Figure 1. Manufacturing of Thin-Walled Steel Sections - Press Brake Operation

The use of thin-walled sections in the construction of residential and industrial buildings is very common. Thin-walled section elements are vulnerable to local buckling due to their slender nature. As a result, they will be unable to fulfil their minimum yielding capacity. Due to their high slenderness, mono-symmetric nature, eccentricity of shear centre, and low-torsional rigidity, they suffer from certain buckling modes due to their simple forming techniques and easy connectivity. Hence, it is necessary that these buckling modes are either delayed or eliminated to increase the ultimate capacity of thin-walled members. In multi-storey towers, where the Buckling Restrained Braces (BRBs) are thicker than the thin-walled portions, BRBs are widely used as lateral load resistant systems. The amount of strength required to prevent buckling of thin-walled parts would be less than that required by BRB. As a result, similar techniques cannot be employed due to the infill weight and tube sections involved. Therefore, a mechanism to avoid buckling must be created in order to enhance the efficiency and failure modes of such sections. The review comprises research that has been done to examine the consequences of buckling mode and its behaviour under various loading conditions. Buckling restraining the thin-walled part using Ultra- LightweightConcrete Composite (ULCC) can be used instead of BRBs.

Modern thin-walled structural materials have the potential to scale back the weight of structures without decreasing their load capacity. This leads to the development of theoretical and experimental investigations of such structures. The research works devoted to these problems are steadily increasing in recent years. Thin-walled steel members find their extensive applications in automobile industries, aerospace, and various secondary civil engineering structural elements such as purlin, especially when lightweight members will be sufficed in achieving substantial economy. Compared to hot-rolled steel sections, cold steel sections are less expensive in manufacturing and offer greater flexibility in producing any desired shape. They can be used effectively as a structural element of lightweight structures in cases where hot-rolled sections or other methods are not efficient. However, these members undergo local, distortional, flexural, and lateral tensional buckling, and the exact strength of the structure becomes more complex as a result of interaction between them or between the aforesaid buckling modes.

Thus, light gauge steel structural members can lead to more economic design than hot rolled members as a result of their high strength to weight ratio, ease of fabrication and construction. Further their increased yield strength, their post buckling strength and their suitability for wide range of applications are the key advantages of light gauge steel sections. Such members are susceptible to local buckling at relatively low compressive, shear, bending or bearing stress. However, a considerable reserve of post-buckling strength exists due to the possibility of membrane actions after local buckling.

The use of light gauge steel structures has become increasingly popular in different fields of building construction.

Thin steel profiles are cold formed due to their manufacturing process, which consists of producing steel profiles in the cold state from steel sheets of uniform thickness ranging from 0.4 mm to 6.4 mm using three main processes: cold rolling, folding, and folding in any shape depending on the requirement.

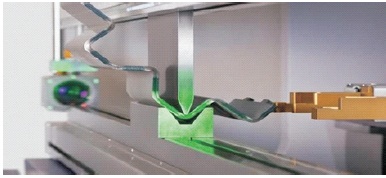

As illustrated in Figure 1 and 2, the cold formed steel section can be made in any shape to meet the requirements using three basic methods: cold roll forming, press brake operation, and bending break operation.

Figure 1. Manufacturing of Thin-Walled Steel Sections - Press Brake Operation

Figure 2. Manufacturing of Thin-Walled Steel Sections - Bending Brake Operation

Thin-walled sections used in the building industry include: Open Sections, Closed Sections, and Constructed Sections and these are the various types of cold formed shapes available as structural elements. As seen in Figure 3, open profiles include C, Z, double channel, I, hat, and angle profiles, whereas closed profiles include box profiles and tubes. These forms of construction can be used in buildings as eaves struts, purlins, beams, bolts, headers, floor beams, tie rods and other structural components. Various shapes are also available for walls, floors and ceilings, membranes and cladding.

