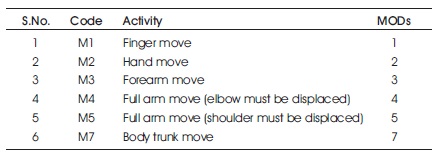

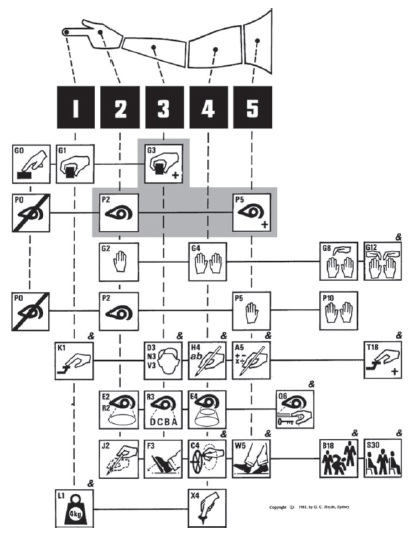

Table 1. MODs in Accordance with Codes of the Movement Tasks

In this competitive world, productivity is a most crucial factor. Every organization must maintain an enough productivity to satisfy the market's demand, to sustain in this world of competition. Productivity of an assembly line mainly depends on the standard time required to complete the assigned task. Therefore, the work measurement techniques have great importance in enhancing the productivity of the assembly line. This study aims to improve the productivity of an automotive assembly line where in the productivity of existing assembly process is insufficient to fulfil the required demand. In this study, a new combination of a work measurement technique Modular Arrangement of Predetermined Time Standards (MODAPTS) and elimination of Non-Value-Added (NVA) activities, is used to enhance the productivity of assembly line. Firstly, the NVA activities are eliminated to smooth the workflow. Further, MODAPTS has been used to estimate the appropriate standard time required to complete the assembly tasks. Modular Arrangement of Predetermined Time Standards revealed the excessive movements of operators, and helps to minimize the fatigue of the operators working on the assembly line. The elimination of NVA activities followed by implementation of MODAPTS, has been used as an effective approach that enhances the productivity of assembly line by 25.85%. Further, the significance of the applied approach is validated by conducting a statistical test.

An industry must retain the essential assembly processes, materials, manpower and research innovations for ensuring the sufficient productivity to meet the demand of customers. The customer satisfaction plays an important role for sustainability of an organization in competitive market (Rosa et al., 2017). A better quality and sufficient productivity are mainly required to comply with the customer needs (Almström & Kinnander, 2011). The small and medium sized enterprises (SMEs) have to face more competition in respect of rapid marked changes and high fluctuation in customer demands (Ghafoorpoor Yazdi et al., 2018). These small and medium-sized enterprises have to achieve and sustain the defined standard of product quality and quantity to satisfy the customer needs (Ghafoorpoor Yazdi et al., 2019). An efficient and smart manufacturing helps to connect the industries with the applications that are proceeded around the production (Azizi, 2019). With elimination of Non-Value-Added (NVA) activities, the execution of the work-study techniques helps any industry to enhance the productivity, quality and reduce production cost and time (Azizi, 2019). This improves the levels of customer satisfaction and, results in huge profits (Patel et al., 2017). The work study method is widely used in manufacturing industries to improve productivity (Kumar et al., 2020). The work study method is categorized in two parts: Method study and Work measurement (Kanawaty, 1992).

Method study is a systematic approach for studying the method of performing a task, including workflow and human motions, to improve the productivity. Basically, method study is focused to develop a best way for performing a task with less time and effort (Groover, 2006). Work measurement is a process of establishing the time required to perform the assigned task by a qualified and well-trained operator, with normal pace and defined performance in standard conditions (Bondhare et al., 2016). Numerous work measurement techniques have been developed to measure the work and, establish the time required to perform a task. Specifically, work measurement techniques include time study, work sampling, synthesis method analytical estimating and Predetermined Motion Time system (PMTS), and these are basic tools for improving performance of any process. These techniques are introduced in a systematic way for maximizing the utilization of available resources in order to enhance productivity and performance of the system (Jain et al., 2016). Additionally, the non-value-added activities which does not add any value in the working system, are required to be eliminated to improve the productivity of the system. Work measurement techniques and elimination of non-value-added activities can be combined to achieve the excellent performance and productivity (Karim et al., 2016). Non-value-added activities consists of all wastages which require an extra effort and time but do not add in value to the working system (Aughney & O'Donnell, 2015). Accordingly, it becomes necessity to eliminate the nonvalue- added activities to improve the performance and productivity of a system.

