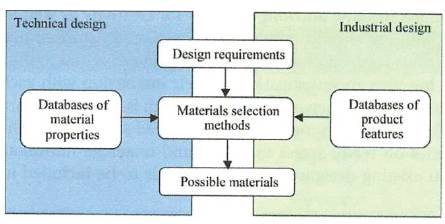

For designers, understanding the terminology used in technical and industrial design would be crucial. Industrial design involves defining the product's aesthetics, perception, and semantics, whereas in technical design, limits and attributes associated with the product's performance would be defined. A designer should possess the ability to understand and interpret information in both technical and industrial design, and this skill would be most vital in ensuring that their product's design intent can be successfully expressed through material selection (Ashby and Johnson, 2010).

Examples of the terminology used by an Industrial Designer could be aesthetics, texture, sensation; whereas these may be perceived by the Technical designer as optical properties, surface roughness, weight, or specific heat capacity. In order to help readers understand the differences between technical and industrial design, Figures 6 and 7 by Ashby and Edward were used to show the differences in the design approach and the database referred to by their respective designers.

Figure 7. The Role of Material Selection in Product Design and Comparison by (Edwards, 2014)

It is crucial for a designer to consider the technical and sensorial characteristics of materials as well, which the technical properties should fulfil the functional requirements and the sensorial properties should appeal to the senses of the user. An account comparing 9 different authors' viewpoint of effective material aspects in the material selection process was presented by Karana et al. (2008), and how these material aspects could be considered and used to give meanings to the material were also discussed in Karana (2010).

Apart from the usual consideration factors, such as mechanical, processing, cost, and eco design, A 'business issue' factor was proposed by Budinski, which took into consideration the availability of the material, the approval of use in regulation agencies such as the Food and Drug Administration (2014) on regulations with regards to food safety and medication instruments. By considering these factors in material selection, designers can have information which can then be used to convince investors or clients of the feasibility of their design concept, as well as using these data for predictions associated with the product.

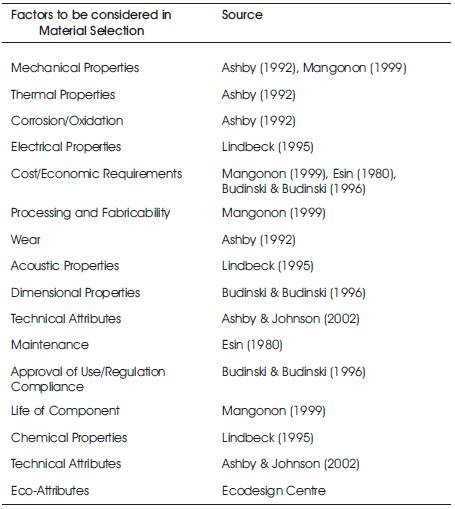

Having reviewed the researched data, the most important factors that a designer should consider in material selection were presented in Table 1.

Table 1. Factors for Consideration in Material Selection

However, there were other factors apart from those listed in Table 1, which should also be considered, but could not be measured. They were the intangible issues ( Ashby andJohnson 2002; Oxford dictionaries, 2014 () or known as the 'indefinable characteristics of materials' which included ( Lindbeck, 1995 ; Karana et al., 2008) : appearance; odour; feel; general impression of the material; non-active functions of the materials; material personality; and perceived values and characteristics of material. The desired sensations of a product could be delivered through an effective combination of the sensorial properties of materials. These properties may then be used to achieve a product that delivers the desired emotion to the user ( van Kesteren et al., 2007; Karana et al., 2009).

Although the published materials data could be obtained by the designers, it may not cover the precise and end-ofuse conditions for materials. Designers should aim to understand and be updated about the trend associated with the material, to help them make a sound and informed choice of material selection (Lanxess, 2007). However, they should also be cautious of the change in the characteristics of the materials under different environments, such as temperature and humidity to avoid possible failures of the material used (Lough et al., 2008).

In addition, designers should be knowledgeable about the material's real character, such as its strengths and weaknesses, shaping and joining methods, its previous application in products, and its history of failure. By having a good understanding of the materials, designers should be able to reduce the chances of errors or failures of their future design (Ashby, 2011).

