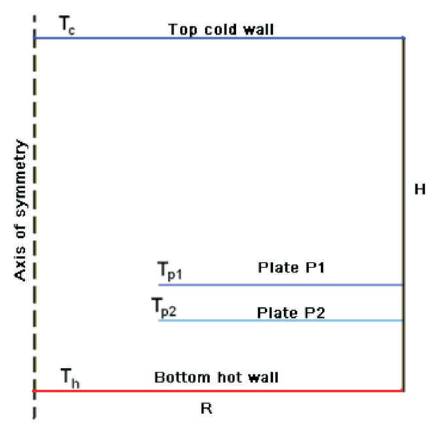

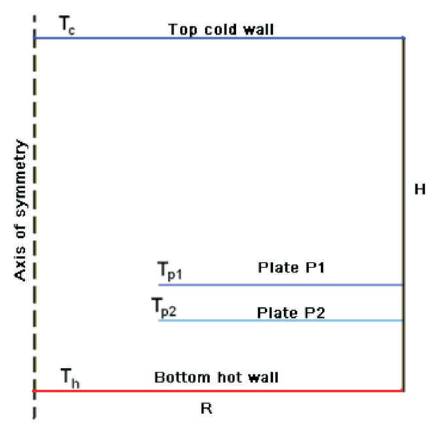

Figure 1. Computational Domain

Natural convection in enclosures has numerous industrial applications, such as cooling of electronic equipment, emergency core cooling in nuclear reactors, and energy storage systems. A cylindrical cavity with aspect ratio (H/D) of 0.5, filled with liquid metal sodium is analyzed numerically for the natural convection setting inside the cavity due to the heated bottom side. The top of the cavity is cooled. Apart from the bottom wall heat source, there are two more plates which serve as either partitions or as additional internal heat sources in the cavity. The effect of their presence and their temperature on steady state thermal and velocity fields is evaluated in this analysis. The analysis has been carried out using the CFD (Computational Fluid Dynamics) code, PHOENICS (Parabolic Hyperbolic Or Elliptic Numerical Integration Code Series). The peak natural convective velocity is compared for different cases when the internal plates act as heat sources or as simple partial partitions inside the cylindrical enclosure. It is evident from the analysis that, natural convection is reduced inside the cavity when partial partitions are present in the cavity either in the form of heated plates or unheated plates.

The research interest in studying natural convection in cylindrical enclosures always shows a rising trend because of the innumerable applications it finds in industries such as cooling of cans of beverages, air conditioning of buildings, solar collectors, cryogenic storage, cooling of electronic components, and emergency core cooling of nuclear reactors. In natural convective flow, the fluid is driven by density variations in a body-force field, and the flow patterns depend critically on the geometry of the system, applied heating conditions and the boundary conditions (Lin and Armfield, 2001; Akins and Lin, 1986). These systems are governed by the Navier-Stokes equations, but, due to the non linearity of the equations and the coupling of the dependent variables, general analytical solutions are still not possible except for a few simple cases. Most research efforts have been based on experimental work and recently, on numerical approaches particularly for liquid metals (Lin and Armfield, 2004).

Fontana, et al., (2011) have studied the steady natural convection in a partially open air filled cavity having an internal heat source and differentially heated side walls. At low Rayleigh number, the effect of the source was dominant, but as Rayleigh number increased, the flow becomes dominated by the temperature difference between the walls. The transient processes of cooling down and stratifying in an initially homogeneous fluid by natural convection in a vertical circular cylinder have been investigated numerically by Lin and Armfield (1999) .

Natural convection in an enclosure with distributed heat sources at the bottom wall was analysed by Bazylak, et al., (2006). They found that, as the source length increased the transition from conduction to convection dominance occurred. Heat transfer is also dependent on the aspect ratio of the enclosure. Silva, et al., (2004) optimized the distribution of heat sources on a vertical wall with a view to maximize the heat transfer. They found that, for optimal heat transfer distribution, the sources are not equidistant. The heat source should be continuous at the tip of the boundary layer. Wu and Ching (2010) have experimentally investigated the laminar natural convection in a square cavity with partitions in the top wall. They observed that, changes in the temperature and velocity fields were limited to the vicinity of the partitions. The effects of aspect ratio, inclination angles, and heat source length at the bottom wall on the convection and heat transfer process in a rectangular cavity are analysed by Sharif and Mohammad (2005). Martyushev and Sheremet (2014) have analysed the effect of thick bounding walls of the enclosure on the overall heat transfer including the effects of radiation. In most of the above cited literature, air with Prandtl number Pr=0.7 is the heat transfer fluid.