Figure 3. Various Forms of Thin-Walled Steel Sections

Thin-walled, open-section pillars are widely used in the design of structural components in various fields of engineering, including mechanical, civil, marine, and aerospace structures. These thin-walled profiles create structures with a high strength-to-weight ratio compared to their thick-walled counterparts, resulting in lower material costs, easier handling and transport and better fuel efficiency. The disadvantage of these columns, however, is that the torsional rigidity of the open cross-sections is significantly lower than that of the closed profiles. As a result, these structural elements are prone to buckling failure. Therefore, in order to effectively and efficiently use these thin-walled open section supports, it is important to understand the behavior of these supports towards their common failure modes, such as buckling instability.

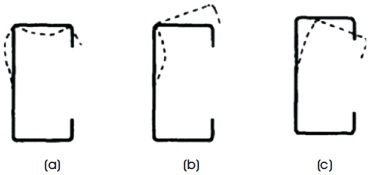

The following three buckling patterns as shown in Figure 4 can occur in the thin-walled steel sections.

Figure 4. Buckling Modes of Thin-Walled Steel Sections (a) Local Buckling (b) Outward Distortional Buckling (c) Inward Distortional Buckling (Dandu, 2014)

Due to the fact that very thin parts used to buckle in place before yielding, local buckling is a critical component of thin steel sections.

This is a deformation buckling mode in which the member does not deform in its cross-sectional shape. Global buckling is classified as follows:

It is a global buckling mode in which members can bend without change of cross sectional shape.

It is a global buckling mode in which members can twist without change of cross sectional shape.

It is a global buckling mode in which members can twist and bend simultaneously without change of cross sectional shape.

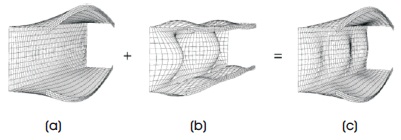

It is a buckling mode with cross sectional distortion that involves the translation of some of the fold lines. Figure 5 shows combined distortional buckling.

Figure 5. Combined Distortional-Local Buckling Model (a) Distortional Mode (b) Local Mode(c) Local-Distortional Interaction(Martins et al., 2015)

Cold-formed steel building components are reported to fail under different buckling modes due to the slender nature of the elements of the cross-sections. These failure modes are considered as brittle and these sections have lesser efficiency. Therefore, in order to improve the efficiency and the failure modes of such sections, there is a need to develop a mechanism to restrain the buckling. Open cold formed steel sections such as C, Z cross section profiles are relatively common because of their simple forming procedures and easy connections, but they suffer from certain buckling modes due to their high slenderness, mono-symmetric nature, eccentricity of shear center and low-torsional rigidity. Hence, it is necessary that these buckling modes are either delayed or eliminated to increase the ultimate capacity of cold-formed steel members.

A brief review of the researches carried out on the behavior of cold form channel section to compression loading as well buckling restrained mechanism has been done.

Paczos and Wasilewicz (2009) investigated cold-shaped thin-walled beams with open cross-sections, which are widely used in specialised industries. Because of the curves in their cross-sections, they tend to buckle locally. The results of experimental research of lipped I phase beams are described in this work. Bending moments and a concentrated force had been applied to the beams. The essential load values obtained experimentally are compared to those obtained using FEM and theoretical studies.

With the aid of enhanced numerical modelling, Haidarali and Nethercot (2012) investigated the genuine buckling behaviour of cold-formed metal beams with each region and intermediate stiffeners of their compression flanges that had been predicted. The flexural behaviour of coldshaped Z sections with each aspect and intermediate stiffeners of their flanges has been investigated using a series of nonlinear finite detail studies, with the failure handled using local or distortional buckling. The effect of intermediate stiffener dimensions and function, as well as the effect of the brink stiffener/intermediate stiffener interplay on the buckling behavior and closing energy of those sections has been studied.

Gardner and Yun (2018) used a rounded stress strain reaction instead of a sharply defined yield point to characterise cold-shaped steels. This fabric behaviour can be accurately characterised using a two-degree Ramberg-Osgood model, provided that the values of the essential parameters can be determined. The purpose of this article is to extend predictive formulations for those essential parameters in order to reflect the total engineering stress-pressure reaction of cold-shaped steels. Rokilan and Mahendran (2020) evaluated the mechanical properties of low and high strength cold-rolled steel sheets, as well as high energy CFS lipped channel sections and ground decks, which were tested in the temperature range of 20-70 oC under isothermal conditions. The yield strength and Young's modulus predictive equations in AS/NZS 4600 were confirmed, and additional predictive equations for closure energy, strain at 2% general strain, 0.05% proof strain, and proportional limit stress were provided.

