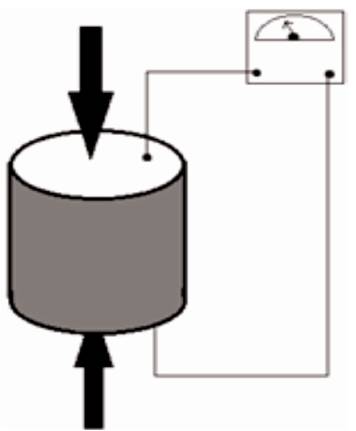

Figure 1. A Piezoelectric Cylindrical Structure generates Voltage when Deformed

In the present era as there is a decrease in energy consumption of portable electronic devices, the hypothesis of harvesting renewable energy in our surroundings provoke a renewed interest. The need for energy is also increasing at a fast rate, which has exhausted lots of resources. So, there is a need to produce more energy. Mechanical energy harvesting happens to be the most prominent energy harvesting technique. This utilizes piezoelectric components where electric charge is generated by deformations produced. This technical paper emphasis on one such method through piezoelectric material. The motive is to obtain pollution–free energy source and to utilize the energy being wasted. A piezoelectric substance is one that produces an electric charge when a mechanical stress is applied. Piezoelectric materials can be used as a mechanism to transfer mechanical energy, usually ambient vibration, into electrical energy that can be stored and used to power other devices. Conversely, a mechanical deformation is produced when an electric field is applied. Piezo-film can generate enough electrical density that can be stored in a rechargeable battery for later use. Currently, there is a need to utilize other forms of energy at passenger terminals like airports and railways across the world. Cleaner, more useful forms of electrical power are needed in order to keep costs lower and to ensure a pollution free environment for future generations. The use of piezoelectric devices installed in the terminals will capture the kinetic energy from foot traffic. Such a source of power can then be used to operate lighting systems. In this paper, the concept of piezoelectricity and piezoelectric effect is well discussed. The various applications based on piezoelectric effect are also elaborated. Future prospects regarding piezoelectric materials in day-to-day life are also well highlighted.

It is the electric charge that accumulates in certain solid materials in response to applied mechanical stress. The word piezoelectricity means electricity resulting from pressure, this word is derived from a Greek word “piezein” which means to squeeze or press and “electric” which means amber, an ancient source of electric charge. The piezoelectric effect describes the relation between a mechanical stress and an electrical voltage in solids. It is a reversible, i.e. when a mechanical stress is given to the material, an electrical voltage will generate in the material and a mechanical strain will occur, when an electric voltage is applied to the material. Piezoelectricity was discovered in 1880 by Jacques and Pierre Curie when studying how pressure generates electrical charge in crystals (such as quartz and tourmaline). Its use in submarine sonar in World War 1 generated intense development interest in piezoelectric devices. Most modern piezoelectric materials are ceramics and are used commercially in many applications. The term ceramic has evolved from a Greek word “keramos”, (meaning pottery or potter's clay). Ceramic materials are broadly considered to be all inorganic non-metallic materials. But it is much better to classify them as polycr ystalline non-metallic materials that gain mechanical strength through sintering process. The physical properties of ceramics has made them desirable for use in wide range of industries. Discovery in 1940s of materials with high dielectric constants and the realization that this phenomenon was result of their ferroelectric nature, led to an increase in the demand of their use. These materials were firstly used in high dielectric capacitors and were later developed into: electro-optic light waves, positive temperature coefficient devices, and piezoelectric transducers.

The invention of ferroelectric ceramics as a very useful class of materials came about as a result of following,

Harvesting energy stands alone as one of the most promising techniques for approaching the global energy problem without depleting natural resources. The objective of this technical paper is to build a system that can harvest and generate electrical energy by applying mechanical stress. Huge amount of energy is wasted in the form of heat, sound when mechanical stress is applied. So, in this paper an approach has been made to make use of this wasted energy to generate electrical power. This technical paper describes the use of piezoelectric materials in order to harvest energy from people walking vibration for generating and accumulating the energy. It also represents a footstep of piezoelectric energy harvesting model which is cost effective and easy to implement. Also important techniques are stressed upon to harness the energy generated from piezo crystals.