Sheriff and Davies (1979) have made experimental measurements for natural convection from plane surfaces in liquid sodium. In their paper, they have also included a review of natural convection heat transfer for low Prandtl number fluids which brings out the importance of the surface orientations, namely, vertical, inclined and horizontal surfaces. Viskanta, et al. (1986) have studied 2- D and 3-D natural convection in liquid metals contained in a rectangular cross sectional cavity with differential heating of side walls. They have conducted experiments in liquid gallium and validated their computational results. Sudha and Velusamy (2013) have numerically analysed the convective heat transfer in a sodium filled top heated and sidewall cooled cylindrical cavity and developed correlations for Nusselt number. Horanyi, et al. (1999) have experimentally investigated the Rayleigh-Benard convection in low Prandtl number liquids in a cylindrical test cell. They have also summarized some frequently used heat transfer correlations applicable to liquid metals.

In the present numerical heat transfer study, the focus is on liquid metal heat transfer which is different from high Prandtl number liquids (Pr>1) heat transfer because of the difference in the development of the boundary layer. The cylindrical enclosure/cavity is filled liquid sodium (Pr<<1), heated at the bottom surface and cooled at the top. Two more internal plates parallel to the bottom surface/wall are considered either to be adiabatic or held at constant temperature which is lesser than the source temperature. The top wall which is at the lowest temperature acts as the heat sink. The temperature and velocity fields are obtained and compared for the different initial conditions and configurations of the plate. The natural convective velocity is treated as the index based upon which the effect of the intermediate hot plates on heat transfer is assessed.

In the safety analysis of sodium cooled fast reactors, it is essential to assess the long term coolability of the core debris following the very rare occurrence of a severe core melt-down accident with the main objective of ensuring its in-vessel coolability. In case of such an accident whose probability of occurrence is <10-6 /reactor year, the nuclear reactor fuel gets fragmented in liquid sodium coolant and results in the formation of the core debris. In defining the accident scenario, many researchers have expressed the opinion that the core debris can settle on any of the available flat surfaces such as the grid plate while getting fragmented and traversing through the liquid sodium (Voronov, et al., 1994). Depending upon its decay heat level and its mass, it can either settle on the grid plates permanently or can breach through the structure and a portion of it can further migrate downwards to the core catcher. Therefore, eventually a major fraction is expected to reach the core catcher which is placed at the bottom of the reactor main vessel. Due to the settling of the core debris on various internal surfaces, the heat source is now distributed within the sodium plenum. Heat removal from the core debris following a severe accident, is taken care of by dedicated decay heat removal system which relies on natural convection setting in the liquid sodium.

To understand the phenomenon of natural convection in the presence of multiple sources qualitatively, a small cylindrical cavity with distributed heat sources is considered. In the reactor scene, decay heat is a rapidly decreasing function of time. But in the present study, steady state analysis has been performed with heat sources held at constant temperatures. Therefore, this numerical study is a basic study undertaken to study the effect of presence of partial partitions and multiplicity of heat sources on the convective pattern developed within the cavity and the magnitude of the natural convective velocity which affects the heat transfer rate within the cavity.

