Internet of Things (IoT) has become a buzz word in the society, as it is emerging in different sectors with broad applications such as smart cities, smart home, connected cars, industries and so on. Already many devices have merged into the market. The industries have turned into the fourth revolution, i.e. Industry 4.0, where the departments such as manufacturing, production, and deployment have already automated with the invention of IoT. Coming to the Industries, Safety is the main measure which should be considered by the industrialists. Presently followed prediction models depend on the previous data of the accidents and other health issues related to employee which are collected from the industries. From that, precautions are taken for reducing the death and injuries of employees in future. In this paper, a new approach has been proposed with the invention of IoT in Industrial Safety, where the live information is tracked and immediate measures are taken on demand so that the loss that occurs due to accidents or other health related issues can be reduced to the maximum extent. The implementation is shown in two models; Monitoring Employee Health (MEH), Safety Automation Model (SAM).

Industrial safety means taking certain measures in the industries/factories for saving people from accidents and other health issues, that occur in industries. An industrial accident is the one which may occur due to the failure of the machinery or due to the negligence of the employee at the workplace. Every year, a huge number of accidents are occurring in the industries which are leading to the death and injuries of the employee. Industries are implementing several safety measures for saving people, but only to some extent, they were able to save the employees from losing their lives. As of today, the world is upgrading towards the advancement of smarter technologies with the introduction of Internet of Things leading to automation in every sector. The IoT has already shown its impact in smart cities, homes and several applications; it has also entered into the Industries as Industry 4.0.

In this paper, a new approach has been proposed with the introduction of IoT in Industrial safety, focusing on the theme of providing a healthier environment in industries for employees. This paper proposes two perspectives; Monitoring Employee's Health (MEH) condition and Safety Automation Model (SAM ) in industries.

In the past two decades, the IoT has achieved more significant attention all over the world in industries and academics (Perera et al., 2014a). As the concept was introduced in the end of the decade of 1990s, it resulted in giving ways for the innovative solutions in the market of IoT with the implementation of services in government, startups, industries, academic educational institutions and also in larger enterprises (Perera et al., 2014b). The IoT creates an environment for connecting things with people at any time/any place with anyone/anything, using any network/any service (Sundmaeker et al., 2010). This help to move the world towards a better environment for human beings, in which the objects communicate and revolve among human beings without any assistance from them (Perera et al., 2014b). Here comes the Entity (a thing with distinct and independent existence) which may be people, place or object (software service), provides interaction within users and applications themselves (Abowd et al., 1999). In the past years, the concept of IoT has been proposing a series of inventions across scenarios of different sectors such as intelligent smart cities, in the health sectors and in the transport sectors such as the connected vehicles, and also traffic monitoring and home automation with further security mechanisms and a great change in the industry (Zanella et al., 2014).

IoT has entered into the industries by implementing Automation services with the new name coined as Industry 4.0 (Neugebauer et al., 2016; Thoben et al., 2017). The term Industry 4.0 is recent, and the concept is starting to take shape with the increase of research and academic studies on the theme (Thoben et al., 2017). The idea behind Industry 4.0, converges on the execution of industries referred to as intelligent (Kolberg and Zühlke, 2015). Today, there is a new paradigm called Industry 4.0, which on the first glimpse seems to be a rebirth of the old CIM (Computer Integrated Manufacturing) idea (Bullers Jr and Reid, 1990). Driven by modern Information and Communication Technologies (ICT), Industry 4.0 is a network approach where components and machines are becoming smart and a part of a standardized network, based on the well-proven internet standards (Kolberg and Zühlke, 2015). The Automation of Industries is already playing a crucial role in the fields of Manufacturing, Production, and Delivery of Products. Industries such as Automobiles, Power Generation, Chemical, Oil and Gas, Steel Plants and many of them are using the Automation in different sectors (da Cunha et al., 2016).