The work measurement techniques are extensively used for estimating the time required to perform the assigned task, redesigning the layout of assembly line, redistributing tasks and balancing the assembly line, which enhances the productivity (Mathur et al., 2012). The academic researchers and practitioners are using various PMTS techniques to get appropriate standard time required to complete a specific task. The appropriate standard time helps to enhance the productivity of an assembly line and reduce the production time. This leads to better profitability and sustainability of an organization in this era of competition. The PMTS techniques are Methods Time Measurement (MTM), MOST (Maynard Operation Sequence Technique) and Modular Arrangement of Predetermined Time Standards (MODAPTS), are widely implemented to estimate the standard time required to complete any task (Razmi & Shakhs-Niyaee, 2008). The implementation of PMTS can be valuable approach to improve existing process, balance assembly lines and estimate the standard time (Cakmakci & Karasu, 2007). From the fast few decades, the implementation of PMTS techniques in various industries, is broadly adopted by the several developing nations (Laring et al., 2002).

MODAPTS is one of the most popular PMTS techniques, which is widely used to evaluate the standard times in which an operator should complete the assign task (León- Duarte et al., 2019). In MODAPTS, the standard time required to complete a task, can be predicted before to the actual execution of task and motion of the operators is rationalized accordingly. MODAPTS classifies the movement of operators into twenty-one types, and a constant value is estimated as the standard time required to complete certain task (Hoffmann & Hui, 2010). In a study, MODAPTS has been implemented in a compiling yarn rolls process in the textiles industry to eliminate the unproductive motions of the operators, reducing 75.87% of the production time (Patel et al., 2017). The removal of non-value-added activities to enhance the performance and productivity of assembly lines, is widely accepted by the manufacturing organizations (Jin et al., 2008). According to Jin et al. (2008), researchers, the MODAPTS is found to be valuable approach to estimate appropriate time required to perform the assigned task and to evaluate the bottlenecks. Further, elimination of non-value-added activities and modification of existing methods, helps to remove bottlenecks.

PMTS is a procedure which is used to analyze the manual activities in terms of micro motions required to perform those activities, without the use of a stopwatch. This can be implemented on assembly operations and non-cyclic working environments, in less time with more accuracy. PMTS methods such as MTM, MOST and MODAPTS are widely used to enhance the productivity and, balance workflow of production lines. MTM is categorized as MTM-1, MTM-2 and MTM-3. MTM-1 has been introduced in 1940s, to establish the standard time required to complete a task prior to the task being processed (Zandin, 2001). Further, MTM-2 has been introduced in 1965, to estimate the standard time for tasks having small cycle time and repetition and, MTM-3 has been established in 1970, to estimate standard time of tasks where the working distances and approaches are varying in continuous manner. The major drawback associated with the use of MTM is that it includes analysis of huge amount of data, huge paperwork and, requires much time for execution. In 1967, a new PMTS technique known as MOST has been introduced, to overcome the drawbacks of MTM. MOST consumes less time and easy to execute with more accuracy as compared to MTM (Zandin, 2001). For implementation of MOST, an operation is broken into several sub-operations and, assigning numerical values in terms of time, to every sub-operation for estimating the standard time. These numerical values are known as Time Measurement Units (TMUs). One TMU is equal to .036 seconds. MOST is also categorized as basic MOST, maxi MOST, mini MOST and admin MOST. However, MOST requires less time for implementation than MTM, but still required a lot of time and a huge paperwork. MOST and MTM are complicated methods which consumes a lot of time.