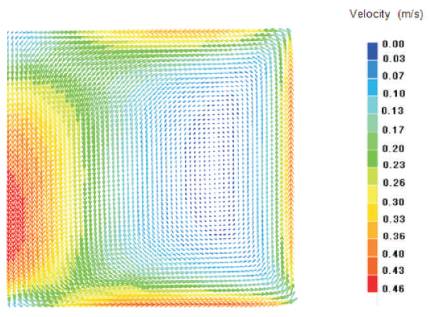

The computational domain consists of a cylindrical cavity with a heated bottom wall (Th =673 K) and a cold top wall (Tc =473 K). The cavity is filled with liquid sodium at 473 K. Two internal plates are placed inside the domain at the heights of 0.09 m and 0.06 m from the bottom wall. There is a central opening of 0.1 m radius on both the plates, so that there is a communication between sodium below and above the plates. Therefore, the plates serve as partial partitions within the cavity. The plates are considered as adiabatic or held at specific constant temperatures. The height of the cavity (H) is 0.3 m and the radius (R) is 0.3 m. The aspect ratio which is the ratio of height of the cylinder to its diameter is 0.5. Exploiting the axisymmetry of the domain, computation is carried out in the right half of the cylindrical cavity. The domain is shown schematically in Figure 1. The commercial CFD code PHOENICS has been employed for the numerical study. Grid optimization has been carried out.

Figure 1. Computational Domain

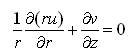

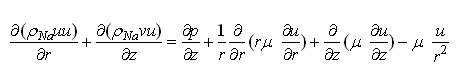

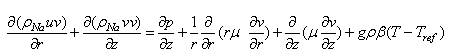

Laminar steady state natural convection in the cavity is studied using the commercial CFD code PHOENICS. The equations of conservation of mass, momentum and energy given in equations (1) to (4) are solved in finite volume formulation using staggered grid.

Continuity Equation:

Radial Momentum Equation:

Axial momentum Equation:

Energy equation:

SIMPLE (Semi Implicit Method for Pressure Linked Equations) algorithm, which is a well established and widely used procedure, is used for pressure velocity coupling. Boussinesq approximation is used for the buoyancy effect. The convergence criterion is fixed at 0.1% for all the variables. No slip and impermeability conditions are imposed at the walls. The temperature of liquid sodium is 473 K which is also the temperature of the cold top wall. The bottom hot wall is held at 673 K. The curved surface of the cylinder is adiabatic. A few case studies have been conducted by assigning different conditions to the internal plates.

As stated earlier, for all the cases considered in the present study, the bottom wall is at 673 K and the cold wall is at 473 K. The temperature conditions on the internal plates are changed and their effect on the velocity field and temperature field at steady state of the system is studied.

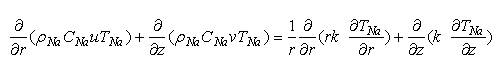

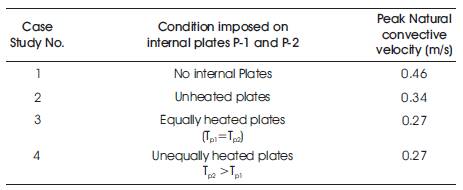

The conditions imposed for the four case studies undertaken are given in Table 1. In all the Figures 1 to 9, the horizontal axis is the radial direction 'r' and the vertical axis is the axial direction 'z'. The computations are carried out in r-z axisymmetric cylindrical geometry.

Table 1. Thermal Conditions on Internal Plates

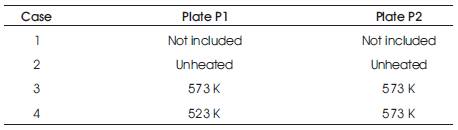

As the base case, natural convection in the cavity is studied without inclusion of internal plates. Therefore, the problem is that of natural convection in a bottom heated and top cooled cylindrical cavity. The velocity vectors obtained at steady state in the cavity is shown in Figure 2. The maximum observed velocity is 0.46 m/s. The hot liquid from the base of the cylinder rises up towards the top rejects heat at the top cold wall and returns to the bottom of the cavity, flowing down along the central axis of symmetry.

Figure 2. Velocity Vectors in the Cylindrical Cavity without Internal Plates

The temperature contours are given in Figure 3. From Figures 2 and 3 it can be seen that, where there is a larger temperature difference between the fluid and the hot plate, the natural convective velocity is higher. Since the fluid after rejecting heat at the top wall flows down along the axis of symmetry, the central region of the cavity is at a lower temperature than the peripheral region where the hot fluid is moving up.