Experiments were carried out to evaluate the mechanical properties of cold-formed steel sections as well as the builtin residual stresses. The tests were carried out on coldformed steel sections in the shape of a channel, which were made using the cold-roll forming technique. The mechanical properties of the section were evaluated using tensile coup on tests at various locations. The magnitudes and distributions of residual stresses within the channel section were determined using electrical strain gauges and an electric discharge machine cutting technique. Analysis models for the stress-strain relationship, yield strength variation, and residual stresses in coldformed steel channel sections were developed based on the experimental results. To create an analysis model for cold-formed steel sections, the proposed material property analysis models were incorporated into a large deformation shell finite element. By comparing the finite element analysis (FEA) results with the corresponding experimental results of cold-formed steel sections subjected to axial compressive loads, the efficiency and accuracy of the proposed material models were assessed (Abdel-Rahman & Sivakumaran, 1997).

Ananthi (2016) in her paper compares the behavior of lipped and plain channel members with various slenderness ratios to the various international codes of practice for compression-formed cold-formed sections. Load carrying capacities for seven plain and lipped channels with different slenderness ratio are compared. The plain and lipped channel load versus axial shortening behavior is also shown. The mode of failure observed is combined local buckling in the case of unstiffened elements, flexural buckling about minor axis for slenderness ratios of 30 to 100, and overall flexural buckling about the weak axis for slenderness ratios of 120 to 200.

Feng et al. (2003) published an experimental study of the axial strength of cold-formed thin channel sections at ambient temperature and uniform high temperature. The purpose of this study is twofold. It gives insight into the physical behavior and failure mode of this type of structure, and provided some experimental results for detailed numerical studies. A total of 52 strength tests were run on short cold formed rib channels with and without service holes and channels without ribs at ambient temperature and various high temperatures. It is observed in these experimental studies that the failure modes of two nominally identical columns may differ even when the failure loads are close.

Ananthi et al. (2012) studied on the cold-formed steel plain single channel columns with fixed ends, loaded concentrically and eccentrically. Two different cold formed channel cross sections, CFC 200502 mm and CFC 150502 mm, were chosen for forty different analytical studies. The effect of slenderness ratio and eccentricity on load carrying capacity is presented based on the studies. The variation in stress contours and the load versus deformation behavior of columns were studied and compared with the experimental results using the finite element software ABAQUS. For both concentrically and eccentrically loaded columns, the design strengths predicted by the various standards are generally conservative. Local buckling of the flanges caused failure in specimens with low slenderness ratios, whereas overall flexural buckling caused failure in specimens with higher slenderness ratios of 100 and 120. The numerical analysis predicted failure modes that were similar to the experimental results.

The lateral buckling of cold-formed thin-walled beams under pure bending moments has been explored by Sastry et al. (2015). An optimization criterion has been used to estimate the critical buckling loads, and the predicted critical buckling stresses were found to be extremely close to the published results. For various combinations of the geometrical characteristics of the beam, the influence of the beam length, the radius and thickness of the flanges, and the length of the extended open flanges on the critical buckling stresses has been examined. The elongated open flange beams are the tallest of the three beams, therefore the elongated open flange beam has the highest critical buckling moments for the given load conditions and beam dimensions. However, considering the material and manufacturing costs, beams with rounded cross-sections are effective in withstanding buckling loads.

Young (2008) investigated the strength and behavior of cold-formed steel channel columns using both experimental and numerical methods. The column strength from previous studies has been compared with the design strengths calculated using various international standards for cold-formed steel structures. As established experimentally, the shift in the line of action of the internal force induced by local buckling does not induce overall bending in fixed-ended channel columns as it does in pinended channel columns. For a fixed-ended singly symmetric column that failed due to local and overall buckling, a concentrically loaded component has been recommended.