Further, MODAPTS has been introduced in 1966. Like Basic- MOST, implementation of MODAPTS includes a coding technique that consists of at least one alphabetic letter and at least one integer number, where the sum of all integer numbers in a single code represents MODs. MODs can be simply converted into seconds or minutes to estimate the standard time required to complete an assigned task. Unlike the MTM and MOST techniques, MODAPTS uses a MOD as basic unit of time measurement, wherein one MOD is equal to 0.129 seconds. MODAPTS is most popular PMTS technique, widely used in the manufacturing, healthcare, service and garment industries. While implementing MODAPTS there is no need of stopwatch. MODAPTS analyzing the body motion required to complete the assigned work. MODAPTS is a most accurate and quick technique to determine the standard time. MODAPTS is easy to implement and it also reduce the possibility of errors. In present days, the productbased industries have to employ various modifications in the products by changing their shapes, manufacturing processes and parts (Wu et al., 2016). MODAPTS provides a provision to establish the standard time required to perform a task prior to the execution of that task. The sum of standard times for each task, results cycle time of the assembly process executed to get final product. Therefore, the product designers and industrial engineers can estimate the appropriate cycle time for a product before establishing the final product and assembly line. Accordingly, changes can be made in the assembly process of actual product and layout of assembly line to improve the productivity of the assembly line. MODAPTS can also be implemented on the existing assembly operations to improve their productivity wherein the production of existing assembly lines has been unable to meet the required demand. Therefore, the working methods, machines can be modified to finish the task in the estimated standard time. This helps the product designers and industrial engineers to make necessary changes in the assembly line for reducing and reestimating standard time for each task, without changing the whole assembly process.

Basically, MODAPTS is related to the movement of body parts including hands, arms, and shoulders and load on the body parts. In addition, the integer numbers are provided to represent the distance covered by the body parts while performing the assigned task. Every task is represented with two-part codes. First part is an alphabetic component which represent the type task and second part is an integer number which represent the time to complete the assigned task in MODs. MODAPTS categorized the motion of the operator in three types such as movement task, terminal task and auxiliary task. Movement task includes the movements done by fingers, hand, arm, shoulder and trunk system. The values of MODs in accordance with codes of the movement tasks are presented in the Table 1.

Table 1. MODs in Accordance with Codes of the Movement Tasks

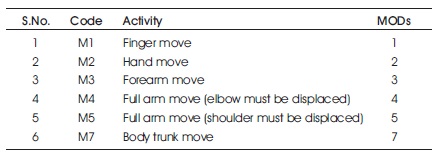

Movement class tasks are always followed by terminal tasks. Terminal tasks are performed after the execution of movement tasks. Further, terminal task is divided into two activities, Get and Put. In Get activity, G0, G1 and G3 codes have been used. G0 is used to get an object with low conscious control. For example, touch the button or placing palm on piece of paper. Further, G1 is used for the simple grasping with low conscious control and G3 is used for complex getting operation with high conscious control. In Put activity, P0, P2 and P5 has been used to represent the performed motion. P0 is used for simply putting an object with low conscious control and without specific positioning requirement. Furthermore, P2 is used for putting an object in a defined location with high conscious control and, P5 is used for putting an object with multiple feedbacks with high conscious control. This code is used to place an object in defined location. Third task is auxiliary class task which are not executed by fingers, arm, forearm, shoulder and trunk system. The auxiliary tasks include walking, bending, inspection, deciding etc. The auxiliary tasks have various codes such as X4 is used to represent extra force, J2 used to represent juggle, F3 used to represent foot action, B18 used to represent bend and arise, S30 used to represent sit and stand, W5 used to represent walking and, C3 and C4 used to define the motion of hand and arm in circular path. The codes for the movement task, terminal task and auxiliary tasks are represented in the Figure 1.

