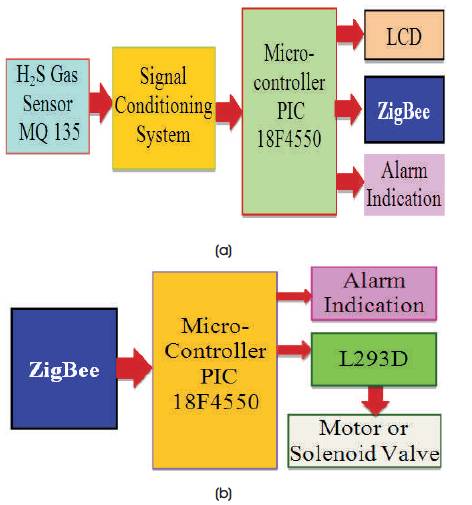

Figure 1. (a) Sensor Node for Monitoring of H2S Gas, (b) Coordinator Node

The environmental pollution is a serious problem, which is caused due to the leakage of toxic gasses at the time of transportation, storage, and during industrial processes of these gases. In industry, different types of hazardous gases are processed, stored, and transported through pipeline. The leakage of such pipeline occurs at any catastrophic accident, which may cause danger to the society as well as the environment. The gas pipeline may spread wide within the industry. Considering such facts, it is proposed to develop Wireless Sensor Network to detect, monitor, and control the leakage of gases. The Wireless Sensor Network (WSN) is a challenging technology in the field of Industrial sectors. Recently, it is used to monitor agricultural, industrial, environmental, and medical parameters. WSN is the network of systematically distributed sensor nodes to collaboratively collect information from physical world. The present research work is carried out to detect, monitor, and control the hazardous gas Hydrogen Sulfide in industrial transportation system, to avoid catastrophic accidents as well as to reduce the effect on environment. For this purpose, sensor nodes are wired about advanced PIC 18F4550 microcontroller along with sensing and signal conditioning capabilities. The IEEE 802.15.4 slandered based ZigBee device is deployed for wireless communication. On the other hand, the control action is carried out through Coordinator Node, which is capable with electromechanical action to close the main valve of the gas source.

Gas leakages are resulting into fatal accidents, which becomes a serious problem in industries for workers and surrounding environments. Moreover, it happens during transportation of such hazardous gas from tank to process point. Gas leakage leads to various accidents resulting in financial loss as well as human injuries and losses. Hence it is essential to design a system that detects gas leakage, alarm, display the amount of leakage, and turn OFF the main valve as a primary safety measure. The gas pipeline may spread in a wide area within the industry, so to detect and monitor site specific gas leakage, a suitable system is necessary. To exchange information from remote location which overcomes the limitations of traditional telemetry system, the Wireless Sensor Network is more suitable. For designing the desired system, field of an embedded instrumentation system (Tilekar et al., 2017) opens space for emerging wireless communication technology (Kumbhar & Mane-Deshmukh, 2017). Moreover, modern semiconductor technologies are producing the devices of promising features, such as small size and low power consumption, great configurability, flexibility in design, etc., which can be developed for dedicated tasks in embedded system (Priyanka & Shinde, 2015) like, signal processing, storage, and wireless transceiver. Deploying such devices, the field of wireless sensor network could be made more pervasive. The Wireless Sensor Network is the composition of either mobile or fixed located small devices equipped with functionalities, such as sensing, signal conditioning, signal processing, capability of wireless communication throughRadio Frequency (RF) module, etc. (Nageswararao & Murthy, 2017). Such devices are familiar as sensor nodes or sensor motes, which are operated on tiny rechargeable batteries. Furthermore, Coordinator Node is a device in Wireless Sensor Network, which collects sensed signal from scattered active nodes in the investigation area Mane-Deshmukh et al., 2013).

