Figure 1. Tunnel-1, Portal-2 of J&K Railway Project, India where major slump slide has taken place.

Most of the geotechnical projects focus on assessing the existing ground and rock conditions. On some project, the soil condition may be poor, so the authors may have to consider the methods for soil improvement. Presently used techniques for ground improvement are removal and replacement of weak soils; grouting the weak soil, vibrocompactions, dynamic compaction, blast densification; insitu replacement of weak soils, stabilisation using admixtures, concrete soil reinforcement and use of geosynthetics such as geotextiles, geogrids, geowebs, etc. But these methods may be either expensive or time consuming. These may also prove a hazard to the environment. This is a serious problem experienced by the civil engineers. To overcome this problem, they introduce the use of waste plastic materials for soil improvement. These can perform five primary functions such as separation between different layers, reinforcement, fluid barriers, protection of geosynthetics, erosion control. This technique is found to be simple, cost effective and does not require any special equipment. Also, helps to save our environment, as disposal of plastics is a problem creating environmental hazard.

Whenever any civil engineering project is undertaken existing soil and rock conditions are assessed then a design is developed that is compatible with these conditions. For example If the project involves designing a structural foundation and soil conditions are poor, it is necessary to use deep foundations. However, on some projects the soil conditions are so poor that it becomes very expensive to accommodate the design. When this happens, various methods of soil improvement are often considered. These methods are intended to improve the quality of soil. Although soil improvement is generally expensive and in some cases proposed construction cannot be practical unless the soil is first improved.

Some soil improvement methods are proprietary (i.e. they are protected by patent) and many of the methods require special equipments. Often proprietary methods are implemented by the design and build firms that do both the engineering design and the construction. However, other methods can be implemented by any qualified persons with ordinary equipments.

Presently used methods for ground improvement are removal and replacement of unsuitable soils, precompression, preloading or surcharging the soil before construction, drilling of vertical drains for removal of water, insitu-densification, vibrocompaction, dynamic compaction, blast densification, in-situ replacement of the soil, stabilization using admixtures, in-situ deep mixing, concrete- soil reinforcement and the use of geosynthetics (Rao and Kaushish, 2001), such as geotextiles, geogrids, geomembranes, geocomposites, geonets and other products such as geomats, geomeshes, geowebs, etc. But these methods are expensive, time consuming and some of them may cause damage to the existing structure or cause landslides by inducing excessive vibrations during compaction.

The use of recycled plastics in highway construction is vide and varied and as an additive to asphaltic concrete is not new, however, the influence of waste plastic reinforcement in soils has not been investigated so far. During the last two decades a large amount of research has been carried out on recycled material. Even though the research carried on the use of waste plastics is vast and extreme, but the dissemination of information is often limited. The problem is compounded by lack of a single resource containing relevant engineering and environmental characteristics of each material (Alaa et al., 2006). The majority of early studies dealt with new material identification and laboratory testing to determine material properties (Collins and Ciesielski, 1994; Edil and Benson, 1998). More recent research has included large-scale field tests, predominantly environmental studies, and processing technique characterization (O'Shaughnessy and Garga, 1999; Liu et al., 2000; Consoli et al., 2002).

This is a rapidly developing topic that is being driven by economic pressure to build on sites with marginal soils, the need to rebuild ageing infrastructure in urban areas, increased recognition of seismic hazards and various geoenvironmental problems (Conduito, 2002). Many new techniques have been developed and redefined during the last quarter of the twentieth century and contractors equipped to implement them have become much more common (Schaefer, 1997). This serious problem experienced by civil engineers is driving civil engineering to look for new techniques at a frequent rate. Methods that were only recently considered to be experimental are now proved and widely accepted (Conduito, 2002). Here in, we introduce the use of waste plastic material as a material for soil improvement which reduces permeability; increases shear strength and can also act as a separator between different layers, reinforcement, fluid barrier and protection of geosynthetics. By using this as a material for soil improvement, we can also save our environment as disposal of plastic is itself an environmental hazard. This technique is simple, economical and does not require any special equipment for use.