Figure 1. The Methodology for Implementation of MODAPTS (Cho & Park, 2012)

Accordingly, the implementation of MODAPTS with elimination of NVA activities, seems to be precious technique to enhance the productivity of a system as it is also essential to remove NVA activities along with the standard time measurement. The present study has been carried out in a small scale automotive industry to improve the productivity of an assembly line, where an unbalance exists between demand and supply, due to insufficient productivity. This assembly process consists of seven operations to be performed by seven operators on the corresponding seven workstations. The present study has following objectives:

The combination of MODAPTS and elimination of NVAs, has been used for estimating the appropriate standard time required to complete assigned tasks and maximizing the utilization of resources respectively. This improves the productivity and efficiency of the assembly line.

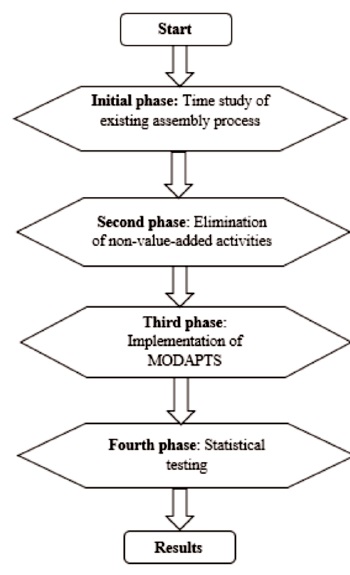

The methodology followed to perform the present study, has four phases as shown in Figure 2. The initial phase includes the time study of existing assembly line to estimate the standard time, efficiency and productivity. Further, the second phase includes elimination of non-value-added activities and balance of workflow through the assembly line. Accordingly, a new assembly process has been proposed. In the third phase, MODAPTS is implemented on the proposed assembly process to estimate the appropriate standard time for performing the assigned task. The fourth phase includes a statistical testing which is carried out to test the significance of implemented MODAPTS technique.

Figure 2. Flowchart of Methodology Followed to Perform the Present Study

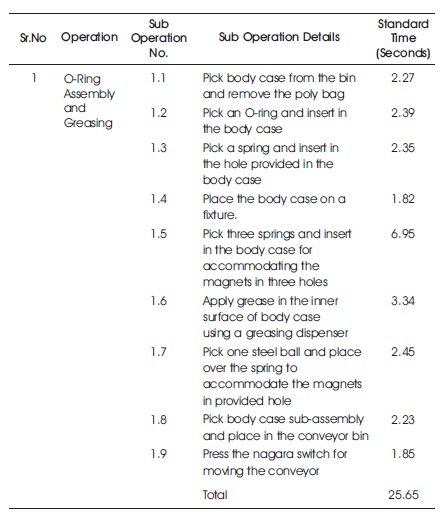

The operations of the assembly line are broken into various sub-operations to examine the micro motion of operators. Seven operators are working on the assembly line for performing seven operations. The operation breakdown of the workstation is shown in the Table 2. Another six operations performed on the corresponding six workstations, are broken in similar manner. Further, the time study is carried out for estimating the observed time taken by the operators to perform the assigned tasks. The stopwatch is used to measure the observed time. As per the norms of automotive industry and visual observation, the performance rating is considered. The performance rating is multiplied with observed time to get normal time. Further, the standard time has been obtained by adding the allowances in the normal time. Herein, the allowances are taken as 10% of normal time which includes 6% fixed allowance and 4% of variable allowances. Then, the total allowances i.e., 10% of normal time are added to normal time to get standard time. Table 3 represents the standard time for each workstation, in which the operator is performing the assigned task in standard time.

Table 2. Standard Time Calculated by Time Study for First Workstation of Assembly Line

Table 3. Standard Time Calculated by Time Study for all Seven Work Stations of Assembly Line