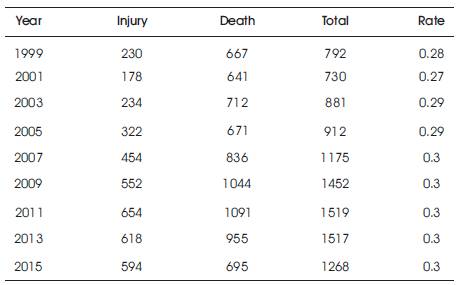

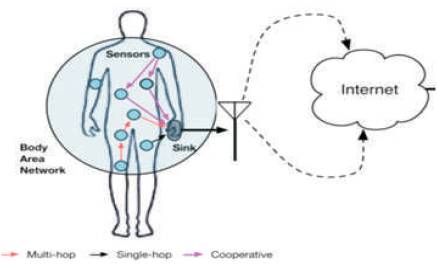

In Industries, the biggest challenging problem is the industrial accidents that occur in the factories leading to severe loss of manpower in the form of death and injuries. An accident is referred as an acute and unintended event that leads to an injury (da Cunha et al., 2016). “Industrial Accidents are caused by chemical, mechanical, civil, electrical, or other process failures negligence or incompetence, in an industrial plant which may spill over to the areas outside the plant causing damage to life and property” (Trivedi et al., 2014). Many preventive measures are proposed by analyzing the previous accidents; to some extent, they were reduced as per the Report of Indiastat.com (Source: The Ministry of Home affairs, Govt. of India.) (Indiastat.(n.d).). The Report shows that there are hundreds of people are injured/ dead; every year 0.3 rates of people are caught dead due to accidents that occur in the industries all over India (Negra et al., 2016). The values in Table 1 represent the number of people who are injured or dead due to the accidents in factories from 1999-2015. According to the report in 1999, the number of injured persons is 230 and number of persons dead is 667. Coming to 2007, it has been increased to injured-454 and dead-836. In 2009 and 2011, the death number has crossed 1000 and the last report of 2015 shows that the rate of death-695 and that of injured-594. Although many of the safety precautions are implemented in most of the industries, the number has not been reduced yet (Negra et al., 2016).

Table 1 shows the report that was officially released by the Government of India. But unofficially, still many of the employees are losing their lives in industries. As per Government norms, many of the industries are taking care of their employees, with upgradation of technologies and implementing safety measures, but still the number of accidents are increasing, as they were unable to predict when the accident occurs, and whether that is a mistake from the employee side or from the machinery part.

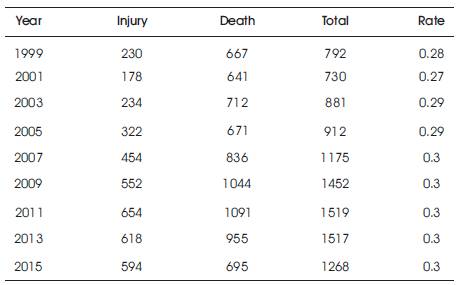

IoT which gave the concept of automation to Smart world, with the combination of sensors and Actuators is shown in Figure 1 (Perera et al., 2014b).

Figure 1. Sensors and Architecture

There are different sensors such as Ultrasonic, Infra-Red, Pulse, Temperature, Humidity, Proximity, Gas, Smoke, Touch and Pressure, and so on. For reading the Human Health condition, here the Wireless Body Area Network is introduced.

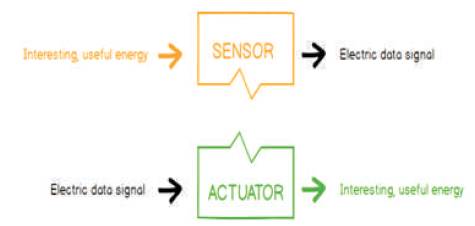

Wireless Body Area Networks (WBAN): WBAN are connected with the human body for tracking the health information of human beings. Sensors such as Electrocardiogram (ECG), Electroencephalography (EEG), Electromyogram (EMG), Temperature, Pulse- Oximeter and insulin pump are connected to the body as shown in Figure 2. They will detect the changes in the human body from time to time and forward to the cloud for monitoring via the gateway using internet (Patkar and Tasgaonkar, 2016).

Figure 2. WBAN for Reading the Human Health Condition

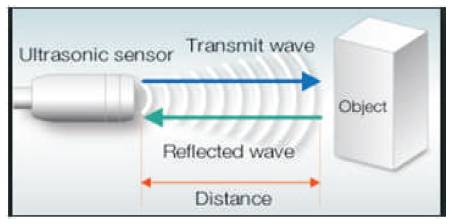

Ultrasonic Sensor: These are used for finding the distances of the nearby objects. The high-frequency sound waves generated by active ultrasonic sensors are received back by the ultrasonic sensor for evaluating the echo. Thus, the time interval taken for transmitting and receiving the echo is used for determining the distance of an object shown in Figure 3 (Wang et al., 2008).

