Figure 1. Asphalt Aggregate Material

In this project, unpolished reclaimed asphalt pavement (RAP) aggregate is tested in the form of RAP concrete to use it in rigid pavement application. Accordingly, mix proportions were designed by varying the percentage of RAP aggregate in RAP concrete. For rigid pavement application, concrete must satisfy required flexural resistance along with stability and durability for its entire design period. So, strength requirement of RAP concrete containing various percentage of RAP aggregate is determined by casting and conducting tests on cubes, beams and cylinders. It has been found that up to 30% of virgin aggregates can be replaced by unpolished RAP aggregate without compromising on strength requirements. Durability aspect of RAP concrete is found out by conducting coefficient of thermal expansion and fatigue behaviour (subjected to various stress ratios) tests. Results of coefficient of thermal expansion are 15-20% higher compared to the values of conventional concrete (10 x 10-6). Thermal expansion of concrete containing RAP is little on higher side yet it satisfies the code requirements. The reason for the higher value owes the inclusion of bitumen in the form of RAP. These values are still below the threshold values because of the high stiffness of the concrete matrix relative to that of the RAP aggregate. Results of Flexural fatigue test showed that there is a decrease (20-25%) in the values of elastic modulus of RAP concrete subjected to various stress ratios. Reason for decrease in the elastic modulus of concrete owes to the addition of unpolished RAP aggregate. Overall fatigue behaviour is satisfactory up to 30% aggregate replacement in conventional concrete by RAP aggregate.

Concrete is the most widely and commonly used construction material due to its versatility, economy, sustainability and durability. Concrete is the second-highest consuming building material next to water used throughout than all other building materials in infrastructural work. As we all know that cement is one of the major ingredients of concrete, this cement manufacturing produces or emits lot of greenhouse gases into the atmosphere. This emitted gas makes the atmosphere to hold the temperature for more period of time than the usual time. This phenomenon itself known as greenhouse effect. This effect is the primary cause of global warming. We already started to witness the harsh impacts of global warming. Global warming shifts the pattern, distribution and way of life on this earth. This will severely impact flora and fauna of this world. Creates a situation where survival will be next to impossible. To put it in a simple manner, we are overusing the available natural resource at the cost of environmental degradation. It made the problem look more real than ever before. So, it necessitated a situation where we have to go for an alternative material which is sustainable in nature at the same time affordable and durable. Sustainable solutions are those that balance economic, environmental, and social benefits.

Keeping these things in background, some researchers all over the globe tried to develop an alternate material or conventional material, i.e., concrete with full or partial replacement of some of its ingredients such as cement and/or aggregate. Some researchers also developed so many admixtures which would decrease the consumption of natural materials at the same time improving the overall performance of concrete according to the situation. Other faction of researchers wants to reuse the wastes generated in various fields in order to mitigate the waste disposal problem along with using it in a concrete.

RAP is the expression given to remove as well as reprocess asphalt materials containing asphalt and aggregate as shown in Figure 1. These materials are produced when asphalt pavements are expelled for recreation, reconstruction or to acquire access to buried utilities. When appropriately crushed and screened, RAP comprises of top notch, all around reviewed aggregate covered by asphalt concrete.