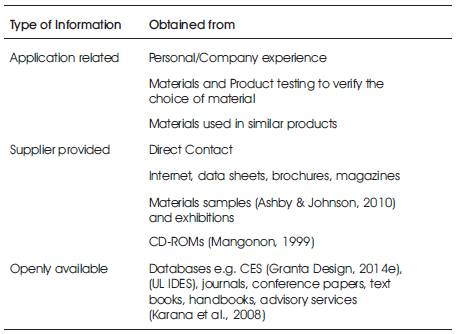

Designer may often need to search for specific material information and data from various resources. Table 2 had summarised the types of material information and where these can be found as suggested by Edwards (2014) and van Kesteren (2008).

Table 2. Types of Material Information and Possible Sources of Information

As a starting point to gather material information, using the Internet would allow the designer to access various websites associated with material selection and their background information. Designers could also access databases for further detailed information on the material characteristics such as the ASM database of materials or use a 'design assistant' program as proposed by Bamkin, which aimed to provide detailed information about a specific material's full properties ( ASM International, 2014 ; Bamkin and Piearcey, 1990).

Moreover, designers should pay attention to the quality of the information obtained, because data for newer materials may be incomplete or unreliable, hence engineers may be more conservative with their choice of material. In comparison, data for old materials could appear to be more comprehensive and accurate (Ashby, 2011).

The need for cataloguing and communicating the knowledge of potential failures was well recognised, as doing so would allow the future analysis of material application failures. Though analysis and evaluation, this history should generate insights and methods of correction or prevention of similar material failures (Lough et al., 2008). It was suggested that all high-risk product development companies needed tool which can effectively prevent product failures which emphasised the importance of having an effective system that allows storage of failure records of materials (Lough et al., 2008). Furthermore, this system should be accessible to designers who are the key decision makers in material selection.

A classic example would be the Challenger and Columbia Space Shuttle disaster which through investigations, the required knowledge to prevent both disasters were available, however, this was not recorded or stored for retrieval ( National Aeronautical and Space Administration, 2014, referred to as NASA ; Howell, 2014). If this knowledge was recorded and harnessed, such disaster could have been prevented, and therefore designers should not underestimate the consequences of material application failures.

At present, many companies have adopted a failure reporting system to record their engineering failures to avoid failures in the future (Lough et al., 2008). The information recorded usually contains: 1. Description of which part of the product has failed; 2. How the part failed; and 3. The circumstances behind failure. Although it was important to learn from these failures, this information was not often stored so that designers or engineers would have no access to it in order to improve their designs, which justified the need for more effective systems for cataloguing and utilising the corporate memory of recorded failures (Lough et al., 2008).

Almost any component that fails in service was due to wear, corrosion or breakage, and understanding the most common failure mode for a particular type of material would be a great advantage for a designer. It allows them to know the limits and constraints and the most frequent mode of failure and subsequently, they can use this information to inform their design decisions (Budinski and Budinski, 2005)

It would be extremely important that designers use their common sense when designing products as design error was a common cause of failure in applications ( Budinski and Budinski 2005; Brooks and Choudhur y, 2001). Designers were also encouraged to have their designs checked against the material guidelines in order to prevent failures in application which an example can be found in (Budinski and Budinski 2005). Figure 8 was included to provide readers a clearer idea on the percentage of the failure modes associated with different types of materials. This information can be taken into account and considered as a reference when designing with materials.

In response to the need of an effective system for cataloguing and utilising the memory of the recorded failure, which also enables easy access for designers, the system should consider providing the following information ( Brooks and Choudhary, 2001; Wirth et al., 1996).

This should include details such as the design of the component and materials used, their properties and how the component was used. Photographs showing the component and the failure situation were also highly recommended to supplement the description. The cause of failure should be highlighted and explained to help warn the designers against potential future failures of the material.