On literature survey, it is found that Hydrogen Sulfide gas is a colourless, flammable gas with a characteristic odour of rotten eggs. The Hydrogen Sulfide (H S) gas is Hazardous 2 and harmful for life and health of humans, animals, and plants (Souhir et al., 2015; Lim et al., 2016), when it exceeds above a specific level (Chou, 2003). Hydrogen Sulfide is found naturally in crude petroleum, natural gas, volcanic gases, and hot springs. It is also found in groundwater. H2S produced naturally as a result of human activity (Chou, 2003). Considering such factors, it is proposed to detect, monitor, and control the Hydrogen Sulfide Gas concentration.

For the present research work, Sensor Nodes and Coordinator Nodes are designed to realize wireless sensor network. The major aim of this present work is to detect the Hydrogen Sulfide Gas leakage, monitor, and control the same. For this, the MQ 135 Hydrogen Sulfide gas sensor is wired with signal conditioning circuit along with the microcontroller PIC 18F4550 of promising features. Wherein, Zigbee module is deployed for wireless communication. In fact, for establishment of WSN for dedicated application, the design of Coordinator node is equally important. Therefore, hardware of both nodes and the coordinator are designed and described through the following points. On the other hand, the firmware is codeveloped and flashed in the computing unit of Sensor Nodes and Coordinator Node. The designing of system and development of firmware are discussed through the following points in this paper.

According to the architecture of the Wireless Sensor Network, the sensor nodes and coordinator plays a vital role in the Wireless Sensor Network ( Gungor & Hancke, 2009). For the present investigation, the sensor nodes as well as coordinator are designed.

The block diagram of sensor node and coordinator are shown in Figure 1, which is an modified work of Mane- Deshmukh et al. (2018). According to the block diagram of sensor node, the salient features of the components are extensively studied, compared with the available others and selected for present design. From this investigation, the points, such as needs of the devices, pin configurations, characteristics, performances, output signal levels, etc., are emphasized. The hardware part of the wireless sensor mote is designed and fabricated in the laboratory. The schematic of the hardware of the sensor node and coordinator are depicted in Figure 2.

Figure 1. (a) Sensor Node for Monitoring of H2S Gas, (b) Coordinator Node

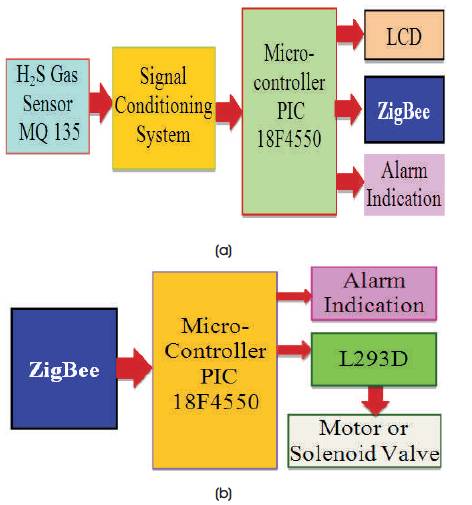

Figure 2. Circuit Schematic of the Designed Sensor Node for Detection and Monitoring of Concentration of Hydrogen Sulfide Gas

The details regarding components integrated in the circuit diagram are briefly discussed through the following points.

Realizing the concept of an embedded technology, the sensor nodes and coordinator node are designed. To achieve the desired aim, smart devices are extensively studied and selected, such as sensors, signal conditioning, processing, communication, actuators, etc.

The sensor node is designed to detect the hazardous Hydrogen sulfide gas concentration, monitor the same and transmit it to coordinator node. A sensor interacts with the physical world, depending upon the characteristics of the sensing element and sensing principles, which produces output signal in typical form. Moreover, for instrumentation, the signal must be either voltage or current form. To ensure this conversion, essentially the signal conditioning circuit is used. As discussed earlier, the Hydrogen Sulfide Gas is considered for present system, accordingly the system is designed to monitor and control the gas leakage.