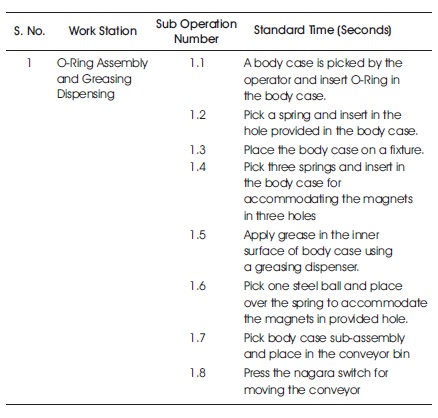

The existing assembly process consists of seven operations to be performed on corresponding seven workstations. The first operation of existing assembly line has nine sub operations as already represented in Table 2. The sub operation 1.1 of first operation includes picking of body case from the bin followed by removal of the poly bag in which the body case is covered. The use of poly bag to cover the body case is found to be non-value-added activity which does not add any value instead of increasing the standard time of the operation. This is non-value-added activity for the supplier as well as assembly process. The use of poly bag is replaced by using structured bins. The structured bin includes various body case shaped cavities to accommodate the body case. The structured bins are placed one over one. 5S is already implemented in the assembly section and, also at supplier's workspace. The structured bins prevent the body cases from dust, moisture, dents, notch, etc. Accordingly, there is no need to use poly bags to cover body case. The body cases can be securely placed in the structured bins and transported to assembly section. Therefore, the activity including removal of poly bag is eliminated from the existing sub-operation 1.1 of existing first operation and, existing sub-operations 1.1 and 1.2 are combined to balance the workflow. The proposed assembly process of first operation is shown in Table 4. Similarly, the non-value-added activities are removed from the other six operations of the existing assembly process. Total seven non-value-added activities are eliminated from the existing assembly process and, remaining 33 valued added activities are relocated to balance the workflow through the assembly line. Accordingly, a modified assembly is proposed. These seven non-value-added activities are excluded by selecting these activities on basis of the lean wastages such as MUDA, MURI and MURA (Asif et al., 2019).

Table 4. Proposed Assembly Process with Elimination of Non-Value-Added Activities

The modified assembly process is proposed with various changes by eliminating the NVAs. Further, MODAPTS is used on the various operations of the proposed assembly process after the elimination of non-value-added activities wherein each operation is broken into several sub-operations by operation breakdown for better implementation of MODAPTS. The task included in every sub-operation are observed and categorized into movement task, terminal tasks and auxiliary tasks. In accordance with the category of the task, codes consist of integer numbers and alphabets, which are designated to each sub-operation, and estimate the MODs. Further, the MODs are converted to seconds to calculate normal time. The standard time required to complete assigned task, is calculated by adding the allowances in the normal. In present study, 10% of the normal time is used as allowances to estimate the appropriate standard time as required to complete assigned task. The results of the MODAPTS implementation on the first operation (Workstation No. 1) are described in the Table 5. As represented in Table 5, the standard time required to complete the first operation, is calculated as 19.014 seconds.

Table 5. Standard Time Estimated by MODAPTS Analysis for First Work Station of Proposed Assembly Process

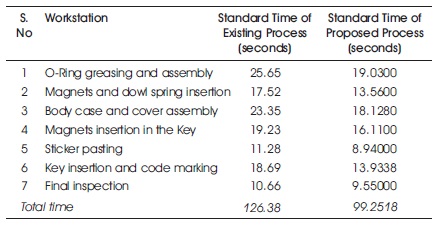

In similar manner, MODAPTS is implemented on each operation of the assembly process to get total standard time. The total standard time required to complete the assembly process is determined as 99.24 seconds. The final product is assembled in the 99.24 seconds. This is the appropriate value of standard time in which a healthy operator should complete the entire assembly process. The standard time estimated by MODAPTS for each workstation is shown in the Table 6.

Table 6. Standard Time Estimated by MODAPTS Analysis for all Seven Workstation of Proposed Assembly Process

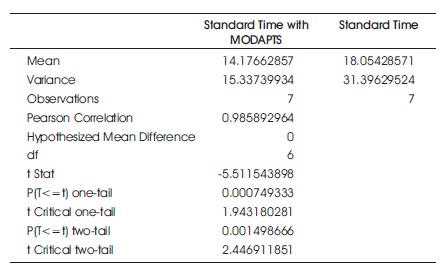

The statistical test has been conducted using Microsoft Excel for the significance of the implemented technique, on standard time of each operation. Table 7 describes a statistical paired sample t-test conducted with the Microsoft Excel. The paired sample t-test is conducted by considering the 5% of significance level or 95% of confidence level. This test results 0.074933% of p-value that is less than 5%. Thus, it can be stated with 95% of confidence that implemented technique is an effective technique to reduce the standard time of every operation of assembly line. This improves the productivity of the assembly process.