The materials used in products may have changed throughout its history, as illustrated in Case study of the design of Pens in ( Ashby and Johnson, 2010; Historical Writings, 2013). The material used for the fountain pen nibs at the beginning was steel, which was prone to corrosion due to the acidity of the ink used for writing. The next material used was gold, and the failure learned was that gold was relatively soft and would wear when writing on paper. As the technology advanced with time, manufacturers have changed their decisions on the materials used to include osmium and iridium granules, which was much harder metal than gold, and the development of neutral ink enabled materials such as steel (alloyed or coated) to be used for the pen nib again.

By providing designers with the history of failure of the materials, this should help to inform and warn the designers against the potential repeat of failures in applications. When designing a component, it would be vital to consider a very wide range of factors (as suggested in section 2), which may affect the product from processing, manufacture and the working environment to the end of life recyclability issues, etc. An effective failure record system should provide the information to designers to ensure the cause of failure is understood with insightful comments from knowledgeable experts.

The idea of a design assistant program for material selection was proposed by Bamkin in 1990 and its potential benefits to designers were described below (Bamkin and Piearcey, 1990).

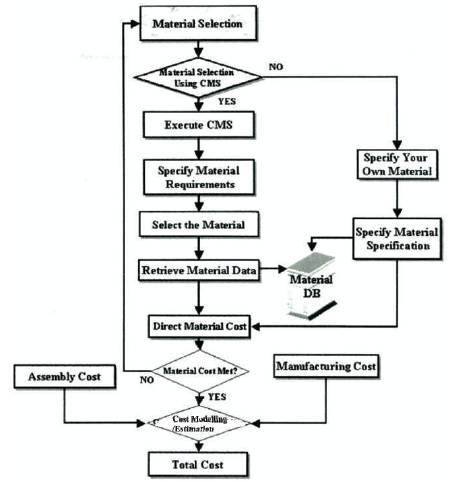

The general requirements of the design assistant software as proposed by Bamkin could be answered by the CES Selector software, which allowed a rational material selection process to take place, allowing users to input limits and constraints as part of the material selection process ( Bamkin and Piearcey, 1990;Granta Design, 2014e ).

A flow diagram (Figure 9) demonstrating the material selection process using the Cambridge Materials Selector (CMS), presently known as the Cambridge Engineering Selector (CES Selector) is shown for readers. This software was regarded as a widely available software tool for material selection in the industry because it enabled the identification of the small subset of the materials, and the selection of the most suitable material for the product requirement ( Granta Design, 2014a, 2014c, 2014d; Rodgers and Mitton, 2011 ; Shehab and Abdalla, 2002).

Figure 9. Flowchart of the Material Selection Procedure using the Cambridge Material Selector with Cost considerations (Shehab, 2002)

The material selection process using the CMS was logical, requirements for the material were first specified and if this software was not used (see the path on the right when the CMS is not used for material selection), there are alternatives which the designer may refer to, such as the ASM handbook of materials, or the material information sheet as supplied by material manufacturers.

For designers, searching for this information may require an extensive amount of time spent in order to find and process the data obtained. Through using the CES Selector, the gathering and filtering of this data can be quickly completed increasing the efficiency of the design process overall (Granta Design, 2014a).

The CES Selector software was first developed by Granta Design, founded by Mike Ashby and David Cebon from the Engineering Department of Cambridge University, who are both experts in materials (Transport research group, University of Cambridge) (Engineering Design Centre, University of Cambridge, 2014). The CES software played an important role in the material selection process because it comprehensively addresses the requirements as suggested at the beginning of this paper. The main benefits of using the CES Selector for designers were:

In addition, the success of Granta Design's CES Selector was covered in (Vargas, 2011) stating that their clients involved some blue chip firms and over 700 universities which showed its importance and popularity in university education and the industry. Justification for recommending the CES Selector software to designers were that through the wide application in the industry, the CES software had proved to be a successful design assistant which acts as a source of material information for designers ( Vargas, 2011; Ashby, 2009). It also enabled them to find the desired materials quickly with the ability to repeat and amend the selection process. As a computer software, the CES Selector was easy to use and had produced updated versions every year with improvements ( WordNet, 2014; Azom.com, 2010). This meant that designers will get the most recent, accurate, and comprehensive information at the time to inform the material selection process. Although other forms of data selection, such as ASM and MatWeb were available, in comparison the CES Selector offered an easy-to-use and intuitive way of presenting the information to designers compared to the tabular data format in the above named sources ( ASM International, 2014; MatWeb, 2014).