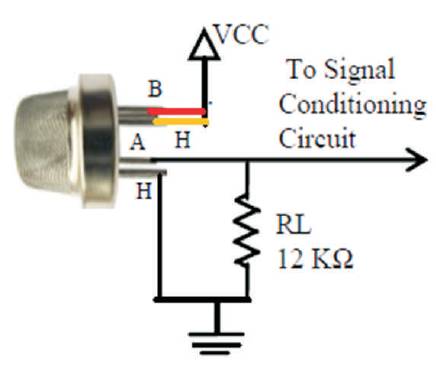

The MQ-135 sensor is sensitive to different gasses, such as Ammonia, Benzene, etc. However, on investigation of the datasheet of MQ-135 (Datasheet of MQ-135; Simić et al., 2017) and comparing with the datasheet of MQ-136 gas sensor, it is found that the thick film of ceramic material SnO2 is used as the sensing element, which is also sensitive to H2S gas. Moreover, the structure and configuration, basic principle, and measuring circuits are identical for both the sensors (Mane-Deshmukh, 2018). Hence it is proposed to deploy MQ 135 sensor for monitoring of Hydrogen Sulfide gas concentration present in the environment. It is a resistive sensor, wherein the thick film of ceramic material SnO2 is used as the sensing element. SnO2 has very low conductivity in clean air. The resistance of the sensing material proportionally decreases with increase in the H2S gas in the surrounding environment. An analog part of the circuit used to extract the H2S dependent emf, is depicted in Figure 3. The load resistance of 12 KΩ is wired to get suitable output signal within the range of investigation. The output of this sensor is applied to the signal conditioning stage.

Figure 3. The Schematic of Interfacing of Hydrogen Sulfide Gas Sensor

Signal conditioning stage of sensor node plays a vital role on the salient features of the measurement and control instrumentation. Recently, Texas Instruments has launched TLV 2772 CMOS operational amplifier to fulfill the need of user for more than one input, typically for two inputs. For selection of most excellent operational amplifier, the parameters, such as low supply voltage, high precision, real to real out, cost and package size, etc., are emphasized. The TLV 2772 satisfies all these requirements. Hence, the signal conditioning circuit is built with TLV 2772 operational amplifier. The output of the TLV 2772 is coupled to the analog channels of analog to digital converter of PIC18F4550.

To process the sensed signal from sensor, the microcontroller is essential according to the architecture of an embedded system. For this, the smart microcontroller is required, smart in the sense, the capability of processing with promising features and wide on-chip peripherals. To cater this need, the 8-bit microcontroller, PIC 18F4550 from Peripheral Interface Controller (PIC) family is selected. It depicts RISC ISA of only 35 instructions (Mane-Deshmukh et al., 2016,). It has promising on-chip peripherals like Analog to Digital Conversion (ADC), Enhanced Universal Synchronous Asynchronous Receiver Transmitter (EUSART), Timer, Memory, Counters, USB connectivity, etc. Out of these, the ADC is used to acquire the signal from signal conditioning stage. It is converted into digital form and processed according to the user firmware. The processed data is transmitted via EUSART to the RF module. For this, the ADC is configured using ADC resistors for first analog channel (AN0), 10 bit resolution with right justification of result through firmware. In addition, EUSART is configured to transmit 8 bit data serially with 9600 baud rate. The output of EUSART is connected to the RF module for wireless transmission. Moreover, the alarm indication circuit is wired with a speaker and when the gas concentration exceeds the desired value, the alarm indication starts.