Table 7. T-test: Paired Two Sample for Means

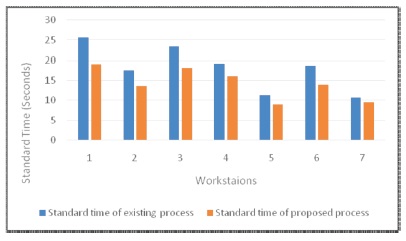

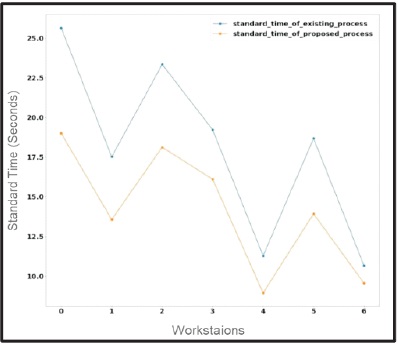

The comparison of standard time of the existing assembly process is estimated by time study and standard time of the proposed assembly process by MODAPTS, is detailed in the Table 8. MODAPTS is found to be effective technique to reduce the standard time for each operation as compared to the standard time of the existing assembly process estimated by time study. The maximum standard time of the proposed assembly process is estimated as 19.03 seconds. The maximum standard time is reduced by 6.64 seconds. The total time of the assembly process is reduced by 27.14 seconds. The elimination of non-valueadded activities and, implementation of MODAPTS reduces the standard time of each workstation, as shown in Figure 3 and 4.

Table 8. Comparison of Standard Times of Existing and Proposed Process of Assembly Line

Figure 3. Reduction in Standard Times of Proposed Assembly Process as Compared to Existing Assembly Process

Figure 4. Comparison of Standard Times of Existing and Proposed Assembly Process

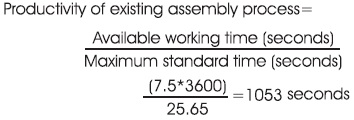

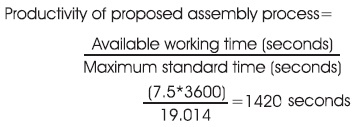

The reduction in standard time of each operation, enhances the productivity of assembly process. Further, the proposed line can have sufficient production to meet customer demand within available time. The productivity of the assembly process is enhanced by 25.85%. The calculation of enhancement in productivity is followed as:

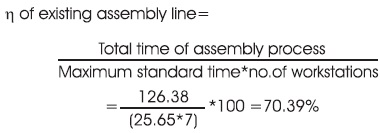

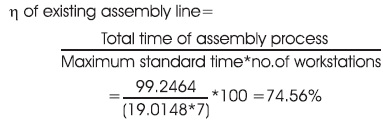

Further, line efficiency of the proposed assembly line is improved from 70.39% to 74.56% and, balance delay is also reduced by 29.61% to 25.44%. The line efficiency is calculated as followed:

h is line efficiency of the assembly line.

The results show the importance of proposed assembly process over the existing assembly process. The elimination of NVAs and implementation of MODAPTS improves efficiency and productivity of the assembly process by reducing the standard time for every operation.

This study consists of elimination of non-valued added activities followed by implementation of MODAPTS. The micro motions of the operators have been analyzed to improve their performance. In this study, MODAPTS is effectively implemented to establish the appropriate standard time for each operation. Seven non-valueadded activities are eliminated from the assembly process. MODAPTS reduce the total standard time of the assembly process from 126.38 seconds to 99.2518 seconds. Further, this also improves the assembly line efficiency by 4.17%. Moreover, the assembly line's productivity is improved by 25.85%. The present study revealed that the productivity and efficiency of the assembly are effectively improved by implementing the MODAPTS. The significance of the implemented technique is also statistically proved in this study. The findings of this study helps the managers, practitioners to effectively implement the MODAPTS on different assembly lines. The present study is based on the specific industrial problem but can be also extended towards other industries.