In summary, designers should consider material selection as early as possible in the design process; the benefits of early involvement of material selection would help to promote Original, Adaptive, and Variant design (Ashby and Johnson, 2010). Establishing a product's attributes as early as possible would help to define the design specification, which the product's features and requirements from industrial design can be translated into numerical values or limits in technical design (Eger et al., 2013). The sensorial properties of a material can be manipulated by the designer to deliver a particular sensation or evoke a specific emotion on the consumer, therefore designers can select suitable materials to deliver the expected product semantics ( Krippendorff, 1989; Demirbilek and Sener, 2003).

With supportive arguments, providing a detailed description on the history of failure of materials could help designers to prevent future failure of products or design errors. However, the history of failure of the material has not been mentioned as frequently as the common factors for consideration in material selection, and the level of details was found to be varied (Budinski and Budinski, 2005). The CES Selector software should act as a design assistant for designers where expert knowledge in material can be delivered.

As part of an extended literature review, a case study was used to reveal additional information around the topic based on the CES EduPack 2013 Software. These were conducted as part of the empirical research case study supportive of this work (Olsen, 2012).

The existing material information and the history of material application failures provided across all levels in the CES EduPack 2013 were reviewed and analysed. The objective was to establish gaps for further improvement within the software.

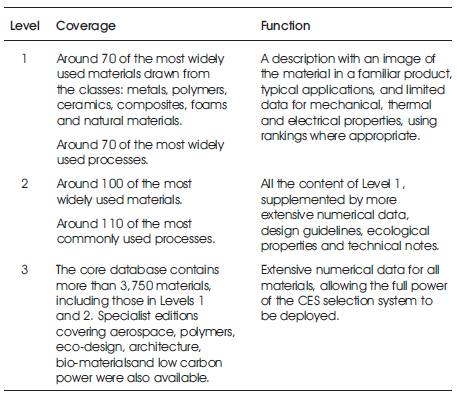

In the CES EduPack software 2013, the software was classified into three levels for users (Table 3).

Table 3. Coverage and Content provided in Different Levels of the CES Edupack 2013 (Ashby, 2013)

As an example of its application in design education, the CES software was introduced to second year Industrial and Product design students at Loughborough University as part of their module in the degree course and they were encouraged to use this as a practical tool for material selection in the design process. Although level two was recommended for design students as a source of material knowledge, this case study was conducted to examine the information on the history of material application failures provided at all levels within the CES EduPack 2013 software to show readers the classification of the database based on the level of details provided.

Figure 10 shows the typical screen when the software is started, with Level One as introductory, Level Two as intermediate, and Level Three as advanced.

In the material selection database available within the CES software, Level 1 contained the most basic and general information about a material, which gave a foundation understanding of the material to the designer.

In the screen print shown in Figure 11, level one from the material database was selected. The layer tree on the left showed that the list terminated at Zinc alloys which represented the most in-depth material information provided at level one in the class of zinc alloys.

The material information provided at this level includes:

As well as the properties provided above, level one also included the typical uses in the supporting information and a link to the process universe for further information in the processing of the materials. However, no information on the history of failed applications was included at this level.

Figure 12 shows the screen print with level 2 database, with the same selection of zinc alloys, which the layer tree now terminates at Zinc die-casting alloys with more material variants.

The level two database contained all information provided in level one, with a more descriptive caption and the addition of the following supporting information:

No information on the history of failed applications was included at this level.

In the level 3 database shown in Figure 13, the layer tree on the left for Zinc contained a wide variety of zinc with different metal alloys. Some zinc alloys for specific purpose or grade were available. Each alloy's information page contained all information from level 2 with other information, such as composition detail, energy and CO 2 emissions, processing and recycling information.