To transmit data wirelessly, a number of RF modules are available. Out of these, the ZigBee module has found suitable advantages over all other devices, hence it is wired in present work. The Digi international corporation produces RF module, the ZigBee, which is designed to follow IEEE 802.15.4 standards (Kumbhar & Mane- Deshmukh, 2018). It operates within Industrial Scientific and Medical (ISM) band with 2.4 GHz frequency. It operates at 3.3 V and depicts the range of data communication up to 0.9 km for indoor environment and 1.5 km for outdoor environment, with the speed of 250 kbps. It consumes current of 145 mA at transmitter and 45 mA at receiver. Moreover, by using hierarchical clustered network or multi-hoping, the data exchange range can be increased up to several kilometers. Also, it can withstand in industrial temperature conditions, and its o typical operating temperature range is -40 to 85oC. The ZigBee module is self configurable in any network topology, such as Bus, Star, Tree, Mesh, etc. It has UART port which can be easily interfaced to the microcontroller. As given in the datasheet of ZigBee, the two pins DIN and DOUT are made available to interface this module to microcontroller. For configuration of the ZigBee devices, the Digi Corporation has provided a smart IDE called ZigBee Configuration and Testing Utility (X-CTU). Employing this X-CTU, the ZigBee can be programmed as per the specification of the Nodes. The developed sensor node is shown in Figure 4. The same technique is utilized to design the sensor nodes. To cover wide area, the four sensor nodes and one coordinator node are designed. The details of coordinator node designing are discussed in the next paragraph.

Figure 4. Developed Wireless Sensor Node for Wireless Sensor Network

The coordinator node is designed to receive the signal from sensor nodes wirelessly, to process the same, PIC 18F4550 is used that generates control signal if the gas leakage concentration exceeds the set point value. Hence to perform the control action of open or close valve by the coordinator node, the L293D devices are connected in addition with minimum microcontroller base system as shown in Figure 5 (Mane-Deshmukh et al., 2018). The L293D is quadruple high- current half-H drivers (Quadri & Sathish, 2018). The L293D is bidirectional drive currents of up to 600 mA at voltages from 4.5 V to 36 V.

Figure 5. L293D Device with Minimum Microcontroller (Mane-Deshmukh et al., 2018)

L293D is capable to drive inductive loads, such as relays, solenoids, DC, and bipolar stepping motors, as well as other high-current/high-voltage loads in positive supply applications. Hence, L293D is wired as shown in Figure 5 to drive the solenoid valve. The output control signal of microcontroller is coupled to L293D and the output of L293D is connected to solenoid valve to convey the control action of valve as Open or Close. The solenoid valve is used to control the flow of gas through pipeline. When the signal of gas detection from sensor node is received at the coordinator node, then solenoid valve is de-energized to stop the flow gas through pipeline, as programmed in microcontroller.

The main aim of the present research work is to detect the Hydrogen Sulfide gas leakage and control the same. The firmware is developed for both sensor node and coordinator node. The firmware is developed in embedded C environment using PIC C Wizard IDE, which is more convenient for PIC 18F4550. At the time of firmware development, the concept of Real Time Operating System (RTOS) is deployed. The firmware for sensor nodes is developed to acquire signal from signal conditioning stage and process accordingly, as ADC, signal conversation in real unit. The acquired signal is calibrated in % unit of H2S gas concentration and transmits to coordinator node if signal is above threshold level. Moreover, the RTOS task is created to display the gas concentration on the smart LCD connected at port D of PIC.

On the other hand, the coordinator node is programmed in such a way that after receiving the signal, the coordinator node produces the actuating signal to turn OFF valve of gas pipeline. The developed firmware is flashed in program memory using PICpgm IDE. The algorithm of developed firmware is listed below.

The algorithm of firmware for sensor node:

The algorithm of firmware for coordinator node:

After successful development of sensor nodes and base station, it is ready for practical validation of the system (Adat et al., 2017). On industrial visits, it is found that the chemical industries have adopted safety concerns to prevent catastrophic accidents. It is found that molasses processing is also source of the H2S (Hilton & Archer, 1988). Hence the wireless sensor network is implemented at molasses processing plant of Sahyadri Sahakari Sakhar Karkhana Ltd. The area of Molasses process plant is about 80 x 60 m. For deployment of the system, area under investigation is fragmented in four hypothetical cells and each node is located in each cell. On observation, the nodes are located in four cells where possibility linkage occurs. Initially, the coordinator node is located near the gas tank as shown in Figure 6 and the sensor nodes, Node 1 to Node 4 are located at typical points. Figure 7 shows the typical sensor nodes in area under investigation. Initially, the coordinator node is activated. The coordinator ZigBee of coordinator node initiates the Personal Area Network (PAN) with PAN ID 25 of the Wireless Sensor Network. The self-powered sensor nodes respond to the network joining request of coordinator and joins the PAN of coordinator having PAN ID 25. At the time of deployment of the Wireless Sensor Nodes, the WSN parameters are considered, such as Receiver Signal Strength Indicator (RSSI), Link Quality Indicator (LQI), etc. The result of the WSN is discussed in the next section.

Figure 6. Implementation of the Developed Wireless Sensor Network

As discussed earlier, sensor nodes and coordinator node are successfully designed. Moreover, both are programmed to carry out the main aim of the present research work. The sensor mote is calibrated using two point calibration to monitor H2S gas concentration in % unit. The developed system is implemented in Molasses storage and processing plant for different days for different time period. At the time of investigation, the WSN parameters, such as Receiver Signal Strength Indicator (RSSI), Link Quality Indicator (LQI), etc., are recorded. The RSSI of sensor nodes varies between -35 and -55 dB and LQI varies from 245 to 223 dBm. The variation of these parameters observed are due to positions of sensor nodes from coordinator, battery capacity, line of sight, etc.

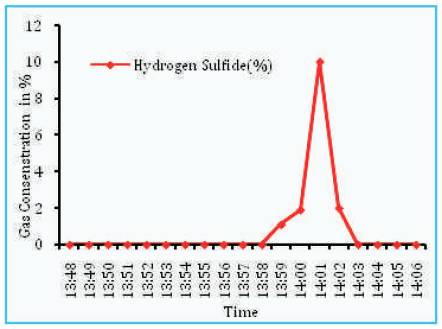

The molasses processing industry is secure. The 0% Hydrogen Sulfide gas concentration is observed at the area under investigation. Hence for the present investigation, the manual gas leak was created near source node 2, and the response of Wireless Sensor Network is monitored. The sensor node 2 senses the Hydrogen Sulfide gas leakage and displays gas concentration on an LCD in %. When gas concentration increases above threshold, the sensor node transmits to the coordinator node and generates alarm. Receiving the same signal, the coordinator node produces a control signal to drive motor. The motor is associated with the main valve to H2S gas pipeline. The rotation motor closes the valve. This action stops the flow of gas. The gas leakage is thus monitored and controlled at threshold level for Hydrogen Sulfide gas concentration. The response of sensor mote with respect to time is plotted in Figure 8. On the investigation of Figure 8, it is found that the wireless sensor node and coordinator node are successfully designed and implemented for Hydrogen Sulfide gas leakage detection and control.

Figure 8. The Hydrogen Sulfide Gas Concentration Recorded by Sensor Node 2

The Wireless Sensor Network for detection, monitoring, and control of leakage of the H S gas have been 2 successfully designed and established for practical implementation of the system. Both the sensor nodes and coordinator node are designed using PIC18F4550 microcontroller, ZigBee device, etc. Moreover, the firmware of the nodes is developed using PCW of CCS IDE realizing real time operating system to achieve the accuracy. Before implementation of the WSN, the developed nodes are calibrated for % unit using two point calibration systems. On investigation of observed result, it is found that system works with high accuracy.

When the gas leak occurs, the system provides control action by closing the solenoid valve. It has more advantageous function than the existing system by operating in real time and helping to avoid catastrophic accidents. Moreover, the system demonstrates the leakage of the gas concentration in % unit. This monitoring and controlling system is proposed mainly to meet the safety standards and to avoid accidents because of leakage.

Further, the system could be extended to monitor the status of LPG, CO2, etc., transportation pipeline. The present WSN also depicts its application for monitoring of mine gases.