Figure 3. Ultrasonic Principle

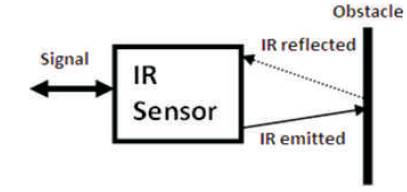

IR Sensor: The IR sensor works on the principle of Infrared waves which are emitted and reflected, using that property, it will detect the distance of the object, as shown in Figure 4(Wang et al., 2008) .

Figure 4. IR Principle

In the literature survey, the complete description of IoT, Industrial IoT and Safety is given. In this, section the proposals of safety in industries are described in two perspective models namely,

Employees are the ones who are playing a key role in the industrial growth; without them, the industries cannot run. So the industried should take care of their employees. As of now, many of the industries are providing various facilities such as house schemes, and medical facilities for the employees who are working in their organization, thus keeping them safe and healthy. But still, the health conditions of the employees are not traceable until they move to a doctor for any cause of illness. So, sometimes the employees are not aware of their health problems, and they enter their workplace and continue their work, as they don't have that much awareness of the symptoms of the health issues which are related to the Heart, and some high priority diseases which are leading to sudden fall of their consciousness and sometimes without proper precautions leading to death.

In order to eliminate such situations and to get awareness of the employee health conditions from time to time, a new model is proposed, named as Monitoring Employee Health (MEH) for the employees. With this model, the employee health is continuously monitored from his entry and until he leaves the workplace. In MEH, the concept of IoT is introduced, where sensors are connected to the employee using the WBAN and the health issues are analyzed for every short time span and the accurate information of health are forwarded such as pulse rate, heart beats and body temperatures to the cloud. The cloud will receive and store the information, then processes with monitoring the health issues on demand. Whenever any changes occur, it gives alerts and further precautions such as implementing the first aid, and also the information will be passed to the nearby hospitals, Doctors and Ambulance and Industry Managers, so that everyone will be alerted and the interaction takes place among all. Thus, within a short time the immediate measures can be implemented for saving the employee. By this model, if any of the employees met with an accident, the information is monitored, and hence immediate measures can be taken by implementing this model. The MEH model shown in Figure 5, is represented with four steps,

Figure 6 shows the Human body connected to Wireless Body Area Network attached with sensors such as Temperature sensor, ECG, EEG, EMG Blood pressure and the Insulin pump. The sensors are going to read the human body continuously from time to time, and forward the information to the cloud via Gateway through the base control unit. The reports are monitored automatically by checking the conditions as the information received from sensors will be stored in the prescribed format such as graphs, tables and so on. These reports are traced frequently, compared with the levels if any mismatch occurs, depending on the report further actions are alerted and implemented for saving the employee from death.

Figure 6. WBAN for Reading the Human Health

The Model consists of five modules

The employees are the workers who work in the factory. They are connected with sensors for reading the health status such as Pulse rate, Heartbeat and Body temperatures, and the information is forwarded to the CHM.

This is the one which sits between all, and always present in active state. It continuously monitors the information that is received from the employee for every fraction of second and if any disorder occurs, the immediate action is taken with connection to the hospital, ambulance, and the industry.

In this module, the industrial departments are connected. If any employee is affected by health issue, the immediate information will be passed from CHM module, so that the measures that should be taken, will be aware of the present situations and proceed with further actions.

The ambulance also plays a critical role, which is connected through Global Positioning System (GPS) to the CHM. If any employee is in a serious situation, the near ambulance on the instructions of CHM will respond and go to the spot for moving the employee to the nearby hospital on time.