Figure 3. Temperature Field in the Cylindrical Cavity without Internal Plates

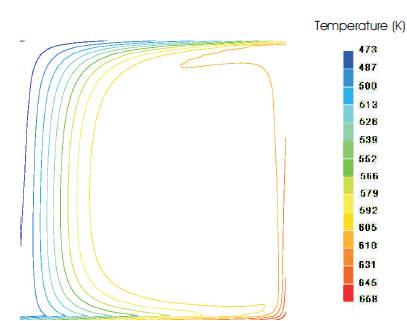

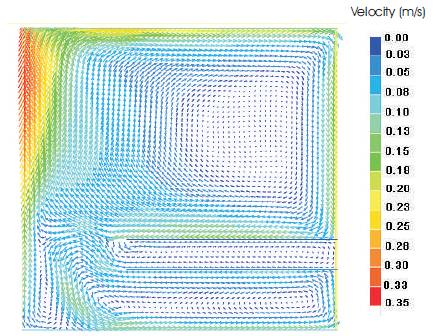

In this case, the two internal plates are added to the cavity as explained earlier. Here, both the internal plates are unheated and treated as adiabatic, i.e., they neither absorb heat nor reject heat, but act only as partial blockage for the flow of the liquid. Because of the new plates added inside the cavity, the convection pattern changes within the domain as shown in the velocity vectors given in Figure 4. The temperature field is plotted in Figure 5. The maximum velocity occurs close to the vertical axis of symmetry through the central opening in the plates. The hot liquid rejects heat to the top cold wall and flows down along the side curved wall and flows parallel to the surface of P1 and then moves downwards once again to P1 to be heated again. However in this case, the maximum observed velocity in liquid sodium drops down to 0.35 m/s as against 0.46 m/s in case 1 without the plates. There is not much circulation in the space between the two plates. From the temperature mapping given in Figure 5, it is observed that, there is high temperature prevailing in the region between the bottom of the cavity and the lower plate P2. Most of the hot fluid is seen to be confined in this region between plate P2 and bottom of the cavity. This shows that, there is not thorough mixing of fluid in the cavity owing to the presence of internal plates.

Figure 4. Velocity Vectors for Unheated Internal Plates

Figure 5. Temperature Field for Unheated Internal Plates

The core region of the convective loop above the top plate P1 is almost stagnant and the temperature in this region is lower pointing to the fact that the effect of the heated bottom wall is not much reflected here because of the presence of these internal plates.

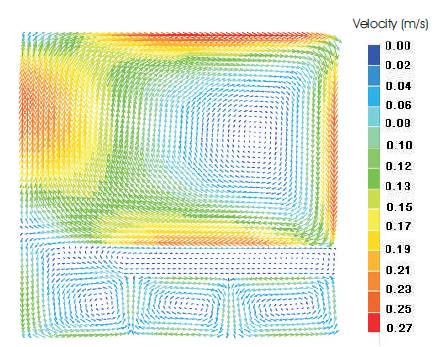

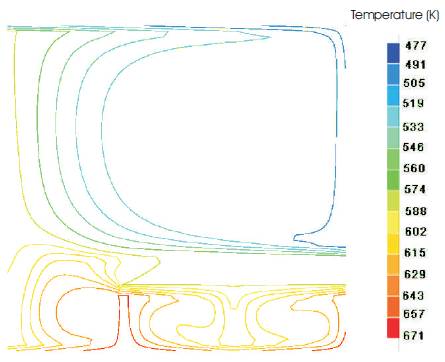

In this case, both the plates become additional heat sources other than the already existing heat source at the bottom of the cavity. Both the plates are held at equal temperature 573 K, such that their temperatures lie between the temperature of the bottom wall and the top wall of the cavity. The velocity vectors obtained at steady state is depicted in Figure 6.

Figure 6. Velocity Vectors for Equally Heated Internal Plates

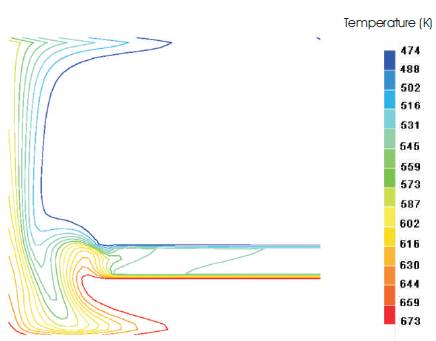

Here too, there is no convection observed in the region between the two plates because there is no temperature difference between the plates. Counter rotating convective rolls which are the well known Rayleigh-Benard convection cells are seen between the cavity bottom and the plate P2 because of the existing temperature difference between them. The maximum of the convective velocity is 0.27 m/s which is less than that observed in case 2. A very good circulation is observed in the cavity above plate P1. Temperature field is given in Figure 7. The region between the bottom of the cavity and plate P2 is the hottest zone in the cavity, but there is a temperature variation ranging from 600 to 673 K even within that zone leading to circulation.