Figure 1. Asphalt Aggregate Material

Reyes-Ortiz et al. (2012) evaluated the effects of total replacement or partial replacement of aggregate by reclaimed asphalt pavement materials on the mechanical properties. Results showed improved indirect tensile strength and resilient modulus values in both the conditions, dry and wet state. Abraham and Ransinchung (2019) evaluated the feasibility of reclaimed asphalt pavement aggregate in cement mortar. Results showed improved resistance against sulphate attack due to the presence of entrained air in the cement mortar. In other words, cement paste survived because of the protection against salt decay and damage. Sabouri (2020) conducted tests to know the fatigue and rutting behaviour of the asphalt mixtures containing reclaimed asphalt pavement materials. To have a better control over the quality, he conducted experiments in laboratory conditions. Fatigue is evaluated by Simplified visco-elastic continuum damage and rutting is evaluated by triaxial stress sweep test. Mansourian et al. (2018) investigated fracture toughness of concrete mixtures with varying proportion of reclaimed asphalt pavement. They found that fracture toughness decreases as the RAP content increases. Zhang et al. (2019) conducted research on the rejuvenated reclaimed asphalt pavement mixture to know the behaviour of mixture in terms of mechanical properties like fatigue resistance, and higher bending strain withstanding capacity. López et al. (2018) evaluated fatigue behaviour of reclaimed asphalt pavement and crushed aggregate mixture treated with cement. They concluded that the mixture composition and thickness of asphalt wearing courses play a key role in the fatigue life of cement treated recycled bases. Sun et al. (2019) focused to develop the applicability of RAP in geo-technical application. They conducted study on the two parameters namely water characteristic curve and permeability of recycled materials in an unsaturated state. Cliatt et al. (2016) studied the usage of stabilized reclaimed asphalt pavement in full depth reclamation method in order to avoid distress in pavement. They found the optimum content of cement to be used with RAP to use it in soil stabilization in turn to overcome the distressed pavement base. Farina et al. (2017) discussed the environmental impacts, mechanical performance and economic benefit of asphalt mixtures having high percentage RAP. Findings revealed that the reclaimed mixture is above par in mechanical and environmental properties when compared with conventional mixtures having virgin materials. Moaveni et al. (2016) presented the justification for the use of reclaimed asphalt pavement materials in high performing mixes like multigrade asphalt to enhance the performance than the conventional asphalt mixtures. Montanez et al. (2020) adopted semi-adiabatic calorimetry test to know the effects of cement hydration process on the strength parameter of Portland cement concrete containing reclaimed asphalt pavement aggregate. They found that percentage of increase in RAP content adversely affect the mechanical properties of PCC. Daryaee et al. (2020) studied the durability aspect of a high-strength reclaimed asphalt pavement concrete to render it for the structural application such as transportation infrastructures. Durability aspect is confirmed by testing different parameters involved in determining the long life of concrete namely freeze thaw durability, chloride permeability and coefficient of thermal expansion.

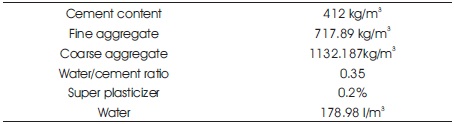

The materials used for the casting of concrete cubes, cylinders and beams are cement of OPC grade 53 with a water cement ratio of 0.35, coarse aggregate with 20 mm down size, fine aggregate (M-sand), RAP aggregate with 20 mm down size and super plasticizer-Master Glenium sky 8233. Mix design calculated using Bureau of Indian Standards (2000, 2019) and Indian Road Congress (2017). Mix proportion of 1:1.742:2.748 is used for virgin M-40 grade concrete.

The methodology of this study involves the following steps:

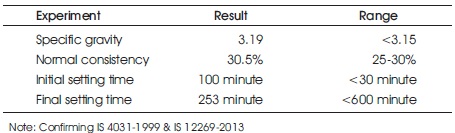

Ordinary Portland Cement (OPC) of 53 grade as per Bureau of Indian Standard (2013) is used in present investigation and testing has been conducted in accordance with Bureau of Indian Standard (1999). Table 1 shows the properties of Cement.

Table 1. Tests on Cement

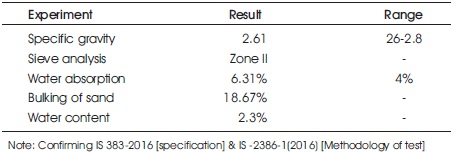

Fine aggregate is used in present investigation and testing has been conducted in accordance with Bureau of Indian Standards (2016a, 2016b). Table 2 shows the properties of fine aggregate.

Table 2. Tests on Fine Aggregate

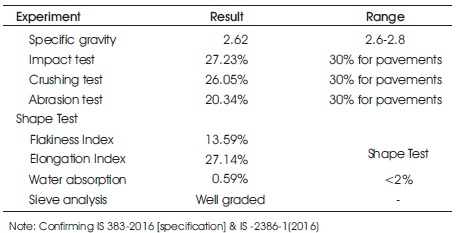

The specific gravity of course aggregate indirectly measures its density; hence it is the essential parameter of strength and quality of the aggregate.

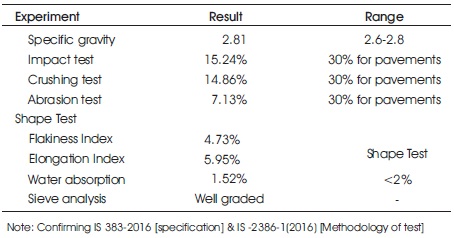

Coarse aggregate is used in present investigation and testing has been conducted in accordance with Bureau of Indian Standards (2016a, 2016b). Table 3 shows the properties of coarse aggregate.