The Hospitals are connected to the CHM. When any of the employee is detected with health issues, the CHM will forward the information which it noted by monitoring the employee, with the sensors. If any critical situation occurs, it will communicate with the hospital by forwarding all the reports of the employee before the employee reaches the hospital, so that the hospital will take the immediate precautions and certain measures depending on the reports, thus the employee can be saved immediately. The different steps of MEH are shown in Figure 7. Initially, the input is read using sensors such as Temperature sensor, Pulse detector and ECG, and the information is passed to the gateway using RF signals. Then from the Gateway, the information is passed to the central cloud where the cloud collects, stores, processes and monitors the information, and in the next step, the health conditions of every employee such as their Heartbeats, Pulse rates, Body temperatures and ECG are validated for time span. If for a particular employee, all reports are ok then the information is passed to the industry and then vice versa. If any disorder occurs in the Validation step, the information is passed to the hospital. If any severe condition occurs, it will automatically detect the nearby Ambulance using GPS and requests the ambulance to pick up the patient from a particular place using the GPS location tracker and then move to the Hospital. So if any accident occurs, as the information is monitored for every time span, it can be easily detected and immediate measures can be implemented.

The Safety Automation Model is employed completely for industrial safety. In this model, the Industrial Automation plays a key role, as of now the Automation is already implemented in several departments such as Manufacturing, Production and Deployment, and so on. So, this paper shows a new proposal for implementing the automation (IoT) for industrial safety. The Safety Automation model is also a part of Industrial-IoT, where sensors and actuators are coming into a picture for serving industries in their safety.

Industries are equipped with huge machinery, where the employees have to deal with larger machinery, cranes and trucks, and so on. When employees are dealing with machines, sometimes without their vision, they would get hit by any of the machinery and gets affected. In this model, a new proposal is implemented by placing a third party equipment in industries which are going to monitor the complete environment in industries from the employee view and also from the machinery view. Whenever any hazard is going to happen, it will detect (sense) with some sensors, and alerts (actuates) with some safety measures using actuators, thus preventing the hazard from occuring.

The third party equipment consists of sensors such as live detection with Opticals or Cameras, Ultrasonic sensors and IR sensors, Gas sensors, Smoke sensors and Humidity sensors for detecting the hazards. If any hazard occurs due to harmful smokes, gasses and so on, the sensors will detect the hazard using their properties and responds with alerting. Figure 8 shows the Safety Automation model. The industries are going to get connected to the sensors which are going to be placed at the most hazardous areas; live detection cameras will be placed covering all the industrial surveillance, which is going to track what is going on both from the employee part as well as from the machinery part. Using with its properties, it will detect all the motions of the employee and forwards it to the Cloud which is going to monitor whether any hazard is going to raise. If so, it will automatically alert the employee and also the precautions will be implemented.

Ultrasonic sensors, IR and Proximity sensors are placed at the risky places, as they have the capability of finding the distances using the Infrared waves, refraction value of light waves and electromagnetic waves emitted from the transducer which are refracted back; using these, they will find the distances. So, they will continuously detect the distances of the objects that are coming near it; if any object is near to them, they will automatically send an alert to the cloud, so that the next precaution measures are implemented immediately. Smoke sensors, gas sensors, and humidity sensors are placed for detecting the danger which occurs due to harmful smoke, gases and water. The information tracked by the sensors will be forwarded to the central cloud. So if any hazard is going to take place, the central cloud will given an alert regarding the hazard, and implements the measures for reducing the harm. By the end of this model, the industrial safety can be in the hands of central cloud which can monitor and track what is going on, thus reducing hazards and accidents.

This paper focuses on contributing to the safety of an employee in industries, by the implementing this model in industries. As of now, it may cost, more for implementing the approach. As the sensors’ cost is reasonable, the maintenance of information in the cloud is difficult and expensive, and also high-security mechanisms should be implemented as the information is related to the personal health of an individual employee, which should not be revealed to anyone at any time. The complete communication between sensors and the cloud should be implemented with encryption and decryption algorithms.

In this paper, the Safety in industries is proposed with two perspective models, MEH and SAM. In MEH the safety measures for taking care of the employees are shown with the smart sensors attached with WBAN, so that tracking employee's health on time will be useful for taking care and in SAM, the safety measures in industry are proposed with a third party equipment, placing the sensors in the industry surveillance for tracking the live information, on that immediate measures can be implemented. These proposed models are going to be useful for the industries in future in order to reduce employee injuries and death.