The piezoelectric effect's nature is nearly linked to the occurrence of electric dipole moments in solids. The latter may be either directly carried by molecular groups or may be induced for ions on crystal lattice sites with asymmetric charge surroundings (as in PZTs). Dipoles in the vicinity of each other tend to be aligned in regions called Weiss domains (It is a region within a magnetic material in which the magnetization is in a uniform direction, i.e., individual magnetic moments of the atoms are aligned with one another and point in same direction) [4]. The domains are generally arbitrarily oriented but can be brought in to line using process of poling (Process by which a strong electric field is applied across the material generally at elevated temperatures).

Piezoelectricity is a combined effect of,

(i) The linear electrical behavior of material,

D = Ɛ E

where,

D = electric displacement,

Ɛ = permittivity,

E = electric field strength.

(ii) Hook's law for linear elastic materials.

Piezoelectric effect occurs in two types of domains as follows,

It explains the ability of the material to convert mechanical strain into electrical energy and generate voltage when deformed as shown in Figure 1. The direct piezoelectric effect is responsible for the capability of the material to behave as sensors.

Figure 1. A Piezoelectric Cylindrical Structure generates Voltage when Deformed

It elucidates the capability of the material to adapt an applied electric potential in to mechanical strain energy. Converse piezoelectric effect is accountable for the ability of material to act like an actuator (a type of motor that is responsible for moving or controlling a mechanism or system. It is operated by a source of energy like electric current).

Many materials, natural as well as synthetic reveals piezoelectricity.

Biological materials revealing piezoelectric properties include,

It is an inorganic compound most commonly used nowa- days. This compound is used in a number of practical applications in the area of electro ceramics. This white solid is insoluble in all solvents. Being pyroelectric (ability of materials to generate a temporary voltage when heated or cooled), this material develops a voltage difference across the two faces. It can be used as heat sensor. It has extremely high dielectric constant ranging from 300 to 3850. According to a previous work, the V-I characteristic of PZT shows that the voltage from PZT is 2 volts and acts as a better output with respect to PVDF. These are used in making ultrasound transducers, sensors, actuators, and ceramic capacitors.

It is a highly non-reactive and pure fluoropolymer produced by polymerization of vinyl diene difluoride. It has a piezoelectric coefficient of poled thin films as large as 6-7 pC/N. It is a ferroelectric polymer, presenting efficient piezoelectric and pyroelectric properties. Unlike other piezoelectric materials, PVDF will compress instead of expanding, when exposed to electric field. It can be used in making sensors, batteries, and some thermal camera sensors. The V-I characteristic of PVDF shows that the voltage from PVDF is 0.4 volts.

In today's era, industrial and manufacturing is the largest application market of piezoelectric devices, trailed by automotive industry. Strong application of these devices also comes from medical instruments as well as information and telecommunications. These materials are now used in many ways.

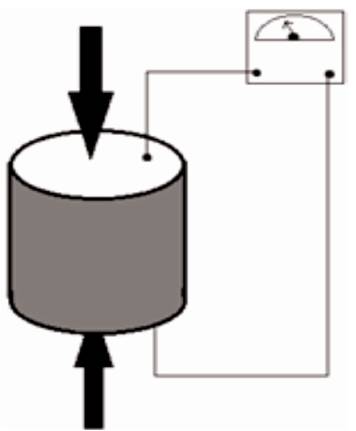

Humans have used energy at an increasing rate. The demand for consumption of energy is more than that of supply. Due to this, lot of resources have been exhausted. Therefore, the scheme of consumption of useless energy of foot power is very vital for highly populated countries like India. When flooring is planned with piezoelectric technology, the electrical energy produced by the pressure of the foot is seized by floor sensors and transformed into an electrical charge by piezo transducers and then can be used as electrical power source or can be stored in batteries for further use as shown in Figure 2. The advantage of this method is cost effective. This technique can be applied in dance clubs (on dance floors) [12], street lighting [5], airports, railways, and home applications [3].

Figure 2. Application of Piezoelectric Materials on Dance Floors

Under this, piezoelectric crystals can be laid down beneath the keys of a mobile unit or keyboards as shown in Figure 3. With the press of the keys, a mechanical pressure is developed which is created on piezo crystals. The potential is induced due to which charging is done. The material used for current application is PZT with 1.5 Mpa lateral stresses operating at 15 Hz. Volume of material used is 0.2 cm3 . Output power produced is 1.2 W. Output voltage is 9 V. This voltage can be used to produce the required amount of charge after being processed [11] .