Schafer (2002) studied the thin-walled columns for their local, distortional, and Euler buckling behavior. The numerical results agreed well with a closed-form prediction of the buckling stress in the local and distortional modes. The interactions of the connected elements, as well as the elastic and geometric stiffness at the web and flange juncture were all factored into the equation. The postbuckling capacity of the distortional mode is lower than the local mode, according to numerical analyses and experiments. Local, distortional, and Euler buckling are all explicitly addressed in a new design method. For thinwalled columns, a rational analysis for predicting elastic buckling stress has been presented.

In axial compression, stiffened and unstiffened coldformed channel parts performed differently, according to El-Sheikh et al. (2001). A parametric research has been carried out on channel members with varied aspect ratios, stiffener sizes, and slenderness ratios. It has been determined that raising the web stiffener beyond a certain point has been ineffective. Due to load eccentricity in the weak direction, the buckling strength has been drastically lowered. Web stiffeners reduce torsional buckling strength below flexural buckling strength, resulting in overall strength losses. On the other hand, using flange stiffeners in channel sections resulted in a constant increase in the member's buckling strength.

Lam et al. (2006) studied the load-bearing capacity of cold-formed steel cut-stub columns with lipped C-sections. Ten stub columns were cut from two separate sections and tested under axial compression. The flanges of the stub columns showed symptoms of distortional failure, whereas the webs had local buckling. The ultimate compressive strength has been estimated to be 75 to 77% of the strength obtained from the test findings. This implies that cutting-induced geometric flaws may affect the ultimate strength of stub columns.

Nandini and Kalyanaraman (2010) investigated the interaction behaviour of buckling modes including short half-wavelength local buckling, intermediate half wave length distortional buckling, and long half wave length lateral-torsional buckling, or any of these combination. After filtering the experimental results available in the literature, finite element models evaluate such beam behaviour and intensities in various sorts of interactions with changes in the properties of materials and members utilised to execute parametric tests. They analysed alternative equations for predicting the intensity of these cold-formed ribbed channel beams using the enormous quantities of synthetic data obtained from these varied failure types and existing inspection results. The design technique of damaged ribbed channel beams has been recommended based on the comparison, both with local distortion and in the interplay of global lateral torsional buckling.

Vijayasimhan et al. (2013) compared the flexural strength design of different channel components to the design rules developed in various practical rules. Documents are used to collect experimental outcomes. Direct intensity methods (DSM), which offer flexural strength around the desired test findings, are being investigated to further study of the parameters based on comparative research. There are varieties of failure types, and deformation locks are one of them. They have an impact on the performance of the sections. In order to evaluate the effects of disturbances, a parameter study has been performed by changing the lip depth, which has been the factor that influenced the disturbance strength.

Ungureanu et al. (2018) investigated the possibility that could be used to characterize the ultimate strength of short, thin cold-formed steel members that undergo eccentric compression for the development and shortening of firing mechanisms. This is done especially in the case of members with a lip channel cross section. Five types of firing mechanisms for other compression members with eccentricity are identified and inspected based on FE numerical simulations. Preliminary results of experimental verification with numerical results are presented.

Riahi et al. (2018) made a qualitative evaluation of the seat stability of axial compression plates with different support conditions within the framework of classical plate theory. They investigated some public aspects of the plate's seat stability, taking into account the effects of support conditions, aspect ratios, and thin ratios. The result is an efficient design of such a thin structure. For this purpose, as well as validation of numerical simulations, several case studies were performed to understand various aspects of the in-situ quality of such thin-walled structures.

Sabelli et al. (2003) investigated the ground motion and structural characteristics that determine the seismic performance of concentrically restrained steel beams to improve design methods and location specifications. The mechanical properties and advantages of this type of stent are discussed. For specific situations and for different groups of ground motions, the detailed results of the nonlinear dynamic analysis will be checked. Characterizing has been done on the impact of various structural configurations and relationships on key response parameters.