Table 3. Tests on Virgin Aggregate

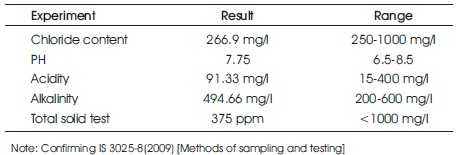

Water fit for drinking which is free from minerals and all soluble salts is used, as any contamination in water may affect the fresh as well as hardened state concrete. The tests are done on the basis of Bureau of Indian Standard (1987, 2000) and the data is within the permissible range of Bureau of Indian Standard (1987, 2000) as shown in Table 4.

Table 4. Tests on Water

In this present experimental investigation, high range water reducing admixture commercially termed as Master Glenium Sky 8233 has been used. Recommended dosage ranges between 0.5 to 2 percent of cementations material for most of the concrete mixes. The specific gravity of the above-mentioned super plasticizer is 1.08 and is of reddish-brown color.

Specific gravity and water absorption are the important parameters to determine the strength and durability of the material. RAP aggregate is used in the present investigation and testing has been conducted in accordance with Bureau of Indian Standards (2016a, 2016b). Table 5 shows the properties of coarse aggregate.

Table 5. Tests on RAP Aggregate

Mix design done using Bureau of Indian Standards (2000, 2019) and Indian Road Congress (2017). Mix proportion of 1:1.742:2.748 is used for M-40 grade concrete as shown in Table 6.

Table 6. Mix Design

Following tests were done on the concrete specimens:

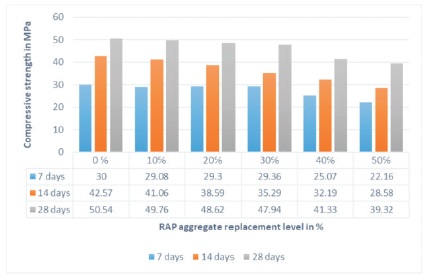

The compressive strength of concrete mould is a measure of the concrete's ability to resist load which tends to compress it. The concrete mould are prepared in order to determine the compressive strength of the mix design and the 7, 14 and 28-days strength of the concrete has been found. The variations of compressive strength of the mix with the variation of the days are plotted against the different percentage mix as shown in Figure 2.

Figure 2. Variation of Compressive Strength

By interpolating the obtained values, the optimum percentage of RAP aggregate is 29.72%, i.e., for M40 grade of concrete, the strength requirement is 48.25 MPa. So, up to 30% of RAP aggregate replacement can be done without affecting the strength requirement as shown in above Figure 2.

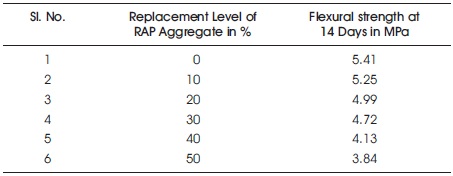

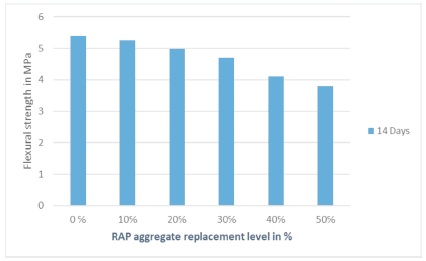

Flexural strength is a measure of the tensile strength of concrete. It is a measure of concrete beam or slab to resist failure in bending. The mould of size 100 mm x 100 mm x 500 mm.

The flexural strength values vary from 3.52 to 5.42 MPa as shown in Table 7. This satisfies the flexural criteria for 30% replacement as shown in Figure 3. Here the important thing to be noticed is that all the specimens are passing the test but when compared to compressive strength it does not have strength for 40% and 50% replacement. Thus 30% replacement is viable.