Due to heavy rainfall during winters in February 2005, a major slide (Figure 1) developed over Tunnel No. 1 -North Portal of J&K railway project, India. The maximum width of slide zone is above 90m. Besides acute cracks mostly develop at many places between toe of the slide and portal faces, about 19m long false portal and 35m long tunnel have been badly damaged. The tunnel is located at the foot of Vaishno Devi hill along the Reasi thrust zone or within the thrust. The Reasi thrust (M.B.F) separates the underlying younger rocks i.e. Siwalik Group of rocks from overlying older Pre-Cambrian Sirbon dolomite. This site consists of crushed dolomite and overburden derived from crushed rocks. Some outcrops of sandstone and claystone of Murree Formation were also recorded within the thrust zone. These outcrops are caught up pieces during the thrusting of the area.

Figure 1. Tunnel-1, Portal-2 of J&K Railway Project, India where major slump slide has taken place.

During monsoon rains, a crater of 8m dia. and 5m deep (well shaped) formed above the tunnel. This development indicated that ribs around this change got collapsed due to water pressure developed in the crushed material above the tunnel resulting in subsidence of slope area in the well formed. Due to this slide, time delay of 2 years has taken place.

Remedial measures (Figure 2) taken to tackle this problem

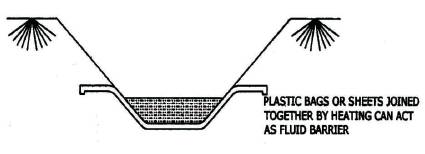

It has been observed that most of the problems occur when water comes in contact with such strata; so we require a fluid barrier to reduce the problems.

Figure 2. Remedial measures being taken to tackle the major slump slide.

Figure 3. Excessive Settlement that occurred in Sangaldhan region of J&K Railway Project, India.

Figure 4. Accumulation of too much of wet and cohesive muck.

Figure 5. Protection work for slopes.

Figure 6. RCC slabs of 30 cm thickness laid in nallahs near by tunnel site

Figure 7. Installation of self drilling anchors at various points to remove water

Plastic as a soil improvement material can perform five primary functions:-

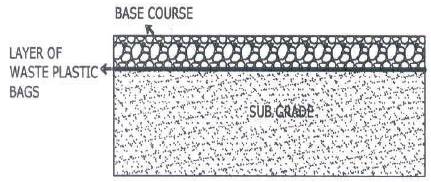

Figure 8. Waste plastic as a separator.

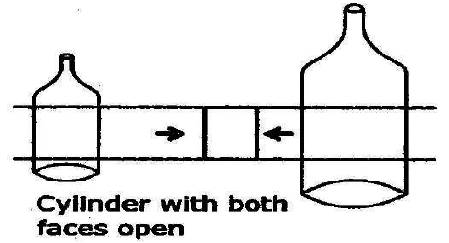

Figure 9. Plastic bottles cut from both ends to form a cylinder.

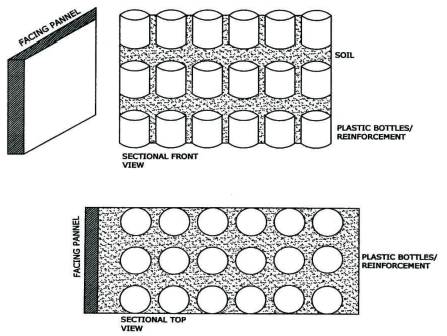

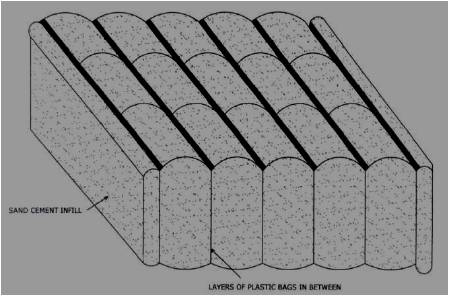

Figure 10. Waste plastic as reinforcement for oil

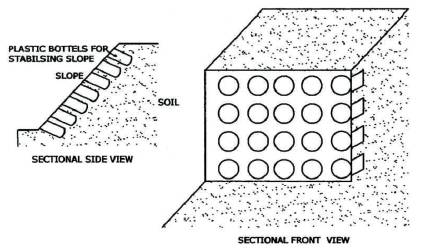

Figure 11. Waste Plastic for Stabilising a Slope

Figure12. Waste Plastic Material as a Fluid Barrier.