Figure 3. Harvesting Energy through Keyboards

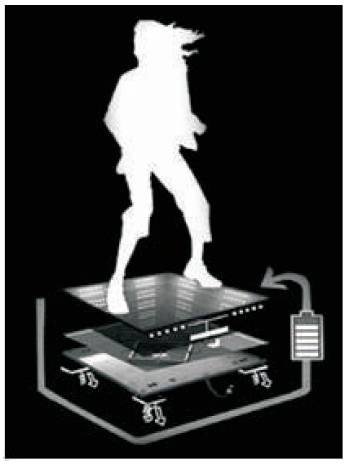

This invention was initiated by DARPA (United Defense Advance Research Project Agency). It has made easy to charge our mobiles wherever possible. This has been turned into reality with the help of piezo-electric materials. The piezo cell is fitted into shoes with a thick heel. When the person wearing it walks, the pressure exerted onto the piezo cell is converted into electrical energy, which is then stored in a storage cell fitted in the shoe as shown in Figure 4. The cell used to store the energy can then be connected to electrical gadgets to charge them. But this method of harvesting put an impact on the body so it was abandoned.

Figure 4. A Piezoelectric Material Placed Inside a Shoe

This is the best known application of piezoelectric materials. In this technique by pressing the button, effects the spring loaded-hammer to hit the piezo crystal. This produces enough current that traverse through a small spark gap consequently igniting the gas. Many gas burners have implied this system now-a-days.

The most recent innovation with piezoelectric materials is in sports industry. Previously racquets were designed to be stiff so as to return maximum energy to the ball which means the racquets return shock vibrations to player's arms [8]. Therefore to reduce vibrations, piezo fibers have been embedded around the throat of the racquet and a computer chip is embedded in the handle. The frame deflects slightly when ball hits so as to produce the charge, which is collected by the electrodes placed in it.

This charge is sent to the silicon chip via circuits (containing inductors, capacitors and resistors), which boost the current and sends it back to the fibers out of phase so as to reduce the vibration by destructive interference.

In this modern era, generation of power has been of utmost importance due to increase in the demand for resources. The rate of consumption is more than the rate of generation and therefore there is a need of producing more power. Therefore, the technique of capturing energy with the help of piezo materials has been of most importance in utilizing the unused energy developed by different means. This method of utilizing has been used in the following places,

Figure 5. Harvesting Energy from Road Traffic to Glow the Street Lights

The future lies in tapping the unused energy produced from different means. It lies in the inclusion of advanced material used to design the piezoelectric crystals which further amplifies the crystal output in terms of voltage as well as current. By this, it can make a world that is completely self-sustainable and which is not dependent on any external sources of power to operate it. One of the way is by piezoelectric materials which has largest application in nanoscale devices. Nano-devices using piezoelectricity would be light and environment–friendly. The future application of these materials are as follows.

India is a country where along with growing industries, demand for power is also growing. With this there is a need to develop more power, so the idea is using piezoelectric crystal in hydro power plants, so as to produce power with waterfall. The kinetic energy of water is used to run turbines which run electric generators, also “the free falling water from the brink of waterfall and base of waterfall can be used to generate power”. This is possible with the help of piezoelectric crystals placed in these places. Thus efficiency of the plant is also increased [1].

During rainy season when water droplets fall on the surface of earth, some energy is released. This energy is usually untapped. To use this energy piezoelectric sheet can be placed so that when droplets fall, due to vibration energy the charge is generated on the surface which can be used in certain applications afterwards. According to researchers, piezoelectric materials also convert vibration energy into electrical energy [2].

The piezoelectric system can be employed under the railway tracks so as when the train passes over it, will lead to generation of electric power as shown in Figure 6. The power generated by the trains will be very large as the force exerted by the train is too large. This generated power can be used to enlighten huge number of villages, which will be very economic.

Figure 6. Energy Harvesting by Railway Tracks

The method that is used to gain waste power is by the use of piezoelectric materials that can transform vibration energy [10] surrounding them into electrical energy. This electrical energy can then be used to power the devices. Through this paper, the authors have proposed the ideas through which energy can be gained and used in different applications. Harvesting energy through piezoelectric materials is a cleaner way of powering lighting systems and other equipment. These are a onetime installment and require less maintenance, so they are cost effective. This technique can't be used in sparsely populated areas as the foot traffic is quite low in these areas. Further experimentation has to be carried out for its use on a larger scale.