In the supporting information section, this included a Warning section to the user (Figure 14), which consisted of a short descriptive sentence of the past failure history of this material.

Warning messages were displayed only in the note section in the Level 3 database of the CES software, which implied that unless the user has the initiative to find out more about a specific material in the level 3 database, this warning will not be displayed automatically to warn the users. The warning notes for most materials were short in general and did not provide detailed information to the user about the application, the history, the cause of failure nor the corrective procedures applied.

In conjunction to the history of material failure, the ASM Failure Analysis Database was a good example of material failure record management, with the screen view (Figure 15) showing the similar layout to the CES software for the material failure database.

Figure 15. Example of the Case History of Failure of Zinc Die-casting Alloy (ASM Failure Analysis Database)

In the ASM failure analysis database, the failure situation, function of the part, cause of failure and the potential way to correct the failure were described in much detail, which this database itself may be regarded as a reference library of material application failures. This ASM material database was recognised by NASA and implemented into the Material and Processes Technical Information System (MAPTIS) database. MAPTIS is a comprehensive system that holds comprehensive information on metallic and nonmetallic materials for NASA and NASA contractors.

Using the information and knowledge gained from Case Study 1, the CES EduPack 2013 software was used as a demonstrator to show how the information of material failure can be applied and communicated to designers in the material selection process.

Note: Screen prints (Windows, 2014) were used to provide readers a basic understanding of the layout and work environment of the CES EduPack 2013 for illustration purpose. All the screen print images shown in the Case Study were captured on a PC which CES EduPack 2013 was installed. Although the screen prints were not provided by Granta Design, reproduction of this paper with such images may require copyright permission from Granta Design as the publisher of the CES EduPack 2013.

Figure 16 shows the screen print of the CES EduPack 2013, with a Warning section under the Notes. The original description for the warning contained a general description of the applications warned against.

Figure 16. Example of Warning Information provided to Users of the CES EduPack 2013 (Source: Author)

In Figure 17, the modified screen print based on Figure 16 was presented. The history of failed applications of the material was added to the material information database, which should provide designers and engineers specific and detailed information on the failed applications of the material when they search in the database. It is important that designers can have access to this information at an early stage, to inform their design decision through learning the failed applications of a material of which they have proposed to use for their design.

Although the warning notes were provided where possible in the Level 3 database, there were opportunities for similar warning notes to be delivered in level 2 where it may be simplified for ease of understanding. This would allow lessexperienced users (including designers) using the CES software to gain an awareness of the potential limits and constraints of a selected material in industrial application.

As failed materials in applications were recorded, the database of failure analysis should also expand with time. An improvement was realised that the CES database can include an active link to an online reference library for failed materials in application such as the (ASM Failure Analysis Database), which the user of the software can access the detailed information on the history of material application failures of their chosen material. If this recommendation was brought forward for implementation in the future updates, this may have some positive changes and influences to the design of products in the future.

From the literature survey, a background understanding of the materials selection process for designers was provided. The involvement of material selection in the design process was evaluated in order to inform readers the importance of material selection in design and what potential changes this can make to a product. Considering material selection early in the design process would not only help designers to enhance their design decision, it would also allow designers to make use of new materials and explore the qualities that can be delivered through using a mix of carefully selected materials.

New strategies for material selection for designers as in (Ashby and Johnson, 2010) suggested that as well as using an analytical approach to material selection, many creative ideas can arise from inductive thinking with successive guess based on the experience of the designer. It is therefore important for designers to learn and expand on their existing knowledge of material as much as possible, to reduce the difficulty when selecting a material in the future.

Although personal experience of the designer was suggested as a strong and frequent source where the material information is obtained by designers, it may be limited to a few classes of materials. Designers also need to be aware of the new trends and technologies in materials as these may be points where inspirations for successful designs come in the future. In addition, this information can be accessed from other sources such as supplier's information and samples to material handbooks and databases. As suggested by van Kesteren et al. (2007), using actual material samples with supporting images would help designers choose the best and desired material with sensorial properties.