Table 7. Tests on Flexural Strength

Figure 3. Variation of Flexural Strength

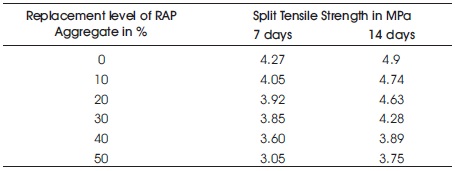

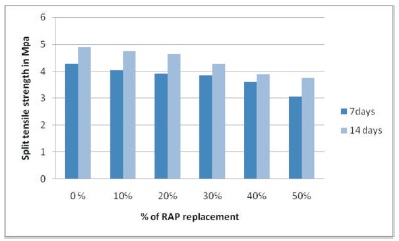

The concrete specimens are of cylindrical in shape. The dimensions of the mould are 150 mm diameter and 300 mm height. Tensile strength for concrete specimen is defined as the tensile stresses developed due to application of the compressive load at which the concrete specimen may crack. The test for split tensile strength is shown in Table 8.

Table 8. Tests on Split Tensile Strength

The split tensile test values for 14 days are supposed to be greater than 3.55 MPa and the specimens having percentage of replacement up to 50% has more than this value as shown in Figure 4. But it lacks the compressive strength. Considering all the three analysis, 30% replacement can be considered to be the optimum for the road construction.

Figure 4. Variation of Split Tensile Strength

Due to COVID-19 outbreak, experimental investigations could not be conducted. This pushed to go for prediction models established by previous researchers. So, after examining several various models, Neville and Brooks Model is adopted in this project. Model selection is based on the accuracy of developed model with of real values.

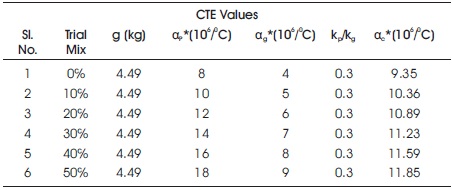

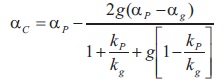

The concrete CTE, αc, is related to the thermal coefficient of aggregate,αg, and of cement paste, αp, as shown in Table 9.

Table 9. Values for Coefficient of Thermal Expansion

where,

g = volumetric content of aggregate, and

kp/kg = stiffness ratio of cement paste to aggregate, approximately equal to the ratio of their moduli of elasticity.

Remarks: Obtained results of coefficient of thermal expansion are 15-20% higher compared to the values of conventional concrete (10 x 10-6). This result and Neville and Brooks Model have showed the increase in the CTE values compared to conventional concrete. Though, thermal expansion of concrete containing RAP is little on higher side; it still satisfies the code requirements. The reason for the higher value owes the inclusion of bitumen in the form of RAP. These values are still below the threshold values because of the high stiffness of the concrete matrix relative to that of the RAP aggregate.

As we all know concrete is a composite material and it has various ingredients such as coarse aggregate, fine aggregate, and cement paste. Finding the durability aspect of concrete such as fatigue behavior under various stress ratios is on tougher side when there is no availability of experimental data. In this project my aim is to find out fatigue behavior of concrete containing RAP in optimized percentage of replacement. But because of COVID-19 pandemic, it has been not possible to conduct experiments. So, reviewing of previous research papers led to the conclusion that fatigue behavior of concrete depends on several factors. Multi-scale modeling of concrete containing rap aggregate is not available.

Following are the various factors which will affect the fatigue behavior of concrete.

Evaluation of fatigue resistance under flexural cyclic loading of concrete containing RAP aggregate is not possible based on the available initial data. It requires special set of data with which one can able to use such existing models. The most relevant numerical prediction model is given for reference.

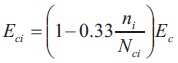

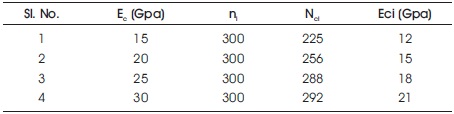

Elastic Modulus Degradation of Concrete is calculated as

where Eci is the effective elastic modulus of concrete at the ith cycle and Ec is the initial elastic modulus and Nci of concrete is the number of loading cycles to failure for concrete and the values are given in Table 10.

Table 10. Tests for Elastic Modulus of Concrete

Remarks:

Model to predict the fatigue resistance subjected to flexural cyclic loading is not available. Some models are available, but they require basic testing data which is not conducted in this project. The results obtained from the model are slightly on lower side as compared to general values. Results showed that there is a decrease in the values of elastic modulus of RAP concrete because of addition of RAP aggregates (up to 20-25%). Further research needs to be conducted.