Li et al. (2019) studied the buckling restrained braces (BRB) widely used in mechanical engineering. However, the traditional BRB is designed to be inelastic during frequent earthquakes, thereby avoiding cyclic fatigue and unable to provide seismic energy. In order to overcome this shortcoming, it is recommended to combine the traditional BRB with the tubular metal bumper to form the TYBRB type. The results show that the low-cycle fatigue performance of the shock absorber can meet the requirements of TYBRB to withstand frequent earthquakes. TYBRB can be realized through reasonable design and the performance of BRB in TYBRB is not affected by the combination of impact load.

Wu et al. (2017) investigated the design formula for BRBs with restricted buckling that took into account the impacts of partial stiffness and friction of the steel core, based on theoretical analyses of the buckling mechanism of the steel core in the presence of a gap between the core and the restraining member. Finite element analysis backs up the theoretical analysis. The suggested analysis findings are frequently superior to existing approaches, and they have the best correlation with finite element analysis results.

Takeuchi et al. (2010) proposed a study on the BRB which is usually used as the support unit of the seismic zone. The important limit state that defines the BRB design is to prevent bending. Compared with the cross-section of the substrate, the substrate is relatively small, and the boundary conditions that resist local buckling of the substrate are critical to the stability and strength of the BRB. In this study, the BRB cyclic stress test and numerical analysis were performed using different anti-theft locking devices. The configuration has been used to study the influence of restrainer local buckling on the strength and ductility of BRB.

Chou et al. (2019) developed a novel steel dual-core selfcentering brace (DCSCB) with two characteristics: recentering to seismic loads and wasting energy. Therefore, it is possible to reduce the residual deformation of the frame structure by using a buckling restraint brace (BRB). Three fulllength, two-layer, one-bay steel specimens, designated DCSCBF, SBRBF, and SMBF, equipped with DCSCB, BRB and a combination of DCSCB and BRB were tested periodically. Nonlinear time history analysis has been performed on three prototype brace frames to obtain the seismic demands of the test protocol. The two-layer structure specimen worked well up to an interlayer drift of 2%. No damage to DCSCB or BRB has been observed, but damage to the steel beam flange near the beam web stiffener and triangular plate toe joint has been observed by low cycle fatigue loading. Contrary to the testing of braced components, the energy dissipation of two-layer structural specimens using DCSCB is higher than that using BRB because DCSCB has high post-yield stiffness.

Guerrero et al. (2018) conducted an experiment to investigate the damping effect of a structure equipped with Buckling Restrained Braces (BRB) operating within the linear elastic range. For comparison, tests were also performed on exposed structures without BRB and structures with existing stanchions. All experiments were performed on a shaking table. The results shows that tests with existing struts did not show an increase in damping ratio, while BRB increased significantly. A model has been proposed to explain the power consumption observed in the experiment. The results of this study are important to show that the BRB begins energy consumption at low levels of displacement and these energy consumptions should be considered in the context of performance-based seismic design.

In the work by Galatage and Sawant (2017), the CFS sections are encased in Polystyrene aggregate concrete and their flexural performance is assessed. A three-point bending test has been used to evaluate the flexural performance of three different fabricated CFS sections. The accuracy of the experimental approach has been verified using a finite element analysis. The outcomes of both studies were compared. This comparison of several cold formed steel sections enclosed in polystyrene aggregate concrete will provide a better alternative option for flexural members and earthquake-resistant structure design in future.

Wang et al. (2014) investigated ULCC, which is characterised by low unit weights of 1500 kg/m3 and compressive strengths of up to 65 MPa. The low unit weight is achieved by integrating cenospheres as micro lightweight aggregates into the cement paste. A new design method is developed and proposed in this research, that can be used to effectively determine the mixture proportions of workable ULCC to achieve a desired target unit weight with minimal laboratory trials. This layout technique is based on the link between the spacing between round cenospheres and the water-to-cementitious material ratio (w/cm) required to achieve the desired work ability.

Huang et al. (2017) investigated the mechanical conduct of a brand-new kind of ultra lightweight cement composite (ULCC) with density much less than 1400 kg/m3 and power as much as 60 MPa after exposing to expanded temperature. The residual compressive strength, elastic modulus, weight loss, failure modes and stress-strain curve behavior are studied experimentally. This work presents empirical equations to calculate residual compressive strength and elastic modulus based on the data. As a result of the critical mechanical behaviour of novel ULCC material after exposure to elevated temperatures, a layout guidance for fire resistance design of ULCC systems will be developed in the future.