Designers may be considered a generalist in materials’ selection therefore may not possess any expert knowledge on the specific class and type of a material which would be the best for the desired application. The CES software was introduced in the previous sections because it acts as a link for designers to obtain professional knowledge when selecting a material, which itself may be regarded as a 'design assistant' that enables designers to make rapid changes and amendments in the selection process which is repeatable.

From the case studies, it was found that the CES EduPack 2013 did not contain a detailed description to the material's history of failure in application. This information was only available to users who have selected the level 3 database, which would likely to be experienced by users, engineers, or expert designers who has a sound knowledge on specific classes of materials and are aware of the types of materials offered within the same class. Such user may already have an understanding of the limitations of their desired materials and their history of failure, therefore the failure history of material in application should also be included in the level 2 database, where the less experienced users can be informed of the possible limitations and constraints of any materials. In addition, there were no direct online links to the history of the material's application failures through the software, therefore the users may not have the most accurate and up-to-date information to inform their decision on material selection.

However, it was found that in this software, the identification and indication of a chosen material's previous history of failure was lacking in detail, which provided further room for improvement. The suggested improvement demonstrated in section 2 should be regarded as a starting point, and this should be considered so that future users can be warned against using the history of material failures in application. Although the best effort was made to provide a literature review based on varied and wide ranged sources, there were other professionals in this field such as Ashby whose work would be most dominant and recognisable in the field of material selection. His works were also cited in many different related articles found in the bibliography, which may have been more influential here than other authors.

The limitation of this literature survey also included the lack of professional comments from expert designers, who may have their own strategies when selecting a material and this knowledge may be incorporated into other 'design assistant' software in the future to help other designers achieve an easy and accurate material selection. In addition, the view point from a materialist and a designer can be discussed and analysed in hope to find out what opportunities and requirements do they foresee in the development of new material selection software based on their current experience in material selection.

Could a reference library of material application failures enhance design decisions?

In conclusion, the answer to the proposed research question above was YES. Through reviewing the background literature and the case studies, the design decisions made by designers would be better informed. The ability to understand the interlinked relationship between material selection and design would be a clear advantage for a designer. By informing themselves well about the desired material's characteristics and history, and through making the best choice on material selection, their product should match up well against the design specification and function as expected. Through obtaining a detailed knowledge about materials, this offers unique possibilities for a material based approach in design where the original design may take place. Designers should not underestimate the importance and advantages of choosing a suitable material for an application, but they should also realize the possible disastrous consequences that a wrong choice of material can bring.

The most important reason that justifies the inclusion of a reference library to material selection was the valuable knowledge and insights obtained from the experts and professionals through the analysis of failures may be passed onto designers, which would be an alternative source to further broaden their design skills and experience. By reading and understanding the information provided through case histories of material failures, designers and engineers are not just rewarded with specific and in-depth knowledge in this field, it also enables them to become more accurate and precise in their future decisions when selecting a material.

Based on the summaries and findings, the following topics for further research were identified in hope to assist the material selection for designers:

This system should provide a pro-active form of warning such as alert messages warning the user of the selected material's previous history of failure in application. At present, designers will have to conduct some research and browse in the database before they can find this information. By allowing easy access to this information for designers, this should help them to make informed decisions more quickly.

This system may incorporate the sensorial, emotional properties of materials as well as the mechanical and general properties. Examples of product semantics that can be achieved through a particular mix of material should be provided. It is very important that designers can have a physical material sample to design or work with, and there could be physical handbook of comprehensive swatches of materials provided to accompany the software following the same format or style such as the Pantone Colour matching system (Pantone LLC, 2014), which is widely used in the industry. Manufacturers or suppliers of materials may therefore relate their products to a specific standard or composition of the material.

The information of the history of failed material applications can be brought into the Design education curriculum to help educate and increase the awareness of materials' limitations and constraints to the future designers. The earlier this information is delivered, the more effective it would be in preventing failed material applications being repeated. Once the failed history is learned, the students may consider using alternative or new materials which the same problem can be resolved, leading to more creative solutions.