Good specifications (Holtz, 2001) are essential for the success of any civil engineering project, especially when ground improvement is being done. Specifications should be based on the specific properties requirement for design, installation and long term performance.

All specifications include:-

Figure 13. Waste Plastics for Erosion Control

Figure 14. UCS Test being performed in Laboratory.

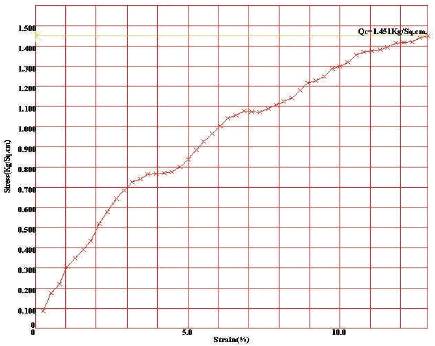

Figure 15. Stress v/s Displacement for Sample 1

Figure 16. Sample at Failure.

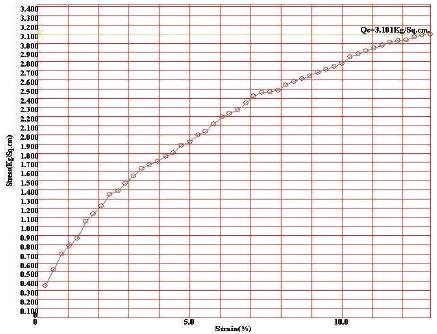

Figure17. Stress v/s Displacement graph for Sample 2.

Figure 18. Sample at Failure.

Figure 19. Stress v/s Displacement graph for Sample 3.

Figure 20. Triaxial Test being performed in the laboratory.

Figure 21. Sample at Failure.

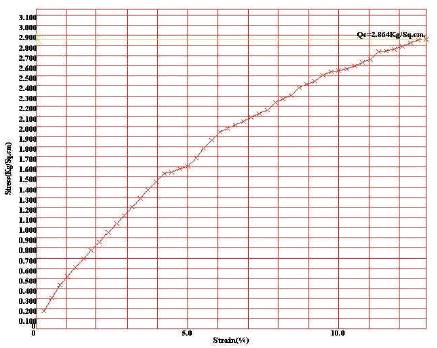

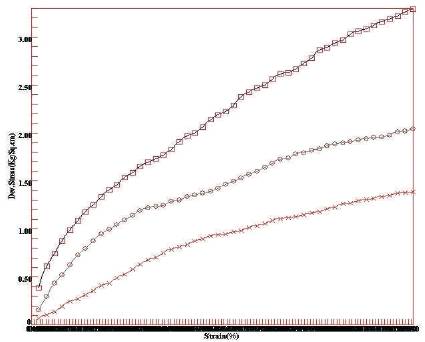

Figure 22. Stress v/s Displacement for normal sand sample.

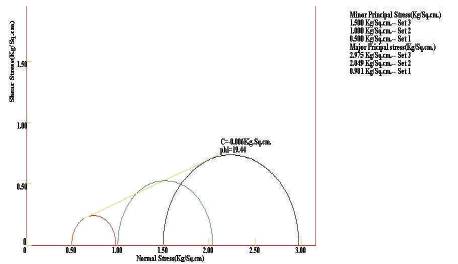

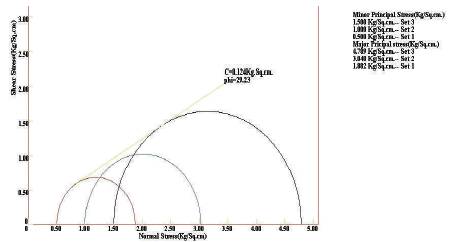

Figure 23. Mohr Circle for normal sand sample.