Figure 7. Temperature Field for Equally Heated Internal Plates

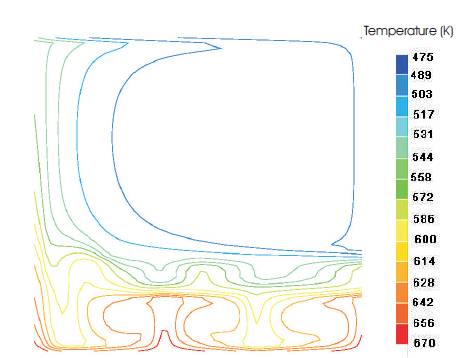

In this case, the plates have different temperatures. P1 is maintained at 523 K and plate P2 is maintained at 573 K. These temperatures are chosen such that it is greater than the top wall temperature which is sink and it is lower than the bottom wall which acts as a heat source. The temperature goes on decreasing as one moves from the bottom wall and the two plates to the top of the cavity. The velocity vectors obtained is plotted in Figure 8. It is seen that, convective rolls is seen to occupy the space between the bottom wall and plate P2 and also in the gap between the plates P1 and P2. The temperature difference existing between the plates with TP2 >TP1 has eliminated the stagnant zone which was earlier present in case 3 when the plates were at equal temperatures. The maximum velocity has not changed and it is equal to 0.27 m/s. Temperature field is depicted in Figure 9. Here again, the region above plate P1 is not heated much as in cases 2 and 3.

Figure 8. Velocity Vectors for Unequally Heated Internal Plates TP2 >TP1

Figure 9. Temperature Field for Unequally Heated Internal Plates TP2 >TP1

The summary of the entire study is presented in Table 2. From the table it is evident that, the maximum of the convective velocity decreases with the introduction of internal plates. For cases 3 and 4, the maximum observed velocity remains the same. The reason is that in both the cases plate P2 has the same temperature. It is a known fact that, higher the convective velocity, higher the heat transfer coefficient. Hence, it is inferred that, the presence of internal plates whether heated or not tends to decrease the convective heat transfer from the bottom of the cylindrical cavity. The presence of distributed constant temperature heat sources without altering the heat sink affects the magnitude of the convective currents as seen from Table 2.

Table 2. Summary of Results

In order to overcome this reduction in the convective heat transfer rate as seen from the magnitude of peak convective velocity, the heat sink temperature has to be further reduced, or the internal plates can be made porous by providing holes or slits in their surface for allowing circulation of the fluid through them.

The effect due to presence and the heating conditions of two internal plates, placed horizontally in a bottom heated and top cooled cylindrical cavity is studied numerically using CFD analysis. The cavity is filled with sodium, a low prandtl number liquid. Steady state natural convection is analyzed for the base case without any internal plates. Subsequently, two internal plates are added inside the cavity forming partial partitions and the analysis is repeated for unheated plates and also for two combinations of heating conditions on the internal plates. Velocity and temperature fields are obtained for all the cases. It is observed that, the natural convective velocity and hence the rate of heat transfer decreases considerably with the introduction of internal plates. It is found that, when the internal plates themselves act as additional heat sources with a prescribed constant temperature, peak convective velocity reduces further than the case when the plates were not heated.

c - Specific heat capacity

D - Diameter of the cavity

H - Height of the cavity

k - Thermal Conductivity

Na - Sodium

T - Temperature

g - Acceleration due to gravity

P1 - Plate 1

P2 - Plate 2

R - Radius of the cavity

r - Radial coordinate

u - Radial velocity

v - Axial velocity

z - Axial coordinate

β - Coefficient of thermal expansion of sodium

μ - Dynamic viscosity of Sodium

ρ - density