Liu et al. (2016) investigated the mechanical properties of a progressive ULCC at low temperatures of -60 oC in comparison with those at room temperature. The properties include stress-strain curve, ultimate strength, elastic modulus, Poisson's ratio, and flexural tensile behaviour. The impact of the curing situation is also evaluated. Furthermore, the ULCC's overall performance is comparable to that of normal weight concrete (NWC) and lightweight concrete (LWC) with similar 28-day compressive strength.

Hegyi and Dunai (2016) used an experimental programme to investigate the flexural and axial behaviour of PAC braced CFS elements and panels. Both unbraced and braced members were tested to determine the increment in load-bearing capacity. Several different element sizes were employed to study the various stability failure scenarios i.e., local, distortional and global). In steel elements, PAC has been found to be effective in preventing global and distortional buckling. The slenderness of the steel core plate has a bracing effect on local buckling; the higher the slenderness, the greater the increase in load-bearing capacity.

Huang et al. (2015) created a new ultra-lightweight cement composite (ULCC) that could be filled into double steel plates to create a new lightweight double skin system. For the double skin structure, shear connectors, overlapping headed studs, and J–J hooks were introduced to mobilise the material strength. The structural performance of a lightweight double skin composite system stuffed with ULCC is the focus of this article. A series of tests on double skin composite beams, shells, and walls with shear connectors were conducted. According to the test results, the double skin composite system has a comparable performance to that of typical concrete when it comes to ultimate resistance and load–deflection behaviour. The results of the investigation, which were backed by ACI and Eurocode approaches, suggest that the formula obtained may be used to predict the resistance of double skin structures stuffed with ULCC.

Wu et al. (2015) focused on the development of ULCC with low thermal conductivity but high specific strength so that they can be used for structural applications. The lightweight is achieved by incorporating hollow cenospheres from fly ash generated in thermal power plants. The ULCCs had 1-day density ranges from 1154 to 1471 kg/m3 and 28-day compressive strengths ranges from 33.0 to 69.4 MPa. The properties of the ULCCs were compared with those of cement pastes with comparable water/binder and those of a concrete with 28-day compressive strength of 67.6 MPa. The results of this study indicate that the compressive strength, flexural tensile strength, and elastic modulus of the ULCCs have been reduced with the decrease in density.

From the detailed discussions, it can be observed that not much work on buckling restrained methods on thin-walled sections are been carried out by using theoretical procedure, which are subjected to different loading conditions. Hence, further studies on thin-walled sections can be performed to reduce the possible failure mechanism and to increase the load carrying capacity of the entire section. It can be stated that intensive research is required to understand the behavior of the ULCC with the action of thin-walled section. Based on literature reviewed on the theoretical, numerical and experimental studies, it has been inferred that much work is not reported in the area of thin-walled sections under the buckling restrained mechanism corresponding to ultra-light weight material as a core system. Also, various buckling modes of the thin walled section of various shapes under different loading conditions needs to be studied.

This review briefly introduces the behavior of cold-formed steel under compression, properties of ultra lightweight cement composite and the mechanism of buckling restrained braces. It can be seen that the geometric shape, section symmetry, the slenderness ratio and the ratio of the flat width to the thickness are some of the parameters that determine these buckling parameters. It can be said that a lot of research is needed to understand the behavior of cold-formed profiles. Through a review of theoretical, numerical and experimental research literature, it can be concluded that there is not much work in this field. Typically used cold-formed steel sections such as C, Z, hat sections are found to be more susceptible to structural instabilities due to their profile geometry. For different loading mechanisms under static conditions, it is necessary to modify the cold-formed steel regulations also focusing on the performance assessment of buckling restrained thin-walled sections. Buckling restrained mechanism is typically an alternative to arrest the buckling modes of the thin-walled section. ULCC has beneficial effect on the behavior of the steel specimen, as it does not let the steel core to produce greater deformation.