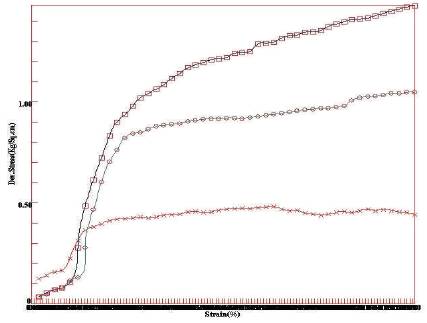

Figure 24. Stress v/s Displacement for sand having plastic confinement around it.

Figure 25. Mohr Circle for sand sample having plastic Confinement around it.

Figure 26. Permeability tests being performed done in the laboratory.

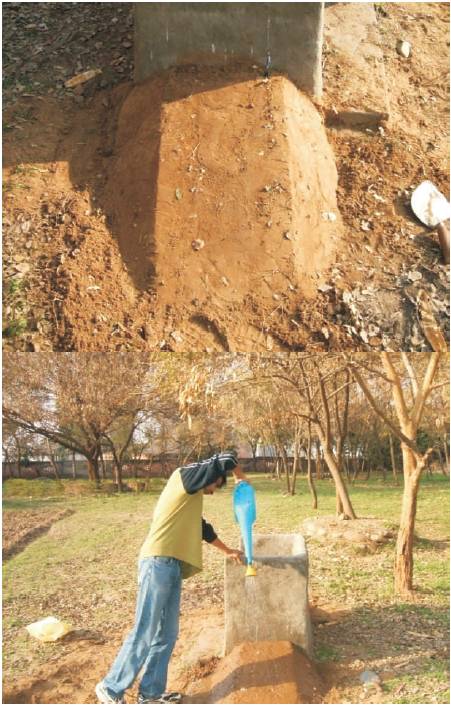

Figure 27. Slope with Plastic Reinforcement.

Figure 28. Slope with-out plastic.

Figure 29. Effect of showering water on slope with without plastic reinforcement

Figure 30. Effect of showering water on slope plastic reinforcement.

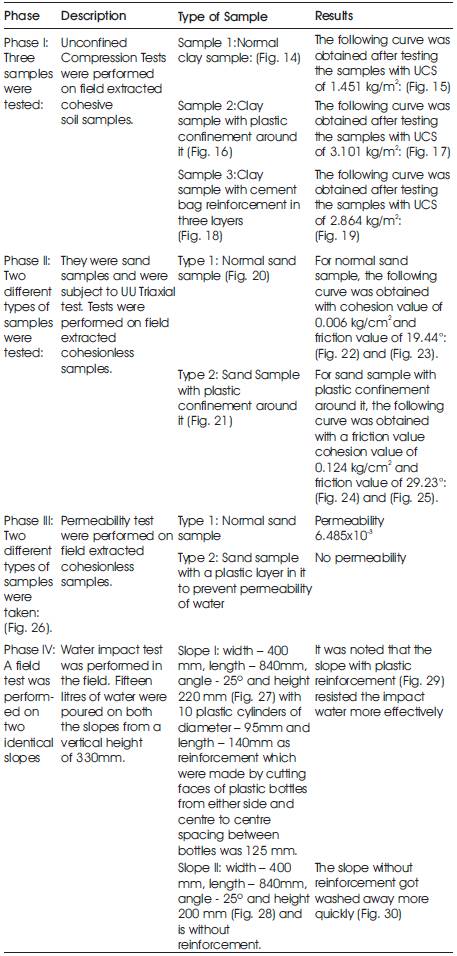

Table 1. Four Phase Experimental Program

On the basis of this investigation, it has been observed that the engineering properties of soils are considerably altered and usage of waste plastics can be recommended as an effective agent for improvement of soils. This study has shown that the treatment of soils using waste plastics can be effectively used in the stabilization of problematic soils. More importantly it offers an interesting potential for making use of an industrial waste, which otherwise adversely affects the environment. This material can be used for fine grained soils in bulk to stabilize the unstable slopes.

In this paper, an attempt has been made to make use of waste plastics which proves to be an effective admixture for improving the quality of weak soils. Waste plastic materials such as scrap plastics, plastic bags provide a viable alternative both for their relatively lower cost and desirable engineering properties.

Based on the results obtained from experimental programme, the following can be concluded: